A geyser remains one of the most optimal ways to solve water supply problems. But despite the convenience and simplicity, installation of heating equipment requires at least superficial knowledge of what a flow-type water heater is.

Here you will learn how a gas water heater works and how to connect it; The article also presents in detail the diagram of a flow-through gas water heater.

Unit design

Most gas water heaters are instantaneous type. Each instantaneous water heater (gas) has approximately the same operating principle and similar components. The operating principle of an instantaneous gas water heater is quite simple: gas heats cold water from a heat exchanger.

In this case, the unit itself automatically shuts off the gas flow as soon as a decrease in water pressure is detected. This eliminates the possibility of the unit overheating. In addition, using a special sensor, the device monitors gas leakage, completely turning off the column if there is no traction. Thus, the geyser remains safe for owners.

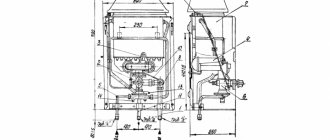

The design of a Neva gas water heater is given as an example.

Device structure from the outside

Connecting a gas water heater can be quite confusing. Below is a drawing in which you can see what the gas water heater consists of.

Scheme of operation of the “Neva” model

What is included in the external part of the device:

- Metal casing (No. 1) covering the device.

- A special viewing window (No. 2) located on the facade of the water heater. Through it you can visually monitor what is happening in the column.

- Under the window there are two regulator handles (latches) - one for gas (No. 3), the other for water (No. 4). The operating principle of valves is based on the action of a drive mechanism, which can be either a human hand or an electric drive. Under the influence of force, the valve spindle rotates, which, when rotated, ensures a change in the shut-off element of the valve.

- Between the regulators there is a liquid crystal display (No. 5), on which you can see the current temperature of the supplied water.

- At the bottom of the unit there are pipes responsible for the supply and removal of water, and for the supply of gas. A pipe (No. 6) is installed in the right half of the water heater, into which cold water coming from the water supply is introduced on one side, and on the other side there is a pipe connected (No. 7) that leads warm water out to the consumer.

- A little to the left (No. 8) there is another pipe connected to a gas outlet hose. The hose is connected to the gas line or gas cylinder.

- At the very top of the device (No. 9) there is a flange that connects to the gas exhaust pipe.

- All of the above mechanisms are attached to a special “wall” (No. 10) with two holes for brackets.

REFERENCE: The design of the Neva gas water heater, of course, is not something unique: the design of the Astra water column has a similar structure. Many other models also have a similar structure.

Internal structure of the unit

To inspect the inside of the device, you need to remove the outer casing.

So, what does a gas water heater consist of:

- The water regulator (No. 12) opens the gas when you turn the tap handle. It is connected to the water pipe (No. 6). A (No. 13) rod is attached to the water unit of the column for (No. 13) adjusting the water pressure.

- The cylinder (No. 14), with a small section on the walls, works like a plug, when removed, all the liquid in the heater is urgently drained. This is necessary, for example, if repairs need to be carried out. In addition, this cylinder is equipped with a gas safety valve, which opens when there is a serious change in pressure in the line.

- In the central part there is a control unit for the gas water heater (No. 16), which is necessary to control the pressure temperature. There are many wires coming from it that connect various sensors and other internal mechanisms to the unit.

- As with the water regulator, a rod with a handle is removed from the gas regulator (No. 17). (No. 18). The gas unit leads gas pipes to the burners.

- Directly between the gas pipe and the tap to regulate the flow of gas there is an electromagnetic valve for the gas water heater (No. 19). It serves to transport gas to the gas unit. In addition, a handle is attached to it that controls the power level and ignition of the device.

- Located slightly higher (No. 20) is a manifold, which is connected to the gas block through a flange pipe. It is attached to the speaker body with two screws (No. 21). On the manifold you can find special nozzles through which the gas flows directly to the burner, consisting of ten rows (No. 22). There is also a spark plug attached to the manifold, which forms a spark to ignite the burner and a flame sensor (No. 24)

- The principle of operation of a battery-powered geyser is that in the central part of the block there is a switch (No. 15), which is acted upon by a special pusher connected to a rod. It is the switch that “releases” electricity from the battery in the gas water heater. First it goes to the control section, and then to the igniter, where a spark is formed.

