Possible causes of malfunction

If the refrigeration section of an LG refrigerator has stopped freezing, it means that the freezer will soon fail if the fault is not corrected in time.

Why did the refrigerator stop freezing?

- the defrost mode function is faulty;

- the door seal has moved or worn out;

- the temperature sensor or thermal relay has failed;

- there is a refrigerant leak;

- the cooling system is clogged;

- the electric motor, compressor or electronic unit has failed;

- The Express Cool system fan, which provides the main and freezer compartments with fresh air flows, does not work;

- The damper does not function and cooled air from the freezer does not enter the upper compartment.

Malfunctions of the LG refrigerator with the No Frost system of the GR brand - 389 SQF

The device is Russian-assembled, two-chamber, with a “no-frost” system, a large freezer at the bottom - has gained popularity in Russian families. Full No Frost, height 188, bottom freezer, LED lighting and trouble-free operation for more than ten years - this is how users characterize the device.

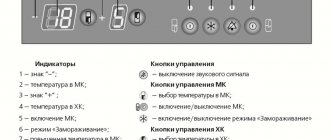

A remote control with push-button mode switching signals deviations on the Freeze Temp display. After turning off the power, all settings are set to the middle position. The electronic module is located in the upper part under the decorative panel. The built-in self-diagnosis mode can be activated manually, testing all systems will take 2 hours.

Typical faults detected during diagnostics:

- the second light on the left indicates an open or shorted freezer sensor;

- the fourth light on the left is on - there is a malfunction of the defrost sensor;

- All the lights are on - No Frost is not working.

If ice is found under the bottom shelf of the freezer, the condensate drainage system is clogged. To clean it you will need to remove the decorative lining and find the drain hole. You can defrost the tube yourself. During all manipulations, the refrigerator must be de-energized.

If No Frost is working, the sensors are working properly - there is a problem in the cooling circuit. Only a master can check the amount of freon, whether there is a passage in the capillary tube, and the operability of the compressor.

How to eliminate them

If the freezer or main compartment does not work, you should:

- Make sure that the thermostat is set to a position between numbers 3 and 4 or the indicator shows the desired temperature setting.

- If the electronics fail or are stuck in defrost mode, you need to contact a specialist. The defrost button may become stuck, so you need to check its operation and replace it if necessary.

- A loose seal must be put back in place and secured with heat-resistant tape, and a worn seal must be replaced.

- A faulty temperature sensor must be replaced.

- If the compressor motor runs for 5-10 minutes and turns off, you need to contact specialists who will replace the failed parts. The entire assembly may need to be replaced.

- A faulty air sensor in an electronically controlled model must be replaced, since it does not supply information about the temperature mode to the control module and the electric motor does not turn on.

- If a lot of snow and ice has accumulated on the walls of the chamber, cooling it becomes difficult. It is necessary to defrost the refrigerator and leave it for 24 hours with the doors open. It is also recommended to remove the back cover on the evaporator and remove all water from there.

- A faulty thermostat in an electromechanically controlled refrigerator must be replaced because it does not inform the control module that the temperature in the freezer has exceeded the norm.

- If the switching valve fails in an LG No Frost refrigerator with one compressor, the power supply of cold air from the main chamber to the freezer is reduced. The part should be replaced.

- If the refrigerator does not freeze, the capillary tubes of the cooling system may be damaged. The lower chamber stops freezing because a refrigerant leak occurs. It is necessary to solder them and refuel them.

- A malfunction in the control module results in the system not receiving the command to cool the freezer. It is necessary to call a specialist who will restore its operation or replace the board.

- A large layer of ice can block the operation of the fan blades. It is necessary to defrost the refrigerator, wipe it dry and turn it on after 12 hours. If the cause is a burnt-out sensor, it must be replaced.

- A malfunction of the electric motor will lead to failure of all systems of the unit. The technician will be able to identify the problem and fix it.

LG M589ZMGZ refrigerator malfunctions

A silver model with a linear inverter compressor, 200 cm high. A multi-flow cooling system and No Frost are used. Electronic control with self-diagnosis.

An analysis of equipment failures before the end of the warranty period shows that the model is reliable and rarely needs repairs. Main causes of breakdowns:

- the starting relay does not work;

- the electronic control unit burned out;

- The temperature sensor has failed;

- The sealing rubber has worn out.

Most often, problems arise in switching operating modes of two circuits or incorrect operation of the No Frost system. The inverter motor has a 10-year manufacturer's warranty. Continuous operation of the sealed circuit allows you to relieve pipe connections from starting shocks and vibration, preventing freon leakage.

Video: LG No Frost refrigerator does not freeze

Watch this video on YouTube

Do you want to understand better than others?

