A geyser is a compact, functional, practical and reliable device for providing an apartment with hot water. It will not take up much space on the wall, and any teenager can understand the principle of operation of the device. The equipment is durable, practical, reliable, durable, and will serve the owner for decades.

The main thing is not to forget about the need for regular maintenance, namely, periodically cleaning and repairing the unit if necessary. In practice, a geyser can last much longer than its rated life if it is properly maintained. Where does scale and soot come from, what is needed to remove them, how to clean the main working parts of the device, read the review.

Geyser - principle of operation, causes of clogging

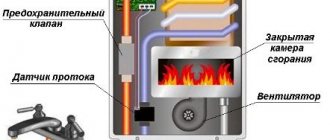

A instantaneous gas water heater is essentially a heat exchange device. Its main element is a special pipe circuit. A water stream flows through it and is heated by an open external flame of a gas burner. Modern models turn on automatically - as soon as the mixer valve opens, ignition occurs and thermal energy is transferred to the walls of the circuit, and from them to the flow. As a result, the user receives hot water at the outlet.

Despite the simplicity of the design and operation scheme, the operation of such a device constantly creates harmful factors that interfere with normal functioning - first of all, these are:

- Carbon deposits are on the outer walls of the heat exchange circuit. It impairs heat transfer from the burner to the water, reduces efficiency, and leads to excessive fuel consumption.

- Scale – builds up on the inner walls of the heat exchanger. It is formed as a result of the decomposition of salts dissolved in water and the precipitation of a solid insoluble precipitate. Reduces flow, reduces pressure, impairs performance.

Scale build-up in the heat exchanger significantly reduces the performance of the heater Source bigam.ru

- Soot - solid products of gas combustion inevitably settle on the burner itself and the igniter. The flame periodically goes out, the combustion intensity decreases, performance deteriorates, and there is a risk of gas leakage.

In addition, depending on the quality of the water, other impurities may settle in the heating device - rust, silt, sand, etc. To eliminate their influence, periodic and timely proper cleaning of the gas water heater is required.

Signs you need cleaning

The primary symptoms that the device is clogged and needs urgent cleaning are the following:

- The pressure of hot water is noticeably lower than that of cold water. Occurs due to a narrowing of the pipe lumen as a result of overgrowing with deposits.

- There is a regular shutdown of the device immediately after startup. The reason is the formation of carbon deposits on the ignition element.

- The level of water heating has decreased while the power of the device remains unchanged. It is a consequence of external fouling of the heat exchange circuit by carbon deposits.

- The time for heating water to the set value has increased. Occurs due to a decrease in burner flame power.

When the heat exchanger is clogged, the water flows extremely slowly and hardly heats up. Source cosmo-frost.ru

- There is noise inside the device during operation. Extraneous sounds are a consequence of uncharacteristic boiling of water inside the heat exchanger due to loss of sensitivity of contact thermal sensors with the walls of the thermal circuit.

- Switching off the device upon command from thermal protection sensors. Due to scale build-up, the walls of the heat exchange circuit begin to overheat.

In addition, when the heater is turned on, a strong bang may occur, indicating that the burner ignition is not working properly, and soot may simply begin to fall out from under the housing. All these signs indicate an urgent need to clean the gas water heater. Otherwise, the situation may get out of control, which will lead not only to damage to the device, but also to a leak of household gas with the ensuing serious consequences.

Important! Before starting cleaning procedures, the instantaneous water heater must be disconnected from the water and gas supply.

Before starting cleaning work, be sure to turn off the water and gas supply Source baltgaz.ru

How to remove the casing of a Bosch water heater?

The decorative and protective casing of the speaker is easy to remove:

- you need to unfasten the round adjustment knobs by pulling them towards you;

- move the rectangular gas adjustment knob to the body cavity (the “ignition” position). Please note that not every Bosch water heater model has such a handle;

- Using a Phillips screwdriver, unscrew the two self-tapping screws securing the casing to the column frame. They are located at the bottom, on the sides of the device.

All that remains is to carefully push the lower part of the water heater casing towards you with both hands. Then lift up, remove completely and set aside. Now you can visually assess the contamination of the device and determine the scale of cleaning work.

Features of cleaning main components

In domestic conditions, the owner of a gas instantaneous water heater is allowed to clean the following main parts:

- The burner surface is free from soot and deposits.

- Heat exchanger against scale build-up.

- The surfaces of the components inside the case are free of dust.

- The water supply part from clogging.

In addition, it would be useful to check the condition of the water intake module, the correct operation of traction sensors, the presence of lubrication of critical components and the tightness of all connections.

In this case, the most significant and often leading to malfunctions are the following column elements:

- Water intake.

- Heat exchanger.

- Burner.

Let's look at the specifics of cleaning each of them.

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

Water intake

The water entry into the heat exchange circuit pipeline begins through a special water inlet equipped with a strainer. Its purpose is to protect the unit from various kinds of mechanical impurities coming with the water flow.

