A refrigerator is a familiar piece of equipment, but it is quite complex and not insured against breakdowns. Some faults are not immediately noticeable. For example, there are times when the refrigerator does not turn off. The device produces the required amount of cold, the food does not spoil, but the engine runs continuously.

This situation cannot be left unattended; it can get worse very quickly. We will tell you how to independently cope with a dangerous malfunction in the operation of refrigeration equipment. We'll show you how to fix the problem and prevent it from happening in the future.

Why does the refrigerator constantly work and not turn off?

Here are the main reasons why the refrigerator compressor does not turn off:

- Super freezing (super cooling) mode is turned on;

- Problems due to summer heat;

- The habit of putting hot items in the refrigerator;

- The temperature is set incorrectly;

- The door is not tightly closed;

- Wear of the sealing rubber;

- Increased room temperature;

- Installing the refrigerator in the wrong place;

- The temperature sensor does not work;

- Temperature sensor failure;

- Freon leak;

- Compressor fan (cooler) failure;

- Master's incompetence.

You have set this mode

If the refrigerator is cold and running non-stop, it is likely that the appropriate mode has been set. Modern devices allow you to set low temperatures. The features of this problem are as follows:

- If the temperature is set too low, the device operates constantly even with high-quality insulation.

- To check for this reason, it is enough to reduce the temperature to a minimum value. If the device stops working constantly, you can set the temperature slightly below the minimum.

We invite you to familiarize yourself with Mold in an apartment: causes of occurrence and methods of combating infection - an article from an OBI Club user.

Do not forget that constant operation causes high electrical costs and a reduction in service life. After defrosting, the refrigerator does not turn off for a long period due to the fact that it takes a long time to reduce the temperature.

Amateur's mistake

Often we ourselves are the reason for the misunderstanding why the refrigerator does not turn off or why it often and constantly turns on and rarely turns off. We, unwittingly, operate the unit incorrectly, making simple mistakes. For example:

- The freezer is set to fast cooling mode or Super Freeze mode. The control options for these modes are manual and/or automatic. The electronics should turn off the compressor after 8 hours, but manual control is just that: manual: you can forget, and then the refrigerator will work until you turn it off;

- Summer heat is not a reason to set a lower temperature in all chambers. The refrigerator is assembled as a sealed device and can withstand large temperature differences. But, the wider the temperature spread inside and outside, the less often the thermal relay will turn off the load;

- Do not place food that is too hot in any compartment. Hot objects will heat it up, and the blower, accordingly, will work even more intensely and turn off less often.

- The standard temperature regime recommended by manufacturers in the main refrigerator compartment should not exceed +4°C; in the freezer, the temperature should be kept at approximately -18°C and lower (-20°C-22°C). In summer, it is recommended to set the temperature 2°C-5°C higher.

Signs of malfunction and why it is dangerous

The design of a modern refrigerator includes a special timer, due to which the compressor is periodically switched off. In this case, the shutdown time depends on the temperature that needs to be maintained. The refrigerator can work without turning off for a variety of reasons. Symptoms of malfunction are as follows:

- Formation of an ice cushion on the walls of devices. Even in the freezer compartment, a large amount of ice should not form; this sign indicates constant operation. If the compressor runs for a long time, you need to set the temperature to a lower temperature.

- Some residents notice a significant increase in energy consumption. This is due to the fact that refrigerators are equipped with powerful motors. If the refrigerator is constantly running and does not turn off, this will increase costs by 30%.

- Constant operation causes the engine to overheat. It is quite difficult to check this, since the device is located on the reverse side.

- If water is stored in the refrigerator and it freezes, then there is a possibility that the device will operate continuously.

You can only check that the refrigerator does not turn off by monitoring the device. The danger of this phenomenon lies in the following points:

- Overheating of the installed compressor. This element largely determines the cost of the refrigerator, so its failure can lead to large costs. The refrigerator compressor is not designed for long-term operation.

- High energy consumption causes increased costs, as well as excessive load on the electrical cable. Heating it may damage the insulation.

- Incorrect operation of the refrigerator leads to severe freezing of stored food.

- Modern models are also noisy, and constant operation can create discomfort.

We suggest you familiarize yourself with How to clean metal from oxidation and rust at home

In most cases, the fact that a new refrigerator does not turn off is determined only by paying attention to its constant humming. If the problem that arises is not resolved in a timely manner, there is a possibility that the installed compressor will burn out.

The refrigerator door is not closed tightly

Why might the door be left open or not closed tightly? Let's start with the fact that the main reason why a two-chamber refrigerator does not turn off is our own carelessness: we simply forgot to close it. An equally simple reason is products that do not fit into the chamber, large dishes, etc.

The next reason: the refrigerator may not be installed in a horizontal plane, but with a slight slope, and a slight push of the door is not enough for it to close spontaneously during movement. Sometimes the door even rolls back (opens by itself).

Even a door fastening that has become loose over time is also an obstacle to sealing. The removable hinge is usually attached to the top right or left of the body and can be adjusted or tightened. As a last resort, remove and bend. The bottom of the canopy is secured by welding or non-adjustable bolting and cannot be reattached or moved.

Removing the top hinge of the refrigerator door.

Possible causes of the malfunction

The problem associated with the constant operation of the refrigeration compressor can be caused by two factors:

- Violation of the thermal regime.

- Equipment malfunctions.

In the first case, you can almost always cope with the problem on your own; in the second, you may need the help of a specialist. Let's consider both options in detail.

Violation of the thermal regime

The simplest, but nevertheless most common case is the door not closing tightly. Quite often this is due to poor placement of products inside the unit. For example, a shelf on the door may rest against something, or a foreign object (for example, plastic packaging from food) has gotten between the seal and the body.

Fridge filling prevents door from closing tightly

A small gap is enough to upset the thermal balance. The thermal relay located inside the chamber will not register the set temperature threshold to turn off the compressor. As a result, the refrigerator will try to cool the entire apartment, and it will honestly try to cope with this. As a result, the compressor is constantly turned on, which significantly reduces its service life. To solve the problem, it is enough to place the contents of the refrigeration chamber more rationally.

There are other reasons for thermal disturbances:

- Problems with the seal.

- The unit is not positioned horizontally correctly.

- Violation of operating conditions.

- Increased level of freezing.

Let's look at each of the problems separately, and also tell you how to deal with them yourself.

Problems with the seal

Over time, or it may lose its properties, as a result the door will not fit tightly to the body. Please note that most manufacturers classify this structural element as consumables, therefore, the warranty does not apply to it.

Wear of the seal is the most common cause of depressurization of the refrigeration chamber

In most cases, you can make sure that the problem is connected with the seal by external inspection. If that's not enough, there is a fairly simple technique called "probe testing." To do this, you will need to take a sheet of thin paper and cut a strip 5 cm wide and 25-30 cm long from it. The strip is inserted perpendicular to the seal, after which an attempt is made to pull it out. If this can be done easily, it can be stated that the sealing gasket is worn out, therefore, it needs to be replaced.

Briefly about installing a new seal.

There are three installation options:

- The seal “sits” on polymer glue, which does not lose its properties when the temperature drops. This is a universal option.

- Installation in a special groove, in this case you will need to purchase a seal of the appropriate profile. It is advisable that the rubber gasket be produced by the manufacturer of the refrigeration unit, then there will be no problems with installation. True, “original” consumables are not cheap. As an option, you can purchase a Chinese-made analogue; its quality will be inferior to the original, but the cost of such a seal will be significantly lower, sometimes even by an order of magnitude or more.