- Above the collector there is a copper heat exchange module (No. 25), attached to the housing with two screws (No. 28). It is this that transfers heat to cold water. On the right side of the exchanger there is a water reducer for the gas water heater (No. 26), and on the left there is a pipe for outputting warm water (No. 27). The drainage pipe is equipped with two safety sensors: one (29) is for protection against overheating, the other serves as a thermometer that transmits information through wires directly to the LCD display.

- At the top of the column there is (No. 31) a system for removing burnt gas. Through many jumpers, waste combustion products are discharged directly into the chimney channel. To the left is (No. 32) the traction sensor. The principle of operation of the traction sensor is simple: it serves as a fuse that turns off the device in the absence of traction. The draft sensor is connected to the overheating sensor (No. 29), while the operating principle of the draft sensor is not much different from the operation of the overheating sensor, it’s just that the first protects the system from gas leakage, and the second directly from overheating.

- At the very bottom you can see a special block (No. 34), where there are two batteries. The principle of operation of a battery-powered gas water heater is based on complete automation of ignition. The installed batteries provide a spark for ignition and ensure autonomous operation of the unit. The only downside is that the batteries don't last long. Ignition of older speakers is carried out manually.

- There are holes on both sides of the cabinet (#33) for screws that secure the cabinet to the wall.

REFERENCE: The design of the Oasis speaker is practically no different from the above. The gas and water blocks of the Oasis gas water heater have a similar structure, the only difference is that the Oasis has a special “Winter and Summer” switch on the front panel, which in the summer turns off half of the operating burners to save money. If your gas water heater does not work at all in the summer, then you can turn off the gas supply completely.

Causes of problems and DIY repairs

The use of geysers, however, like any other equipment, is accompanied by malfunctions, frequent or rare. At the same time, there are some malfunctions that can only be eliminated by specialists who have the necessary knowledge and permission to do so. But there are also some that can be easily eliminated with your own hands, so we will consider them.

Video - sensor malfunction

Video - repair of a Chinese gas water heater

- The most “popular” type of failure is that it simply does not turn on. If it has an electronic ignition, then you can easily solve a similar problem - just check the batteries and, if necessary, replace them with new ones. Often, such troubles overtake the owners a year after purchase, since the batteries last only that long.

- Also, when using a gas water heater, it may happen that the water in it does not warm up or warms up, but not well enough. Often the cause of such problems is the water node, or more precisely, its defect. As a result, the membrane stops responding to changes in pressure in the water supply system. And if this membrane stops stretching under the pressure of water, then, as a result, the gas valve will not open, or it will open, but not completely. To solve this problem, you must know at least in general terms the structure of the geyser, because the defect can be of several types. If salt deposits have accumulated.

- If the system is clogged.

- If cracks have formed, etc.

To fix this problem, you must first disconnect the column from the gas supply, then clean the water unit and check the membrane.

If the internal elements of the device are covered with soot or dirt, this can also lead to failure. To solve this problem, you must remove the outer casing of the device, then clean each of the elements using a vacuum cleaner. The next sign that the gas water heater has stopped working correctly may be that the burner goes out immediately after turning on. This happens because the ventilation duct is clogged. Modern models of geysers are equipped with special sensors for such cases, which will inform the owner if there is no draft. After this, the gas supply should be turned off immediately. Next, the chimney should be checked. To do this, the plug is dismantled and everything that has accumulated there is removed.

Important! You can check the draft of a chimney in the old “old-fashioned” way: bring a lit match to it. If the fire on the match deviates in the direction of the chimney, then everything is fine with it

If this does not happen, then it needs complete cleaning.

It is for this reason that the gas water heater should be inspected annually - this is the only way it will work correctly.

We also recommend that you familiarize yourself with the basic requirements

Principle of operation

To correctly understand the principle of operation of a gas water heater, you must first understand how its security system works.

If the device is turned off, the control unit of the geyser stops receiving power, because The electrical circuit in the switch is broken. This occurs due to the fact that the pushing mechanism presses the switch plate and keeps it off.

The electromagnetic valve on the gas column is also in a closed state and blocks the gas flow from the inlet pipe, because No power is supplied to it either. However, not only does it prevent the passage of gas: the spring valve located in the gas module is also turned off, and the outflow of gas into the manifold is completely closed.

