Horror stories about the dangers of microwave ovens are shattered by their sales figures. It’s rare in any home today that you don’t see a microwave. And although the average service life of these devices is determined to be 5–7 years, many of them faithfully serve their owners for 10 years or more. But quite often they are scrapped not because of the failure of the electronic part, but because of the banal wear and tear of the case. Most often it rusts from the inside.

At the factory, most of these stoves are coated with high-quality enamel, which can last for many years with basic care.

There are microwave ovens that have internal chambers made of stainless steel or ceramic coating. We will not talk about such devices in this article; they have other problems not related to painting.

How to extend the life of a microwave oven.

First, you need to understand that when working with the device, you cannot use metal or tightly closed containers. The metal can spark and completely damage the stove. And under a hermetically sealed lid, a lot of pressure is formed (as in products with a hard shell or peel, for example, eggs), which can cause an explosion.

Important! When heating food, do not close the lid of the dish tightly. The inner surface must be wiped after each use.

Preferably with a dry cloth. If there are stuck crumbs, you can use a damp cloth, but still try to avoid excess moisture.

The inner surface must be wiped after each use. Preferably with a dry cloth. If there are any stuck crumbs, you can use a damp cloth, but still try to avoid excess moisture.

Important! Make sure that water and cleaning fluids do not get into the ventilation openings!

To clean your microwave oven, use only cleaning products that do not contain abrasive particles. The presence of these thins the enamel and leads to scratches and chips.

Summarize. Damage to the enamel is a signal that the microwave needs repair, but does not affect the quality of the food cooked in it. If the paint chips are too large or rust is already appearing on the exposed metal, it is better to replace the device with a new one.

Is it possible to use a microwave if the enamel inside has peeled off?

The destruction of the enamel is not always immediately visible, especially if the microwave oven rusts under the plate: the swelling of the coating remains unnoticed until a characteristic crack appears when the metal is exposed to waves. The main reason for damage to the enamel is the lack of regular maintenance of the device. After use, spilled liquid, crumbs, drops of fat remain in the oven; all this heats up repeatedly during further use, sticks to the enamel and destroys it.

The bottom and ceiling suffer the most: everything that has boiled or overflowed spills onto the bottom, and the ceiling is constantly exposed to hot steam - the slightest mechanical damage to the enamel is enough for the process to go further. Without care (at least minimal) for the oven chamber, the walls of the oven also suffer: adhered fat gradually destroys the entire coating. If you continue to use a microwave with damaged enamel, it will deteriorate until it starts to spark and breaks.

Is it possible to use a microwave if the enamel has peeled off? It all depends on the extent of the damage. This in itself is not dangerous: you can still heat food in the oven, because the chamber remains protected from high-frequency waves by a metal casing.

Nevertheless, the process must not be left to chance: further destruction of the coating leads to sparking and cracking, which can lead to the device catching fire. There is a danger of through corrosion: with constant exposure of the damaged area to moisture or grease in combination with microwave waves, the casing will rust through. This means the device is completely unusable - its further use is prohibited.

To avoid such problems, it is enough to regularly clean the inside of the camera with a damp cloth soaked in soapy water. If you do this immediately after using the oven, the food residues will not have time to dry out and will be easy to clean. It is recommended to ensure that water and other liquids do not get into the openings on the chamber walls.

Attention! Do not use abrasive or harsh chemical cleaners. They damage the top layer of enamel, making it loose and more vulnerable to thermal and mechanical stress.

It is recommended to cover the container with water or heated food with a lid to prevent splashing. At the same time, it should not be closed hermetically, since in this case high pressure arises inside, and this is dangerous due to explosion.

What are the dangers of using a microwave when the enamel inside has peeled off?

Enamel in a microwave oven not only serves as an aesthetic surface. In addition to its external properties, it provides protection against various bacteria for heated food and saves the housing from wear, contamination or basic breakdown.

When the enamel chips, the “iron box” is exposed. It would seem that there is nothing wrong. The problem is that unprotected metal can begin to corrode. If you aggravate this process, then a hole will appear due to rust, and fire can pass through. As a result, the device may catch fire or simply fail.

Among other things, the very presence of a metal surface (object) inside threatens the possibility of an explosion. The metal acts as a shield for microwaves and has excellent electrical conductivity. The latter circumstance just causes the redistribution of currents on it, which, in the presence of an electromagnetic field around, leads to breakdown.

Is it possible to use a microwave if the paint inside is cracked?

Of course, if you have already heated up your lunch and then only notice that the surface of the inner chamber is damaged, there is no need to throw it away. The products are reliably protected from the penetration of high-frequency waves by a metal casing. If the metal is not rusted, but only the integrity of the enamel is damaged, it is not dangerous. But it is better to refuse further use of the device in this condition.

