How to choose a plotter

There is a huge selection of models in different price categories on the equipment market. However, it is impossible to choose the right plotter based on cost alone. You must have at least basic knowledge of the technical parameters of the purchased device.

The video provides information about the purpose of the plotter:

Purpose

In general terms, the purpose of the equipment is clear. The equipment is designed for large format printing. However, this concept is vague. In order to choose the right plotter for printing on canvas, it is important to know the existing varieties, because each model is capable of performing certain operations.

According to their purpose, all plotters are divided into three groups:

- Printing models have the same purpose as printers. They apply a design onto paper or other consumables.

Printing equipment is intended for printing only - Cutting models are used to cut out shapes of any complexity from film, paper and other consumables. The equipment is in demand for the production of labels, advertising posters, and logos.

Cutting equipment can only cut out shapes of the desired shape - Cutting and printing models are combined. Plotters are capable of applying an image to a consumable material and using a cutting mechanism to cut out figures from it.

The cutting and printing plotter will perform two functions simultaneously

Important! The most popular are cutting and printing plotters. They are often called simply cutting, meaning that such models must cut and apply an image to a medium.

If you plan to choose a plotter for printing drawings, it is reasonable to choose a budget model with a small set of basic functions. When you plan to produce advertising posters, banners, and other complex products, it is optimal to purchase equipment with cutting and printing functions.

Advice! The cutting type of plotter is useful if printing is not needed, but only cutting a blank canvas or a finished image is intended.

Media format and type

Films, fabrics, cardboard, paper, synthetic materials - these are the media (consumables). This is where the plotter prints the design or cuts out the shape. The operating costs depend on the type of media. The more expensive the material, the larger they will be.

Each model has its own format. This concept refers to the size of the media that fits within the boundaries of the working field of the equipment. Cutting models work with sheet and roll material. The main limitation of the media is width. The setting must match the cutting device format. Roll media cutting equipment is capable of cutting to any length. However, huge rolls are inconvenient to use due to their large dimensions and weight. Here, manufacturers have also created certain restrictions. There is such a thing as permissible roll diameter. Media for cutting equipment is not produced beyond this parameter. However, the length of the web varies between rolls, regardless of their same diameter. It all depends on the thickness of the media. The thinner the fabric, the more of it is wound in the roll.

When choosing a technique, it is important to consider the format. If you intend to produce only thermal decals for textile products, then it is better to buy a cutting plotter with a cutting width of 20 to 30 cm. The A3 format is considered optimal. When cutting a wide format is required, then cutting equipment must be selected with the appropriate working area of movement of the knife.

Printing technology

Cutting models with a printing function are distinguished by the technology of applying an image to a medium. According to this parameter, plotters are of the following types:

- Pen cutting models are considered vector electromechanical devices. They apply a design with liquid dye using special devices called pens.

- Pencil-pen cutting models have a similar device. The difference is the ability to install a drawing unit with pencil-type leads.

- Inkjet cutting models with a printing function apply a design by spraying paint from a nozzle. The technology resembles printing from a conventional inkjet printer.

- Electrostatic cutting models resemble inkjet plotters. They work with liquid ink, but create a latent electrical image on the medium. Electrostatic paper is used as a consumable.

- Cutting models with direct image output (DIO) function are printed with a special comb consisting of small heaters. The carrier is special thermal paper. Depending on the degree of heating, an image of a certain shade appears on the canvas.

- Cutting models with thermal printing function operate on the PVI principle. However, a color carrier in the form of a thin film is placed between the comb and thermal paper. To get a color image, the cutting plotter needs to make 4 passes with the heating block. For monochrome printing, 1 pass is sufficient.

- Cutting laser models apply an image using electrographic technology. Beams of light in the selenium-containing media remove the selenium charge, capture the magnetized toner and transfer it to the paper passing through the charged areas of the rotating drum.

When choosing a cutting model, it is important to compare plotters based on printing technology. The final result of the resulting product depends on this, as well as the costs of media, paints and other materials.

cutting

If the goal is to select a cutting plotter with a printing function, then the device will naturally have the option of cutting the media. Here, it is similarly important to select a cutting model according to the desired parameter. This refers to the maximum cutting width. In other words - format. For domestic use, a cutting model is selected with a cutting width of 250 mm or more. For use in production, a plotter with a cutting width of 1000 mm is suitable.

