To find out the size of a part down to small fractions of millimeters, a type of measuring device such as a micrometer is used. It is a relative of the caliper, but differs from it not only in appearance, but also in the measurement results obtained. When there is a question about specifying the size of a part down to hundredths and even thousandths of millimeters, then you cannot do without such a device. But not everyone knows what kind of device this is, how it works, and especially how to correctly carry out measuring work with a micrometer. The instructions presented in the material will help you figure this out.

Tool design and application

To learn how to use a micrometer, you must first understand the design features of this instrument. Structurally, it resembles a caliper, but with minor differences in appearance. One of the most important differences is the incomprehensible number system, which is displayed on a cylindrical base. Many are misled by this design, and there is a desire to refuse to carry out measurement procedures. However, everything is much simpler, and the material describes in detail the principle of using a micrometer to calculate the minimum values of the part being measured.

The type of measuring device under consideration consists of a number of components. These elements include the following details:

- A bracket or base in which the part to be measured is placed. By the way, the sizes of the bracket are different, which determines the possibility of measuring parts of the corresponding sizes

- The heel is the stationary part (jaw) on the clamp that serves as a clamping device when measuring parts

- A movable screw or jaw - it is responsible not only for pressing the part, but also for displaying relevant information, which depends on the size of the part

- Clamp - located on the bracket, and serves to fix the movable jaw in the appropriate position. This clamp is needed to ensure that the sponge does not move from its position when taking measurements.

- The stem scale is horizontal and consists of two parts separated by a line. The lower part is responsible for reading whole numbers in millimeters, and the upper part for tenths. The straight line is used to carry out calculations on a vernier scale

- The drum is a cylindrical movable part that moves along with the movable jaw. A vernier scale is applied around the circumference of the drum (it is also called circular), which determines hundredths and even thousandths of millimeters

- The ratchet unit is a mechanism that allows you to tightly fix the part in the jaws, but at the same time prevent its deformation. The ratchet is set to the appropriate torque force, so when the movable jaw is tightly connected to the wall of the part being measured, it rotates

The device has a simple design. Depending on the type, the design may differ slightly, but one of the first meters was a conventional device, as shown in the photo above. Such devices are still in demand today and are found quite often in various fields. In the household, a micrometer is also necessary, since there is often a need to measure the diameter of a piston or the size of small parts. Many people don’t even know what can be measured with this device, so it’s worth finding out.

How to use a micrometer correctly: an example of care and maintenance

Any model should be treated with care. Throughout the entire period of operation, it is important to follow the following recommendations:

- Keep all elements and functional units clean - remove any remaining chips and dirt immediately after performing technological operations.

- Gently wipe the paws with a thin sheet of paper or sponge.

- Reconfigure the instrument as soon as the slightest discrepancy or failure of readings is detected.

- Remove the ratchet when working with workpieces made of soft materials.

It is important to know not only how to measure the parameters of a part with a micrometer, but also how to store it afterwards, until the next time it is used.

If we are talking about an analog or lever version, then its internal moving parts should be lubricated (with machine oil, grease). Absolutely any model must be set to zero and placed in the original case in which it was sold. After this, all that remains is to send this container to a niche in the closet or leave it in a personal workshop, in a warehouse or other room with a low level of humidity; just place it so that it does not fall from a height and receive any damage.

We described in detail how to measure the diameter and thickness of a part with a micrometer, we also gave examples of instruments - the choice is yours. Well, we will help you make it - contact us, we will recommend the best tool for you.

The principle of measurement and what is measured with a micrometer

The principle of operation of the device in question is based on a certain concept like a screw pair. The screw pair began to be used quite a long time ago, and served to adjust the sights of ship guns. Soon after, a measuring device was invented based on a screw pair, which was called a micrometer. It is called that because it allows you to measure a part down to a hundredth or even a thousandth of a millimeter.

The movable drum is connected to a screw, which serves to clamp the part. The movement of the drum allows for measuring manipulations, since the dimensions of the part being measured depend on where this element stops. The drum has a scale with 50 divisions. The pitch of the microscrew is 0.5 mm, and one revolution of the drum is also equal to a distance of 0.5 mm. To get the final result of the part size, you need to add the resulting values.

This is interesting!

The tightening force of the screw plays a very important role, since the slightest overtightening will lead to the integrity of the thread being damaged and the device will become unsuitable for measurements. The absence of a ratchet would also lead to deformation of small and fragile parts being measured (eg wire).