- The freezer does not freeze or does not freeze well - the reason and recommendations from specialists to troubleshoot problems - Why might the freezer stop freezing? There are many parts that affect the operation of the freezer. Among them: The motor, which is directly responsible for the operation of the freezer. If…

- Why the upper chamber in the Samsung No Frost refrigerator does not freeze - The Samsung refrigerator is a fairly successful household appliance in terms of design, which rarely fails in the next few years after its purchase. However, according to…

- The freezer does not turn off: the most common causes of failure - During normal operation of the freezer, the set temperature must be maintained inside the compartment. At the same time, ice build-ups should not appear on the walls, and during operation...

- The main malfunctions of household refrigerators "Stinol" by model - The Stinol refrigerator is a domestic brand with Italian roots. This equipment is quite reliable, the technical characteristics and other indicators of these units...

- The refrigerator does not cool, but the freezer works: what needs to be done - Sometimes, during long-term operation, it happens that the freezer works, but the refrigerator does not or cools very weakly. In the main refrigerator compartment…

Faults in the LG GA-B409 UEQA refrigerator

The refrigerator is a two-chamber, beige color with a quiet inverter compressor and a No Frost full defrosting system. The freezer compartment is located at the bottom. Electronic control, push-button display. No temperature display. The illumination is produced by an incandescent lamp.

The malfunctions of the LG refrigerator of this model and their solutions are not original. But using an inverter compressor eliminates problems with the refrigerant circuit. Isobutane is used and the capillary tube is unlikely to clog. Radiator leaks are rare. Therefore the circuit is reliable.

Problems may arise with the No Frost system, the serviceability of temperature sensors and relays, and the removal of condensate. A specialist can determine the exact reason why it is warm in the plus chamber, but ice freezes in the freezer. It is the user's responsibility to comply with the operating conditions.

What to check first if the freezer in the refrigerator does not work

Sometimes, the freezer does not freeze not because of breakdowns of the unit itself, but because of simple carelessness during operation. Before you pronounce your refrigerator “broken,” be sure to look at the thermostat data . The optimal position, in which both the products are normal and there is no excessive load on the motor, is between 3 and 4, which corresponds to minus 18-19 degrees Celsius . Perhaps, through negligence, you yourself turned the regulator to minimum, which is why there was a “thaw” in the freezer?

An equally common reason is ice freezing . If there is so much of it that the seal does not fit tightly, warm air enters the freezer. While the motor is “resting,” the ice melts and a puddle forms under the refrigerator. It is necessary to defrost the refrigerator and thoroughly wipe the rubber seal.

If the temperature mode is selected correctly and no ice blocks are detected, and the freezer still does not work, then some kind of problem has occurred.

Refrigerator LG GC -339NGLS - malfunctions

Model with a mirror front surface, two-chamber, with a bottom freezer. There is only one compressor. Electronic control. Defrosting the upper chamber is automatic, the lower one is manual.

Refrigerator malfunctions are related to their design:

- The freezer or refrigerator does not work;

- a layer of ice builds up in the refrigerator compartment;

- Water accumulates under the refrigerator drawers;

- there are puddles on the floor, under the refrigerator.

If the regime in the chambers is disrupted, one of the temperature sensors may have failed. Another cause is often a malfunction of the bypass solenoid valve. The temperature in the refrigerator may be high due to the door not closing tightly or the rubber seal being worn out. It happens that the contact is broken, the light in the chamber is on even when the door is closed.

If you have done everything that the instructions prescribe, all that remains is to call a specialist. He will establish the reasons. In addition to the listed malfunctions, there may be:

- Freon leakage from a damaged circuit;

- malfunction of the compressor or engine start relay;

- Compressor tube clogged.

The signs of problems are similar, and only a specialist can find and fix the problem.

Possible malfunctions if the refrigerator stops working after turning off the lights

Most often, surge voltage damages the following components.

Electronic control module – from 1900 rubles*

Due to a sharp jump, radio components, for example, a starting capacitor, burn. Therefore, the refrigerator does not turn on or the motor starts for a few seconds. This is the most common refrigerator breakdown due to power surges. The module needs to be repaired or completely replaced, depending on the extent of damage to the board.

Motor-compressor – from 1900 rubles*

The difference causes a short circuit in the motor windings or burns the wiring in the compressor connection circuit. There is lighting, the start relay clicks, but the engine is silent. The compressor needs to be replaced or the wiring repaired.

Start-up protection relay – from 1600 RUR*

Often an electrical surge “burns out” the starter protection device. Without it, the motor does not work or turns on for seconds if the protective part of the relay has burned out. You need to install a new relay for the refrigerator to work.

Other breakdowns

In the design of Indesit refrigeration units, additional components are used that are involved in electrical circuits or in circuits for maintaining a given temperature inside the product. If the components fail, the upper camera may not work, and error codes will appear on the display. If the refrigerator does not work after turning on the power, it is recommended to check the condition of the electrical power cables, plug and fuse box.