The cutting width is the format for the cutting plotter

Another important parameter of cutting models is the cutting accuracy. The higher the indicator, the more accurately the machine will cut out the design according to a given program.

Attention! Cheap cutting plotters made in China have poor cutting accuracy. Often the knife moves away from the markings.

Other characteristics

When choosing a plotter for scrapbooking, it’s a good idea to pay attention to other characteristics.

For print function:

- The number of sheets that the cutting plotter can process in 1 minute depends on the printing speed.

- Resolution is denoted by dpi, which means the number of dots per inch. The higher the value, the clearer the image.

- The quality of color affects the beauty of the image. In this regard, professional-type cutting plotters benefit.

For large format cutting machines, it is important to choose the right media type - Large-format devices work with a certain type of media: fabric, vinyl, banner mesh and other materials. When purchasing a model, you first determine what media you need to print on, and then select a plotter based on its characteristics.

For the cutting function:

- A cutting device with an optical positioning sensor makes cuts more accurately. The function is useful in the production of applications, icons, and other products that require precision.

The optical sensor of the cutting equipment creates special marks that accurately determine the edges of the cut object - The cutting force of the device depends on the pressure of the knife. To cut thin film or paper, a pressure of 200 g is sufficient. If you intend to cut cardboard or other dense media, the knife must create a pressure of at least 500 g.

- The cutting speed determines the performance of the cutting equipment. However, it is better to cut small parts at low speed within 5-10 cm/sec to ensure high-quality parts.

When all the parameters have been precisely determined, you can begin to look for the best plotters for drawings, cutting, color and monochrome printing.

What is a plotter and where is it used?

A plotter is equipment that is used for large-format printing, including A0 format. A plotter, also called a plotter, depending on the specifics of the work, can print not only on paper, but also other materials, synthetic media, film, and so on. In addition, some models are equipped with a cutting function, which is used when printing on hot-melt film, labels, logos, and so on.

A plotter performs similar functions to a printer, but specializes in large-format printing. It is used for printing:

- drawings and projects;

- advertising posters and announcements;

- topographic maps;

- presentations;

- products on hot-melt film and other wide format materials, and so on.

Due to their large size and functionality, these devices are not purchased for home use. The most common areas of application include:

- design bureaus;

- design companies;

- cartography centers;

- advertising firms;

- printing services companies and so on.

The best cutting plotters

The rating should start with a review of cutting plotter models from popular manufacturers. Models are presented in different price ranges. The devices are suitable for household use and small businesses.

Brother ScanNCut CM900

The cutting model works with roll media.

The plotter carries out cutting on roll material. The device has an A3 format. Important information is shown on the display. A special feature is the average cutting speed – 112 mm/sec. Cutting width – 297 mm.

GRAPHTEC CE6000-40

The cutting plotter is equipped with a servo drive.

The manufacturer offers a good and inexpensive cutting plotter that works with roll media. A3 format. The device is equipped with a servomotor and has a display for settings and information display. High cutting speed – 600 mm/sec. Knife pressure – 330 g. Cutting width – 375 mm.

GCC Expert II-52

The plotter works with roll material with a width of 1635 mm.

The cutting apparatus is suitable for the production of large-format products.

A special feature is working with roll material with a width of 1635 mm. Cutting width – 1320 mm. Maximum knife pressure – 350 g. Cutting speed – 635 mm/sec. There is a memory buffer of 32 MB.

Top 6. Silhouette Cameo

Rating (2021): 4.48

14 reviews from resources were taken into account: Yandex.Market, Otzovik, IRecommend

- Characteristics

Average price, rub.: 25,000 rub.

- Country: USA

- Format: A3

- Cutting: yes, 100 mm/s, up to 30 cm

- Buffer memory capacity: 2MB

- Interfaces: Bluetooth

The model is designed as a powerful and “omnivorous” desktop option. It has a remarkable knife pressure force of up to 500 g, due to which it copes well with precise cutting of materials of various densities: fabric, photo and craft paper, vinyl. With the appropriate selection of blades, it will work on leather, as well as cork and foam materials. The maximum thickness of the sheet, provided it is soft enough to be secured between the rollers, is 3 mm. At the same time, the carriage accommodates two tools, each of which the plotter can recognize automatically. The basic package comes with an Autoknife chip and 5 adapters, and control occurs through Silhouette Studio - this software is provided free of charge.