The type of measuring device in question is used to measure the following parts:

- Piston diameters and crankshaft dimensions

- Tooth spacing of gears, gears and chains

- Pipe wall thickness

- Thickness of sheet structures

- Wire thickness

- Thread sizes

- Drill diameter

- Internal diameters of different products

To carry out measurements of certain parts, the use of appropriate types of micrometers is required. What they are is described in detail below. In any case, a micrometer will always help determine the size of certain parts with the highest possible accuracy. To verify this, let’s consider the types of instruments by type of display of readings.

Historical reference

A screw pair for precise sizing was used back in the sixteenth century. It was an integral part of the sighting devices for guns, which were progressive at that time, and was part of the designs of geodetic instruments.

In 1848, the Frenchman Palmer first received a patent for a micrometer. More precisely, then the invention was called a screw caliper with a circular vernier. This device could revolutionize the field of measurement. However, industry at that time did not provide such high accuracy of material processing. The instrument was not popular and was forgotten.

Americans Lusnan Sharpe and Joseph Brown remembered him in 1867. Industry developed, production was filled with new technologies and progressive metalworking machines. American engineers sensed the need for a forgotten measuring instrument and began mass production of micrometers. Subsequently, other micrometric instruments appeared.

Micrometers, their types according to the method of displaying readings

The devices are used not only in the home, but are also used by professionals, for example, turners, mechanics and workers in other fields. These specialists know all the features of measuring with a micrometer, but if there is a need to clarify the size of a part with high accuracy of values, then first you need to understand the types of manufactured devices. According to the method of displaying values, micrometers are classified into analog, dial or clock, digital and laser. What each modification of the device is, and in what cases it is worth using certain types of meters, we will find out in detail below.

How to measure with a micrometer: instructions for using standard, lever, electronic models

It all depends on the option for recording indicators. In the case of standard analog instruments, it is necessary to add all the obtained parameters from the stem and drums. Naturally, such results are extremely inaccurate, since they are determined “by eye”, and the errors can be significant.

There are much fewer problems with digital and laser devices, because they read the dimensions automatically and show the final values on the display. You can’t go wrong here even if you have no experience. Although much more often they are used by professionals employed in research institutes and laboratories, since they are relatively expensive for household purchases.

What is an analog micrometer and how does it measure?

An analog micrometer is also called a mechanical micrometer, as it has a simple operating principle and design. Based on the simplicity of the design, the device is durable, which is why even today you can often find devices produced back in Soviet times. A mechanical micrometer is resistant to physical impact, and to all the advantages, you can add a relatively low cost, which ranges from 400-500 rubles, depending on the model.

This is interesting!

On all types of micrometers, the clamps are different, and are presented in the form of a lever switch or a moving washer. Both clamping options are reliable, but the main disadvantage of washer devices is that they are not visible when the clamp is engaged.

Lever micrometer and its design

Lever models are also called a pointer micrometer or a clock device. Based on the name, it becomes clear that the device has a dial scale on which measurements are taken. The pointer scale increases the accuracy of measurements, since with such a device you can determine not only hundredths of values, but also thousandths. An additional pointer scale is used to determine thousandths of millimeters. The whole value of the part size in millimeters is determined by the stem of the device, and hundredths of millimeters are calculated by the drum scale.

The main disadvantage of lever models is that they are very fragile, so it is enough to drop it once for the switch mechanism to fail. It is precisely due to their fragility that such models have not gained wide popularity. Compared to analog models, lever micrometers cost 2 times more, which is due to the complexity of the pointer mechanism. If we talk about accuracy, then with a pointer micrometer you can determine the size of a part with high accuracy down to thousandths of millimeters.

This is interesting!

On dial micrometers, the clock mechanism is designed not only to determine thousandths of millimeters, but also to determine the clamping force of the part being measured.

How to use standard, electronic and lever micrometers (instructions)

When using standard and analog micrometers, part measurements are determined by adding the values obtained on the micrometer drums and stems. As you can see, the instructions for using a micrometer look very simple.

Important! Always remember the following rule. If on the lower half of the stem the last visible mark is to the right, then another 0.5 must be added to the resulting value. Schematically it looks like this.

Image No. 3: instructions for reading measurement results

There are much fewer complications when using lever and electronic micrometers.

Electronic instrument with dial for high precision measurements

Electronic micrometers are considered one of the simplest and most accurate micrometers. It combines the design of an analog and pointer device, and at the same time allows you to identify the size with the highest possible accuracy. Such models are in demand where thousandths of millimeters are important.

Instead of a vernier scale, the device has an electronic display, on which the corresponding readings are displayed during measuring manipulations. It is easiest to measure with an electronic device, and the likelihood of making a mistake in measurements is reduced to zero. The only drawback of such a device is its high price, which is 3-4 times higher than the cost of a dial meter. Some models even have not only a display, but also a vernier scale, which allows you to verify the accuracy of the readings. Manufacturers also produce shockproof devices, which are somewhat more expensive.

