One of the significant physical parameters that are most often studied, observed and adjusted, be it in everyday human life, production cycles or laboratory studies, is the temperature indicator. Depending on the properties, technical features and the determining mechanism of operation, there is a certain classification of temperature measuring devices into separate types: conventional liquid devices or complex, advanced electronic and laser meters, which represent a worthy alternative to the familiar household thermometer. Of course, the fundamental and decisive factor is the place where such devices are used.

Types of temperature measuring instruments

Devices for carrying out the necessary research, including a device for measuring air temperature, differ in design, as well as in the principle of operation that is used to carry out measurements. Contact and remote thermometers, otherwise called pyrometers, are quite widely used. In addition, the classification of temperature measuring instruments includes:

- Glass and metal liquid expansion thermometers, operating on the property of changing the volume of bodies at different temperatures. Their spectrum of action is from -190 to +500 °C.

- Manometric thermometers that use the relationship between the changing temperature of a gaseous substance placed in a closed volume and pressure. They operate at temperatures from -160 to +600 °C.

- Electrical resistance thermometers operate by relying on the ability of conductive materials to change electrical resistance when heated and cooled. Effective at temperatures from -200 to +650 °C.

- Thermoelectric converters – thermocouples. They are used in the range from 0 to +1800 °C. These temperature measuring instruments use the property of two different metals and metal alloys to produce an electromotive force when the degree of heating of the junction changes.

- A device for determining temperature from +100 to +2500 °C – radiation pyrometer (photoelectric, optical, radiation). The action is due to the fact that the recorded indicator affects the amount of heat emitted by the body. Refers to the non-contact type of measurements. There are stationary and mobile, low- and high-temperature pyrometers.

Features of the operation of meters and sensors

Measuring the temperature of a certain environment can be carried out by several types of devices that have different functionality and are characterized by certain specific application:

- Temperature sensors. All meters include special temperature sensors. They can be contact or non-contact. It is possible to include this element in the meter or connect it to equipment.

- Indicators - used to take measurements, and then display the data on the screen.

- Thermometers are mobile devices that monitor temperature levels.

- Meters-recorders – provide data accumulation for subsequent transfer to a third-party device.

- Thermostats - include the function of recording temperature indicators with subsequent control of the corresponding control device.

- Temperature controllers are multi-channel meters that have advanced functionality that combines the options of different devices.

Thermometers and sensors

According to another classification of heat-fixing devices, they are divided into thermometers and temperature sensors.

The first are mechanical instruments, including gas-filled pressure gauges, bimetallic, glass temperature meters and combination regulators.

Thermal sensors are ultra-precise, advanced electronic devices for recording temperature readings in liquids and solids. These should include resistance thermometers, thermocouples, sensor reading converters and alarms equipped with relay mechanisms.

The latest thermal detectors are equipped with a USB interface, memory for saving and analyzing studies, and a laser target designator.

Glass Type Liquid Devices

These are common devices, characterized by a simple system of counting indicators. The measurement accuracy is quite high with an acceptable range from -190 to +10000C.

The operating mechanism is based on the expansion of the liquid in the reservoir. When this tank heats up, it will rise, as can be seen in the photo of the temperature meters.

Mercury is most often used as a liquid, but there are models with toluene, ethyl alcohol, and pentane. Disadvantages - fragility of the structure, unclear scale, lack of ability to accumulate data.

Liquid thermometers

Glass liquid meters are known as the most basic and accurate thermometers, which are available in straight and angled versions. And the scope of their application is the analysis of technological equipment, as well as public utilities (measurements in pipelines). The devices are suitable for temperatures from -35 to +600 °C, and mercury is most often used as a sensitive element, and readings are recorded on a scale.

Depending on the place of application and structural features, medical, technical, electrical contact, liquid, stick and other devices are distinguished.

A specific device for measuring water temperature is selected taking into account the permissible error in measurements.

Main types of thermometers

Depending on the purpose and principle of operation, thermometers differ into several main types, including:

| Liquid thermometers, the operation of which is based on the property of liquids to expand when heated and contract when cooled. The working fluids used are mercury (mercury thermometers) or colored alcohol (alcohol thermometers), placed in thin glass vessels with a graduated vertical scale attached to them. The division price is 1 degree. The disadvantage of liquid thermometers is the fragility of the glass components. |

| Mechanical thermometers use the effect of deformation (expansion) of a bimetallic spiral when heated. When the spiral bends due to a change in the temperature of the medium, an arrow connected to it indicates the temperature value on the thermometer dial. The main advantage of this type of device is the increased accuracy of readings and mechanical strength of the system as a whole. |

| A gas thermometer consists of a container filled with nitrogen, helium or hydrogen, a connecting tube and a measuring device with a scale. As the temperature rises, the gas expands, which is reflected in the readings of the device. The use of gas significantly increases the measurement range to +1000°C, which allows the use of gas thermometers for measurements in environments with elevated temperatures. |

