New equipment in the house requires studying the operating instructions. Boring activity. Valuable information is always hidden behind a pile of technical terms and is often difficult to digest. But the correct and correct operation of the devices depends on this. To connect the boiler, you can call a specialist, but you can save money and do all the work yourself. We invite you to familiarize yourself with the standard instructions for connecting the boiler. Everything is presented here, clearly and concisely.

First start of the boiler

The installation work has been completed, so you can begin using it for the first time. First, check whether it was installed and connected to the system correctly: professionals always connect it with grounding (many home craftsmen neglect this electrical safety rule). After this, inspect the pipe joints: there should be no holes or chips, as hot water can leak through them. Only after this proceed to connecting the boiler.

System check algorithm

To test equipment mounted on a wall or floor, you must:

- supply cold water under pressure to identify and eliminate leaks;

- make sure that the product is connected correctly to the household electrical network;

- test the operation and make sure there are no leaks or spontaneous premature shutdown;

- turn on the device again to check the liquid temperature.

Starting water supply

Turning on the water heater begins with checking the tightness of the joints of the water pipes and the supply tank. To test, you will need to open the cold liquid supply tap and the mixer valve. Small drops of water are not allowed to appear at the joints of pipes or from under the casing of the device. If a leak appears from the housing, the equipment must be changed; warranty and post-warranty service or repair of heating devices is provided.

If water is supplied to the heater from a well or well, then a coarse filter must be provided in the main line. Even short-term operation of equipment on dirty liquid is not recommended. The mesh allows you to separate large particles of dirt that settle on the surface of the tank and the body of the heating element. Deposits lead to corrosion or local overheating and serve as grounds for refusal of warranty repairs.

Before starting the water supply, it is necessary to check the tightness of the joints of the water pipes and the supply tank.

System diagnostics

After checking the tightness of the water supply circuit, the electrical wiring is tested. If the boiler is connected without a socket, you should make sure that the phase and neutral wires are in the correct position, and then tighten the fastening screws. It is also necessary to check that the packet switch is connected correctly. To carry out the test, you need an indicator screwdriver or a digital device operating in voltmeter or circuit test mode.

Water heater parameters

At the parameter checking stage you must:

- Fill the tank with water and turn on the heater in different power modes.

- Rotate the regulator and press the buttons to check the functionality of the equipment.

- Open the mixer valves and make sure that heated liquid is supplied. If the house has a multi-channel water supply system, it is recommended to check the operation of each distribution point.

- Turn off the power and re-inspect the piping and housing.

Re-check functionality

During the secondary check of the equipment, it is necessary to determine the temperature of the water in the cold water supply system (with a household thermometer or thermocouple connected to a multimeter). Turn on the power and set the operating mode, and after 10-15 minutes, re-measure the water temperature at the outlet of the mixer.

Additional control is carried out after turning off the heating element; some owners check the heating time of the liquid for compliance with the passport data.

When testing equipment in winter, users experience a drop in outlet water temperature or an increase in heating time. The reason is the cold liquid, which cools in reservoirs and when supplied through pipes to a residential building. In warm weather or when the hot water supply is turned off, a drop in pressure may occur. In this case, you should check the tightness of the shut-off valve. When cracks form, part of the liquid goes into the empty mains of the central water supply.

Procedure

The connection sequence is suitable for both storage and flow devices:

- Turn off the hot water. Without this step, all your hot water will go into the common riser.

- Open the faucet to release any remaining stagnant hot water.

- There are 2 pipes at the bottom of the water heater: one with blue color and the other with red color. It is the latter that serves to supply heated water. We open the valve with the blue marker, and water flows to the boiler.

- We turn the valve of the “red” pipe and wait for water to flow out of it.

- Open the faucet tap and water will flow out.

- We connect our installation to the network and adjust it to the desired temperature.

Electrical connection

To switch the boiler to the power supply, a separate circuit is used, equipped with an automatic fuse and a protection device. The cross-section and length of the cable are selected in accordance with the power consumption; a grounding conductor should be provided with a connection to the general circuit of the house.

The rating of the machine must correspond to the energy consumption of the equipment (for example, with a power of 3.5 kW, a device rated for a current of 16 A will be required). The socket must have a housing protected from moisture and dust in accordance with a standard of at least IP44.

When choosing a location for installing an outlet, it is necessary to take into account the radius of spray from water distribution points. Boilers are equipped with power cables with 3 stranded wires with a cross-section of 1.5 mm², covered with a double layer of elastic insulation. There is a point for grounding switching inside the terminal box; information about the location of the element is indicated by the manufacturer in the instructions. It is strictly forbidden to use extension cords or tees for connection, or to connect the ground wire to metal water or gas pipes.

Heating mode selection

This action depends only on the user’s preferences; temperature regulation should be on the touch screen for new models and on the thermometer for old ones.

Manufacturers make systems with temperatures ranging from 30 to 90 degrees Celsius.

Most often, people heat water to 40. But there are a few tips that are useful for everyone:

- At 30-40 degrees, bacteria are very active. These living conditions suit them very well, and death does not occur at such low temperatures.

- The best option is 50. At this temperature, scale will not form inside the mechanism, and it will last much longer. In addition, mold and mildew will not bother you.

- Once every 2 weeks you need to use the maximum temperature for several hours. This is necessary to kill bacteria. Water should not poison the body.

- Many users turn off the heater at night and use only cold water in the morning. Most often this is done for the purpose of saving, but does not in any way affect the total amount of electricity in the apartment. Maximum 50-100 rubles for the sake of savings and a frosty morning shower.

Do I need to drain the water?