- Rigid installation with self-tapping screws. With the advent of polymer adhesives becoming widely available, such a “barbaric” method of attaching a seal is no longer practiced.

Horizontal level violation

A slight tilt of the housing forward (towards the door) will lead to problems with sealing the chamber. Moreover, such a level violation may not be visually noticeable. You can check the installation using a building level. If you don't have one, take a glass filled with water and place it on the refrigerator. Such a simple level sensor will help determine the horizontal tilt.

If the housing is positioned incorrectly or the violation was caused by moving the refrigeration unit, you can correct the situation by tilting the housing slightly back. To do this, just twist the front legs so that they are higher than the back legs, about a centimeter.

By adjusting the legs you can set the correct horizontal position of the refrigerator body

Violation of operating conditions

This definition includes incorrect installation of the unit, as well as an error in choosing the climatic version category. If in the latter case the situation can be corrected only by replacing the equipment, then for incorrect installation it is enough to select a location according to the recommendations specified in the operating instructions.

As a rule, such instructions are standard, they are not difficult to list:

- When installing a refrigeration unit, it is necessary to leave space between the radiator grille (located on the rear side) and the wall. If this rule is not followed, the refrigerant will not perform its functions, the temperature in the chamber will not drop to the threshold of the thermostat, and therefore the compressor will operate continuously. This is not the way to place a refrigerator!

- Heat sources are located near the unit (heating radiator, heating devices, etc.).

- The body is exposed to direct sunlight.

Read also: Tool for spp clamp

To correct the situation, it is enough to select an installation location that complies with the recommendations specified in the instruction manual.

Increased level of freezing

Activating the super-freeze mode results in the refrigeration unit not turning off at the specified time. Modern installations, as a rule, automatically turn off this mode after 8-10 hours. Earlier models require manual adjustment of the thermostat.

Disable super freeze mode

Equipment malfunctions

Now let's look at more serious situations. As noted above, some of them can be solved on your own, but in most cases you will need the help of specialists. Let's consider possible options for abnormal operation of the refrigeration unit (the compressor does not turn off):

- The camera operates in super-freeze mode.

- The refrigeration unit has stopped freezing, but the compressor is still running.

As a rule, in both the first and second cases, refrigeration equipment operates continuously. Let's look at the causes and ways to eliminate them.

The camera operates in super-freeze mode

In this situation, we can state that the refrigerant circulation system is working and we need to look for the cause in the control module. Simply put, the reason may be related to the relay or thermostat (in most modern models, the thermostat). Now, in order.

Problems with the relay.

This device is a start-up mechanism that controls the operation of the compressor.

Start-up protection relay of the Atlant refrigerator

With a long service life of the refrigeration unit, there is a high probability of “contact sticking”. Note that relay failure may be associated with loss of elasticity of the spring and burnout of the heating coil. But in the last two cases, the compressor, as a rule, does not start, that is, these problems cannot cause its constant operation.

“Sticking” can be corrected in two ways:

- Disassemble the relay and clean the contacts.

- Replace with a similar element.

Despite the simplicity of the first option, it is not always possible to implement it, for example, when the contacts are “welded” to each other. In this case, there is no alternative to replacement.

Thermostat or thermostat malfunction.

This device is essentially an adjustable temperature sensor. Models with electromechanical control are equipped with such devices.

Typical refrigerator thermostat

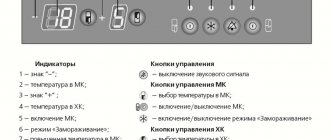

Designations:

- A – Regulator that controls the pressure on the opening contacts.

- B – Hermetically sealed tube.

- C – Contact group.

If this device fails, replacing it with a device of the same type does not cause problems.

Everything is much more serious if we are dealing with the thermostat of modern refrigeration equipment. In this case, the electronic control module receives a signal from the air sensor. If problems occur, an error code is displayed on the display.

Thermostat module

In such cases, you can solve the problem yourself only by replacing the module, provided that it is available for free sale, otherwise you will need the help of service center specialists.

The unit works, but does not freeze

This version of the problem is also quite common. The reason is clear - there is a refrigerant leak in the system. As a result, the compressor runs “idle,” which reduces efficiency to zero. The sensor does not detect a decrease in temperature, therefore, the control module does not receive a stop signal.

Note that modern control modules monitor this situation and display an error code on the information display.

This problem cannot be solved on its own, since the cost of purchasing the necessary equipment will significantly exceed the payment for the work of a repair specialist. Let us explain why by listing the algorithm of actions:

- Freon leakage is caused by a leak in the system, therefore, it is necessary to find the place where it occurred and eliminate the “leak.” In most cases, the problem is related to the refrigeration circuit (freezer) due to the “acceleration” of the defrosting process. That is, attempts are made to remove ice from the freezer using foreign objects (knives are most often used as the latter).

- In such situations, it is enough to lubricate the tubes with soap and swollen bubbles will indicate the problem area. It is much more difficult if the leak occurred elsewhere. But this problem can be solved with a gas analyzer. Gas analyzer for freon leaks

- Having detected a leak, it is sealed using silver solder and a special torch.

- Once the leak has been eliminated, the filter drier should be replaced. According to the rules, this should always be done if the system’s sealing is broken, but in order to reduce costs, they sometimes “forget” about it.

- The final stage is refilling with freon. This is also not a problem, especially since the refrigerant is now available in “puncture-proof” containers, that is, for one-time refilling.

Despite the apparent simplicity of the operation, rarely anyone succeeds in performing it without problems the first time. This job requires skill, otherwise the situation can get worse.

About the warranty for self-repairs.

Before you repair the refrigerator yourself, you should take into account that in almost all cases this leads to loss of rights to warranty service.

Problems with the rubber seal

Less commonly, the cause of the compressor constantly running due to a loose refrigerator door can be an old or damaged door seal. A deformed part of the rubber gasket may prevent the door from sealing tightly.

Cracks in the seal force the compressor to constantly minimize temperature leakage and operate without shutting down. The old seal may lose its magnetic properties, and the fit of the rubber around the entire perimeter will be loose, with cold air leaking.

Atlant two-chamber refrigerator does not turn off: reasons

Since most models from this manufacturer are made using No-Frost technology, continuous operation is often associated with a malfunction of the thermostat. This is a device that records the temperature inside the refrigerator and freezer. This device contains a relay, the main task of which is to open the circuit to stop the motor from working.

The Atlant two-chamber refrigerator does not turn off, reasons:

- Often it is the thermostat that does not work, as a result of which the device continues to operate. It is necessary to check the thermostat of the device. The easiest way is to dismantle the device and test the plate, which is located near the nut.

- If there is no click, then the relay does not operate. You can use a multimeter to check the functionality of the relay. This kind of work should be done by a master.

- Often the reason for the constant operation of the device is the rapid evaporation of freon. This substance is odorless, so a leak can only be diagnosed using special equipment.

- Leakage may occur during a move or change of installation location. While moving, you may accidentally hit the device. If there is not enough refrigerant in the device, then the device works in enhanced mode to reduce the temperature.

Diagnostics

The room temperature is constantly elevated

There are an infinite number of reasons why the refrigerator works non-stop, and all of them are not obvious. For example, hot summers or poor ventilation in winter, a gas (electric) stove, an oven, a drying chamber, and even a microwave oven that is constantly on or frequently running (if you have a large family, this is not surprising).