| Electric thermometers are convenient to use as temperature sensors. The design of the devices is based on the principle of increasing the resistance of a conductor as its temperature increases. Depending on the material of the conductor, the range of measured temperatures of the thermometer varies significantly. For a thermometer with a platinum conductor, the range is -200 ... +750 ° C, with a copper conductor - -50 ... +180 ° C. |

| Optical (fiber optic) thermometers contain a main component - a stretched optical fiber, which stretches and contracts with temperature fluctuations. The refraction of a light beam passing through an optical fiber is detected by a sensor and transmitted to the thermometer display. |

| Thermoelectric thermometers are designed to measure a wide range of temperatures (-100 ... +2500 ° C) and use the property of two dissimilar conductors (thermocouples) soldered together to create thermo-EMF, which is recorded by the sensor and transmitted to the display of the thermometer. The temperature is recorded with an accuracy of 0.01°C. |

| Infrared non-contact thermometers (pyrometers) are devices designed for non-contact temperature measurement. The device allows you to capture thermal radiation in the infrared range emanating from the surface of the object under study within 1 second. The beam received and focused by the optical system of the device is transmitted to the temperature sensor, converted into an electrical signal, which is then processed in a counting and measuring device and displayed on the pyrometer screen in the form of a digital temperature value. Used for measurements in the temperature range from -50 to 4000° in industry, construction and in everyday life. |

Devices for determining air temperature

The first device for measuring air temperature is a glass thermometer, the active liquid element in which can be mercury, ethyl alcohol, toluene and other substances.

High-precision mercury meters come in stick type and with an embedded glass scale. They are in demand in laboratory research in various fields of production and medicine. A stick thermometer is equipped with a transparent heat-resistant graduated capillary tube, and the second type of meters is characterized by the fact that the scale divisions are located behind it on a separate plate, and the entire mechanism is protected by a durable glass case.

If the device has electrical contacts, it is called a thermal alarm, and the sensitive liquid inside the reservoir and capillary shows the real temperature of the surrounding space.

Features of thermostats and alarms

In addition to the above, there are other instruments for measuring temperature. For example, rod dilatometers with sensitive parts made of dissimilar metal alloys, which elongate by different amounts when heated, are used as thermostats and alarms.

The same principle characterizes another type of thermometer - a bimetallic one, with an inserted heat-sensitive spring soldered to a pair of metal plates with different temperature expansion. During the heating process, the spring bends towards the plate with a lower thermal coefficient, and the desired temperature indicator is found from the bending value.

Electric thermometer

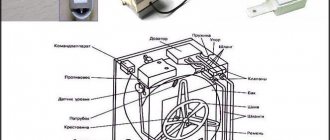

For remote recording of environmental thermal indicators in the range from -15 to +125 °C, a non-contact temperature measuring device - an aspiration electrothermometer - is excellent. Its device includes a meter and a sensor connected to each other by a cord.

The sensitive element is the thinnest copper wire of the sensor, wound in a spiral onto a thread frame.

Mercury thermometers

- Toxic mercury inside

- Cheapest option

It's surprising, but there are still classic mercury thermometers on sale. The ones that everyone is so afraid of breaking. And they are rightly afraid: mercury vapor is very toxic and spreads quickly. Nevertheless, as a device for measuring temperature, they are quite accurate and reliable.

It is advisable to buy a mercury thermometer only in cases where there is no other option. We really hope that in the near future this type of measuring device will remain only in our memory.

We wish you not to get sick and carefully monitor your health. By the way, we have several more relevant articles during the pandemic:

- Can a medical mask be used several times?

- On guard of health: what do masks and respirators really protect against?

What devices exist for measuring body temperature?

Body temperature is usually measured with a thermometer. But today there are many other thermometers that differ in appearance and basic operating principles.

The most common devices, to which our thermometer belongs, operate on the thermal expansion of mercury, kerosene, alcohol and other liquids. They are inexpensive, practical and quite accurate, especially mercury ones, although the poisonous contents in the fragile glass case carry some risk.

An electronic or digital device for measuring body temperature shows the desired value thanks to the built-in sensor, but its cost is much higher than the price of its liquid “brothers”. These thermometers are contact.

Infrared pyrometers do not require direct contact with a person, operating remotely. An ultra-sensitive sensor reads the amount of radiation in 2-15 seconds, displaying the result on the display. These non-contact temperature measuring devices are excellent for families with small children, situations with sleeping patients, etc. In addition, they are applicable in everyday life during the cooking process, and more powerful types are used in the electric power industry, on construction sites, in metallurgy and other industries .

Weather stations

Weather stations are a home digital device for complex indicators of temperature and humidity. Often, more advanced models also have a clock, alarm clock and barometric pressure indicators.

There are also weather stations that can provide short-term weather forecasts and display the history of readings for one of the measurements on the indicator: temperature, humidity, pressure.

There is also a feature: some types of weather stations to which you can connect 1 to 3-4 additional external sensors.

For example, - place one in another room (for example, in a child's room), - the second one outside, - and the third sensor is already built into the weather station itself. |

And watch 3 readings in order to get dressed in time to go outside, turn on the humidifier in the nursery or, conversely, the dehumidifier in the main room.