Advantages and disadvantages

- High pressure force

- Precise cutting

- Auto tool detection

- Runs loudly

The best inkjet plotters

To produce bright posters, all you need is an inkjet plotter. The devices are affordable, operate at high speed, and use paint sparingly. Inkjet printing technology makes it possible to create beautiful colors and apply them in the form of pictures on the media.

Canon image PROGRAF iPF670

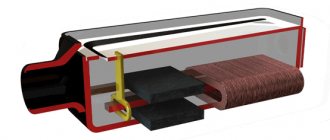

The plotter is equipped with an intermediate ink chamber.

A popular manufacturer offers a high-quality plotter with inkjet printing technology. Image clarity is achieved due to high resolution – 2400x1200 dpi. Printing width – 610 mm. The device works with A1 format. It has its own memory of 256 MB, 4 color and 1 black cartridge.

Epson Sure Color SC-T5200

The model is designed for creating construction drawings.

If there is a need to choose a plotter for printing drawings, the ideal option would be a model with a resolution of 2880x1440 dpi. The maximum width of the image is 914 mm. A1 format printing speed is 28 seconds. There is 1 GB RAM and a 320 GB hard drive. The maximum diameter of the roll used is 150 mm.

HP Design Jet Z9+ 24 Postscript (W3Z71A)

A high-quality plotter for printing on paper and cardboard.

The rating of inkjet printers is completed by an American plotter equipped with 9 cartridges. Each container holds 300 ml of ink. The device is equipped with a touch screen. Print resolution – 2400×1200 dpi. For convenience, side and rear feeding of sheets is provided. The carrier can be cardboard - 500 g/m2 and paper with a minimum density of 80 g/m2. The width of roll media is from 279 to 610 mm. There is 4 GB of RAM and a 500 GB hard drive.

Choosing the right plotter

First of all, you should consider future expenses, namely, take into account not only the price of the device itself, but also the additional costs of its maintenance, repairs, and the purchase of consumables. Only by calculating these indicators will it be possible to make a conclusion about the high/low cost of the selected model. Especially the hidden costs have the biggest impact on the overall picture. At the same time, this printing machine, due to its high technology, should always be considered as an investment in the workflow.

If we talk about the need to replace an old device with a new one, then it is best to consider a more modern model with advanced functionality. At the same time, if the budget has significant restrictions, then it is better to choose an older model, but with improved functions. It is worth noting that if a radically different model from the one to be replaced was selected, then all obvious and hidden costs for it will have to be recalculated. It is quite possible that the remaining cartridges and other consumables from the old model simply will not fit the newly purchased one.

And yet, as a last resort, you can always use financial rent (leasing) of the necessary equipment.

Picture quality

Depending on future needs, it is necessary to focus on indicators such as image resolution in dots per inch, printing speed and performance, as well as the printing technology itself. For example, if a plotter is purchased for short-term use, for example, printing advertising banners for candidates as part of an election campaign, which will be installed on objects remote from the human eye, then there is no point in overpaying for technically high image quality. If long-term use of the device for printing drawings and engineering diagrams is expected, then attention should be paid to direct input plotters or those operating on the principle of heat treatment. In turn, for the advertising business, cutting or drum models will be the best option.

Ease of use

This category includes several features and is not limited to a set of buttons on the plotter body itself. When assessing the comfort of using the plotter functions, you should rely on:

- The types of jobs most often sent to print – will they be mostly the same type or will the settings of the printing device need to be changed from time to time? If the same type of tasks prevails, then it is necessary to ensure that the plotter’s memory can accommodate the required number of required templates. If frequent reconfiguration is required, then it should be as less labor-intensive as possible and not require pressing many buttons;

- The number of expected regular users is no secret that each operator will customize any equipment specifically “for themselves.” Thus, if the number of users is large enough, then reconfiguring printing should not take much time and should not require special knowledge or explanations for operation;

- The maintenance process - replacing consumables (reinstalling cartridges, refilling ink) and loading media should not create any special difficulties for the operator. The preferred option would be a model that would allow these processes to be performed, as they say, “on the fly”;

- Ergonomics - this criterion indicates that when working with the device, its user should not require any significant physical effort. For example, it is advisable to install a roll of paper and wind it onto a drum using automatic modes; the operator panel is located in a convenient way, i.e., access to it is not hampered by other working elements; changing the media feed angle is easy and relaxed, etc.