The water inlet of the geyser is disassembled and cleaned Source cosmo-frost.ru

Cleaning the filter element located in front of the geyser heat exchanger is possible in the following 2 ways:

- Mechanical.

In most cases, the strainer becomes clogged with sand, rust particles and other sediment. Therefore, the fastest and easiest way to restore its functionality is to disassemble it and then clean it according to the following algorithm:

- The water and gas supply is turned off.

- The instrument panel is being disassembled.

- The water receiver is removed.

- The housing cover is removed.

- The filter is cleaned directly with a brush and a stream of water.

- If necessary, replace the membrane (if during disassembly it turns out to be curved rather than flat).

- After cleaning and drying, the filter is installed in place.

- The device is being assembled.

If the membrane fails - it breaks or bends - you can replace it with a new silicone-based model. Unlike traditional ones, it will last much longer.

The cross-section of the heat exchanger pipe becomes overgrown with scale during operation Source terman-s.ru

- Chemical.

It is not always possible to clean the pores of the mesh filter with a stream of water or a brush. Therefore, different types of acids are used:

- 9% vinegar.

- 20% lemon.

- Salt 5-8%.

- Sulfur 5%.

In order for the mesh to be cleaned of stubborn particles, it is enough to place it in hydrochloric or sulfuric acid for 10 minutes, or for about 1-1.5 hours in citric or acetic acid. After settling in an acidic environment, it must be thoroughly rinsed and, if necessary, cleaned with a brush.

Note! Working with acids is allowed in a well-ventilated area or outdoors, observing safety precautions and using personal protective equipment - gloves, goggles.

Heat exchanger

To restore normal operation of the gas water heater, it is also necessary to clean the heat exchanger from external carbon deposits and internal scale. The following methods are available for this purpose:

- From carbon deposits mechanically.

Cleaning the heat exchange circuit requires mandatory disassembly with preliminary shutdown of the gas and water mains. The procedure is performed using some kind of mechanical device.

Cleaning the heat exchanger housing with a brush Source teploburg.ru

Chemical reagents for dissolving scale

Typically, cleaning the column heat exchanger is carried out on average once every 1 year; the frequency of work depends on the duration of operation of the water heating unit, water hardness, the presence of additional filters, and can range from 6 months to 3 years.

The heat exchanger can be descaled in a static mode without removing it from the column body and in a dynamic mode, when it is simultaneously washed from soot, the following reagents are used for the work:

Anti-scale agents . The retail chain sells a wide range of household chemicals to combat scale; Antiscale, Detex, Master Boiler, Cillit Bang are well known; in principle, you can use any substance from a huge range of manufactured brands to clean household kettles, irons, water heaters, household washing and dishwashers. If the product is sold as a concentrate, it is diluted with water in the required proportion before pouring into the heat exchanger.

Hydrochloric acid HCl is obtained by mixing water with hydrogen chloride; it is a colorless liquid with a sour, suffocating odor; the technical solution has a yellowish tint due to the content of diatomic chlorine and iron molecules in it. When the acid content in water is more than 38%, it evaporates, so concentrated solutions cannot be purchased in retail stores. Since any acid corrodes metals, special additives and inhibitors are added to HCl to prevent the chemical reaction of decomposition of copper or stainless steel.

Acids

Orthophosphoric acid H3PO4 . It is an inorganic, colorless, odorless substance with a syrupy consistency; in the chemical industry, the starting component for further use is an 85% aqueous solution of H3PO4. Phosphoric acid is well known as an excellent rust remover (it is included in most metal corrosion inhibitors), but it does not have a destructive effect on metal surfaces. To clean heat exchanger coils from oxides, different concentrations of its solutions are used, the optimal ratio is 1 to 6.

Aminosulfonic acid (NH3SO3) . Sulfamic acid is widely used in industry to remove poorly soluble salt deposits, scale, limescale from pipelines and various types of heat exchangers. It is part of many industrial and household anti-scale agents, is highly soluble in water, and has a much less destructive effect on metals than sulfuric and hydrochloric acids. It is produced and supplied to the market in the form of a powder of small white crystals; before use it is diluted with water in the required proportion.

Household acids . Citric (C6H8O7) and acetic (C2H4O2) acids, which are the undisputed leaders in everyday use, are not as harmful to human health as solutions of the above technical acids. They have less negative impact on the metal, but at the same time, they do not so intensively decompose the salt oxides that make up the scale. When using vinegar and citric acid, the cleaning time increases several times, and there is no guarantee that the work will be carried out effectively.

Features of the use of various means

When deciding what to rinse with and how to clean a geyser from scale and carbon deposits at home, two types of products are used:

- Professional. Special industrially produced products for removing soot, soot, carbon deposits and dissolving scale are widely available today. They should be used strictly according to the factory instructions and recommendations. The disadvantage is the need to buy specially, the high price.