The fact is that during cooking, a certain amount of steam is generated inside the microwave oven. When iron interacts with moisture, it begins to corrode. Therefore, at a certain moment, in a place where there was just a small chip of paint, a hole may appear due to rust. It is through this hole that the radiation will penetrate into the chamber itself. Moreover, this situation also threatens that due to the high temperature of the internal coil, without proper protection, the device may even catch fire.

However, if a defect is discovered, it is not necessary to throw away the microwave and run to the store for a new one. The situation can be saved by nitro paint or any other enamel that is safest for everyday use (the degree of safety is usually indicated on the can).

Microwave oven repair from the inside - from mechanical restoration to painting

Horror stories about the dangers of microwave ovens are shattered by their sales figures. It’s rare in any home today that you don’t see a microwave. And although the average service life of these devices is determined to be 5–7 years, many of them faithfully serve their owners for 10 years or more. But quite often they are scrapped not because of the failure of the electronic part, but because of the banal wear and tear of the case. Most often it rusts from the inside.

At the factory, most of these stoves are coated with high-quality enamel, which can last for many years with basic care.

There are microwave ovens that have internal chambers made of stainless steel or ceramic coating. We will not talk about such devices in this article; they have other problems not related to painting.

Causes of damage to the enamel inside a microwave oven

First of all, let's talk about what causes rapid damage to the enamel surfaces inside the microwave, what should be done to prevent this from happening, and how to eliminate minor flaws in the enamel coating.

If your microwave has minor damage to the enamel where the door fits or minor scratches caused mechanically that have not yet become rusty, then degrease them and cover the defects with any enamel, nitro paint, or even nail polish that matches the color. Such repairs will delay the more labor-intensive and expensive restoration of the paintwork for a long time.

And more serious accelerated wear occurs due to:

- failure to comply with basic operating rules;

- irregular stove maintenance;

- inattention.

- Thermal processing of products in a microwave oven should be carried out by first covering them with a plastic cap or other container that is approved for use in microwave ovens. Splashing food particles during heating or cooking, settling on the walls of the chamber, destroy the enamel at an accelerated pace. Electrical discharges are also possible between them, causing sparking and crackling.

- The oven requires basic cleaning, which is best done at least once or twice a week or after each case of splashing of fat, and even more so of spilling liquid under the glass tray.

- It is the latter that leads to the most typical wear of not only the paint coating, but also the metal of the body.

Moreover, it accelerates due to the rolling of the wheels of the pallet rotation mechanism along the recess. And if this liquid is not removed in time, then the result will be exactly like this. And pretty soon.

How to paint the inside of a microwave - choosing paint

If you don't change the microwave, all that's left to do is paint it. First of all, let's figure out what.

The answer suggests itself - enamel, since that is what they paint at the factory. When choosing a paint, make sure it can be used on items that come into contact with food. This should be indicated on the label.

If you have a regular microwave without a grill, then the heat resistance of the paint does not matter, because the body does not heat up during operation.

https://www.youtube.com/watch?v=XtTHXRxBe6M

And if you have a stove with a grill, then you should use paints that can withstand temperatures from 250°C. There can be no talk of any 600 degrees, because at such a high temperature food is simply destroyed and cannot be there.

The inside of the microwave is rusty - what to do?

If the owner of the microwave equipment did not pay attention and found small or significant traces of corrosion inside the chamber, he must turn off the power, wash it with detergent, dry it and begin repairs. If the damage is minor, the restoration process will be simple.

Procedure:

- We clean the chipped areas and rust with coarse sandpaper.

- Remove debris and dust using a vacuum cleaner.

- We treat the surface with fine-grained sandpaper.

- We degrease the metal with a solvent, white alcohol is quite suitable.

- We prime the surface so as to repeat the bottom topography using primers GF-021, GF-0119, FL-03K, PF-0244.

- We level it with alkyd putty (if there are depressions or potholes).

- We go through with fine sandpaper.

- Let it dry completely.

- Cover the holes inside the camera with masking tape.

- We apply the enamel in 2, preferably 3 layers, using a foam swab, a brush, a mini roller, or a paint can.

- Dry each layer for at least 20-24 hours at a temperature of +20 degrees.

- It is better to do the work outdoors.

If the inside of the microwave has not just a dent from rust, but a hole, you can repair it at home using a piece of gauze and two-component glue.

It is better to use dyes for protection and prevention of corrosion:

- food organic;

- electrically conductive;

- acrylic aerosol.

After drying, the microwave looks, if not like new, then ready for safe and efficient operation.

How to paint the inside of a microwave at home, instructions

Now you know how to paint the inside of a microwave. The type of material used is also extremely important. To do everything correctly, follow the simple step-by-step instructions:

- Unplug the equipment. Place the device on a flat surface with the door facing up so that access to the equipment is not restricted.

- Seal the air duct, wave duct, and other compartments that you don't want paint getting into with tape or tape.