Usually the remaining water in the boiler is not drained. It remains in the water heater until the next time it is turned on, provided that the period of inactivity is short. If you turn off the boiler for several weeks or months, the water must be drained. Otherwise, oxidation or scale formation may occur, which will shorten the service life of water heating equipment.

It is necessary to drain the water after the boiler is disconnected from the power supply in poorly heated housing. In a home with low temperatures, water can freeze and rupture the water heater. To eliminate any remaining water, you should use a check valve. It is located on the equipment body.

Rules for using the device

If you follow all the conditions for proper operation, you can extend the life of the boiler for many years. Therefore, read carefully and use the following recommendations:

- Do not turn off the boiler at night, as this will wear it out faster.

- Before connecting it, check the presence of water. If it is missing, the device will break down.

- Clean the tank every year to descale it and check for rust.

- Monitor the anode and its performance.

- Check flow devices to ensure that the water pressure is strong.

- Turn off the boiler as soon as water appears from the city system.

The lifespan of a heater depends not only on the manufacturer and the quality of the equipment, but also on installation, proper use and regular maintenance.

Subscribe to TechnoCouncil on social networks so you don’t miss anything:

Possible malfunctions when turning on

Common breakdowns during equipment operation:

- failure or incorrect operation of the temperature sensor;

- liquid leaking from the drain valve fitting when the heating element is turned off;

- failure of the water heating system due to incorrect connection or breakdown.

Thermometer not working

The design of the boilers includes a temperature sensor that controls the operation of the heating element and allows maintaining the specified heating parameters. If scale or dirt gets on the sensitive element, normal operation is disrupted.

The water is heated above the set parameter or has insufficient temperature. It is recommended to repair the equipment in a specialized service center.

Safety valve leaking

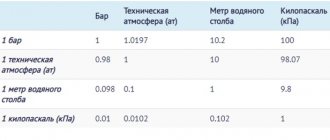

The valve allows you to compensate for the thermal expansion of water; the fuse fitting is connected to the sewer drain with a flexible hose. If liquid flows when the equipment is turned off, you should check the pressure in the water supply system. If the pressure exceeds 4 bar, it is recommended to install a pressure reducing valve. If the pressure meets the standards, you should check the fuse; the cause of the leak is a damaged or lost elasticity spring.

Water heater does not turn on

If, when you try to turn on the heating element, it does not warm up and the control indicator does not light up, you need to check the correct connection and the automatic fuse. If the control lamp is on, you must adjust the temperature correctly by rotating the knob. An additional reason is that the thermal fuse has tripped; it is necessary to return the bimetallic strip to its original position. To restore functionality, you will need to press the button located at the bottom of the case.

Rules for operating the water heater

Regular operation of a storage water heater requires a constant connection to the electrical network. This way, when the device cools down, it will be possible to heat the water to the set temperature without significant expenditure of electricity. At the same time, a filled tank is less susceptible to corrosion.

If the boiler is constantly turned off, savings cannot be achieved, because the equipment spends more electricity on heating the liquid. Disabling is possible with rare use (once a month).

A switched-off device cannot be left in an unheated room if the temperature in it drops below +5⁰ C. When choosing heating equipment for a summer house, this fact must be taken into account.

When switching on the operating mode, it is necessary to check the presence of water inside the tank. Otherwise, the water heater will immediately fail.

Features of operation of a wood-burning water heater

Operating rules for the Edison water heater

The Edison flow-through storage water heating device is designed to heat the water mass inside the tank, but the manufacturer warns that continuous flow mode is not possible.

Once a month, the liquid should be drained through the outlet pipe of the safety valve to remove lime deposits and check the functioning of the valve.

The first launch is carried out according to the standard scheme. It is allowed to supply liquid from an auxiliary container (if there is no water supply system) located at a height of 5 m.

Maintenance must be carried out on time. The first maintenance demonstrates how quickly scale forms inside the tank and how often it is necessary to clean it and replace the anode. According to the instructions, the anode rod is changed once a year.

Properly organized installation, testing, further operation, together with timely maintenance, ensure a long service life and reliable operation of the water heating system.

Briefly about the device and principle of operation

In order to save money, users try to turn on the boiler according to a certain schedule. But if you want to reduce energy consumption when operating a water heating device, you need to understand in general terms how it functions.

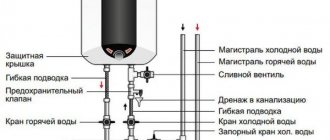

The picture below shows a storage boiler - an insulated tank made of stainless steel or enameled steel with a built-in tubular electric heater (TEH), which has its own thermostat. At the bottom there are water supply and extraction pipes, and there (or on the front panel) there is a heating regulator and a thermometer.

Main elements of an electric water heater

The water heater operation algorithm looks like this:

- Through a pipe equipped with a non-return and safety valve, the container is filled with cold water. The heating element is automatically turned on and the heating process begins.

- When the contents of the tank reach the temperature set by the user, the thermostat turns off the electric heater. If there is no water supply, the automation maintains heating at the set level, periodically turning the heating element on and off.

- When you open the DHW tap on any mixer, water is drawn from the upper zone of the tank, where the corresponding pipe is connected.

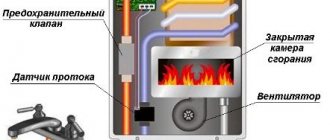

For reference. Boilers are not only electric, but also gas. In them, heating is carried out not by a heating element, but by burning liquefied or natural gas. A comparison of various storage units with flow columns is described in our other publication.

To prevent electrochemical reactions that occur between dissimilar metals during the heating process from causing corrosion of the steel container, a magnesium anode is built into it, which takes the “blow” upon itself. That is, due to the activity of this metal, the rod gradually collapses instead of the tank and heating element.