There are two options for solving this problem: arrange good ventilation, or increase the temperature in the refrigerator compartments. We recommend trying to change the temperature in the freezer. If this does not help, then go to the main camera.

Common mistakes

Often the reason that the refrigerator constantly turns on, works for a long time and rarely turns off is improper operation. Owners make mistakes due to their own negligence. If your refrigerator freezes but does not turn off for a long time, then:

- Check if the Super Frost function is turned on. On some models, it is turned off manually rather than automatically.

- Provide cooling for the radiator on the rear wall. Do not move the refrigerator close to the wall, do not place it near heat sources (heaters, stove, radiators).

- Do not set the temperature in the cells low in summer. The greater the temperature difference between the room and inside the refrigerator, the more often it will turn on.

- Do not put hot food in the refrigerator. Heated dishes and products increase the temperature inside the chambers and force the compressor to work with greater intensity.

- Set the temperature in the main chamber to no lower than +4 degrees, in the freezer -18°C or higher. In summer, increase it by 2-5 degrees.

Separately, it is worth mentioning about inverter compressors. They always work, but with different intensity. Sometimes noise appears and it may seem that the compressor has started to work constantly at high power. The reason is usually loose fastenings and slight vibration.

Incorrect installation of the refrigerator

If you have placed the refrigerator very close to the wall, and the panel with the heat exchanger is not blown by natural air currents, if it is located near a hot water pipe, heating line or radiator, if a boiler or air heater, electric fireplace or other device that emits heat is attached next to it – all this negatively affects the temperature shutdown sensor of the compressor.

If you need to install a refrigerator near the stove, you cannot do it as in the photo. There should be free space between them.

The solution is simple - eliminate all these reasons. Take turns: one thing doesn’t work, try another. It's a long process, but as a result, your experiments can save you a lot of money on refrigerator repairs. In addition, improper installation is one of the reasons why the refrigerator makes strange sounds.

Many modern refrigerators are equipped with a condenser on all sides except the front surface. You can learn about this from the instructions for the unit. For such models, it is important to ensure comprehensive and constant air circulation.

Pro tip that works for any refrigerator model:

- Move the unit 30-70 cm from any heat source;

- If the nearby wall is cold, then the distance between it and the condenser should be more than 50 mm;

- The bottom gap between the floor and the bottom of the refrigerator should be as wide as possible. It can be adjusted by unscrewing the threads on the legs of the housing;

- There should be no furniture or other bulky items on top of the refrigerator.

The refrigerator is running non-stop, what should I do?

The motor is the heart of the device, which helps move the refrigerant and lower the temperature inside the device. Incorrect operation affects the functioning of the device as a whole.

The refrigerator works without stopping, what to do:

- Be sure to look at the part that is located at the bottom of the device and is a large tank. It may have a cubic or slightly rounded shape. Please note that this part should under no circumstances come into contact with the wall or pieces of furniture.

- There should be a distance of at least 15 cm between the wall and the motor. Bring your hand to this part and feel the warmth from it. Heating is felt during the summer heat, when the device operates much longer than at lower ambient temperatures.

- Be sure to place the device in a place where there is no direct sunlight. Under no circumstances should the rays fall on the main part of the device, that is, the motor. This will heat it up further and cause continuous operation.

- Move the equipment away from the wall or move it to a new location. If you hear a noise like a tin can hitting asphalt, level the equipment using feet and a level. It's the motor rattling.

Ice crust

The temperature sensor does not work

It is either broken, in which case you need to call a repairman, or a layer of ice has built up on it. You can remove the ice yourself by defrosting the refrigerator. In modern refrigerators, the temperature sensor is a sensor device; in older models, it is an electromechanical thermostat. But the operating principle is similar. To restore the functionality of the mechanism, it needs to be provided with optimal external operating conditions.

The simplest reason regarding the temperature sensor is that you yourself set the wrong (low) relay response level, and the refrigerator stopped turning off. Check the electronic and mechanical settings of the device.

In modern models, the level of sensor response is displayed on the display in the form of temperature readings (they can be changed using buttons on the display). In older devices, the temperature limit is set by turning the control knob to a certain point.

Error due to ignorance:

The inverter-type compressor is always on, but it operates under different conditions with automatic power changes, so when the intensity of cold production is increased, it can make noise, and you may find it strange why the refrigerator runs for a long time and does not turn off.

We repeat - such a unit always works. Vibrations and extraneous sounds appear from friction of poorly secured elements and assemblies. Therefore, it is worth checking all mechanical connections. We wrote more about extraneous noise in the article 30+ reasons: Why does the refrigerator make strange sounds, how to fix the problem.

When uninterrupted operation is not a breakdown

The compressor is constantly active, but there is no breakdown. Is it possible? Non-stop operation of the motor occurs in the following cases:

- increasing the temperature after defrosting. After defrosting is completed, the equipment is connected to the network and operates cyclically. But why then does the refrigerator wear out and not turn off? The phenomenon is associated with the temperature increase by the compressor. After a few hours, the device will return to normal mode;

- The fan of the device with No Frost is noisy. The fan noise of modern models is similar to the hum of a compressor. You need to check the motor, but before that you should study the instructions;

- voltage drops in the network. The vulnerability of the electronic boards causes the microprocessor to malfunction and the motor cannot stop. After detecting the error code on the display, reboot the device. It is advisable to install a stabilizer;

- improper care. Non-stop functionality of the engine will be prevented by regular defrosting and careful cleaning of dirt. Ice and snow coats cannot be removed with a knife. It is contraindicated to place hot dishes for cooling.

Important! For models with No Frost, the evaporator heater breaks and they do not turn off. The part is being replaced.

The thermostat (temperature sensor) or thermostat is broken

This is found out by cutting off the possible reasons listed above. There are so many different models of refrigerators and thermostats that it is simply pointless to advise you to repair it yourself - they all work differently.

Only a specialist can know the detailed structure of a specific temperature sensor, so get ready to call a specialist. Repair (replacement of the device) will not cost much, since this part is not the most complicated in the refrigerator.

Thermostat with mechanical temperature control.

If it's very cold

So, you noticed that the operating cycle of turning on/off the compressor clearly does not correspond to the standard 10-20 minutes, and maybe the refrigerator does not turn off at all for the whole day. In addition, it is very cold. There are two explanations why this might happen:

- You have turned on the freezing mode or set the temperature to the lowest possible level. The uninterruptible cooling function is just beginning to actively spread in modern models and can be disabled. But older refrigerators do not provide direct switching to this mode, but they behave the same way if they are set to the lowest temperature.

- The compressor does not turn off due to a breakdown. Most often this indicates a faulty trip relay. When its contacts stick to each other, the refrigerator cools the air in the chambers, but the freezing does not turn off, because the compressor circuit is physically impossible to open.

- Thermal sensor does not work. Everything is simple here - if the device that sends the signal to open the compressor circuit is out of order, then the compressor, accordingly, does not turn off and is constantly freezing. In modern refrigerator models, this is often caused by electronic boards that lose control.

The compressor motor or the compressor itself has broken down

The compressor may be running continuously as it tries to reach the set temperature level, but... It could be:

- The rotor or stator winding is burnt;

- Critical wear of the bearings has occurred;

- Drying of lubricant in rubbing units;

- Wear of bushings (sometimes installed instead of bearings);

- Burnt contact at the terminals;

- Wear of piston rings or crankshaft bushings;

- Other reasons (you can’t list them all).