- Clean the surface of old paint that has peeled off. If the coating on a certain wall is not damaged, then it can be left untouched.

- If you do everything in a timely manner, then rust should not have appeared. It is necessary to clean damaged areas and uneven areas with sandpaper.

- If the rust has spread sufficiently, you need to treat these areas with a special acid converter.

- Immediately after completing the process of cleaning the peeling areas of enamel, remove dust and dirt from the surface with an ordinary rag.

- Be sure to degrease the surface with special products or regular alcohol.

- Follow basic safety rules. You need to work exclusively with gloves. Be sure to provide proper ventilation in the room. It is advisable to apply layers of paint outdoors.

- To prevent dirt from accumulating in the workplace, you need to lay a special oilcloth or film on it; newspapers are a good alternative.

- If you plan to spray paint your microwave, then place it on edge. Start painting with recessed surfaces.

- To prevent drips, do not put too much paint on the roller, which should be applied in a thin layer. The corners must be painted with a brush.

- When the first layer of paint is completely dry, apply the second layer using the same principle.

- Paint from spray cans is applied in a zigzag pattern; there should be no delays. This will allow the layer to be applied evenly.

- After final drying, evaluate the work done and, if necessary, apply another layer.

- When everything is dry, you can remove the tape. Wait for the paint to fully adhere to the surface.

- After restoration work is completed, the stove should not be turned on for several days.

Coloring stages

Now you know that even if the enamel peels off in the microwave, you can still restore the integrity of the surface

However, it is extremely important to apply the paint material correctly. Conventionally, the coloring process can be divided into 4 stages:

Bubbling, rusty and flaking areas should be carefully cleaned using sandpaper. The surface on which paint will be subsequently applied is degreased with an alcohol solution. It is extremely important that no paint splashes get into the important hardware compartments of the oven, so they are sealed with tape. The dyeing process itself. The second layer is applied at the user's discretion

The decision is made only after complete drying.

After reading this step-by-step instructions, you will know what you can use to paint a microwave if the enamel has peeled off, as well as how to do it correctly.

How to melt metal in the microwave

How to melt metal in the microwave

In a conventional microwave oven you can easily melt lead, tin, glass, aluminum, copper, gold after minor modifications. The modification boils down to removing the rotating plate and making a muffle furnace from two halves of heat-resistant brick.

microwave magnetron 800 watt

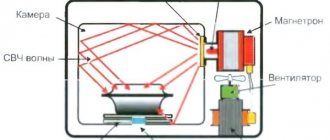

As you know, a microwave oven contains a magnetron, which generates an electromagnetic wave from 2.450 GHz. Using this wave, the microwave oven heats the food to the desired temperature. Typical microwave power is 800 watts. Magnetrons with a power of up to 1450 watts are available for microwave ovens; such an oven will melt much faster.

For microwave waves generated by the magnetron of a microwave oven, air, glass, plastic are transparent, metals, graphite reflect the microwave wave. Some materials absorb microwave waves and are converted into heat. Theoretically, temperatures can be very significant, but for our needs 1200 - 1500 degrees will be enough. Melting 50 grams of bronze or gold in the microwave takes 30 minutes.

Making a muffle

To make a muffle microwave oven, we need a refractory brick and a special crucible made of silicon carbide in which the metal for melting is placed. The refractory brick is transparent to microwave waves and does not allow heat to pass through; the crucible itself heats up.

refractory brick marking

We mark the brick into 2 equal halves and use a diagonal to mark the centers of future holes. It is necessary to drill 2 holes with a diameter of 70 mm in the brick. A perka or forstner drill of the required diameter is suitable for this. You can drill with a drill or drilling machine at low speeds because the material is fragile. For good thermal insulation, the minimum wall thickness is 15-20 mm.

You can make a muffle from ShVT. Fireclay-fiber boards hold a temperature of 1350 degrees and are much easier to process.

A laboratory crucible can be used for melting metal crucibles.

The graphite crucible is unsuitable for microwaves; it has low efficiency and heats up very slowly.

For good efficiency you need a crucible with silicon carbide. Silicon carbide or carborundum, SiC, has a melting point of 2700°. This material is used in industrial heating elements and abrasive products. Silicon carbide is very resistant to acids and not resistant to alkalis. Suitable for melting non-ferrous metals; it dissolves in molten iron.

Making a crucible

To make a crucible, you will need a mold. Approximately 7-10% bentonite must be added to the mixture for manufacturing; it imparts plasticity. You can replace bentonite with dry clay. Dilute the mixture with a small amount of water to form thick clay and press it into a mold using a vice or jack, adding a small amount in 3-4 additions. Then you need to remove the crucible and let it dry for 24 hours.

The second one from the left is made according to these instructions. The first one from the left is made using the same mold but using fireproof ceramic. The crucible second from the right is factory-made silicon carbide, the edge on the right is made of refractory ceramic, it is not suitable for a microwave oven.