When is a remote pyrometer needed?

There are often situations when measuring temperature by contact method is impossible or simply inconvenient. It is in such cases that you will need a pyrometer - a device for remote temperature measurement, namely:

- when measuring parameters of very hot bodies or toxic environments;

- when access is difficult, and with a small error it is possible to make measurements at a distance of tens of meters;

- when observing mechanisms in motion, and this will take a split second;

- when diagnosing the electrical safety of a building, when it is convenient to carry out remote scanning with such a meter in numerous remote areas.

Pyrometer

- Measures remotely

- Result in a second

The most technologically advanced and safest way to measure temperature is remotely. Have you seen doctors in the news with miniature devices that look like hair dryers? These are pyrometers. Their thermal sensors receive infrared radiation from an object and, based on it, determine the temperature. Such devices are actually inexpensive - the simplest models can be bought for 1500-2000 rubles.

In current conditions, a pyrometer is indispensable, for example, for measuring the body temperature of office employees. But after the epidemic is over, it can also be used usefully: for example, it will not be difficult for you to determine the temperature of a car cooling system pipe or the wall of a country house in order to select thermal insulation.

- Home Appliances

Pyrometers for remote temperature measurement: the best models with high accuracy

What devices can measure metal temperature?

In the metallurgical industry, testing molten metal alloys requires a rugged instrument for measuring high temperatures.

These are the pyrometers already described. They detect thermal radiation at a distance, which characterizes the actual temperature of the metal. In difficult conditions with ultra-high heat levels, the non-contact method is ideal. The following data is displayed on the liquid crystal display:

- actual temperature in Fahrenheit and Celsius;

- boundary temperatures;

- battery charge.

Maximum accuracy of the measured variable can be achieved only when there is no interference in the form of heat-absorbing vapors or solids between the object and the remote device. If you need to take measurements of the metal alloy in a transport ladle or during bottling, then you should accept the condition that the temperature indicator will be less than the actual one and will be determined by calculations.

In order to avoid the inaccuracy of this method, another device is used to measure the temperature of the metal, namely a black body simulator. It is immersed in the melt and is presented in the form of a pipe with a sealed or open end, a hollow cone or a glass of refractory metal. In any embodiment, the temperature meter must have increased heat resistance, chemical resistance and excellent thermal conductivity in order to demonstrate extremely accurate data.

Engine temperature measurement

Long-term operation, as well as periodic repairs of machines and mechanisms, require the presence of special equipment, which includes a device for measuring engine temperature. These include thermocouples, thermistors and expansion thermometers.

Thermocouples are very convenient and widely known devices among motorists for measuring the temperature of surfaces, windings and the internal cavity of the engine. Using these temperature sensors, you can record data even in hard-to-reach areas of the engine, in grooves and cores. They are two insulated wires of different metals with ends soldered on one side, which are placed at a certain measuring point. The second ends are connected to a millivoltmeter and a thermometer, and the sum of their indicators determines the actual temperature value.

Mercury and alcohol expansion thermometers are very convenient for carrying out the necessary measurements in accessible areas: the winding, the open surface of various parts, as well as the air flow leaving (or entering) the engine. Thermistors in the form of a copper wire winding are attached simultaneously in several places of the engine, turning them on one by one, taking recorded readings and determining the average value.

Functionality of measuring instruments

The devices that are used to determine the temperature perform several basic functions, so it is important to take these points into account when determining which meter is best:

- measurements of the actual temperature in the environment;

- visual reflection of temperature level;

- recording the results obtained in the device’s memory;

- alarm about violation of the specified temperature range;

- data transfer to working equipment.

Complex units equipped with special temperature sensors are also capable of regulating and maintaining a temperature regime recorded by software.

Secondary instruments used in temperature measurements

Let's try to define what an industrial secondary temperature measuring device is. In fact, this automatic device is an important addition to the main meter, capturing and converting recorded indicators into a readable form. It is necessary for the implementation of clear control, alarm and timely temperature control in those exceptional cases when deviations from the parameters specified by the operating conditions occur. Separately, stationary and portable secondary electrical appliances are distinguished.

Typically, secondary temperature measuring instruments have a durable, protective steel housing and are equipped with a graduated scale. Values are recorded according to a diagram recorded from thermocouples, strain gauges, resistance thermometers, transducers and other devices.

Considering various methods of presenting information, secondary devices should be divided into recording and displaying, single- and multi-channel, dual-function and single-band. If there is a signaling mechanism, these devices instantly indicate an unacceptable temperature change that differs from the required value. This helps maintain the logical flow of all reactions and technological processes in which they are involved.

With all the variety of instruments that record temperature indicators of gases, liquids and solids, you should take a serious approach to choosing the right device. The primary factors that must be taken into account are the permissible limits of temperature values, the maximum distance at which measurements can be taken (sighting), and accuracy. And, of course, the scope of use of a particular type of thermometer is taken into account.