The best way out is to call a technician who will accurately determine the cause of the breakdown and identify the failed part in order to replace it. When replacing a compressor, you will have to re-pump freon or another refrigerant, so the repair will not be cheap.

Cases in which continuous operation of the capacitor is not a breakdown

There are completely normal situations in which the compressor works without stopping, but there is no breakdown and there is no need to worry:

- Uninterrupted operation after defrosting. The refrigerator needs to reduce the temperature inside to standard readings. Therefore, the compressor hums without stopping. On average, the cooling process after defrosting lasts several hours. Be patient.

- It's not the compressor that's humming, it's the fan. In refrigerators with the NoFrost system, a fan is built into the body, which drives cold air around the chamber. Its hum can be confused with the hum of a compressor.

- Power surges in the network. They lead to malfunctions of the microprocessors, and the refrigerator “seizes.” Check the display and read the error code. What to do? If the error is not fatal, unplug the refrigerator and turn it on again. And install the stabilizer.

Refrigerant leak

This breakdown is comparable to replacing a compressor - you will have to call a specialist to completely depressurize the old system and pump in a new volume of refrigerant. There is no need to change the compressor without visible visual wear. How to find out why the refrigerator does not turn off precisely because of a freon leak? We wrote about this in an article about finding and eliminating freon leaks in the refrigerator.

One can only draw conclusions that this is so if all other reasons are not clearly identified. That is, the seal is new and airtight, the thermostat works as it should, the refrigerator does not overheat due to the outside temperature in the room, etc.

Ways to correct the situation yourself

To begin with, you should once again familiarize yourself with the recommendations for operating the refrigerator and check whether the real situation corresponds to what is written in the instructions.

Solving a problem by rearranging

If there is no gap between the refrigerator grille located at the back and the wall, or it is too small, simply move the unit.

If the refrigerator does not turn off, you need to check the thermostat settings. Too low a temperature in hot weather outside can cause excessive load on the compressor

The same should be done if the refrigerator is too close to the heat source. Most likely you will have to make a small rearrangement to place the device in a more suitable place. Then you need to check the temperature settings, measure the overall air temperature in the room, and correct the situation.

If after these simple manipulations the refrigerator begins to turn off regularly, you need to observe its operation. The compressor operating periods should not be too long.

Finding a violation in isolation

If the operating conditions are fine, or if the situation is corrected and the engine continues to run without stopping, it's time to look for other options.

Wear of the sealing gasket on the refrigerator door or its deformation can lead to depressurization and disruption of heat transfer inside the device

First you need to inspect the rubber seal around the perimeter of the refrigerator doors. Over time, the material could become deformed and begin to let air through. If the seal looks new and flexible enough, you can look for damage. A small hole causes many problems.

Replacing the seal is easy. To do this, you need to purchase a new element, remove the old rubber, clean the base and glue the intact gasket using special glue or epoxy resin. Of course, during work the refrigerator must be disconnected from the power supply.

One of the reasons for depressurization of the refrigerator chamber is improper installation of the refrigerator doors. This happens due to the inept actions of the master. This still happens, but happens less often, as a result of using defective elements.

If the seal is in order, you need to inspect the doors and their attachment points. A technician will help you identify and eliminate deficiencies.

The compressor can work without stopping due to the fact that the contacts of the start relay seem to stick at the connection point, breaking the circuit becomes impossible

Identifying technical faults

Problems often arise from the compressor start relay. This element turns the engine on and off to start the process of circulating coolant and cooling the air. Over time, the moving contacts of the device become welded, “stick” and stop opening.

As a result, the compressor remains energized and continues to operate continuously, regardless of the temperature sensor readings. To detect the presence of such a breakdown, you need to use an ohmmeter.

Installing a new relay is a complex operation; for beginners, it is better to delegate such repairs to a specialist so as not to completely damage the compressor. Freon leaks are not easy to diagnose at home. The refrigerant has no odor or color; it simply evaporates into the environment without causing harm.

Using a soap solution allows you to accurately identify areas of damage to the refrigeration circuit. To do this, pressurized air must be pumped into the system.

This video shows checking for freon leaks and diagnosing the condition of the capillary tube using the example of a BOSCH refrigerator:

It is also better to entrust refilling with freon to a specialist who has equipment suitable for this type of work. The location of the leak is determined by visual inspection of the circuit.

But the damage can be so invisible that to identify it you will have to open the refrigeration circuit and drain the remaining freon from it. Air is then pumped into the tubes under pressure.

It should be small so as not to aggravate existing damage, but at the same time sufficient for successful diagnosis. A soap solution is applied to the surface of the tubes, which will bubble in places where the seal is broken.

The air is bled off, the cracks are sealed, and then the refrigerant is poured into the system. In some difficult cases, when it is not possible to restore the tightness of the circuit on site, the refrigerator is taken to a service center for repairs.

If the refrigerator operates without interruption due to a freon leak, you will have to unsolder a special tube to refill the system with a new portion of refrigerant

Refrigerator thermostats can have very different designs depending on the model of the refrigerator. If a rod in a device has come out, it is enough to simply adjust its position so that the unit starts working normally.

But it also happens that during defrosting, water gets inside the regulator. This leads to a short circuit in the electrical system; the thermostat will have to be completely replaced. To perform such work, it is better to invite a specialist who can correctly select the element to replace.

If the thermostat in the refrigerator breaks down and cannot be repaired, you will have to install a new element. The easiest way is to put the fallen rod back in place.

A control module malfunction can also only be diagnosed by a technician using testing equipment. An experienced refrigeration technician can fix minor problems right away.

But if the breakdown is complex, its elimination may require work not at home, but in a service center. For example, to flash the firmware, the electronic control board is removed, repaired at a service center, and then reinstalled.

Sometimes the reason for continuous operation of the unit can be a complex blockage of the capillary tube. Usually, to correct this situation, it is enough to simply defrost the refrigerator correctly.

If this measure does not produce results, the master will have to perform significant disassembly of the mechanisms. It is often more convenient to do this at a service center, especially since the procedure may be associated with significant releases of moisture and technical contaminants.

Replacing a compressor is a complex operation that is best entrusted to an experienced refrigeration equipment repair technician; inept handling can ruin a new expensive unit

It also happens that in order to restore normal operation of the refrigerator it is necessary to completely replace a worn-out compressor or motor. This is a complex operation that amateur craftsmen rarely manage to perform satisfactorily; it is better to call a professional.

Depending on the refrigerator model, such replacement is performed directly on site or at a service center.

The compressor works, but there is no cold

There is refrigerant, and you are sure of it, but the regenerator is covered with ice: failure is typical for models with 1 heat exchanger. In them, the common motor operating for the freezer and refrigerator compartment is forced to turn on more often than provided for by the specified functionality.

To find out if this is true is quite simple - remove the decorative trim on the back of the exchanger panel, and visually determine the volume of condensation on the shirt. If the layer thickness is more than 1 cm, then it’s time to defrost the unit.

Do you want to speed up defrosting? Do not chip ice or scrape snow to avoid damaging the thin aluminum walls of the evaporator! Just direct a stream of warm air at it. After defrosting, set the operating temperature on the thermostat 1°C-3°C higher than before.

Checking the seal: the refrigerator does not turn off, the reason

The task of a Nord refrigerator or any other brand is to quickly reach the desired temperature. To do this, it is not enough to simply provide the required power to the freezer and the engine as a whole.