After drying for 24 hours at a temperature not exceeding 90 degrees, you can test the crucible by placing it in a muffle and turning on the oven for 15 minutes; if everything is done correctly, it will heat up to about 1000 degrees (like the filament of a weak light bulb).

Types of coatings

There are four types of internal coating of the microwave chamber:

- enameled;

- stainless steel;

- ceramic;

- acrylic.

To find out which microwave oven coating is best, let's look at each type in more detail.

Enameled

The most popular and ancient type of finish. Manufacturers often use enamel in budget models of kitchen appliances. Enameled surfaces are easily scratched and difficult to clean, so you can’t do without special detergents, and keeping the electric oven perfectly clean is simply necessary.

Stainless steel

A reliable and durable coating, but, unfortunately, it tends to absorb odors. This surface speeds up the heating of food in the microwave, since steel is a good heat conductor. At the moment, manufacturers are using stainless steel less and less for finishing microwave chambers, so those models that are on the market are somewhat overpriced.

Another disadvantage of steel is that scratches remain on the surface after numerous cleanings, which means that the microwave oven may lose its attractive appearance.

Ceramic

This coating has a wide range of advantages. First of all, the ceramic surface does not become sticky after heating food, it is easy to clean, and it also looks expensive and impressive. On top of that, this microwave finish has antibacterial properties that prevent any bacterial attack.

The biceramic coating has only one drawback: it will take longer to heat up food.

Acrylic

This type of coating was invented quite recently, but has not gained much fame. Acrylic is used in budget kitchen appliances, the power of which is no more than 1400 W. Defrost pizza, cook an omelet or simply warm up sandwiches - this is the list of functions available to a microwave with an acrylic finish. This material is not designed to operate at high power.

Which coating is the best is up to you to decide. If you care about saving energy, opt for stainless steel, and if health is important to you, then ceramics are the best option. Enameled and acrylic surfaces of microwave ovens are considered budget-friendly.

Many consumers cannot answer the question of which is the best interior coating for a microwave oven. The article contains detailed information about microwave ovens and, after reading it, it is easy to determine which internal coating of a microwave oven is better.

A microwave oven is an indispensable tool in any kitchen. You may have already purchased a microwave oven or are just thinking about buying one

In any case, it will be useful to know the parameters that you need to pay attention to

The need to replace the mica plate

This is the most common cause of sparking after malfunction. The reason is that the mica plate burns out during operation. Manufacturers use it in the design of microwave ovens to disperse microwaves. If the stove is not taken care of or is not looked after enough, then fatty deposits, as well as food and product residues, accumulate on this plate. As a result, the plate overheats greatly. This leads to its destruction. If you do not change this plate, you will have to replace a more expensive magnetron.

To find out whether the mica plate is really to blame, you need to understand which side is sparking inside the microwave. If the spark comes from the side of the plate and there is a distinct smell of burning inside the furnace, then this indicates the need to replace the element. It is prohibited to operate a microwave device with burnt mica.

Replacing the mica gasket in a microwave oven with your own hands. | Master Vintik. Everything with your own hands!

The microwave was working and working and suddenly... at some point it started to crackle and something inside sparkled. If you open the microwave door, on the magnetron side (usually on the right, where the control panel is) you will see a mica gasket - the screen. It is needed to protect the magnetron antenna from grease, splashes of moisture and various particles from heated food.

The screen itself is usually made of pressed mica, although there are also plastic ones (heat-resistant special ones that do not release toxic substances when heated).

Why does the gasket (screen) burn out?

Particles of food and fat fall on the screen and become heated and charred. Under the influence of microwave waves, a potential difference arises between the coal and the wall of the furnace, which leads to the appearance of an arc discharge, as in welding, the process is of an avalanche nature and manages to burn out and melt, the metal walls and the metal cap of the magnetron antenna.

In this case, mica is not the best material for the screen; the hygroscopicity and rough surface do their job. A plastic screen behaves much better (smooth does not absorb moisture and fat); such screens burn out extremely rarely.

Below is a photo after the kids turned on the microwave. They got scared and ran away when it started to sparkle. The screen was completely burnt out. There could have been a fire!

I installed a mica screen. I glued it with “second” glue. The client said that he would wash off the soot himself.

How to replace the gasket?

First of all, you need to remove the screen. There is nothing complicated about attaching the screen. One self-tapping screw or two plastic rivets on one side.

On the other hand, the corners are inserted into slots in the walls of the microwave screen or a special protrusion at the screen plate is inserted into the slot in the wall. The self-tapping screw is unscrewed under the screen plate, a knife blade is inserted, and the plate is removed. Plastic rivets can also be pulled out with a knife.

Types of coating

Even one manufacturer can use different materials for coating:

- Ceramics is hard, but on top it is very fragile. You can only scratch it on purpose, but an accidental blow can cause it to crack or chip. Thanks to the smooth surface, dirt does not stick strongly to the ceramics; they can be easily removed with a soft sponge and soap solution.