This is interesting!

In addition to the display itself, the design of electronic micrometer models also includes buttons for setting up the device, as well as storing measured values in memory. Some models can be connected to a computer to exchange information.

How does a laser micrometer measure and what is it used for?

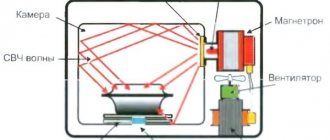

When not only hundredths and thousandths, but also ten-thousandths values play an important role in measurements, then it is recommended to use laser micrometers. The principle of their operation is radically different from analog, pointer and digital. The values are determined by the deviation of the laser beam in which the part being measured is located.

Using a special photocell, the difference in deviation is recorded, and these results are displayed on the display. Such models are considered the most accurate, but also among the most expensive. The devices must not be dropped, and they also require special adjustment manipulations.

This is interesting!

Laser devices are not intended for home use, as this is not necessary. They are very expensive and also measure the dimensions of parts with high accuracy. They are used primarily in specialized control and measurement laboratories.

State standards

The main standard regulating the technical conditions for tool production is GOST 6507-90

In production, and sometimes in everyday life, when the accuracy of caliper readings becomes insufficient, a micrometer comes to the rescue. This device is designed for measuring relatively small linear quantities with high accuracy using the contact method. To ensure this, a simple but very effective conversion mechanism is implemented, based on a screw pair. However, it also causes difficulties when using the tool for people who do not understand the principle of its structure. While almost everyone can freely use a caliper, the same cannot be said about a micrometer.

The purpose of this article is to show that actually using a micrometer is not much more difficult than measuring with a caliper.

Read also: Basic elements of a gear wheel

Types of micrometers by area of their use

The devices under consideration are classified into types not only by the method of displaying information, but also by their area of application. This means that to obtain accurate measurements of various parts, it is recommended to use appropriate micrometers. For example, you can measure the thickness of a steel sheet with a regular universal gauge, but to obtain accurate results (which is important), it is recommended to use a specialized device for determining the thickness of sheet materials. Let us consider in more detail what types of micrometers there are according to their scope of application.

- Smooth device - used to identify the overall dimensions of parts that have a flat or round shape

- Pipe Gauge - To find out the outer or inner diameter of a pipe, a caliper is used for this. A pipe micrometer is used to determine the thickness of the pipe walls. Typically, such manipulations are performed at the stage of rolled metal production in order to check their quality. More measurements are carried out on pipes that are in use to determine the thickness of the corrosion layer

- Gear gauge - when you need to find out the size and distance between the teeth of gears and gear wheels. The device has special conical nozzles, which are attached to the heel and a movable screw. The gear gauges are supplied with a reference blank to determine the accuracy of the device.

- Sheet meter - if you need to find out the exact size of sheet materials, then micrometers with a special scale are used for such purposes. The scale has a small measurement range, so the device provides highly accurate results. There are two types of ML sheet micrometers - with flat attachments and an oblong base. They are used depending on the size of the workpieces

- Wire micrometers are designed to measure wire diameter and bearing ball size. They are distinguished by their compact design, as they do not have a base in the form of a bracket

- Universal micrometers are an excellent solution for those who often use the device to measure various parts (threads, steel sheets, pipes, etc.). This device can measure almost any detail, due to which it received the name of a universal device. Versatility is ensured through the use of interchangeable nozzles, which can be screwed in or out depending on the part whose size needs to be determined.

- Prismatic devices - the instrument got its name due to the special design of a fixed support in the shape of a prism. Used to identify the diameters of multi-blade tools

- Groove micrometer depth gauge - used to determine the size of recesses. The principle of operation is similar to that of a caliper, only instead of a flat scale, the device has a vernier cylindrical marking. Differs from a caliper in that it displays readings with greater accuracy

- A device for measuring threads - you can measure threads using a caliper, but doing this with a specialized micrometer is not only easier, but also more accurate. The device measures metric and inch threads, for which the micrometer is equipped with special attachments

- Double - structurally, the device looks like two micrometers, which are combined on one base. The device is used for taking measurements of one workpiece, that is, when you need to find out different sizes, for example, when taking piston diameters

- Hot rolled measuring device - used to determine the thickness of manufactured parts at the stage of their manufacture. The device is very different from its counterparts, as it has a wheel with a scale

- An internal meter is a type of micrometer that is used to clarify the internal diameters of products. Unlike calipers, they allow you to measure the minimum internal diameters of pipes and other similar workpieces

All types of devices under consideration have their pros and cons, so it is recommended to choose the appropriate micrometer to measure the relevant parts. This will allow you to get the most accurate results. To ensure these results are accurate, you must first calibrate the instrument.