In everyday work, almost perfect tightness is required, provided by seals. If even a small part of them wears out, the freezer will physically cease to cope with its responsibilities.

There is no need to search for such a malfunction for a long time.

It is enough to simply inspect the internal space of the device from time to time:

- If you open the refrigerator even for a short time, frost actively forms on its back wall;

- Visually, you can find that the layer of frost is greater towards the sash where the wear of the seal is noted;

- Often, 4-5 days after the problem occurs, frost forms on the side flaps;

- Repairing a refrigerator in such a situation is simple - you only need to replace the worn-out section.

Violation of the tightness of one or more insulating inserts is the simplest, so to speak, reason why the two-compartment refrigerator “Codri” ceases to cope with the responsibilities assigned to it. You can get rid of the problem yourself.

The compressor air cooler is broken

Older devices do not have such a fan. In new electric refrigerators - not in all. But, if there is a cooler, then it is installed in the compressor compartment. Designed to blow air over the blower motor and ensure air movement within the radius of heat radiation from the condenser.

If the fan is broken, the refrigerant will not be cooled, so the compressor will rarely turn off or even run all the time. You can check if the cooler is working visually - look at it when you hear that the supercharger is working.

If the blades do not spin, the reason may be the bearing, the motor itself, or damaged electrical wiring contacts. If you can find the last reason yourself, then to eliminate the first two you will need to call a refrigeration specialist.

The blower fan (cooler) of the compressor in the refrigerator.

Refrigerator Stinol 101 does not turn on - troubleshooting

The Stinol 101 series of two-chamber refrigerators has one compressor for the cold cabinet and the freezer. If the refrigerator does not turn on, there are possible reasons:

- faulty wiring or lack of power in the network;

- open fuse circuit;

- the compressor does not work;

- low voltage in the network.

You can make sure that there is no voltage if the indicators do not turn on and the internal light does not come on when the refrigerator door is open.

If one of the cabinets of the Stinol 101 refrigerator is not working well, the reason is a malfunction:

- thermostat for one cabinet;

- lack of refrigerant;

- air leak into the chamber;

- The fast freeze button is stuck (the refrigerator freezes).

The freezer is located at the bottom; if there is a lack of freon, the temperature in it remains below zero; in the refrigerator it rises.

A drip system for defrosting the refrigerator compartment is used; if the drain hole is clogged, water can collect. The freezer needs to be defrosted regularly. As ice builds up, the temperature will begin to rise and energy consumption will increase.

The reason is the incompetence of the master

If you had a specialist and repaired everything, but the device still continuously produces cold, then almost always the solution can be found in the low level of qualification of the refrigerator operator. The chance that after professional service something accidentally breaks immediately is minimal.

Therefore, demand that the workshop eliminate the real cause of the breakdown. And the best guarantee not to get into such a situation is to call a specialist who has good recommendations, extensive experience and positive customer reviews.

How to determine a malfunction by sound?

Another effective way to detect a breakdown. Analyze what sounds the refrigerator makes when it turns on and off.

A clear sign of a malfunction is a strong click before turning off. The volume of the engine plays a significant role. A loud sound coming from the motor indicates a breakdown of the refrigerator. Here are the main reasons for the appearance of such clicks:

- Malfunctions in the functioning of the start-up relay. A quick shutdown of the refrigerator, during which a click is heard, indicates a breakdown of the mentioned part. There is only one way out - replacing the relay.

- The strong heating of the motor when turned off gives rise to such an unpleasant sound. Compressor malfunctions are often to blame.

- Violations of the frequency of work and rest. It's all about the control board. It is she who gives the signal about premature shutdown.

Having identified a malfunction, the owner of the refrigerator must correct the problem as quickly as possible. In most cases, they turn to specialists for help.

The new compressor is always on

The situation is standard: you called a technician and he replaced the supercharger. Then you loaded the refrigerator with food and turned it on, and the relay does not turn off the motor for a very long time. This is normal - after all, the device was turned off for a long time, the temperature inside the chamber remained above zero for a long time, and the food was also warm. It takes time to cool the interior and food to the set values. The time period for continuous cold injection depends on the following factors:

- Set temperature;

- Volume of products on all shelves, including the door;

- Station performance and engine power;

- Temperature in the room where the refrigerator is located;

- Model (No Frost or Low Frost, Frost Free or Naturecool, Super Frost). In fact, several dozen modern cooling systems have been developed, and you need to find out which one works in your refrigerator in the documentation. This also includes multi-flow air supply systems (Total No Frost, DoorCooling, etc.).

Manufacturers stipulate the standard time for continuous operation of the electric compressor before the first shutdown of the engine - this is approximately 180 minutes. You can read more in the article: How long should a refrigerator work without turning off - problems and their solutions.

First start after defrosting or idle time

We would like to draw your attention to the fact that a new refrigerator cannot be plugged in immediately. Its system contains compressor oil. After installation, it should drain into the compressor sump. This will take 4-6 hours.

In the refrigerator after transportation, defrosting or long-term inactivity, the inner chamber and everything in it are heated much more than necessary. The compressor will work for a long time without stopping. As soon as the camera cools down to normal, it will turn off. If it doesn't turn off for more than 6 hours, there is a problem.

The time the compressor will operate depends on the load in the refrigerator compartment. If it is empty, then everything will happen quickly. If there is food in it, the compressor can run for more than an hour. After all, he needs to cool not only shelves and drawers, but also food.

Advice

Constant operation of the compressor motor wears it out. Therefore, after defrosting, do not fill the refrigerator to the top. Place perishable food items in it and wait until the compressor stops. After half an hour, place everything you need inside.

Some compartment does not cool when the compressor is running

The reasons depend on the model of refrigeration equipment, its power and performance. So, in a single-circuit unit, the following may occur: any chamber is depressurized, the thermal relay is broken, or the temperature sensor is faulty.

More details about depressurization: warm air from the room entering the refrigerator through an arbitrary gap heats the chamber. The temperature regime is disrupted, and the electric compressor operates until the chamber cools down to the set temperature. If warm air constantly gets inside, then the motor will work around the clock. Tightness is ensured by the door and the seal, so the influx of warm air masses comes from the outside - either the door is poorly closed, or the seal is broken.

A temperature sensor is installed in modern models of refrigerators, and older units are equipped with a thermostat or thermostat. When the refrigerator compartment heats up, the sensor (or relay) turns on the electric compressor. A broken touch sensor may generally issue incorrect, chaotic commands, and if the relay is broken, then there are two options - the refrigerator either works without turning off, or does not work at all.

The thermostat in older units and economy class models regulates the circulation of refrigerant. A thermostat is installed in the heat exchanger tubes, and only a professional with the appropriate equipment can detect its failure.

Features of breakdowns from individual manufacturers

Each brand of refrigerator, depending on the model, has characteristic problems and malfunctions. Premature thermostat failure and engine malfunctions are possible. For example, Bosch electronic indicators often show a code for a problem related to temperature sensors.

Indesit

This is a popular brand of household appliances, problems with which appear after prolonged use. Malfunctions are eliminated by replacing damaged mechanism components.

Typical brand breakdowns that cause equipment to stop turning off include:

- malfunction of the engine start relay and the fan that distributes the cold;

- breakdown of the temperature regulator;

- refrigerant leak due to corrosion or mechanical damage to the pipeline;

- wear of the sealing rubber and leakage.

Samsung

Household appliances from the Korean manufacturer are presented on the market with a wide range from simple to complex devices with many functions and modes.