- Stainless steel can withstand high temperatures, will not crack from impact, and there is nothing to peel off of it. However, dirt and grease that are difficult to remove quickly accumulate on it. Stainless steel should not be cleaned with abrasive or aggressive detergents, which can cause scratches and stains. To clean stainless steel, you should use steam, mild detergents, and special products for microwave ovens.

- The service life of the enamel coating is significantly shorter than that of previous types. A stove with this coating costs less than its ceramic and stainless steel counterparts. Therefore, in terms of popularity, enamel coating confidently holds first place. The enamel surface is smooth, without pores. Fresh dirt can be cleaned without difficulty. But nothing lasts forever, and after some time (determined by the intensity of use and quality of care), the coating begins to peel off. Rust stains form in areas where the enamel has peeled off. This process occurs at an accelerated pace at the top and bottom of the chamber. The top suffers from steam rising from the heated food, and the bottom suffers from accidentally splashed liquid. Without taking measures to restore the coating, the oven will crack, spark, and eventually break. Since enamel coating is used in the vast majority of stoves, we will discuss its replacement below.

How to extend the life of a microwave oven.

First, you need to understand that when working with the device, you cannot use metal or tightly closed containers. The metal can spark and completely damage the stove. And under a hermetically sealed lid, a lot of pressure is formed (as in products with a hard shell or peel, for example, eggs), which can cause an explosion.

The inner surface must be wiped after each use. Preferably with a dry cloth. If there are any stuck crumbs, you can use a damp cloth, but still try to avoid excess moisture.

To clean your microwave oven, use only cleaning products that do not contain abrasive particles. The presence of these thins the enamel and leads to scratches and chips.

Summarize. Damage to the enamel is a signal that the microwave needs repair, but does not affect the quality of the food cooked in it. If the paint chips are too large or rust is already appearing on the exposed metal, it is better to replace the device with a new one.

What are the causes and consequences of using a rusty device?

Microwaves inside a microwave oven act on water molecules, activating them, thereby raising the temperature. Therefore, a moist, aggressive environment appears after each use of the microwave, in the form of drops of water, food debris, and fat. Cracks appear on the walls due to lack of maintenance or due to overly careful maintenance using abrasive agents.

Subsequently, rust appears in places of damage

There are many myths around this technical device. One of them is that rust under the influence of microwaves releases harmful compounds, and the lack of paint makes the waves dangerous.

In fact, if a small layer of enamel is destroyed and corrosion appears, the thermal conductivity will simply decrease, and the food will take longer to cook and heat up than usual.

But if you continue to use the ultra-high-frequency stove, corrosion will destroy the device, and pockets of unprotected metal will appear. But metal cannot be used in this equipment, because it does not have the properties necessary for the action of microwave waves: it does not contain water and its molecules are not accelerated under the influence of waves, but it has electrical conductivity. Waves that are not capable of affecting iron return to the emitter, causing sudden overheating of the mechanism.

As a result, the metal can spark, crack, cause a short circuit and cause a serious explosion.

The main cause of damage is poor care of the device.

If you cook and heat food in a special container and wipe it with a dry cloth after each use, the stove will serve without interruption for many years.

If damage has occurred, you should not immediately get rid of your faithful assistant. As soon as you discover that your microwave oven is rusty, take a little time to repair it in order to extend its life and protect your loved ones from the negative consequences of using a rusty device.

Choosing a paint composition

Paint selection criteria

When purchasing, you should consider several important factors that the composition must comply with:

- The composition does not contain any substances that have a negative impact on human health. After drying, the surface should not emit any harmful substances, because in the compartment under the influence of high humidity of heated products this process is several times more intense.

- The paint and varnish composition must be sufficiently resistant to adverse factors - high humidity and temperature changes. They are the ones that have a negative impact on the finish and cause it to peel and swell.

Very often the coating is damaged at the joints and the door fit; in such cases, it is somewhat more difficult to restore it due to the complexity of preparing these areas

The paint for the microwave must match in shade; if the inside and outside are different in color, the equipment does not look very attractive. Some types of paints and varnishes are available in a limited range of colors, which reduces the scope of their use.

Types of paints used for repairs

Let's look at what compounds are most often used for DIY repairs:

Organosilicon food paints. The price of this solution is quite high, but the result is excellent - the resulting coating is resistant to most adverse influences and mechanical damage. The compositions are specially designed for the food industry and approved by the Ministry of Health, which indicates the highest degree of safety; in addition, they fit perfectly on metal and aluminum surfaces.

In the photo - a group of compositions KO-5102, produced in 0.9 kg cans

- Zinga electrically conductive paint is also sometimes used for this type of work; the dried coating consists almost entirely of zinc, and is therefore resistant to most adverse influences and temperature changes. The coating can withstand heating up to 150 degrees, but is rarely used for painting, since its cost is quite high.