The main element of the water reducer of a gas water heater is a two-chamber module with a bending membrane, popularly called a “frog”. These modules communicate with each other using the appropriate channel. If the water supply is turned off, the pressure in the chambers is equalized.

Recommendations for maintenance and repair

All elements of the column structure are subject to destruction due to various factors. Any gas equipment requires regular maintenance. If defects are identified during maintenance work, they must be eliminated as quickly as possible. Of course, some repair work should be entrusted to a professional, but some can be done independently.

Dismantling and adjusting the gearbox

You must first turn off the fuel and water supplies. Only after this can you begin to carry out preventive or repair work. To remove the gearbox, you need to perform several steps:

- Water is drained from the heat exchanger;

- using an adjustable wrench, the gas and water pipelines are disconnected from the column;

- If no mistakes were made at the previous stages, the gearbox can be easily dismantled.

Depending on the model of the unit, changes may be made to its design. To avoid problems when dismantling the water reducer, you must first disconnect all pipes and parts that make the work difficult. The housing should be easy to remove; no physical effort is required.

Cleaning the water unit

This event must be held at least once every 12 calendar months.

When unscrewing the fastening bolts located on the unit cover, you must be careful not to damage the folds. When the cover is removed, it is necessary not only to clean the internal space of the gearbox, but also to perform the following procedures:

- All solid residues from the bottom of the part must be removed, and the coarse water filter must also be rinsed.

- It is advisable to lubricate the rod with grease or castor oil.

- If you suspect that the gasket has lost its former elasticity, it also needs to be lubricated.

With regular maintenance of the unit, its service life can be significantly extended. Most often, the rod seal and membrane fail. The first element must be replaced once every 3 years, and the second - after the appearance of ruptures or microcracks. In addition, during intensive work the spring for returning the rod to its original position may break.

Having carefully studied the design and principle of operation of the gas water heater, you can carry out all preventive measures yourself. If you don’t have confidence in your own abilities, then you should turn to professionals for help. When working with the unit, you must strictly follow the instructions.

What happens when the water starts

So, the structure of the column is more or less clear, but how does the column work in principle? And it works by launching a whole chain of processes.

First, water flows pass through the “frog”, then a draft is created in its chamber. Under the influence of high pressure, the elastic membrane bends and pushes the plate, which pushes the water unit of the gas column, which then pushes the gas rod.

After this, the pusher connected to the rod ceases to hold the microswitch plate, and it closes the circuit, thus releasing power to the gas water heater control unit.

In addition, as a result of the above process, the spring bellows is pressed out. valve, removing the plate that closes the channel, and freeing it (gas) free passage to the manifold.

Having received power, the solenoid valve of the column opens without interfering with the gas flow through the spring valve to the manifold.

At the same time, the control unit transmits a small impulse to the candle, which is necessary to form a spark that ignites the burner flame. In this case, the flame is controlled by a separate ionization sensor. If within six to seven seconds there is no signal from the sensor and the burner does not ignite, the electronic module shuts off the gas supply.

This is necessary for safety reasons to avoid gas leakage. If ignition was successful, the sensor will signal to turn off the candle. If the burner goes out after ignition, the sensor also immediately blocks the passage of gas through the solenoid valve of the column.

Work when the water is turned off

The design and operating principle of a flow-through heater depend on the automation of the heating process. After all, a water heater is a heating device. But what happens when the water supply stops? Here's what: the pressure inside the “frog” comes into balance. All the elements fall one after another, like dominoes.

The elastic membrane returns from its bent position to its normal position, thereby returning the plate connected to the pusher. The rod, returning to its normal position, in turn returns the mechanical valve to shut off the gas. The rod also returns the pusher to the mode of pressing the microswitch plate, as a result of which the electrical circuit is broken and the power to the control unit is cut off again. The solenoid valve, no longer powered by anything else, also closes.

This is how another chain of processes occurs, the opposite of what happened when the water was turned on. You can check the status of the column simply by looking at the LCD display. The image below shows the components of the device necessary to turn off the water heating process.

Sources of danger

There are, in fact, only two of them.

The fact is that independent work related to opening the gas pipeline will inevitably lead to a gas leak.

- At a certain concentration of natural gas or propane-butane mixture in the air, it will become unbreathable.