The weak points in refrigerators are:

- Thermostat failure, in which the engine receives incorrect signals to start or stop and the cooling does not meet the desired level;

- Freon leakage leads to ice freezing in the freezer and problems in the electronics unit;

- malfunction of the defrost sensor in which the motor stops turning off;

- malfunction of the heater on the evaporator.

Atlant

Refrigerators from Belarus have proven themselves well. Atlants have minor faults, the repair of which is inexpensive.

Common breakdowns include:

- clogging of capillary and drainage systems;

- problems with defrost sensors and a mechanical temperature controller, when the cooling parameters do not correspond to the set ones and the device stops turning off;

- violations in the insulation system, in which a rapid formation of ice build-up occurs on the walls of the freezer;

- problems in the electronics, leading to incorrect display of indicators on the display.

Liebherr

German brand household appliances are of high quality, but European refrigerators are sensitive to voltage changes, which often occur in Russian networks.

The following common problems are noted:

- malfunctions in the electronic control module responsible for the operation of the refrigerator;

- breakdown of the touch sensor, which produces an error code F2, indicating problems in the freezer;

- engine malfunction;

- refrigerant leakage;

- deformation of the sealing rubber on the doors.

Pozis

The technology is attractive to users due to its price-quality ratio.

The main problems of the refrigerator include:

- increased temperature in the chamber;

- weak freezing;

- formation of ice build-up;

- the appearance of a puddle under the unit.

Biryusa

Problems with refrigerators are often associated with non-compliance with the temperature regime of +16...+32°C, as a result of which the thermostat, motor or start relay breaks down. When operating under appropriate conditions, failures occur as a result of metal fatigue and wear of the sealing rubber.

Main problems:

- the refrigerator runs continuously;

- the engine does not start or turns on for seconds;

- the required temperature in the cells is not maintained;

- The compressor switches off with a loud noise.

LG

Refrigeration units serve for a long period, but over time, any equipment breaks down. It is necessary to take care of the control module and the engine, especially if it is an inventory one, from the beginning of operation. It is worth checking the electronic settings of the device if LG is constantly running.

Stinol

In models with two engines, problems arise in the electronics unit; in units without the know-frost system, the freezer compressor often breaks down, and drainage blockages also occur.

Two refrigerator circuits per compressor

A refrigerator with two evaporators operates on the principle of flow separation - the first device lowers the temperature in the freezer, the second cools the main refrigeration compartment. If the temperature suddenly rises somewhere, and the compressor runs for a long time or does not turn off at all, the reasons may be the following:

- The solenoid valve (EMV) is misaligned or broken;

- The regenerator is frozen and icy, and snow or ice appears on the walls. The defect is eliminated by defrosting;

- The capillary tubes in the heat exchanger are clogged with waste oil. Decomposition products and microdebris accumulate on the walls of the tubes, their diameter decreases, and the throughput of the heat exchanger decreases. As a result, the electric compressor does not push the required amount of refrigerant, and the refrigerator operates for a long time without turning off the motor. Remove the blockage by washing and purging the circuit pipe system. At the same time, the refrigerant and oil in the compressor are changed. The work is carried out by a specialist.

The EMC acts as a regulator and switch of the circuit from the compressor to the heat exchanger. A broken valve incorrectly switches the direction of refrigerant and only partially blocks access to the circuit. To identify this malfunction, you must:

- Turn off and unload the refrigerator, wait until it warms up to room temperature;

- Turn off the cooling system in the chamber that was not working well;

- Turn on the unit and wait half an hour. If the disconnected compartment becomes cold again, then the reason is in the EMC - it does not transfer the refrigerant to the disconnected regenerator. The valve must be repaired or replaced by a technician.

Probable causes of breakdowns

There are many different reasons why the unit does not turn off. However, you should focus on the main factors why the engine is constantly running.

- the relay does not work;

- thermostat malfunction;

- the board or thermal control circuit does not work;

- The rubber seal on the door is badly worn;

- the tightness of the tubes was broken, which led to a freon leak;

- the thin capillary tube leading to the filter is clogged;

- The refrigerator operates in a stuffy room or very close to a heat source.

See also -

Why doesn't the refrigerator turn on and how to fix it?

Twin Cooling Plus refrigerator with two compressors and circuits

Such models operate on a separate principle - one compressor serves one compartment. Each supercharger serves its own circuit. All cameras are completely autonomous, and their settings do not change the modes of other compartments.

If both regenerators work without turning off or turn off too often, then modern electronic components should be blamed for this. Since you can hardly organize such complex repairs on your own, order the services of a professional refrigeration technician or take the device to a service center of your brand.

Twin Cooling Plus cooling system options.

What measures to take in case of problems?

So, you've discovered that your refrigerator isn't working as it should: it won't turn off after cooling, or it simply can't lower the temperature to the desired level. What to do about it? Do not ignore the malfunction under any circumstances. Constant freezing may not seem like a big deal to some, but it is reckless. Any device that operates in abnormal mode wears out quickly. And the compressor of many refrigerator models, such as Atlant or Indesit, is at least a quarter of its cost.

Is it possible to do DIY repairs? It’s up to you to decide, of course, but you should objectively evaluate your skills and knowledge: what are the guarantees that you can actually repair or replace a broken part, and how long it will work after that. Here is a list of problems that you can fix yourself:

- Replacing the door seal. The main thing here is to find a spare part specifically for your model or the corresponding family of models. Information can be found in technical documentation, in service centers or on the Internet. Before starting work, it is advisable to watch the video instructions for installing a new seal to avoid mistakes.

- If you have experience in electrical installation and electronics repair, you can replace a faulty temperature sensor or thermostat yourself. Don’t forget to first test the circuit with a multimeter and find information about the characteristics of the elements being replaced.

- Replacing the compressor yourself is also only possible if you have an understanding of its operation, understand the technical characteristics and have sufficient experience.

- You can eliminate the refrigerant deficiency with your own hands. However, this process has many nuances that need to be carefully studied.

Remember also that amateur efforts are not permissible when the warranty on the device is still in force.

Contacting a specialized workshop or service center is the most reliable option. Specialists will conduct diagnostics, determine exactly why the refrigerator is not working correctly, and carry out professional repairs. Once again, pay attention to the warranty - it allows you to save a lot on service costs. Especially if you have an expensive model.

For the fastest and most effective repair, it is better to contact a company service center. Well-known manufacturers (Bosch, Atlant, Indesit, etc.) open them in almost every major city.

Two cameras of the same circuit work the same

If one compressor operates without shutting down, and the circuit connected to it should cool two compartments at different temperature conditions, but this does not happen, the reasons are as follows:

- The heat exchanger line with the refrigerant is clogged;

- The temperature sensor for the air has broken down or the thermostat in the freezer has failed;

- There is a refrigerant leak somewhere in the system;

- Ice has frozen on the outside or sediment has appeared on the internal walls of the evaporator.

Of these four points, only No. 4 can be corrected on your own - if there is ice, but the refrigerator is simply defrosted. After connecting the unit to the network, the temperature in all chambers must be increased by 2°C -3°C. If this is not the reason, call the experts.

How long can a refrigerator compressor run without stopping?

If you have defrosted, moved, or purchased a new refrigerator, the compressor may run longer than usual. A certain time must pass until the walls, shelves, drawers, and products placed in the chambers cool down.

The higher the temperature in the main compartment and freezer is set, the less time it takes for the refrigerator to cool them. The more products you place in the chambers at once, the more time it takes to cool them.

