Home / Boilers

Back

Published: November 23, 2019

Reading time: 3 min

3

5981

Owners of water heating boilers quite often come across information about the magnesium anode, but, as a rule, only a few know what the anode for the boiler looks like and what role it plays.

In short, it can be noted that the primary task of a magnesium electrode is considered to be anti-corrosion protection of the internal surfaces of the tank.

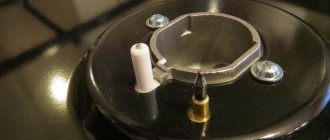

Dismantled anode. Photo source: tehnika.expert

- 1 Purpose of a magnesium anode for a water heater

- 2 Operating principle

- 3 Types of anodes 3.1 Magnesium

- 3.2 Titanium

- 3.3 Aluminum

What is an anode for a water heater

To understand what an anode is and how this part works, it is necessary to imagine the electrochemical processes that occur inside the boiler. In an aqueous environment, the magnesium rod becomes a positive (corrodable) element, and the walls of the heater container become negative.

Purpose of the anode for a water heater

What is an anode for?

- active protection of the tank from corrosion;

- prevention of cracking of the enamel coating;

- increasing the service life of equipment (heating elements, boiler tank walls);

- loosening the layer of scale that settles during operation of the heater;

Anode rod design

A standard water heater anode is a threaded rod coated with a layer of magnesium alloy. The thickness of the coating is about 10 mm. The most common anode material is AZ63 alloy. Analogues of this tread alloy are N-1, MP-1 and MP-2. Magnesium is applied by casting into a chill mold.

The magnesium anode is made of a rod, inside of which there is a threaded steel pin.

Anode designs for different boiler models differ in the length and diameter of the rod itself, as well as the parameters of the pin, which is used to secure the part inside the tank.

Some modern models of water heaters are equipped with flexible plastic rods filled with magnesium granules.

This design facilitates installation and allows you to restore the functions of the anode by adding granules.

How does a magnesium anode rod work?

In the absence of an anode, galvanic couples are formed inside a metal container with water, which lead to the gradual destruction of the walls. If you place a part made of a more active material than iron into this system, it will have a much higher potential for reaction. In this case, the anode will be an additional rod, and the cathode, on which cations of the active metal will be deposited, will be the walls of the boiler.

In addition to corrosion, scale is also a problem when servicing the device. A layer of carbonate salts settles not only on the walls of the container, but also on the element that heats the water. With continuously occurring electrolysis and the formation of magnesium salts, the scale becomes more porous, soft and loose, which makes it easy to clean it from the surface of the heating element and tank.

After a year of operation, corrosion is visible on the magnesium anode - oxides that gradually destroy the electrode.

Principle of operation

The operating principle of the electrode is based on its activity , since magnesium in all compounds is a divalent metal, and the iron from which the tank is made is trivalent. In addition to corrosion, when heating water, scale forms due to settling salts of heavy metals.

Since magnesium has increased activity, the salt atoms interact with it, and not with iron. Therefore, the magnesium anode binds oxygen atoms and attracts iron salts as a magnetic material. At the same time, the formation of calcium carbonate salts sharply decreases, and carbonic acid salts are formed from magnesium.

As a result, the scale becomes looser and can be easily removed when cleaning the unit. This prevents corrosion of the tank and the coating of the heating element. This process is called sacrificial protection, and the electrode is called anode-protector.

What other types of anodes are there?

Aluminum and titanium anodes are also installed in water heaters. They may differ from magnesium in cost and configuration.

Titanium

The titanium anode is connected to a voltage source, so it does not corrode like magnesium. The part does not need to be replaced, since the tank is protected due to external current parameters.

The titanium anode is compact and easy to use.

When connecting a non-destructive electrode, the frequency of boiler maintenance increases to 1-1.5 years.

Aluminum

An aluminum anode has the same operating principle as a magnesium anode. Due to the lower activity, the protective effect extends to a smaller area of the base metal. To prevent corrosion of the entire tank, it is necessary to install an anode with a large length and protector thickness. Several aluminum electrodes are placed in large boilers and boilers at once.

The aluminum anode in a water heater typically lasts three to five years.