Laser interference micrometer made from scrap materials

Well, Sir Ernest Rutherford, President of the Royal Academy and Nobel Prize winner in physics, told the following story, which serves as a great example of the fact that it is not always easy to give the only correct answer to a question. Some time ago, a colleague asked me for help. He was going to give the lowest grade to one of his students in physics, while this student argued that he deserved the highest grade. Both teacher and student agreed to rely on the judgment of a third party, a disinterested arbitrator; the choice fell on me.

The exam question read: “Explain how the height of a building can be measured using a barometer.” The student’s answer was: “You need to go up to the roof of the building with the barometer, lower the barometer down on a long rope, and then pull it back and measure the length of the rope, which will show the exact height of the building.”

The case was truly complicated, since the answer was absolutely complete and correct! On the other hand, the exam was in physics, and the answer had little to do with the application of knowledge in this field.

I suggested that the student try to answer again. After giving him six minutes to prepare, I warned him that his answer must demonstrate knowledge of physical laws. After five minutes, he still hadn't written anything on the exam paper. I asked him if he was giving up, but he stated that he had several solutions to the problem and was simply choosing the best one.

Having become interested, I asked the young man to begin answering without waiting for the allotted time to expire. The new answer to the question read: “Climb to the roof with a barometer and throw it down, timing the fall. Then, using the formula L = (a*t^2)/2, calculate the height of the building.”

Then I asked my colleague, a teacher, if he was satisfied with this answer. He finally gave in, recognizing the answer as satisfactory. However, the student mentioned that he knew some answers, and I asked him to reveal them to us.

“There are several ways to measure the height of a building using a barometer,” the student began. “For example, you can go outside on a sunny day and measure the height of the barometer and its shadow, and also measure the length of the shadow of a building. Then, having solved a simple proportion, determine the height of the building itself.”

“Not bad,” I said. “Are there other ways?”

"Yes. There is a very simple way that I am sure you will like. You take the barometer in your hands and walk up the stairs, placing the barometer against the wall and making marks. By counting the number of these marks and multiplying it by the size of the barometer, you get the height of the building. Quite an obvious method."

“If you want a more complicated method,” he continued, “then tie a string to a barometer and, swinging it like a pendulum, determine the magnitude of gravity at the base of the building and on its roof. From the difference between these values, in principle, it is possible to calculate the height of the building. In the same case, by tying a string to the barometer, you can climb onto the roof with your pendulum and, swinging it, calculate the height of the building from the precession period.”

“Finally,” he concluded, “of the many other ways to solve the problem, perhaps the best is this: take the barometer with you, find the building manager and tell him: “Mr. Manager, I have a wonderful barometer. It is yours if you tell me the height of this building.”

Then I asked the student whether he really didn’t know the generally accepted solution to this problem. He admitted that he knew, but said that he was fed up with schools and colleges where teachers impose their way of thinking on students.

This student was Niels Bohr (1885–1962), Danish physicist, Nobel Prize winner in 1922.

Here are the possible solutions to this problem proposed by him:

1. Measure the time the barometer falls from the top of the tower. The height of the tower is uniquely calculated using time and the acceleration of gravity. This solution is the most traditional and therefore the least interesting. 2. Using a barometer located at the same level with the base of the tower, shoot a sunbeam into the eye of the observer located at its top. The height of the tower is calculated based on the angle of elevation of the sun above the horizon, the angle of inclination of the barometer and the distance from the barometer to the tower. 3. Measure the time it takes for the barometer to rise from the bottom of the water-filled tower. Measure the ascent rate of the barometer in a nearby pool or bucket. If the barometer is heavier than water, tie a balloon to it. 4. Place the barometer on the tower. Measure the magnitude of the compression deformation of the tower. The height of the tower is found through Hooke's law. 5. Place a bunch of barometers the same height as the tower. The height of the tower is calculated through the diameter of the base of the pile and the barometer shedding coefficient, which can be calculated, for example, using a smaller pile. 6. Attach the barometer to the top of the tower. Send someone upstairs to take readings from the barometer. The height of the tower is calculated based on the speed of movement of the sent person and the time of his absence. 7. Rub the barometer onto the fur at the top and base of the tower. Measure the force of mutual repulsion between the top and bottom. It will be inversely proportional to the height of the tower. 8. Bring the tower and barometer into outer space. Install them motionless relative to each other at a fixed distance. Measure the time the barometer falls on the tower. The height of the tower is found through the mass of the barometer, the time of fall, the diameter and density of the tower. 9. Place the tower on the ground. Roll the barometer from top to bottom, counting the number of revolutions. (A method that became popular in Russia under the code name “named after 38 parrots”). 10. Bury the tower in the ground. Take out the tower. Fill the resulting hole with barometers. Knowing the diameter of the tower and the number of barometers per unit volume, calculate the height of the tower. 11. Measure the weight of the barometer on the surface and at the bottom of the hole obtained in the previous experiment. The difference in values will uniquely determine the height of the tower. 12. Tilt the tower. Tie a long rope to the barometer and lower it to the surface of the earth. Calculate the height of the tower based on the distance from the point where the barometer touches the ground to the tower and the angle between the tower and the rope. 13. Place the tower on the barometer, measure the amount of deformation of the barometer. To calculate the height of the tower, you also need to know its mass and diameter. 14. Take one barometer atom. Place it on top of the tower. Measure the probability of finding the electrons of a given atom at the foot of the tower. It will definitely determine the height of the tower. 15. Sell the barometer at the market. Use the money to buy a bottle of whiskey, with which you can find out the height of the tower from the architect. 16. Heat the air in the tower to a certain temperature, having previously sealed it. Make a hole in the tower, around which fasten a barometer on a spring. Draw a graph of spring tension versus time. Integrate the graph and, knowing the diameter of the hole, find the amount of air released from the tower due to thermal expansion. This value will be directly proportional to the volume of the tower. Knowing the volume and diameter of the tower, we can simply find its height. 17. Using a barometer, measure the height of half the tower. Calculate the height of the tower by multiplying the resulting value by 2. 18. Tie a rope the length of the tower to the barometer. Use the resulting structure instead of a pendulum. The period of oscillation of this pendulum will uniquely determine the height of the tower. 19. Pump the air out of the tower. Upload it there again in a strictly fixed quantity. Measure the pressure (!) inside the tower with a barometer. It will be inversely proportional to the volume of the tower. And we have already found the height in terms of volume. 20. Connect the tower and the barometer into an electrical circuit, first in series and then in parallel. Knowing the voltage, the resistance of the barometer, the resistivity of the tower and measuring the current in both cases, calculate the height of the tower. 21. Place the tower on two supports. Hang a barometer in the middle. The height (or in this case length) of the tower is determined by the amount of bending caused by the weight of the barometer. 22. Balance the tower and barometer on the lever. Knowing the density and diameter of the tower, the lever arms and the mass of the barometer, calculate the height of the tower. 23. Measure the difference in potential energies of the barometer at the top and at the base of the tower. It will be directly proportional to the height of the tower. 24. Plant a tree inside the tower. Remove unnecessary parts from the barometer body and use the resulting vessel to water the tree. When the tree reaches the top of the tower, cut it down and burn it. Determine the height of the tower based on the amount of energy released. 25. Place the barometer at an arbitrary point in space. Measure the distance between the barometer and the top and between the barometer and the base of the tower, as well as the angle between the direction from the barometer to the top and the base. Calculate the height of the tower using the law of cosines.

Features of calibrating a micrometer yourself

When the device is used frequently, its scale often gets lost (applies to all models). To obtain accurate data when taking measurements, it is recommended that you learn how to do calibration correctly. Calibration involves setting the accuracy. To find out whether the accuracy of the meter has been compromised, you should use reference samples. Typically, such samples are included with the device.

Before making a control measurement with a micrometer, the clamping jaws of the instrument should be thoroughly cleaned. This is done by using a sheet of paper, which must be pressed into the sponges, and then smoothly removed without damaging it. This method allows you to clean the surface from grease and dust.

This is interesting!

Do not use abrasive materials to clean the surface of the sponges, as this will lead to abrasion of the surface and ultimately reduce the accuracy of measurements.

Once the preparatory work has been completed, a reference sample should be fixed in the jaws of the instrument and the value checked on the scale. If it matches, then the device does not need to be configured. Not only analog instruments, but also pointer and digital instruments need such adjustment.

Setting zero on a micrometer or how to calibrate correctly

Not many people know how to use a micrometer, and even fewer people know that before starting work the device must be set to zero. What does this mean, when and how to do it, we will find out further.

