What is a foreline pump?

The fore-vacuum pump is an inseparable part of absolutely any system. It pumps out the required volume to medium and low levels, while maintaining outlet pressure. The volume of the forevacuum chamber and power affect the speed of operation.

The foreline pump has a long service life

The pump can be dry or oil. Oil cooling in pumps makes them the most popular in use.

The newest structure allows you not to worry about the rapid contamination of the device with oil vapors; a check valve during operation prevents the release of oil. And the inlet and exhaust filter make the process even cleaner. As they improved, fore-vacuum pumps began to be invented without contact between oil and gaseous medium. They are also called dry.

Forevacuum pumps are:

- Spiral;

- Synthetic;

- Diaphragmatic;

- Rotary;

- Claws.

The implementation of such pumps is complex, so they are much more expensive. The shortcomings that oil pumps had were eliminated. But their maintenance requires more careful and frequent disposal and oil changes. Also, some oils cost much more than the pump itself. This is quite unprofitable. All the variety of dry pumps is due to the fact that there is no one optimal option that fits everywhere. Each pump is designed for its own purpose. Every year their improvement increases. But their main drawback - extremely low pressure - still remains. However, the problem can be solved by installing a second booster vacuum pump.

Silicone as an alternative to Vaseline

Silicone injections can lead to the development of cancerous tumors in the human body

Men who intend to pump up their penis with Vaseline can change their minds and do injections with silicone. Many representatives of the stronger sex, who are not happy with the size of their penis, try to change it by introducing this composition.

Any doctor will dissuade a man who is pumping or intends to pump silicone into his penis from such an undertaking. Silicone is a carcinogenic substance. Its presence under the skin is fraught with the development of various diseases. You also need to take into account that silicone is well absorbed by the human body. At the same time, it is almost impossible to get him out of it.

Silicone, like any other carcinogenic substances, leads to the development of cancerous tumors in the human body. All this information about this substance confirms that it is more dangerous to the health and life of men than Vaseline.

Every man should understand that the effect achieved by injecting Vaseline into the penis will not be durable. The composition gradually accumulates in the head. As a result of this, male dignity begins to become severely deformed. At best, this will be the only problem that a man will face if he decides to pump up his own genitals with Vaseline.

Features of water ring equipment

This type of pump is designed to create an aqueous environment with the required level of gas pressure. Centrifugal forces form the work of the pump, pumping out gas due to the formation of a ring. And through the ring, low pressure appears inside.

A liquid ring pump is an apparatus consisting of a cylinder-shaped drum with a span for inlet and outlet.

There is a sealing ring from which purified steam comes out during operation. When the rotor starts, the water is pressed against the cylindrical “shell”, a cavity (loose vacuum) is formed, shaped like a sickle. This type of pump is very popular.

From time to time, water ring equipment should be serviced by replacing worn parts.

They have a number of advantages:

- Unpretentious design;

- Strength;

- Cheap repairs;

- Reliability;

- Economical.

Repairs are done quite rarely, because the elements do not come into contact with each other, and parts do not wear out. Valves, which most often need repair, are missing, as are gears. Rotor bearings need lubrication as they interact with water. There is a risk of breakage only if the sealing ring is neglected. But in general, a liquid ring pump is economical and reliable.

Diaphragm vacuum pumps

The flexible diaphragm is the main part of the operating principle of a diaphragm piston pump. The membrane is connected to the lever mechanism. It is created from the latest composite components that can withstand mechanics. The outer parts of the membrane are firmly attached to the body part, and the central part is bent under the influence of an electric and pneumatic drive. In this way, the inside of the chamber is alternately reduced and enlarged.

The volume changes together with the processes of obtaining and releasing new gaseous or liquid elements. When antiphase combines the actions of two membrane components, a continuous pumping mode occurs. Another element of the pump, namely valves, determines the correct direction of flow and distribution motives. The mechanism does not have elements that can rotate or experience friction and come into contact with the product being pumped.

Advantages of diaphragm piston pumps:

- Tightness

- Dry use for long periods of time

- Using a pneumatic drive in an explosive environment

- Economical.

Advantages of a membrane type unit

This type of pump is used when pumping solutions and liquids that have different viscosities and aggressiveness. They are distinguished by the absence of an engine. The paint and varnish, food, and oil refining industries will not be able to do without such a pump for a day.

The main components are 2 membranes, combined with a rod in the middle of a pair of disks.

When working with powerful pumps, safety rules must be observed.

Air enters first into one chamber, then into another, carrying out a centrifugal cycle of actions, which then return. The valve spool redistributes the medium. The liquid is distributed in the following order: intake manifold - working chamber - exhaust manifold.