There are pseudo-experts on the Internet who claim that after the first turn on, the refrigerator can work for 12 or even 24 hours in a row. This is complete nonsense and nonsense. In this mode, a conventional non-inverter compressor will either shut down or overheat and fail.

If in summer an empty refrigerator runs for more than an hour without stopping, there is a breakdown. If it is loaded with food, then the maximum time of non-stop operation in the warm season is 8 hours.

Important

We indicate the maximum time. It is calculated if the unit is filled with standard freon and oil and normal heat exchange between the condenser and capillary is ensured. Otherwise, the compressor's continuous operation time may be higher than 12 hours. but this negatively affects his condition. Working under increased load leads to premature wear.

If the compressor operates at peak power, it will wear out a lot. To prevent this, after transporting, defrosting or cleaning, the refrigerator needs to sit for 1 to 4 hours. During this time, the oil will drain into the lower part of the compressor and the equipment will be ready for safe start-up.

In normal mode, the refrigerator can turn on 2-8 times per hour. The ratio of idle time to operating time should be at least 2 to 1. If the refrigerator compressor runs longer, there is a problem. Possible reasons:

- Low refrigerant charge;

- Filled with R600 freon instead of R134a;

- There is a freon leak;

- Malfunctions of the refrigerator components.

Two chambers of the same circuit cool differently

Problem conditions: there are two compressors in one refrigerator, one of which is constantly on, but the chambers are cooled differently. Possible causes of breakdowns and solutions:

- Sediment has accumulated in the evaporator;

- The compressor blower cooler has failed;

- Ice has formed on the evaporator;

- The poorly cooled chamber has become depressurized;

- The EMC is out of order.

The presence of sediment in a specific area of the evaporator can only be detected by a specialist with the appropriate equipment, and you can only check the operation of the regenerator cooler yourself, if it is provided for in the circuit.

If the fan is not working, the temperature in the compartment will steadily increase due to the mixing of cold air with warm air. That is, the compressor will work constantly or switch on/off frequently. The cooler itself will be perfectly visible if you remove the rear decorative panel.

If snow or ice forms on any part of the evaporator, the refrigerator is defrosted, since a thick and cold layer of ice will force the compressor to work without interruption. To avoid similar situations in the future, follow these rules:

- Do not place heated foods and hot food in the refrigerator and side compartments;

- It is recommended to store all food only in closed containers - pots with lids, plastic containers. Excess moisture evaporating from food will contribute to the build-up of a layer of ice on the evaporator;

- Do not leave the refrigerator door open for long periods of time. In modern models, a sound signal alerts you to this; older refrigerators need to be monitored visually.

How to understand that the refrigerator is faulty

The malfunction is easy to notice if food spoils, water collects under the unit, and there is an unpleasant smell in the kitchen. If the device, on the contrary, continuously cools, then problems can be identified by the following signs:

- The compressor knocks and rattles a lot. In old-style devices, the motor is located at the end and during installation practically touches the floor, frame casing and rear wall cooling pipes. Therefore, if the engine is constantly running, its mounts become loose, it hums and knocks.

- The device is electrified. Modern cooling units are equipped with a protection system against current leakage to the housing. But when the motor is constantly on, the electric charge on the body increases and if you touch the door with wet hands, you can feel a slight electric shock. This symptom rarely appears if the unit is installed on wooden parquet.

- The “freezer” freezes quickly. Usually the ice “coat” grows within a week after defrosting. But if the device is not turned off, the ice layer grows over several days.

- Food freezes. The recommended temperature in the refrigerator compartment is +2°C, since its task is to cool the food so that it does not spoil. If food lying close to the wall begins to freeze, this is an indication that the compressor is not working properly.

- The refrigerator consumes an unusually large amount of electricity.

Also read: How to troubleshoot common refrigerator problems

In the event of a breakdown, a “coat of ice” on the walls grows over several days

What to pay attention to

The reason for continuous operation of a household refrigerator is most often an internal defect, damage during transportation, or a malfunction of one of the elements of the device. Therefore, if problems arise, you need to check:

What to check first:

Cooling Fan Motor

- Temperature settings - more on them below.

- Compressor (engine) is a device that circulates refrigerant in the cooling system.

- Thermostat. Thanks to its proper functioning, the cold is maintained: when the desired conditions are reached, the thermostat turns off, and when its value rises, it turns on the motor again.

- The amount of refrigerant is the gas that provides cooling. If there is not enough gas, the compressor will generate it without stopping to create the desired temperature.

- Capacitor at the bottom. If repairs are performed poorly, it becomes contaminated with oil or dust. Debris clogs the capillaries through which freon circulates, and the coolant flows down. Because of this, the ice in the freezer begins to melt, and the refrigerator compartment, on the contrary, cools too much.

- Fan motor. If it is disconnected or not working properly, the air will circulate unevenly and the equipment will not function properly.

- Temperature sensor. This device monitors the climate and sends data to the module that controls the operation of the engine and fan. If the sensor fails, thermoregulation is disrupted.

Causes of excessive cooling can range from incorrect settings to broken key parts.

You have set this operating mode

Often the refrigerator does not turn off due to an incorrectly set thermostat.

The main chamber should be between 0°C (freezing point of the liquid) and +5°C (the limit at which the development of bacteria slows down). But thermal stratification occurs inside the cooling device - that is, different places have different climates, and placing food in the wrong places can cause it to freeze. The distribution scheme looks like this:

- in the lower containers (+7°C) - vegetables, fruits, herbs;

- on the lower shelf above the containers (+2°C) - meat and fish;

- on the middle shelves (+4°C) - dairy products, eggs, soups;

- on the top shelves (+7°C) - side dishes, jams.

On door shelves (+10°C) it is recommended to store products that require only slight refrigeration, such as drinks, concentrates, ready-made sauces.

The door seal is damaged

After using the device for a long time, the seal on the door may crack, peel or burst, allowing warm air to enter.

It can be difficult to notice that the seal has worn out, since air penetrates inside through microcracks and small holes. The cold leaves the device, and the compressor works longer to cool.

Thermostat has failed

A broken thermostat is a common cause of elevated temperatures.

The refrigerator runs continuously for a set period of time to achieve the optimal cooling temperature. Then the engine and freon circulation are turned off. After some time, the engine turns on again and stimulates the circulation of coolant (freon) to achieve optimal cooling and heat supply to the radiator.

If the thermostat is functioning smoothly, the cycles will be regular, but if it is broken, the unit will not turn off at the right time.

The correct ratio of working time and downtime can always be checked by comparing the rated power of the unit (according to the table in the instructions) with the declared electricity consumption per day (on average 30 kW per month). If more energy is consumed than normal, then the problem is a problem with the thermostat.

If the ambient temperature is high, the door is opened frequently, or there is a thick layer of ice in the freezer, the compressor will run relatively more often, and your appliance will consume more electricity.

High room temperature

A similar problem occurs in the summer, when the engine does not freeze well - it has to cool in emergency mode without interruption, which leads to breakdown. To prevent overheating, it is recommended:

- do not install the refrigerator in front of a window;

- do not place the unit on a warm floor;

- close the doors tightly.

In addition, you should install an air conditioner in the room, which will cool the air if necessary.

Also read: What to do if the refrigerator does not cool or freeze

Refrigerant has leaked from the system

The reason for the continuous operation of the compressor may be a freon leak, which most often occurs due to wear and tear of the evaporation system or after refilling if it was done incorrectly.