- Fire-retardant paints for metal Polistil are resistant to flame and high temperatures and can also be used as an option. But this is still not worth doing, since the composition is not intended for the food industry, and there is no data on its safety when used in kitchen equipment.

- Acrylic automotive primers are one of the most popular solutions due to a number of positive properties: high coating reliability, ease of use and low cost. It is best to purchase the material in an aerosol can - it will be enough for repairs, and it is very easy to work with. The coating is durable and does not emit any harmful substances during operation.

Acrylic primer can be of different colors, which is also an important advantage

How to paint the inside of a microwave - choosing paint

If you don't change the microwave, all that's left to do is paint it. First of all, let's figure out what.

The answer suggests itself - enamel, since that is what they paint at the factory. When choosing a paint, make sure it can be used on items that come into contact with food. This should be indicated on the label.

If you have a regular microwave without a grill, then the heat resistance of the paint does not matter, because the body does not heat up during operation.

And if you have a stove with a grill, then you should use paints that can withstand temperatures from 250°C. There can be no talk of any 600 degrees, because at such a high temperature food is simply destroyed and cannot be there.

If you have an expensive stove and you are willing to spend adequate money on its repair, then buy silicone food paint KO-5102.

You can also use this paint.

For a cheaper option for painting the inside of a microwave, most DIYers use acrylic automotive primers in aerosol cans. They make repairs much easier.

If the condition of the insides of your microwave is as shown in the photographs, then selective painting is not enough.

Causes of coating deformation

The internal surfaces of the oven must be regularly cleaned of food residues or grease deposits. When using abrasive materials and aggressive detergents, chips appear and the enamel begins to crack and peel off. Damage to the coating contributes to the appearance of rust.

Inner covering material

The restoration method depends on the material from which the coating is made.

Internal surfaces can be treated with the following compounds:

- Enamel. The material has an affordable price, so it is used often. Enameled coatings for metal stoves do not last long. Under the influence of hot steam and grease, the paint begins to peel off. The surface is also damaged by mechanical impact. Renewing the enamel coating is not particularly difficult.

- Stainless steel. The material has an attractive appearance. It is resistant to mechanical damage and high temperature exposure. The coating is difficult to wash off from grease stains and is practically impossible to restore.

- Ceramics. It is characterized by increased strength and long service life. When caring for the stove, do not use sharp objects or abrasive materials. The coating is easily cleaned from grease and other contaminants. Ceramics are not damaged by high temperature and humidity. This surface can be painted with any composition.

What are the dangers of using a microwave when the enamel inside has peeled off?

When the enamel chips, the “iron box” is exposed. It would seem that there is nothing wrong. The problem is that unprotected metal can begin to corrode. If you aggravate this process, then a hole will appear due to rust, and fire can pass through. As a result, the device may catch fire or simply fail.

Among other things, the very presence of a metal surface (object) inside threatens the possibility of an explosion. The metal acts as a shield for microwaves and has excellent electrical conductivity. The latter circumstance just causes the redistribution of currents on it, which, in the presence of an electromagnetic field around, leads to breakdown.

Is it possible to use a microwave if the paint inside is cracked?

Of course, if you have already heated up your lunch and then only notice that the surface of the inner chamber is damaged, there is no need to throw it away. The products are reliably protected from the penetration of high-frequency waves by a metal casing. If the metal is not rusted, but only the integrity of the enamel is damaged, it is not dangerous. But it is better to refuse further use of the device in this condition.

The fact is that during cooking, a certain amount of steam is generated inside the microwave oven. When iron interacts with moisture, it begins to corrode. Therefore, at a certain moment, in a place where there was just a small chip of paint, a hole may appear due to rust. It is through this hole that the radiation will penetrate into the chamber itself. Moreover, this situation also threatens that due to the high temperature of the internal coil, without proper protection, the device may even catch fire.

However, if a defect is discovered, it is not necessary to throw away the microwave and run to the store for a new one. The situation can be saved by nitro paint or any other enamel that is safest for everyday use (the degree of safety is usually indicated on the can).

What to do if the microwave is rusty inside

If the enamel inside the microwave has chipped, it is not advisable to use such an oven: the “bare” metal will crack and spark, which will lead to rapid failure of the device. In addition, this is fraught with the occurrence of an electric arc and fire.

The operating instructions for microwave ovens clearly prohibit their use if the integrity of the internal coating is damaged at the slightest level. However, if there are no other problems with the device, you can try to restore the enamel.

You need to remove the plate and rotating stand from the oven chamber and carefully inspect the damaged areas. If corrosion has affected only the surface of the metal, then the coating is restored according to the above instructions.

If the bottom, ceiling or wall of the microwave oven is rusted through or close to it, the oven cannot be used; it cannot be repaired. It is dangerous to turn on such a device.