What are the advantages of diaphragm (membrane) pumps:

- There is no need to repair parts, since wear does not occur;

- Reliable, simple design;

- Eliminates the formation of sparks, reliability when working with flammable materials;

- If adjustments are necessary, only the air supply volume should be changed.

Impurities do not get inside due to the high level of tightness of the device. They are used in areas where leakage is prevented and sterility is maintained. These are the chemical and food industries, laboratory research, medicine, and printing. The device is completely safe for both animals and people, which is why milking machines are equipped with them. The advantages are considered silent, low energy consumption and compactness.

Checking the pump for vacuum

A vacuum pump is a unit that operates under constant load. In order for it to perform its task smoothly, it is necessary to monitor its condition. The control elements in a vacuum pump are vacuum gauges and leak detectors. Using vacuum gauges, you can constantly monitor the pressure created by the pump, and leak detectors can find leaks in the system.

Depending on the principle of operation of the vacuum pump, membrane, classical, capacitive, thermistor, thermocouple, and insulating vacuum gauges can be used. The instrument includes a sensor that sends the received parameters to a vacuum gauge.

Classic vacuum gauges measure low pressure. As a rule, they contain a working fluid that expands when pressure changes under the influence of temperature. Liquid pressure gauges cannot be used without nitrogen traps, which release vapor that can harm the device.

Device in a diesel engine

The diesel engine includes a rotor, the blade of which divides the space into 2 parts. When the rotor rotates, which is not located in the center, the working space on both sides either decreases or increases.

Often used to lower the temperature of certain engine components.

The oil passes through a special channel, covering and sealing the blades. And for the pump to serve well, you need a connection diagram and the right choice.

The main selection criteria are:

- Maximum outlet pressure;

- Good starting pressure;

- High degree of productivity.

The diesel engine has good efficiency.

Individual mechanisms are not suitable for releasing gases into the atmosphere after pumping, so a forevacuum is created for them. The maximum pressure needs to be measured in a tightly closed container. Maximum outlet – high pressure. The species mentioned are measured in Pascals. Also, during the purchase, you need to take care of the size, pumping stages and their number, engine power, number of revolutions.

Water ring vacuum pumps

Liquid ring vacuum pumps differ from other volumetric devices in that liquid is used in the working chamber when pumping out gases. As a rule, water is poured into the system, which performs several important functions. Firstly, it provides constant lubrication of moving parts. This assumes the absence of other lubricants, which means they can be used to perform clean pumping without contaminating the mixture. Secondly, it cools the system, so the pump does not overheat and can operate uninterruptedly for a long time. The installation is reliable and durable, therefore it is actively used in high-performance enterprises. Thirdly, when pumping contaminated mixtures, it cleans them. This occurs due to the special operating principle of the installation.

This occurs due to the special operating principle of the installation. Due to the action of centrifugal force, the water in the cells undergoes a circular or annular motion, which narrows more and more towards the outlet and causes the gas contained in it to narrow. The installation is popular in the chemical industry because of this feature.

Types of high vacuum pumps

This type of pump is designed to release pressure. The principle of operation may differ when working with a foreline pump, which provides the proper level of vacuum.

There are several types of pumps:

- Cryogenic;

- Magnetic discharge;

- Turbomolecular;

- Diffusion.

Diffusion pumps are used in excavations, creating instruments, alloying various metals, and storing medical supplies. The cryopump is the simplest of all the others. It does not have a liquid medium, so the possibility of contamination is excluded. And also it has a minimum cost, producing the highest quality work. The main condition for the operation of a magnetic discharge pump is that titanium is sprayed with gas in equal quantities.

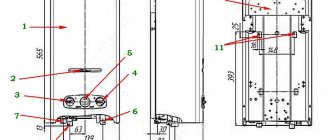

The operating principle of the vacuum pump is shown in the illustration

The main mechanism for pumping out inert gases is the entry of ions into the cathode material.

To maintain a high vacuum, a turbomolecular pump is used. The speed of the pump is determined by the pumping speed. Power and friction increase due to increased pressure. Reliability increases by preventing surface shells from appearing. The drive is controlled by a controller.

Manual hydraulic pumps NRG

The NRG line of pumps contains devices with distributors. The letter “P” is usually placed at the end of the designation of such instruments. This letter means that the tool can work with double-acting hydraulic devices.

- Model NRG-7020R. Creates a maximum pressure of 700 bar, has a nominal tank volume of 2 liters. The kit includes a hydraulic distributor that allows you to work with both single- and double-acting devices.

- Model NRG-7007. Also creates a pressure of 700 bar. The nominal tank volume is 0.7 liters. The advantages of this model are the presence of a safety valve, minimal force on the handle, and two stages of oil supply. This tool is designed for single-acting hydraulic tools with a spring return rod.