Useful tips

Considering why a magnesium anode is used in a water heater, it is appropriate to use the following recommendations to increase the efficiency of the equipment:

- There should be no suspicious sounds when operating the equipment. If there is a hissing sound, you should check the device, as this is a sign of scale.

- It is advisable to carry out routine inspection of water heating equipment twice a year. If damage is detected on the surface of the rod, it is recommended to replace it.

- It is advisable to install a filter on the pipeline supplying water to the boiler. This will extend the service life of the equipment and allow you to increase the time between scheduled repairs.

- If heating occurs very slowly or the device periodically turns off and does not heat the water, it is necessary to check the condition of the magnesium rod and the heating element itself.

How to determine whether an element can be replaced

Boiler manufacturers recommend scheduled maintenance of the device once every 6-9 months. If deep potholes appear on the surface of the corroded rod or it has greatly decreased in size, then it needs to be replaced.

The average service life of the active electrode is 9-12 months.

It is recommended to replace the anode when more than 70% of the coating has been depleted. If there is no electrode, it is not recommended to turn on the heater. During scheduled maintenance, it is also recommended to thoroughly clean the surface of the heating element and tank from a layer of scale.

Regular cleaning of the boiler will ensure its long-term operation.

Signs of heating element contamination are:

- the appearance of a quiet hiss during operation;

- frequent turning on and off of the device;

- slow water heating.

Purpose of the element

During operation of the water heater, substances are released in the water as a result of chemical reactions. Cathodic protection involves the deposition of all foreign substances on the passive anode. This is why this element is needed in the water heater. It performs the following tasks:

- protects the tank and its parts from corrosion;

- prevents the formation of scale on the heating element;

- reduces water hardness.

During prolonged operation of the magnesium electrode, its gradual destruction occurs, but the chemical composition of the water does not change. This suggests that its use is absolutely safe for human health.

Therefore, it is very important to replace this part in a timely manner.

To perform this procedure less frequently, it is necessary to monitor the quality of the water. The frequency of use of the boiler also affects the operating time of the anode. This is interesting: how an electric water heater works.

Depending on all factors, this device can last from 1 to 7 years. It is possible to operate a water heater without an anode, but then the boiler will fail very quickly. By the way, when purchasing a new item, you should pay attention to the quality of the product.

An electrode made of cheap technical magnesium will fail very quickly, and during operation the water will acquire a characteristic smell of hydrogen sulfide.

How to extend the life of the anode

The service life of the anode depends on the specific use of the boiler, the hardness of the water and the quality of the alloy itself, which is used to protect the tank. To extend its service life, you need to:

- turn on the water heater in economy mode;

- install original anodes when servicing the device;

- use flow filters to purify water from carbonate salts, chlorine, dirt and other impurities.

For consultation and purchase of a filter, please contact.

It is important to note that the dissolution of the anode is a normal process. The corrosion that occurs is the main sign that the heating element and tank are protected from destruction. If the magnesium rod has significantly decreased in size or the boiler malfunctions, you need to clean the container and replace the anode.

If the anode is half worn out, it will need to be replaced soon.

Why does the tank collapse?

Quite a few people can claim that the new generation of water heaters today are constructed from stainless steel. This is a reliable fact - the water storage tank is really made of this material. Why does stainless steel need corrosion protection? Several facts can refute theoretical statements about the resistance of this material to destruction when used in domestic conditions.

- The first thing you should pay attention to is that food-grade stainless steel is a material with not the highest resistance. Theoretically, stainless steel can withstand hard water with salt impurities, but only for a while. A couple of months, a year and a half, but no more. If really high quality stainless steel was used to make the tanks, their price would be too high. The device would acquire premium status and become affordable only for some. However, a water heater is a very affordable device that is very popular.

- The next nuance is the presence of seams between the structural elements of the water heater. As a rule, the tank is made of two parts fastened to each other. Under the influence of heat, the joints quite often change their structure, and then the stainless steel loses its main functions. This is how corrosion appears.

Everyone knows that surfaces are coated with special substances, which are also designed to protect against corrosion. But they cannot be called reliable and durable. In addition, the closed environment of the tank and the temperature of the liquid changes periodically. Very hot water expands the metal, then contracts it as it cools. Under the influence of such metamorphoses, the protective composition stretches and loses its integrity.