The device must be set to zero when calibration reveals that the device is showing inaccurate data. Zeroing is what calibrates the instrument and is very easy to do. To do this, you need to pick up the device and check that the zero mark on the moving drum matches the central mark on the stem. To perform the test, the paws must be brought together until the ratchet operates. After this we do the following:

- Let's check the match. If the zero does not coincide with the mark on the fixed scale, then we proceed to adjustment manipulations

- To do this, you will need to use a special hex key or do the work manually, which depends on the modification

- First we bring the sponges together

- Using a switch, we fix them in a stationary state with a sponge

- Loosen the ratchet fastening, and then move the drum until zero coincides with the scale on the stem

- Tighten the ratchet while holding the drum in this position

At this point, zeroing the micrometer is considered complete. The video below shows the principle of calibrating a micrometer using a hex wrench. The principle is almost identical, only you need to unscrew the drum mount with a wrench in order to be able to align its zero with the center line.

How to set it to zero

This is necessary to eliminate errors and make the final results more accurate. The sequence of actions is as follows:

- clean the paws using the method already described above – with a sheet of thin paper;

- then bring these legs together until they stop;

- tighten the screw properly so that the fixation is reliable;

- make sure that the notches on the scale correspond to the zero mark.

You know how to use the micrometer next. But if the risk does not lie at 0, you will have to arm yourself with a tuning key, which is included in the standard kit of any analog or lever instrument. To do this, you just need to twist the rod to the desired position.

If for some reason this unit is missing, you will need to center the knurling by first removing and then replacing the ratchet. Only after this will it be possible to proceed to taking readings, otherwise there will be no practical meaning in the recorded results, because due to the error they will not reflect the real parameters of the object, which is fraught with defects in production.

How to measure with a micrometer step by step training with video instructions

Measurements should be started immediately after the device has been calibrated. To do this, the base of the device is clamped in a vice so that further manipulations are carried out easily. A part is clamped in the jaws, the dimensions of which need to be known. Moreover, this must be done correctly, because the slightest tightening will cause damage to the threaded connection. After the movable jaw rests on the part, you need to set the ratchet in motion. With its help, the sponge will prevent damage to the integrity of the part or destruction of the structure of the device. After this, you should switch the clamp to the fixation mode and start reading the readings.

Instructions for reading readings are as follows:

- There are two scales on the stem. The lower scale is the main one, and the upper one shows tenths of millimeters. There are models on which the upper scale is the main one, and the lower one shows tenths of millimeters (you need to focus on the presence of numbers near the strokes)

- The scale on the drum is designed to measure hundredths of millimeters

- First, we look at the lower scale and determine the whole number in millimeters. For example, if the drum stopped behind the number 5, then the value will be 5 mm

- Next we look at the top of the stem scale. The scale has 0.5 mm divisions at the top and is easy to read. If the drum stops behind the mark, which is located beyond the lower mark, then 0.5 mm must be added to the value. If the drum stops immediately behind the mark below, and the upper mark is located behind the lower value, then there is no need to add half.

- Next, the calculation of hundredths of millimeters is carried out on a rotating drum. To do this, we orient ourselves along a straight line on the stem. To do this, we determine the value on the drum scale, which coincides with the line on the stem. For example, the drum stopped at a value of 40. Add this value to the resulting number: 5.5 + 0.40 = 5.9 mm

In order to understand the principle of calculus, below is a detailed example with a step-by-step description.

Based on the instructions, making calculations using a micrometer will not be difficult. The calculation is performed similarly on all types of analog micrometers. If measurements are performed with an electronic device, then all calculations are performed automatically, and the user can only read them from the display. Users often wonder how to use a dial micrometer. The measurement principle is similar, but has some differences.

The design and principle of operation of a typical micrometer

A typical micrometer consists of a vice and a block with measuring mechanisms. To carry out the operation, the part is clamped in a vice and held tightly there.

Image No. 1: appearance and design of a typical micrometer

The operating principle of this tool is based on a screw pair. By its step, deviations from zero marks are determined. The values are read from blocks with measuring mechanisms.

This cylindrical part of the micrometer has two scales.

- Spinning. Located on the drum. These divisions indicate fractions of a millimeter.

- Motionless. Located on the stem of the micrometer. There are two scales with different division values (0.5 and 1 mm).

Image #2: micrometer scales

How to use a clock micrometer

Unlike analog devices, dial micrometers allow calculations down to thousandths of millimeters. Not many people know how to use clock or lever devices, and if you come across a device of this type, then you should learn how to use it.

First, let's figure out why we need a scale on the device, and how to perform the calculations correctly. Most watch micrometers have an option to control the grip force of the jaws. This option allows you to avoid deformation of the workpiece, which is especially important when you need to measure the size of a part made of soft materials, for example, copper, aluminum, brass, etc. The operating principle of this mechanism is as follows:

- When the part is compressed in the jaws, the arrow of the mechanism deflects upward or downward. If the pressing force exceeds the limit, then the arrow begins to deviate above the zero mark on the scale towards the positive value. If the pressure is weak, then the arrow on the scale will deviate towards minus

- The indicator of the required pressure is when the arrow is set to zero. In this position, it is possible to carry out measuring manipulations by fixing the position of the movable jaw for this purpose.