- Folk. This category includes various detergents and acids. They can be used in compliance with the original instructions and safety regulations. Plus – accessibility, minus – a weak effect is possible.

Full disassembly service

Do not be afraid to disassemble the water heating installation, the procedure is not that complicated. You will need the most common tools - screwdrivers, pliers, standard wrenches. What to do before starting work:

- Close the taps of the cold water, hot water and gas supply pipelines. Unplug the turbocharged dispenser from the outlet.

- Substituting the container, unscrew the union nuts (American) on the connection of the water pipes. Disconnect the connections from the unit without losing the rubber gaskets.

- For convenience, it is recommended to remove the gas heater from the wall. It is not easy to disassemble and clean a unit that is hung too high or installed in a narrow niche.

- To dismantle the water heater, disconnect the gas line and the chimney pipe. Remove the unit from the hooks.

Prevention

In order to reduce the frequency of cleaning and the likelihood of scale formation, it is recommended to observe the following conditions:

- Use a high-quality water filter and monitor its condition. If necessary, clean or replace in time.

- If you use hard water, install special softeners at the inlet.

- Perform preventive cleaning at least once a year, even if there are no obvious signs of clogging of the device.

Advice! In order to flush the gas water heater heat exchanger as completely as possible and in the shortest possible time, a special device is used - a booster. The liquid forcibly circulates along its circuit and quickly corrodes the scale.

How to remove and clean the igniter?

Evidence of contamination of the ignition tube: the igniter flame spontaneously extinguishes; a weak tongue of flame rises up without moving towards the burner due to insufficient gas pressure (if the pressure of the main or bottled gas has weakened, then the igniter has nothing to do with it).

Cleaning the igniter will stabilize the ignition, prevent popping noises and the formation of soot on the heat exchanger grates.

Please note: before you start cleaning a clogged igniter of a Bosch geyser, be sure to double-check that the gas tap of the device is closed!

Tools needed: flat-head (minus) screwdriver or thin pliers with curved “lips” (platypus). The ignition tube should be removed carefully, without pushing through the heat exchanger jacket.

The procedure for dismantling the water heater igniter:

- Top end. You need to pull up the bracket that holds the flared edge of the pilot tube at the end of the burner. Unclench the bracket slightly, then move it upward with duckbill pliers or pry it with a screwdriver until it is completely removed;

- Bottom end. It is necessary to press out the edges of the bracket securing the igniter;

- Removing the igniter. Having freed the ends of the tube, all that remains is to lift it up and remove it in a “pull” motion.

To clean the cavity of the ignition tube, you will need a piece of not too stiff wire, on which a piece of lint-free cloth (for example, a microfiber cloth) is clamped. We stretch a homemade “brush” inside the tube, then lightly tap it and blow through it.

The igniter tube is made of aluminum and can be easily dented. Therefore, cleaning, and especially tapping, must be done carefully, without excessive stress.

It is also necessary to clean the tungsten spring located on the underside of the tube. This will ensure quick ignition from the piezoelectric element. Finally, it is necessary to clean the nozzle at the lower connection point of the ignition tube and the electrode located in front of the upper outlet of the tube from carbon deposits. They should be wiped with microfiber or other lint-free cloth.

Installation of a cleaned igniter into the column is carried out in the reverse order of dismantling. If cleaning is done effectively, the flame from the lit pilot tube will be almost invisible.

Briefly about the main thing

A gas instantaneous water heater contains a coil through which water flows. From the outside it is heated by the open flame of a gas burner. The most common clogging factors are scale, soot, carbon deposits, as well as mechanical particles in the water. The first signs that the device needs cleaning are:

- Reduced hot water pressure.

- Periodic shutdown.

- Reduce heating level.

- Increasing the set temperature period.

- Appearance of noise.

- Triggering of thermal protection sensors.

The owner of the gas water heater is allowed to clean only the water inlet, heat exchanger and burner jets on his own, without disassembling - only a gas service employee has the right to dismantle and clean the ignition installation. In each case, both mechanical and chemical methods can be used using industrial or household means. You can prevent damage to the device due to severe blockage by observing timely preventive measures.

Ratings 0

Electromechanical methods for descaling

To clean the heat exchanger spiral from scale, you can use the mechanical method of supplying a cleaning solution under pressure; in suburban conditions, it is effective to use a mini-high-pressure washer for this purpose, while the water heater is disassembled.

You can also speed up the cleaning process using a small-sized centrifugal electric pump or vibration pump (many people use a unit from an old washing machine). To do this, electric pumping equipment is connected to the inlet of the coil and a container with a cleaning solution, and the liquid from the outlet is drained into the main tank with anti-scale, thereby ensuring circulation of the composition in a circle. The use of an electric pump significantly speeds up the process and improves the quality of cleaning - the liquid is passed through a coil with increased pressure, which promotes effective removal of scale.

Options for connecting pumps and pumps for cleaning the heat exchanger