Availability of upgrades

Naturally, predicting the future is a difficult task. But due to the fact that plotter equipment is quite expensive, it will be easier to update some of its parts separately by assembling a modern model than to purchase a completely new unit. The ideal option for purchasing would be a sample on which the following elements can be changed over time:

- Service maintenance – the possibility of extending the contract for maintenance and repair with a specialized organization;

- Software - the manufacturer independently, as new programs are released, transmits updated firmware versions to the user so that the equipment “keeps up with the times” in terms of the latest technical developments;

- Hardware is the ability to physically add new elements to the equipment design, or replace outdated ones.

The best solvent plotters

This category includes expensive class equipment. The devices can work continuously all day. The main area of application is the production of large outdoor advertising posters and products for interior decoration.

Mimaki JV150-160

Productivity is achieved due to uninterrupted ink supply.

The SBPS unit is equipped in such a way that two cartridges are allocated for each color. After one container is empty, the operator receives a signal, and the plotter automatically switches to another cartridge. An accurate drawing is obtained thanks to the high resolution - 1440x1440 dpi. The maximum print width setting is 1610 mm. Printing speed – 56 m2/hour.

Roland Versa Studio BN-20

The plotter has a cutting function.

The compact model will fit on the table. The maximum image width is 480 mm. The cutting device works with media up to 1 mm thick. The brightness of the pictures is achieved through 6 colors. The SBPS unit is missing.

MIMAKI SWJ-320EA

The latest generation model costs 1,792,035 rubles.

The plotter is equipped with a high-speed printing unit with 4 heads. Maximum productivity reaches 137 m2/hour. The model is distinguished by its economy of paint, but the images are colorful due to the high resolution of 1200 dpi. It is possible to print simultaneously on two media.

The best textile plotters

The equipment is in demand for printing advertising banners on large-sized fabric media. Special dispersion paints are used for refilling. They penetrate deeply into the canvas, retain a colorful pattern for a long time, and do not fade quickly under the sun.

Mimaki JV300-160

Multifunctional equipment is equipped with 9 cartridges.

The professional model works with a maximum width of 1620 mm. The checkerboard arrangement of the heads allows you to get a high-quality picture, as well as increase the passage area at one time. Maximum print speed – 106 m2/hour. Cartridges can be refilled with inks from different manufacturers.

Epson Sure Color SC-F2000

The equipment is capable of printing images on T-shirts.

The plotter is suitable for small entrepreneurs. The equipment is capable of printing images on T-shirts and other lightweight clothing. Special dyes penetrate even semi-synthetic fabrics, where the cotton content is only 50%. The maximum print width is 406 cm. The colors are combined from 5 pigments.

Mimaki TS300P-1800

Wide-format equipment belongs to the professional class.

The plotter works with large formats exceeding A0. Printing width – no more than 1940 mm. The clarity of the pictures is achieved thanks to the high resolution – 1040×1040 dpi. Roll printing only. The speed in roughing mode reaches 115 m2/hour. The uninterrupted ink supply system consists of 2 liter tanks.

Difference between plotters by type of drawing block

In the case of a drawing block, classification is easier to perform. The following varieties exist:

- feather;

- jet type;

- laser type;

- electrostatic type;

- direct output;

- thermal information transfer.

Let's take a closer look at each of the above types of equipment.

Feather

The principle of operation of a pen plotter is simple: the image is applied to the substrate using a pen, which can only move in two directions. A special pencil or liquid paint can be used as a dye. The latter can be solvent and eco-solvent. What does it mean? Solvent inks contain solvents, which allows you to create designs on PVC surfaces for which they were created. Eco-solvent paints also contain solvents, but they are less aggressive and toxic. They do not emit a pungent odor during operation and are used more economically.

An electric motor is responsible for moving the pen in such plotters, so they make a lot of noise when creating drawings and drawings. Another impressive disadvantage of pen plotters is their low print speed. However, there are also advantages:

- high quality of the resulting images;

- rich color and good contrast (for color printing).

Jet

An inkjet plotter uses the same technology as a printer: printing is carried out by applying many small colored dots of 4 primary colors (CMYK). Inkjet plotters are popular because... provide many benefits:

- high speed;

- good resolution;

- affordable maintenance and consumables;

- optimal cost.