- Long before this, the gas-air mixture will become explosive. The slightest spark when turning on an electrical appliance, triggering any relay (for example, a convector thermostat) or clicking a light switch will lead to exactly the consequences that we tried to warn the reader against in the first section of the article.

The rules that will help avoid negative consequences are quite obvious.

- All work is carried out with windows wide open throughout the entire apartment or house. Yes, yes, regardless of the time of year. Don’t be afraid that your favorite cactus will freeze: if everything goes well, forced ventilation will last no more than 10 minutes.

- The room must be completely de-energized. What the instructions relate to is, I think, clear from the previous explanation. Take it seriously: as already mentioned, the cost of a mistake can be the highest.

Let's get started

Tools

What should you prepare before opening a gas pipeline?

- We have already mentioned a pair of gas keys. Precisely a pair - because in most apartments of the old building, the supply to the stove is made of rigid pipes; To unscrew the locknut and coupling, you need to hold the drive in a stationary position, not allowing it to turn the valve.

- To seal gas threads, FUM tape or synthetic thread with Tangit Unilok sealant can be used. Linen with paint is also suitable, but the paint takes a relatively long time to apply to the threads and winding, and in our case, seconds will count.

- When repairing a tap, a special graphite lubricant for gas taps or regular grease can be used. The graphite base is more practical: it retains its properties longer.

- In addition, when repairing the valve, you will need a 1/2-inch female plug and a flathead screwdriver.

Audit

So, what to do if the gas tap smells like gas and replacing it is not in your plans?

- We close the valve by turning its handle perpendicular to the pipe.

- We use one of the gas keys to fix the outlet after the valve and then hold it in a stationary position.

- Using the second wrench, we tighten the locknut and coupling onto the long thread of the drive.

- We partially unscrew the valve with a key until it starts to rotate by hand.

- We completely unscrew the valve and immediately attach a plug to the thread. Do not be afraid that excess pressure will interfere with you: it is only 3 - 5% higher than atmospheric pressure.

- We wind the thread under the plug and tighten it by hand until the end.

- We unscrew the valve from the surge.

- We unscrew the plug with a groove for a screwdriver on the back side of the valve and remove the spring hidden under it; then we push the conical plug out of the body.

- We clean the body and plug from the remnants of the old lubricant and apply a thick layer of new one.

- Reassemble the valve in reverse order.

- We put it in place of the plug, not forgetting to replace the thread winding.

- We screw in the drive and, having re-winded the threads, we drive the coupling and locknut into the working position.

Replacement

What to do if the gas tap in the kitchen is leaking and you want to replace it with a new one?

If the new valve is the same length as the old one, the actions are completely similar to those described above - with the difference that manipulations with the plug are, for obvious reasons, made unnecessary.

How to change a gas tap in an apartment if its length does not match the length of the old one?

- The drive with the coupling and locknut is thrown out.

- The short thread after the drive is equipped with a short extension with internal and external threads. This will allow the union nut to press the gasket against the smooth, wide edge of the extension rather than against the jagged end of the pipe.

A special case

How to change the tap on a gas cylinder if it cannot be opened with a regular key? Heat the valve with a hair dryer - and its expansion will make the force required to unscrew it quite feasible.

Ignition of an old gas water heater

Devices with manual ignition are considered obsolete. Old-style devices provide for constant burning of the wick and manual shutdown. Ignition of an old gas water heater is carried out using a lit match or piezo ignition.

Although structurally they differ little from modern speakers, they have certain features related to heating:

- In order for the flame to burn stably, the room with the column must have good ventilation and regular air flow;

- Due to the lack of automation, you need to check the presence of traction yourself;

- There is a way to check for gas leaks in old dispensers: you need to lubricate the gas valve connections with soap (the appearance of bubbles means a leak).

Conclusion

What conclusions can be drawn from the instructions in this publication? Firstly, the layout of the Astra gas water heater is not much different from the Neva or Oasis: each of these manufacturers provides modern automated flow-type gas water heaters, which means it is enough to have a minimum knowledge of what the column consists of in order to accept the correct purchase decision.

Secondly, there are certain differences in the old and new models that you definitely need to pay attention to. And thirdly, the automated column ignition unit is the most important element of the entire device, ensuring its autonomous operation and convenient and comfortable operation for you.

Types of combustion chambers

Combustion chambers are of two types:

- Manufacturers most often install an open or atmospheric chamber on hot water columns due to the simplicity and low cost of the design. The circulation of air required to maintain combustion enters the chamber naturally.