Water heater device

Removing the element in the water heater

The magnesium electrode is a consumable item, so you need to check its condition regularly. To diagnose and replace a part you must:

- Turn off the boiler and close the valve.

- Drain the water through the tap or check valve.

- Disconnect the hoses and remove the casing from the bottom of the tank. In some heater models (for example, with a strip and a nut), the lower part can only be removed in an inverted position, so the device will have to be completely removed from the wall.

- Remove the boiler control unit and flange, having first taken a photo of the location of the wires. If the flange is secured with a 55 mm nut, then you need to carefully turn it counterclockwise using an adjustable or hub wrench.

- Get the heating element. A thick layer of deposits can lock it tightly into the groove, so it needs to be slightly rocked from side to side before dismantling.

- Remove the magnesium anode from the socket. Inspect its surface and measure the thickness of the residual active layer. If wear is more than 60-70%, replace the part with a new one.

- Reassemble the water heater in reverse order.

When servicing the boiler, it is necessary to clean the tank and heating element from scale.

How to clean a boiler?

Cleaning is needed most of all when the boiler is working normally, as a preventive measure, it needs to undergo preventive inspections once or twice a year, and if you notice that the heating element is becoming dirty, it is very important to periodically clean and replace the anode. To call a technician to your home, you need to free up your workspace so that there is free space and access to the heater, call a water heater repair service, and they will come to you as soon as possible, taking the necessary measures for the safe operation of the heater. If you understand a little about the details of this technique, you can try to repair the boiler and clean it yourself . The procedure for cleaning a boiler is not something complicated and unattainable, but you need to know the basic rules before starting such work. To do this you need:

- Disconnect the water heater from the power system by unplugging it from the outlet.

- Turn off the common tap from which water flows into the boiler.

- Drain the remaining water from the boiler. This procedure is carried out differently for each boiler, so when you begin the procedure of draining the water, you need to carefully look and study the details of your specific model. Most often, boilers have two pipes at the bottom. Pipe when water enters. Typically, such a pipe is marked in blue; it is through it that cold water flows. There is a valve on the tube, with its help it is possible to regulate the pressure and pressure of water in the tank. It is this that prevents water from flowing back into the plumbing system. Heated water enters the mixer through a long tube. Usually marked in red, if the cold water safety mechanism is not turned off, the container will fill with water again, which is why it is so important to turn off the water supply taps.

To drain the water you will need:

- A key and hose specially selected for your boiler for extracting water;

- Close the faucet and identify the nut that holds the cold water. Unscrew the nut using a wrench;

- Find a container into which you plan to drain the water and a hose that will allow the water to flow into the container. Dip one end into the container and hold the other directly next to the boiler;

- Unscrew the valve;

- Remove the cold water supply fitting and quickly insert the hose. Dexterity of hands and movements is very important here so that there is no spillage of residual water from the water heater itself;

- Repeat the same steps with hot water.

Important! Before removing the water, make sure it has cooled down, otherwise you may get burned;

- The next thing you need to do is to proceed directly to disassembling the boiler itself, in order to remove the heating element and anode from the inside, you need to remove the cover that covers all the cords from below. Usually it is attached with screws - you can’t do without a screwdriver. When the cover is removed, free access to the thermostat opens - unscrew the fastening and carefully remove the heating element and the anode attached next to it. Advice!!! We recommend that you photograph the entire disassembly process, from different angles, so that during assembly there is no confusion about what to attach and where.

- It is noted that the main part of the contamination is collected near the heating element, so we take the heating element and the anode, carefully cleaning all deposits from the surface.

- After mechanical cleaning, it would be a good idea to carry out gentle, not very aggressive, chemical cleaning. To do this, place the Tens in a container and cover with citric acid with the addition of hot water, leaving it for a period of at least ten hours. The same needs to be done with the tank.

- After complete cleaning, we install the heating element in place, tightening everything with nuts as it was, connect the water to the boiler and turn it on for heating. You can study this issue in more detail by watching the video:

Myths about magnesium rod

The proliferation of boilers with anode protection has led to the emergence of many myths. The main subject of debate is its actual effectiveness in conditions of high water hardness and in a stainless tank.