- Model NRG-67016R. The nominal tank volume is 14 liters. Handle force 55 kg. Pressure maximum 4 MPa. Capacity is 115 cubic cm. Such a device weighs as much as 30 kg and is quite large. Suitable for a small car service.

Operating principle of the unit and scope of application

Chamber pressure and volume are the leading components of the actions of this type of pump. In the event of a malfunction, the space may be filled with gas at a pressure below atmospheric. Molecules, whether gaseous or liquid, are invariably directed towards areas of low pressure. When taking gas medium, a fore-vacuum pump should be connected. If the device reduces pressure, but without the required speed, you can connect an additional unit. Replacement occurs if the new mechanism provides the required volume of vacuum and has the required characteristics.

There are a number of conditions:

- Resistance to aggressive environments;

- The unfavorable environment will not mix with air or gas.

The use of liquid ring and hydraulic pumps together creates high performance and productivity. They save energy. And the pumping station uses them, ensuring the operation of large pumps.

A liquid ring pump used according to the standard scheme is completely unsuitable for pumping out toxic gas.

With drying and dehydration functions, the vacuum pump is widely used in the pharmaceutical and food industries. This could be pumping out air or drying skin, eliminating impurities in metallurgy, or producing materials. Such equipment is also used in the oil and gas and chemical industries, and agriculture.

If you do not have experience, it is not recommended to repair the pump yourself.

Installation of refrigeration devices is also not complete without the use of a vacuum pump. Sometimes we encounter it in everyday life: packaging products, saving space when sealing by lowering air, creating traction in various designs. Vehicle operation also requires the presence of vacuum pumps, for example to enhance steering or braking. And the electric vacuum type of equipment is necessary for the braking system of the car.

Screw Vacuum Pumps

Screw-type pumps, like all others, operate using the displacement principle. However, unlike other devices, it occurs along a screw, which performs the work of rotation. The pumps have: a drive, 1-2 screw-shaped rotors and a stator of the desired shape. The pumped component does not return back because the parts are manufactured with great precision - this guarantees high-quality pump performance. As a result, excess pressure appears and a vacuum appears in the receiving part.

Pros of screw pumps:

- Minimum noise

- Pumping of components thanks to mechanics

- Even spending

It is important to choose the type of pump according to the requirements of your enterprise and industry. To do this, it is better to seek advice from specialists.

Main differences from the compressor

The differences between a vacuum pump and a compressor are as follows:

- Atmospheric and received pressure are not capable of having a difference greater than 760 mmHg.

- The reduction in air mass as it enters as the vacuum level increases while the compressor has constant efficiency and pressure.

- The pump passes a much smaller amount of air with increasing pressure, and the heat dissolves inside the mechanism, so vacuum equipment does not have difficulties in removing heat.

A vacuum pump transforms mechanical energy into pneumonic energy by pumping out air. The pressure percentage decreases. The amount of gas pumped out affects the rate of work done. The steps taken are similar to air compressors, but the ejection of air from a closed volume is eliminated. The main difference between these two devices is the output of an “absorbing” line of pressure less than atmospheric, which almost disappears with a vacuum of a higher stage.

If the unit is discharged, there is no need to rush to seek the help of specialists. It is possible to repair a house or create a new pump, for example, from a car pump. And the correct connection of the unit will definitely ensure a high level of operation.

MAIN CHARACTERISTICS

First you need to determine for what operations the pump is being purchased. The most important aspects of the choice are presented below.

Pressure

Different production processes require different pressure levels. Therefore, it is possible to eliminate several types of pumps that do not meet the required requirements.

Vibration and noise level

Vibration and noise play a very important role for some types of production, so do not forget about this parameter.

Performance

Capacity is the speed at which a pump pumps out gas or liquid from a limited volume. It is measured in l/min or m3/h. Find out about the correct calculation of the performance of a vacuum pump in our article. The price of a pump depends on its performance. Therefore, it is important to find the most suitable relationship between price and pumping speed.

Substances used

Important parts of a pump used in chemical production are those that come into contact with aggressive substances. This unit must be made of chemical-resistant materials. A conventional pump is suitable for pumping out air. Different types of pumps correspond to different types of gases and liquids.

Monitoring operating parameters

When the pump is used for operations with strict process control, the pump will definitely need a controller connected to a computer. Often such equipment is used for laboratory research.

Price

It is important to remember when choosing a pump to take a balanced approach to price. Currently, there are manufacturers on the market who sell their goods at a clearly inflated price. At the other extreme is an unreasonably low price, which may hide a low-quality product.

If you carefully read all the aspects above, the risk of purchasing a product with low quality will be reduced. Studying these points will take a little time, but will increase your confidence in your choice.

Now let's look at the types of vacuum pumps and analyze their characteristics.