Fan doesn't work

The design of the equipment uses a fan that ensures uniform air circulation in the chamber.

When the impeller stops, error F04 is displayed.

It is possible to repair an Indesit refrigerator by checking the ease of rotation of the fan rotor and the condition of the power circuit. The motor is tested by directly connecting to a household AC power supply. If the rotor does not rotate, the fan needs to be replaced. If the impeller spins, then the problem is in the power cables or the microprocessor control unit.

The heating element in the chamber does not work

If the heating element installed in the freezer of a refrigerator with a No Frost system fails, a message like F07 appears on the display. To eliminate the breakdown, you will need to check the condition of the fuses, and then measure the resistance of the spirals with a test device. Replacing the heating element yourself is not recommended due to the need to use a special tool.

Compressor problems

The compressor design uses a piston unit driven by a commutator motor; the parts are mounted inside a metal casing. If the refrigerator compartment does not work, the reason may be jamming of rotating or moving elements. Stopping or reducing refrigerant circulation (due to difficult shaft rotation or reduced compression in the piston group) leads to poor cooling of the working chambers.

If the compressor motor does not start when the power is turned on, then you need to remove the relay and check the resistance of the starting and operating windings with a test device. Standard values differ depending on the motor and compressor model. If a break is detected, the unit must be replaced. To check the status of the control relay, it is necessary to apply power directly to the motor terminals. If the motor starts working, then you need to check the integrity of the standard power circuits and the functionality of the thermal relay.

Refrigerant leak

If the refrigerator works but does not freeze, then the cause of the breakdown is a refrigerant leak or clogged capillary channels in the heat exchanger. On 2-chamber models with a bottom-mounted freezer compartment, a connecting tube is used that is susceptible to corrosion. If the refrigerator stops freezing, then you need to contact a service center to check the pressure in the lines.

Some products are equipped with 2 compressors with separate heat exchangers. In such installations, a situation occurs when the refrigerator does not freeze, but the freezer works. To restore functionality, you need to invite a specialist who will restore the integrity of the lines and replenish the supply of oil and reagent in the circuit.

If the upper chamber of the Indesit refrigerator does not freeze, but the refrigerant level is normal, then the cause of the breakdown is a blockage of the capillary unit or damage to the thermal regulator. To check the performance of parts, it is necessary to diagnose the components in a specialized service.

The body is electrocuted

The appearance of voltage on the equipment body occurs when electrical cords are damaged or the windings of the compressor motor are broken down. To check, you will need a test device, which is alternately connected to the electrical components and the refrigerator body. The equipment is first disconnected from the household power supply. Under normal conditions, the device will show an open circuit (resistance tends to infinity). After identifying the source of current leakage, it is necessary to replace the unit or restore the insulation.

If there is an electric current from the housing and the equipment does not freeze well, then it is recommended to check the condition of the compressor motor windings. The test device is connected to the terminals located in the relay block and to the compressor housing. Damaged equipment cannot be repaired.

The light doesn't light up

The equipment provides illumination of the refrigerating chamber with a halogen lamp, which is installed in a special protective shade. To control the lighting, a limit switch with a special lever is used, which is pressed by the door leaf. When the door is locked, the circuit is open; after unlocking the door, the backlight automatically turns on.

Methods for eliminating a broken lighting unit:

- Unscrew the screw securing the lampshade, and then inspect the filament in the lamp. The damaged product must be replaced; the design of the refrigeration unit is not designed for the use of lamps with a power higher than 15 W. When screwing the product into the cartridge, it is forbidden to apply excessive force that could tear the bulb from the base.

- If the lamp is intact, then it is necessary to inspect the rotary lever and clean off any adhering dirt. If the lighting does not work, it is recommended to invite a technician to check the condition of the circuits installed inside the equipment.

The refrigerator is noisy and crackling

Noise during operation of the equipment occurs due to the misalignment of the housing. The design of Indesit refrigerators uses front legs equipped with reach regulators. To determine the correctness of installation, a building level is used. Single clicks occur due to temperature deformations during heating or cooling of structural elements; the sounds are not a malfunction.

Water flows under fruit boxes

On the back wall of the equipment there is a channel that drains water into a special tray on the compressor housing (liquid is formed during operation of the automatic defrosting unit). Due to the channel becoming clogged with dirt, liquid flows down the back wall to the bottom of the chamber, gradually accumulating under the pull-out food trays. On some modifications, a special rod is inserted into the hole to prevent clogging. To remove dirt, copper or steel wire is used; it is possible to clean the channel by pushing a piece of dense foam rubber or a rag.

Flowing water penetrates into the internal cavities of the body through cracks in the casing or joints of parts. When liquid gets into the steel refrigerant pipelines, corrosion begins, leading to the destruction of the tubes and the release of gas into the atmosphere.