Does it really help with scale?

Scale is formed from carbonate salts found in tap water. The concentration of these compounds determines its hardness. The presence of magnesium cannot affect this process, since an acidic environment is needed to dissolve scale.

However, the mixture of calcium and magnesium salts, which is formed during the electrolysis process, turns out to be looser than the scale that settles in the absence of an anode.

Do I need a stainless steel tank?

Stainless steels, which contain nickel and chromium, have increased corrosion resistance and do not rust even with constant contact with water and oxygen. In addition, the boiler walls are additionally protected with anti-corrosion paints and enamels.

Magnesium anode can be installed in stainless steel boilers.

However, magnesium anodes are also installed in stainless steel tanks. This is due to the following reasons:

- the composition of the alloy may be uneven, which leads to the formation of galvanic couples and pitting (pitting) corrosion;

- the boiler tank is not solid, but welded, and the joint is more easily destroyed;

- Due to the expansion of the metal during cyclic heating and cooling, the anti-corrosion coating gradually cracks.

Magnesium is much more active than steel of any composition, therefore, with an uneven distribution of alloying elements, stainless alloys do not form galvanic couples. The metal ions that are released during the reaction partially fill the cracks in the enamel, preventing the tank from coming into contact with water.

Is it harmful to health?

Magnesium carbonates do not cause harm or benefit to the health of people who use hot water for domestic purposes. Since the amount of these salts is insignificant, they have little effect on the level of water hardness.

Purpose of a magnesium anode for a water heater

The anode simultaneously performs two functions in the heater. The first is the protection of the boiler and its main components from the corrosive effects of the coolant water. The second is indirect protection against scale formation, since it loosens scale.

Hardness salts are deposited on the surface of the heating element: calcium and carbonates. The magnesium anode is not able to stop the process of scale formation, but makes hard calcium deposits soft, thus helping to solve the cleaning problem.

Draining water and disassembling the water heater

And so, when you decide that you still need to open it, the first thing you do is turn off the power by unplugging the plug from the socket. Then drain the water from the titanium. To do this, turn off the hot and cold water supply taps.

Unscrew the cold water hose, placing a suitable container for drainage.

If water does not flow from the removed hose, this indicates an air lock. We need to remove it. To do this, just slightly loosen the nut at the point where the hot water pipe connects to the pipe.

Next, open the safety valve and release water through it. If the valve suddenly becomes clogged, you will have to twist the entire valve. Water will flow out of the boiler in a continuous stream.

After draining, completely unscrew both valves from the titanium (hot + cold) to open the bottom cover and gain access to the heating elements.

There are modern models where the bottom cover is collapsible and to remove it, it is not necessary to touch the valve. It comes in the form of a plastic insert secured with several screws.

Disconnect the power wires, first remembering or marking with a marker which one is connected where. Better yet, draw a diagram. As a rule, all wires are colored and this will be easy to do. Otherwise, you can get confused in such a pile of wiring.

If you don’t want to draw anything, then just take a couple of photos on your cell phone. You will know exactly the location of all elements and wires.

After this, unscrew the nuts or screws securing the heating element itself around the perimeter.

You can unscrew them in any order, but you need to screw them in the same way as the engine head or the wheels on a car, that is, crosswise.

If you immediately tighten a nut all the way, this will cause the flange to bend and there will not be the required tightness. Consequently, the gasket will not hold and will leak.

Carefully pull the heating element out. It will be all covered in rust, and from the magnesium anode, except for a thin burnt piece of iron, there may be nothing left at all.

Why do you need an anode rod?

The operating principle of the anode is quite simple. Due to the fact that the rod has the lowest electrochemical potential, all oxidative processes that occur during multiple heating cycles of water inside the device affect it, but not the walls of the tank. Over time, its surface ceases to be smooth and becomes overgrown with corrosion, which is how it protects the heating element and the surface of the tank from destruction. It is necessary to change the part on time so that the water heater tank remains intact and can serve you for many years.

Why magnesium

Finding an answer to this question worries many minds. The secret lies in the electrochemical potential. For a substance like magnesium, it is quite weak. Coupled with this, the cost of the material allows it to be used in mass production without increasing the price of the final product. Using it as a consumable is much more effective than sacrificing the walls of the tank. Why exactly is a magnesium anode needed in a water heater? He collects salt on himself. When it comes into contact with magnesium, it settles on the surface of the anode without causing harm to other parts.