Typically, all lever micrometers do not have a ratchet, as they use a pointer-type torque sensing mechanism instead. With such a mechanism, you should be careful not to pinch the part, since if it is fragile, it will be deformed, and with high strength, damage to the threaded structure of the micrometer will occur.

To measure with a lever micrometer, similar manipulations are performed as with analog models, only in this case the user additionally receives information about the size not only to tenths and hundredths of millimeters, but also to thousandths due to the dial scale. The principle of carrying out measurements with a pointer device is as follows:

- The stem scale determines whole and tenth values in millimeters

- Using a vernier scale or on a drum, the value of hundredths of millimeters is calculated, that is, two decimal places

- The value of thousandths is calculated using a pointer scale, that is, three decimal places. It is important to take into account that the value of 10 on the dial scale corresponds to a value of 0.01 mm. For example, when the value of 5.25 mm was set on the stem and vernier scale, and on the hour indicator the hand stopped at a value of 13, then we add the value of 0.013 to 5.25 and we get 5.263 mm

Using micrometers is not difficult, but you need to know the instructions and purpose of each element.

This is interesting!

The design of pointer devices also has the option of quickly determining the dimensions of identical parts, which is very convenient when carrying out quality control of manufactured products. The workpiece is installed between the jaws of the device, and the deviation of the arrow more or less from zero means the presence of a defect.

Micrometer smooth

In everyday life, most often you have to deal with a smooth micrometer . It is the most versatile and most often found in home tool kits. In addition, knowing how to use this tool, everyone can easily use another type of device.

Device

All mechanisms are located on the bracket. The heel is rigidly fixed to it; it serves as a fixed stop during the measurement process. At the opposite end of the bracket the stem is rigidly fixed; it is made in the form of a hollow cylinder.

A scale is marked on the stem ; its division is usually 0.5 mm. There is a screw pair inside the stem. The smooth part of the micrometer screw extends from the stem into the measuring area and ends in a flat measuring surface.

The opposite part of the micrometer screw is rigidly connected to the drum. The drum has a scale that allows you to count hundredths or thousandths of a millimeter. In practice, we more often encounter micrometers with a division value of 0.01 mm.

There is a ratchet at the outer end of the drum. It limits the torque applied by a person's hand when rotating the screw. This allows you to avoid incorrect readings from the device due to elastic deformation of the elements of the screw pair. In addition, the ratchet will prevent damage to the micrometer mechanism by applying excessive force.

As we can see, the micrometer device is quite simple.

Accuracy class

Contrary to popular misconception, the accuracy class of a micrometer does not determine the division price, but the permissible error . For example, for MK25 of the first class the error limit is ±2 µm (±0.002 mm), and for the second class it is already ±4 µm (±0.004 mm).

Marking

GOST 6507–90 defines the symbols of micrometers. For example, the already mentioned smooth micrometer with a measurement range from 0 to 25 mm of the first class is designated “Micrometer MK25−1 GOST 6507–90”.

GOST is a document that requires strict compliance. In the literature, you may find designations for the same micrometer written with a space (micrometer MK 25) or with a hyphen (MK-25). However, the only correct one is the continuous spelling (MK25).

Micrometer with digital display

Commercially available micrometers with digital display have a number of advantages:

- The presence of electronic filling in the device and digital display significantly simplifies the measurement process and reduces the time spent on reading readings.

- A clear advantage of digital devices produced in accordance with GOST 6507–90 is the division price of 0.001 mm, as well as a small margin of permissible error.

- Modern digital models allow not only absolute but also relative measurements. In any position from the measurement range, you can set the zero value. This function is useful for technical control, parts sorting, and complex measurements.

- Inspection and sorting of parts can be carried out even faster if tolerance limits are entered into the device’s memory. Advanced models have this function.

- Devices of recent years have a connector that allows you to display measurement statistics on a computer. This function is useful both for analyzing a series of measurements and for generating various reports.

- Digital instruments are universal for residents of any country in the world, since they allow the use of metric or English measurement systems.

Digital devices also have their disadvantages . The main one is less reliability. Any digital technology requires careful handling. A classic mechanical micrometer will most likely not be damaged if accidentally dropped on the floor, although this is also bad for it. But a digital device, when treated in this way, may refuse to continue working, which will require repairs or even the purchase of a new device.