This is interesting:

Is it possible to sterilize jars in the microwave?

How to properly hang a microwave oven on a bracket.

About the symbols on microwave cookware.

Features of coatings

Why does damage occur? During operation, the inner surface of the device becomes dirty. This necessitates cleaning the chamber walls. If you use abrasive substances or materials, the coating may be scratched. Other types of damage may also occur, depending on the type of surface. The walls of the chamber can be:

- enameled;

- metal;

- ceramic.

Enameled surfaces are the most common. Such devices are cheaper than others, so they are purchased much more often. The enamel is quite easily damaged when cleaning the device. In addition, during operation it gradually loses strength.

The enamel can be washed off quite easily, but this must be done carefully so as not to accidentally scratch it.

Stainless steel coatings are much stronger, but they are more difficult to clean. Fats that accumulate on the walls are difficult to clean off. It is best to clean the inside of such devices using steam, which effectively softens fatty deposits.

Ceramic surfaces are durable and smooth. They get dirty a little and are easy to clean. However, this coating may also crack or chip if the device is accidentally dropped or hit.

To avoid damage, never use abrasives or harsh chemicals to clean your microwave oven.

If chips or scratches appear on the walls inside the microwave chamber, it is considered that the device is out of order and cannot be used anymore. In this case, you can try to restore the coating by treating it with a special compound. If everything is done correctly, the device can work for a long time.

Search data for your request:

One fine, actually not very morning I heard that the microwave inside was sparking and it smelled like something was burning. I look inside and see this picture:. Ok, I turned off the power and went to work, and bought a replacement that same evening. And the old one was dragged into his room by a heavy pancake.

Search data for your request:

Schemes, reference books, datasheets: Discussions, articles, manuals:

Wait for the search to complete in all databases. Upon completion, a link will appear to access the found materials.

WATCH THE VIDEO ON THE TOPIC: Microwave sparks. Repairing holes and rust on the bottom of the microwave

Rust in the microwave

The Dyson Cyclone V10 Absolute vacuum cleaner does not work. In Bluedio Turbine T6S headphones, when connected to a computer, only the middle plays. The spacebar was broken as a result of the shelf falling onto the keyboard. Good evening. Screwdriver on Kirghizskaya Good afternoon! Global Service etc. Good afternoon, if there is not a large amount, then you can simply paint over it with auto-corrector, if the area is large, then just cover it with enamel.

Repairing household appliances at home How to remove the timer adjustment knob on a microwave oven over a year ago Samsung CEN microwave ovens. The Samsung cen timer adjustment knob in the photo is scrolled. Tell me, the handle can be removed by pulling it towards you, or What to do if the microwave sparks more than a year ago Microwave ovens Neff HN0. Please teach me what needs to be done to prevent the Neff HN0 microwave from sparking? Last questions. Add solution. Similar questions. How to remove the timer adjustment knob on a microwave oven over a year ago Samsung CEN microwave ovens The Samsung CEN timer adjustment knob is turned in the photo.

Services and repair technicians for Kuppersbusch microwave ovens Repair of Kuppersbusch microwave ovens in Moscow service centers and private craftsmen Repair of Kuppersbusch microwave ovens in St. Petersburg 8 service centers and private craftsmen Repair of Kuppersbusch microwave ovens in Kazan 10 service centers and private craftsmen Repair of Kuppersbusch microwave ovens in Krasnodar has 12 service centers and private masters.

Microwave enamel

Register Login. Mail replies. Questions - leaders connecting a plasma panel to a soundbar via optics 1 rate. Leaders of the category Anton Vladimirovich Artificial Intelligence. Sour Supreme Intelligence.

How to paint the inside of a microwave to prevent rust. Is it possible to use a microwave if the enamel inside has peeled off, how to do it correctly.

Microwave paint inside

Microwave oven is a daily use item that is firmly established in our daily lives. When buying a device, we expect that it will serve faithfully for a single year. In addition to standard technical faults that can be encountered during operation, there is a problem associated with deformation of the paint on the surface. The paint peels off and chips; this not only spoils the external impression, but also has a negative impact on the functionality of the microwave.

How can you paint the inside of a microwave and is it possible to do it yourself? Let's try to figure this out. In fact, in the event of significant defects in the enamel of the device, most simply prefer to replace the microwave with a new one and not bother with its restoration. However, as a rule, if everything is done correctly, the furnace can last for a very long time, so before you say goodbye to it, read the tips on how to properly restore the device.

There are the following main types of paints and enamels used for processing microwave ovens. This is perhaps the best option, although not the cheapest.

How to paint the inside of a microwave?

Hello, guest Login Registration. Rules of the Academy Town Forum. Search this forum only? Extra options.

While heating up your food once again, did you hear a crackling sound?

The inside of the microwave is rusting - what to do?