- Air is pumped into the closed chamber by a fan. Such geysers are called turbocharged.

The creation of forced draft allows the water heater to operate under any conditions. A unit with an open chamber will not ignite if there is no draft. A similar nuisance occurs in bad weather conditions when the wind blows into the chimney.

Demolition of the water unit

In order to repair this unit, the unit must be removed from its seat. This can only be done simultaneously with dismantling the gas unit:

- it is necessary to close the gas supply valve;

- then disconnect the cold water hose;

- after which, using a wrench, the assembly is disconnected from the pipe section;

- Next you need to turn off the wiring from the gas valve and microswitch;

- Using a screwdriver, you need to unscrew the flange bolts and remove the water-gas unit.

In order not to bring the gas-type water heater to a critical state, once every 6-8 months you check all its components and clean them of scale and dirt.

Then we will proceed to removing and replacing the broken components:

- To separate the gas part from the water part, you need to unscrew two screws. one is placed on top, the other on the bottom. There is no need to unscrew it completely, but just slightly loosen the fastening. It happens that the bolts stick, then they need to be sprayed with VD-40;

- after which the blocks are separated;

- Next you need to unscrew the screws of the assembly from above;

- you will receive a body divided into 2 halves and access to the diaphragm will open;

- you need to remove the rubber part and remove the disk with the rod; a spring is placed behind it;

- you will need to remove the spring and check the seal that is located behind it, it needs to be cleaned and lubricated;

- then carry out the process of installing new parts and reassembling the structure in the reverse order;

- When tightening the bolts, they need to be lubricated with graphite lubricant.

What volume to choose

To choose a gas storage water heater that is ideal for your family, you need to know the hot water consumption per person. Experts assure that this figure is in the range of 50-70 liters. daily consumption. Manufacturers of similar equipment produce various options with a volume of up to 300 liters, so choosing the required option will not be so difficult.

When a water heater is purchased for a family living in their own house outside the city, then it is necessary to consider options no lower than 150 liters - this is the volume that can satisfy the personal hygiene needs of all household members. For those who doubt the validity of this statement, let's do some calculations:

- take a bath - at least 150;

- shower - 50-100;

- morning hygiene - 15 liters;

- for washing dishes - no more than 30 liters.

Now multiply all this by family members - the result is unlikely to please you.

Boilers with a capacity of 200 liters or more are considered the best option for a large family with small children.

Is it possible to do without batteries?

Some resources give advice on how to light a gas water heater without batteries connected . It is recommended to use long fireplace matches.

Most likely, the speaker will not work , since new models have multi-level protection installed, which allows you to turn on the device only if there is power.

In older models, switching sometimes occurs, but it is unsafe - there may be a bang or a gas explosion, and the protection will not work at the right time.

Replacing batteries with rechargeable batteries

Despite the high cost of rechargeable batteries, their use can ultimately be worth it after 2-3 years of use .

It is recommended to use nickel-metal hydride cells, their designation is HR-20 or nickel-cadmium models are designated KR-20 .

Valera

The voice of the construction guru

Ask a Question

Most manufactured batteries provide an output voltage other than 1.5 V. As a rule, they are designed for 1.2 V, which is not enough to power the speaker.

Lithium cells of the 32600 may not be suitable in size and output voltage, which is 3.7 V.

Standard breakdowns

A water block failure is one of the most common failures in gas-type water heaters. The most common reason for block failure is deformation or contamination of the membrane tissue. Salts may be deposited on it, and cracks may also appear. If such damage occurs, the unit stops working, which prevents gas from entering the column.

It is also considered a fairly common problem that the filters of the water reducer become dirty, and due to the constant switching on and off of the device, the unit wears out, which leads to leaks in the places where the seals are located.

You first need to check the water unit if:

- The water pressure is normal, but the column does not turn on (the membrane fabric is damaged or the rod is dirty).

- The cold water pressure is normal, but the hot water comes with weaker pressure (a blockage has appeared).

- The hot water tap is open, but the water heater only started working after a certain period of time (problem with the flow regulator).

- The hot water tap is closed, but the water heater does not stop working for some time (problem with the flow regulator).

- The column turns off during the operating period or does not gain the required power (the membrane tissue is damaged).