What is an anode rod?

Every owner of a water heater should know about the anode in the boiler and its operating principle, because it is this that affects its service life.

The anode is a gray metal rod that has a smooth surface and is located inside the tank next to the heating element. It is made of a specialized magnesium alloy and is attached via a threaded rod to the hole in the heating element flange.

The anode performs several functions inside the boiler tank.

The first function can be considered its direct purpose, namely the protection of the device and its constituent elements from corrosion. The second function is more of a bonus: the anode makes the scale looser, allowing you to remove it from the surface much faster and without spending a lot of effort on this task.

Causes of corrosion of a water heating tank

- Weak anti-corrosion coating of the material

Modern boiler tanks are made of stainless steel, which should reliably protect the mechanism, which is constantly in contact with water, from corrosion. However, high-quality grades of stainless steel are expensive and are not profitable to use in mass production.

Such water heaters would become a luxury for many people. To establish flow output and make water heating products accessible, food grade stainless steel is used. But this type of steel has a less durable coating and begins to gradually fail after three to four months.

- Metal deformation during operation

Water heating devices are constantly in a changing state. The hot liquid acts on the metal, causing it to expand, after which the walls contract again.

In addition, devices, as a rule, consist of two parts that fit tightly together at the joint. Temperatures and increased pressure affect this seam. In all these cases, the integrity of the stainless coating is compromised, microcracks appear in the material, and it is less resistant to corrosion.

- Savings on production

Replacement

Replacing the magnesium anode is necessary only after the electric water heater has been inspected. It needs to be cleaned if it is not turned on, the time for heating the water increases and hissing appears when water is heated. If cleaning occurs infrequently, more electricity will be used to heat the liquids. Scale will appear on the heating element, which will then lead to difficulties when disassembling the water heater. If the heating element does not work, the anode will need to be replaced. It is located near the heating element.

If the first one has not collapsed, then there may be a small pin instead. In this situation, it is necessary to dismantle the anode residues. After this, you need to install a clean tank and a new device. Next, you need to assemble the electric heater in its original position. Assembly occurs in reverse. It is important to ensure that the tank gasket is intact and the electrical components are carefully insulated.

Cleaning the water heater and replacing the anode is easy. If you approach this work with all responsibility, then such a procedure can be performed with your own hands, without resorting to the help of craftsmen.

Types of anodes

Magnesium anode protection is an electrochemical method. It consists of connecting an anode to the protected container. At the same time, the metal surface is made equipotential and exclusively the cathodic process takes place in its areas. The corrosive anodic process transfers to the magnesium anode.

Magnesium

Magnesium anode

A magnesium anode for a boiler is made from a regular threaded rod. It has a metal plate made of silver metal. During use, the magnesium anode is subject to slow dissolution until it disappears completely.

Filling with water and checking functionality

Hang the electric titanium in place.

Connect the hoses and open the cold water and begin to fill the tank. The hot water tap must also be open to allow air to escape. At the same time, make sure that there are no leaks anywhere. As soon as water comes out of the “hot” tap, the boiler is full. There is no need to close the tap immediately; let all the “slurry” spill out and finally flush the tank and pipes.

Only when clean water comes out do you turn off the mixer.

After this, the water heater must stand for at least half an hour or an hour so that condensation leaves all surfaces and there is confidence that there are no leaks.

You can then apply voltage by plugging the titanium into an outlet. To check the operation of the thermostat, use the control knob to force the adjustment to maximum and minimum.

In this case, the boiler on/off light should light up.

If the boiler operates quietly, without making any sounds, and it is not clear to you whether it is heating or not, you can check the energy consumption using the meter.

At maximum heating power of the heater, the counter will spin or blink much faster. This means that the heating elements work as they should. The entire repair with the purchase of spare parts will cost you around 1500-2000 rubles. In any workshop that calls a plumber to your home, they will ask for at least 3,000-5,000 rubles for such work, and this does not include materials.

So self-repair can save you a significant amount of money, the main thing is not to make some mistakes.