Users of microwave ovens often face one problem - the inside of the microwave inevitably becomes dirty, the paint peels off, and the surface rusts. A natural question arises: how to paint the inside of a microwave to prevent rust. The microwave has long become an integral attribute of the modern kitchen.

It is important to keep it in good condition, because with daily use it loses its attractive qualities. The enamel cracks and rust spreads across the surface. Restoration of the internal surface is periodically required.

Many people are interested in the question of whether it is possible to use a microwave if the enamel has peeled off.

Throwing away the microwave is the easiest way, so I decided to look, scratch the coating and rust will quickly form in the “bare” places. The most convenient way to do this is with a soft sponge and soap.

Samsung microwave with bioceramics

Samsung was one of the first to use bioceramics in microwave ovens. Currently, a fairly wide range of microwave ovens with such a coating is produced. Many of them are already popular among users, for example, models such as Samsung CE2813NR, Samsung ME712MR-S, Samsung GE81MRTBBW and others. Other models are only gaining the trust of buyers. According to the manufacturer, the bioceramic coating almost completely protects against bacteria. The latest models have many useful functions, from maintaining the temperature of the finished dish to removing odors. At the same time, even with a grill, the new models are distinguished by an increased internal volume of the microwave chamber.

New models of Samsung microwave ovens with bioceramics also allow, like multicookers, to cook a number of dishes according to pre-prepared programs at the touch of a button. But they also retain the main advantage - durable, beautiful biocermic enamel, which allows you to quickly wash the surface even after grilling food or boiling beets in the microwave.

How to restore coverage

One of the simplest options is to paint problem areas with any heat-resistant composition of the appropriate color. However, if you want to get a strong and durable coating, then you should take the matter more seriously. To eliminate the flaw, you will need an aerosol can with automotive acrylic primer and the same nitro enamel of the desired color (usually white).

Preparation

Inspect and feel the entire inside surface of the camera: it is quite possible that you will find swollen areas. These should be removed to expose clean metal. The entire coating must be cleaned with fine sandpaper and degreased with a solvent (for example, acetone). Further:

- Seal the magnetron exit area and the backlight hole with adhesive tape (insulating tape) so that the pieces of material overlap each other;

- Remove the outer casing to ensure good ventilation during painting;

- Place a plastic bag on the microwave door and secure it with the same tape.

Primer treatment

The stove should be painted in a ventilated area. Place the device on one of the faces at an angle of 45 degrees so that the back wall rests simultaneously on the wall and the floor. Now, holding the door with your hand, apply primer from a can. It is advisable to wear a respirator and gloves. The composition is applied from a distance of 25–30 cm. The number of layers is 3, each of them needs to be dried, for which you can use a regular hairdryer. When the primer has been applied in the required amount, leave the oven to dry completely (1 day).

Types of microwave paints

There are various paint and varnish materials on the market, and sometimes it can be difficult to decide which paint to choose. Various types of paints can be used to paint a microwave at home.

Aerosol heat-resistant acrylic paint

Typically, such painting compositions are sold in spray cans, and this is very convenient for home use, since when sprayed, the paint lays down in an even, beautiful layer. One can is enough to paint the entire interior of the microwave. Aerosol enamel for microwaves such as BeLife Paint for Ceramic will protect against rust and withstand sudden temperature changes and extreme heat. This composition perfectly withstands humidity, it is resistant to steam, completely environmentally friendly and safe for food and humans.

Special food enamel

These are silicone food paints that are best suited for painting microwave walls. The dye contains pigments and additives, as well as fillers and a special silicone varnish. Such materials are absolutely safe for contact with products and meet all standards. The coating will be resistant to high temperatures and will withstand moisture well. At the same time, it will be quite durable, and therefore you can use chemicals and mechanical means to clean it. This type of paint dries quite quickly and can be applied with a simple brush.

Conductive paint

Conductive paints contain aluminum, zinc and silver

The coating will be resistant to high temperatures (up to +200 degrees), and when heated, no harmful substances are released, which is especially important for a microwave due to constant contact with food. The only disadvantage of such coloring products is the rather high price, but it is fully justified by the durability and strength of the resulting coating.

Shungite paint

Shungite is a rock that resembles graphite in structure. Shungite paints have high electrical conductivity properties and provide good protection against fires and overheating of equipment. Products with this composition are most often used in the construction industry, but paint with shungite is also excellent for microwaves. The material is completely harmless and tolerates heat well even up to +300 degrees.

Acrylic primer for car

Special automotive primers always have increased strength and will be a reliable and good coating for damaged microwaves. They are also very resistant and quite durable, and can withstand exposure to increased moisture and high temperatures. An additional advantage of this product is a wide selection of different shades, which allows you to emphasize the style of the kitchen appliance. One significant disadvantage of the paint is that it cannot withstand temperatures of more than +100 degrees and therefore is often recommended for painting the outside of appliances rather than the inside.