It should also be remembered that a cheap digital device from an unknown manufacturer can produce significant errors in the results. And these errors can be much more critical than the errors produced by a cheap mechanical model. Of course, we are talking here about devices that actually do not comply with GOST. Although even digital models manufactured in accordance with GOST sometimes demonstrate mysterious behavior or refuse to work a month after the start of operation.

Read also: Instruments for inspection of buildings and structures

Learning to work with a thread micrometer

The question of how to measure with a thread micrometer remains relevant. This is also not difficult to figure out when you have instructions or the experience of a knowledgeable specialist. To begin with, it should be noted that a thread micrometer is intended for measuring the average diameters of fastening threads.

The design of the device is completely identical to the smooth device, only the corresponding type of nozzle is located on the fixed heel and the movable screw. One nozzle is cone-shaped, and the second is in the form of a prism (fork). Moreover, each pair of nozzles in the configuration is intended for measuring threads that have the corresponding steps:

- 0,4-0,5

- 0,6-0,8

- 1-0,5

- 1,75-2,5

- 3-4,5

There are commercially available devices that allow you to measure threads on connectors with a diameter of up to 350 mm. When taking measurements, it must be taken into account that the drum division price is 0.01 mm. The principle of carrying out measuring work with a thread micrometer is similar to the operation of a smooth device. There are some differences that are useful to know:

- Heel mobility

- When changing each pair of attachments to measure the corresponding thread, you will need to constantly set the device to zero

- The cone-shaped nozzle is installed in the micrometric movable screw, and the prismatic nozzle is installed in the heel structure

- You should not try to press the nozzles into the grooves, since a gap must remain so that they can be removed from their seats

- Installed attachments must not fall out

- Bring the jaws together until the drum scale aligns not only with the center marking of the stem, but is also located in front of the first mark, as shown in the photo below

- It is worth noting that the nozzles should not rest against each other.

- The next step is to move on to adjusting the heel. To do this, it has an adjusting screw, the rotation of which causes the prismatic nozzle to move

- The screw rotates until the insert stops in the cone

- Using the second nut on the back side, you should fix the position of the heel in the installed form

- Calibration in progress. How to do this is described in detail above, and is performed in a similar manner.

- When the device is calibrated, that is, zero is set, you can begin to measure the thread

The prismatic part covers the inter-threaded turn, and the cone-shaped part is located between the turns. In this case, measurements are taken, as shown in the diagram below.

This is interesting!

After each replacement of attachments, it is necessary to repeat the steps described above, that is, adjusting the heel, aligning the drum with the stem scale, and setting the zero.

Instrument care

For a device to serve faithfully, you must not only know how to use it, but also store it correctly. Micrometers are made of steel, so it is recommended to store them exclusively in dry and ventilated areas, avoiding exposure to moisture. Before each use, you must not only wipe the working part of the sponges, but also perform calibration. This is necessary to obtain more accurate measurement results.

In addition, the movable screw is moved by a threaded mechanism, which must be regularly lubricated with machine oil. Electronic devices require an appropriate approach to storage, since when exposed to low temperatures, the batteries quickly discharge. Almost all types of devices are supplied in special cases made of plastic, metal or wood. These cases are used to store devices and also transport them.

This is interesting!

Only with a competent approach to the use and storage of the tool can its complete safety and long service life be achieved. A significant argument in the care of micrometers is their high price.

We focus on prices for devices of different types

To purchase a micrometer today, it is not at all necessary to visit markets and specialized stores. If necessary, you can buy a micrometer in an online store, having first looked at the costs of the devices, their types, functions, parameters, as well as other information.

For comparison, below are several models of micrometers, as well as their costs as of 2021. By comparing electronic models with analog devices by price, one can draw appropriate conclusions about the rationality of purchasing certain models.

- Caliber MKTs-50 - costs 9,500 rubles. This is a digital device that has two calculation systems - metric and inch. Allows you to measure parts down to 0.001mm

- Expert MK-25 - costs about 1000 rubles. Belongs to the category of smooth type analog devices. Allows you to measure parts with an accuracy of 0.01 mm

- Norgau is an analog device whose price is 2,400 rubles. This cost is justified by the presence of a special protective coating on the device that protects it from corrosion.

In conclusion, it should be noted that the cost may vary depending on the point of sale. At the same time, it is important to buy a device for your home or garage so that you can always measure different parts if necessary. When measuring, also take into account the errors of the instruments. Manufacturers indicate the magnitude of the error in the technical description. Whatever you have to do, having a micrometer in your arsenal among the measuring instruments is necessary.