Inkjet models can be equipped with CISS (uninterruptible ink supply system). This quality is very important in conditions of continuous or extreme fast printing, when there is no time to refill a cartridge that has suddenly run out.

Laser

A laser plotter operates on exactly the same principle as a printer. We can say that this is a wide-format laser MFP. It is based on electrographic technology, based on the photoelectric effect of photosensitive semiconductor layers of materials containing selenium, as well as on the influence of electrostatic fields. The image has a so-called an intermediate carrier (a rotating drum with selenium deposited on it), which can be charged to an extremely high potential - hundreds of volts. Using a light beam, this charge is removed, forming an undeveloped electrostatic image, which is attracted by the magnetized fine toner. Subsequently, everything is mechanically transferred to the prepared paper.

Laser plotters are capable of printing an image in a matter of minutes, thanks to which they have gained massive popularity in both the advertising and printing business . However, their cost is quite high compared to the first two types.

Electrostatic

An electrostatic plotter is somewhat similar to a laser plotter. Its operating principle is also based on the formation of latent images (electrical), the so-called. "potential relief". Unfortunately, the disadvantage of this technology is that printing requires special electrostatic paper, thoroughly coated with a dielectric and impregnated with a hydrophilic salt. Such paper requires constant storage conditions, such as humidity, to maintain its electrification. The slightest violation can lead to its damage.

Another disadvantage of electrostatic printing plotters is the very high cost of servicing the devices themselves and purchasing consumables. The advantages include the stability of the finished product. The image obtained using an electrostatic plotter is resistant to UV rays, is stored for a long time without losing brightness, and also has a high degree of protection from other external climatic conditions.

With direct output

Direct output plotters also need specialized paper, without which their operation becomes impossible. Such paper is specially impregnated, and a narrow line “comb” of mini heaters is left along the edges. Heating occurs while paper is fed from the roll. Color changes occur in areas of heating and depend on temperature.

Unfortunately, this printing technology is black and white. Direct output is not capable of producing colors, only a few shades of gray.

At the moment, consumables for direct output plotters have become available and are widely used in the printing industry. Many archival repositories order direct output printing. This is due to the fact that the finished products have a long shelf life and minimal sensitivity to external influences. Printing is carried out on paper, tracing paper and film.

With thermal transfer

Devices operating on the principle of thermal transfer are distinguished by the fact that a color matrix is placed between the heating element and special paper (including film of various levels of transparency). Its thickness usually does not exceed 4-10 microns. The color matrix is placed close to the paper, onto which some of the ink transfers when heated. The coloring layer is made of wax and is not fusible.

One color is applied in one pass. Color correction is achieved in a full four passes. Unfortunately, in this regard, we have to remember the high cost of consumables and the need to replace them quite often. Thus, to create a color image, four times more ink is required than to draw a black and white image. It is because of this factor that this printing technology has not gained mass popularity. Most often, thermal plotters are used where it is necessary to create a three-dimensional image (for example, cartography) with high color rendering quality. In addition, this technology is used to create high-quality presentations.

Best UV plotters

Equipment printing technology is based on ink treatment with UV rays. When exposed to ultraviolet light, the ink polymerizes. They are not absorbed into the media, but harden on the surface.

Mimaki UJF-3042 MkII

Compact equipment for the production of small signs

The plotter is capable of printing on solid media, which allows you to immediately produce a finished sign. Ink is supplied continuously from bottles. It is possible to apply a design to cylindrical objects. Maximum media parameters: thickness – 153 mm, dimensions – 300x420 mm. Picture clarity is achieved with a high resolution of 1200x1200 dpi.

Mimaki JFX200-2531

Professional equipment for the production of large signs

The plotter has a printing width of 2500 mm, which allows you to produce large signs. A carrier weighing up to 50 kg is placed on a special support table. Under the tabletop there are 8 spacious 1 liter tanks with paint. The disadvantage is the weak resolution of 1200x1200 dpi for large media sizes.

Mimaki UCJV300-160

Large-format equipment is used for the production of advertising and packaging products.

The plotter prints in a six-color configuration with the addition of white ink. The equipment has a cutting function. The printing speed is 25.8 m2/hour. Picture clarity is achieved with a resolution of 1200x1200 dpi. Continuous supply of paint is carried out from bottles.