Externally, the problem is manifested by the formation of oily stains and rust on the walls. In modern models, for example, from Samsung, a refrigerant leak leads to freezing of snow in the freezer and failure of the control module.

Compressor failure

Old-style refrigerators have only one motor, so its failure is immediately noticeable: there is no cold and the motor cannot be heard. But new two-chamber models, for example, Whirlpool or Samsung No Frost, are equipped with two compressors: for the freezer and the main chamber. When one motor fails, the second one works as before, but it takes longer to maintain the required temperature.

In this case, the Alarm sign will appear on the panel - a red light, signaling an error.

Marks on the evaporator pipes directly indicate problems in the cooling system

Broken evaporator pipes

Evaporation pipes are part of the engine and affect the entire cooling system. Most often, they fail due to the formation of an ice clot caused by improper operation of the motor, or a leak due to mechanical damage. The reasons for these breakdowns are as follows:

- Overheating. The engine generates too much heat and creates temperatures higher than what the hoses are designed for. This may lead to a violation of their tightness.

- Pollution. There are only 2 substances inside the cooling system: refrigerant and oil. Everything else is considered pollutants. This includes air, moisture, dirt, dust and any other debris that may get inside due to improper maintenance or if defrosting was not performed correctly.

- Lack of lubrication. This problem leads to increased wear on the compressor and a greater likelihood of overheating, as a result of which the pipes also become extremely hot.

Failures in the control module

Modern refrigerators are equipped with a complex electronic system that protects them from power surges, short circuits and other problems.

The control module is responsible for the operation of all electronic systems. Malfunctions in its operation occur due to a violation of the integrity of the contacts inside the unit or due to incorrectly installed software. Only a technician can determine the exact cause by checking the module on the computer.

If the cause of the malfunction is not in the control module, the latter will indicate the location or causes of the breakdown by displaying a malfunction code on the backlit display. For example, in the Bosch electronic display system, an error code regarding temperature sensors appears on the screen.

The indication and error code on the control module indicates the cause of the problem

Problems with single-compressor models

The motor in older models cools both chambers, so it breaks down more often than in two-compressor devices. Each device has its own characteristic problems. For example, units often fail when the external temperature drops below +16˚C or when it rises above +32˚C. Premature thermostat failures and motor malfunctions are possible.

Some Nord models experience problems with the start relay and temperature sensors during prolonged freezing, while Atlant models often experience failures of thermostats and defrost sensors due to an increase in external temperature. Models with one compressor require more frequent replacement of spare parts and maintenance at a company service center.

The refrigerator turns on frequently, runs for a long time and does not turn off

If all compartments of a two-chamber refrigerator operate in the same mode, and the unit itself often turns on or works without turning off the compressor, the reasons may be as follows:

- Microcracks in the heat exchanger capillary tube system, refrigerant leak;

- The relay that turns on the compressor motor has failed;

- The automatic control of the refrigerator is broken;

- Access to fresh air flow to the condenser is limited by furniture or other foreign objects;

- The compressor is not cooled naturally or using a cooler.

If you were unable to solve the problem with a constantly running compressor on your own, call a refrigeration technician or contact a service center for help.

In this article, we described all the reasons why the refrigerator constantly works and does not turn off. We hope you found it useful. Don't forget to save it and share it with your friends!

Do you want to get help from a master, a specialist in this field? Go to the professional search portal. This is a completely free service where you will find a professional who will solve your problem. You do not pay for posting an ad, views, or choosing a contractor. If you are a master of your craft, then register on Pro and receive a flow of clients. Your profit is just one click away!

Latest publications

- Which freezer is better, No Frost or regular?

- Top 10 air conditioners for apartments 2020-2021

- 30+ reasons: Why the refrigerator makes strange sounds, how to fix the problem

- 6 brands and 6 models: Which refrigerator to buy, inexpensive but good, with No Frost

- 20+ reasons: Why the refrigerator works but does not freeze, what is the problem, how to fix it

- Atlant, Biryusa, Indesit - which refrigerator is better and why

- Is it possible to place a refrigerator next to the stove? How to protect your refrigerator?

- TOP 10 best manufacturers and brands of refrigerators today

- Freon R407c - characteristics, features of use and replacement

- 13 reasons why the refrigerator constantly works and does not turn off

How often should the refrigerator compressor turn on?

It is important to understand that the switching frequency does not directly depend on the operating time of the compressor. For example, in one refrigerator it turns on 4 times an hour and runs for 10 minutes. This does not mean that in another the compressor will turn on 8 times per hour and work for 5 minutes.

Check the effectiveness

Calculating how well your refrigerator is performing is easy. To do this, use the formula:

K = Tr / Tp

- Тп – idle time (when the compressor is turned off);

- Тр – operating time (when the compressor is turned on);

- K – efficiency coefficient.

The normal value of K = 1/2 or 0.5. The more it deviates from the norm, the higher the likelihood of problems in the operation of the refrigerator. If less, perhaps:

- You have a refrigerator with a high COP (conversion rate);

- The temperature in the cells is too high;

- The unit is located in a cold room.

The frequency of switching on depends on the loss of cold. The faster heat gets inside the chambers, the more often the refrigerator will turn on. The reasons are divided into two types - model features and malfunctions. Let's look at them.

Cold loss

If heat enters the refrigerator quickly, food will heat up faster. The temperature sensor will respond more often and start the compressor. Heat can enter for several reasons:

- Doors do not close tightly;

- The walls of the refrigerator are poorly insulated;

- Place hot foods and dishes in the chamber;

- You often open the refrigerator door.

Temperature sensor settings

The temperature sensor in the refrigerator has a response limit. For example, if you set it to +4, then one sensor will work when the camera heats up to +4.2, and the second at +4.5 degrees. The smaller this difference, the more often the compressor will turn on.

If the compressor starts to turn on more often, the sensor may have started to malfunction. You won't be able to determine this on your own. Diagnosis of the sensor should be carried out by a specialist.

Thermal protection relay malfunction

The refrigerator compressor becomes hot during operation. Each model has a maximum operating temperature. To protect the compressor from overheating, a thermal protective relay is installed in refrigerators. It automatically turns off the compressor when it overheats.

If the relay fails, it will measure temperature incorrectly. That is, when there is a reserve and the refrigerator can still work, the relay will turn it off. As soon as the compressor cools down a little, it will turn on immediately. After all, the refrigerator did not have time to cool down to the required temperature.

“Weak points” of famous domestic models

Manufacturers of household appliances constantly assure in advertising that their refrigerators are the most reliable and resistant to malfunctions. However, practice shows that each brand has its own characteristic vulnerabilities:

- Atlant. A common cause of incorrect freezing mode is a breakdown of the thermostat. Moreover, the malfunction is often easily corrected by returning the tube to its place. Older models do not tolerate summer heat well, so they require moving to the coolest corner.

- Biryusa. Refrigerators of this brand operate optimally at temperatures from +16˚C to +32˚C. There are often problems with the relay, thermostat, as well as violations of the compressor operating mode.

- Nord. For these models, the starting relay and thermostat often fail, which can be solved by replacing these devices. It is even more profitable that their warranty period is 5 years.

The Belarusian manufacturer's Atlant brand of refrigerators has gained fame as reliable devices with a service life of a decade or more. Currently, 80% of products are varieties of two-chamber models with one and two compressors. There is no technology that lasts forever; breakdowns also happen in the Atlant refrigerator. Let's determine the main causes of malfunctions.