Construction technologies and equipment do not stay in one place. Every year, old instruments are improved and new ones appear. Similar updates have not spared air tools, because... every manufacturer always wants to sell the best product to its end consumer. Therefore, when you decide to figure out how to choose a compressor and outline your goals, you should pay attention to its technical parameters. It is knowledge of the best characteristics that will allow you to choose the best model for subsequent successful work.

Operating principle and design of the compressor

A compressor is a machine that sucks in and compresses air or gas and then pumps it out under pressure.

All units are divided into:

1. Volumetric – piston, membrane and rotary, including screw;

2. Dynamic - jet and turbocompressor, including centrifugal, vortex, axial and diagonal.

When the former operates, the air is compressed after entering the chamber, which is forcibly reduced in the process. Backlash is prevented by alternately opening and closing valves.

The principle of operation of the latter is the influence of the rotor blades on the gas. A more precise operating scheme depends on the design features of the compressor, of which there are plenty of modifications.

Types of electric air compressors

Compressors can be classified according to many criteria, including: power, purpose, drive type, device, etc. But there is a worldwide generally accepted classification of these devices depending on the principle of their operation.

So, they distinguish:

- dynamic compressors;

- positive displacement compressors.

The first type is characterized by the fact that gas compression and pressure increase are provided by the energy of the drive shaft directed to the rotor blades. In a positive displacement electric compressor, compression is the result of a reduction in useful volume. Such models are used in everyday life or in industrial settings where there is no need for high power.

The volumetric electric air compressor 220V, in turn, is divided into subgroups:

- piston (affordable price and wide range of applications, but at the same time produces a lot of noise and vibration);

- screw (typical for production, has high productivity and a more complex design);

- membrane;

- spiral;

- rotary-gear.

The demand is mainly for the first two varieties, which have proven themselves to be more convenient, versatile and productive units.

Advantages and disadvantages of piston compressors

What types of compressors are there?

In all the variety of compressors, they are divided into several characteristics according to the principle of operation, so:

Piston compressor - the operating principle is similar to an internal combustion engine, where air is pumped through the movement of a piston on a connecting rod mechanism. Most household and semi-professional compressors are piston compressors. As a rule, a piston compressor is chosen for a car wash, a small service station, or a tire service.

A screw compressor - its operating principle can be roughly compared to a meat grinder, where the propeller blades operate in a chamber with minimal clearance, thus pumping air. This category refers to expensive professional (industrial) compressors. They have a significantly higher service life, productivity, and lower noise levels. Screw compressors are usually used in large service stations, where there are a large number of compressed air consumers, or in industry.

Oil and oil-free

Oil-oil compressors have a crankcase with a lubricating fluid, which increases the service life of the engine, and also has a lubricating effect on the direct consumer, be it a wrench, impact wrench, grinder, polisher, screwdriver, etc. The same effect has a negative impact when using a spray gun, when oil particles can get into the spray gun and reduce the quality of painting (this can be solved by installing additional filters in the pneumatic line in front of the spray gun). Accordingly, like any equipment that uses oil, this type of compressor requires additional care, monitoring and timely oil changes. Most compressors used in car washes or service stations are oil-based.

Oil-free compressors are easier to maintain and are usually used for personal needs in garages or for hobbies. The service life of oil-free compressors is, as a rule, 2-3 times lower than that of oil-based ones, and the operating mode involves using the compressor for no more than 10-15 minutes per hour.

Direct drive (coaxial), belt drive

Small compressors with low capacity, up to 400 l/min, are usually available with direct delivery, i.e. The piston shaft is located directly on the electric motor shaft, and the engine speed is equal to the piston speed. This design characterizes increased engine wear and service life for this type of compressor below a product with a belt drive.

In compressors where the rotation of the pistons is transmitted through a V-belt drive, the motor speed is lower, thereby achieving an increased service life and compressor performance. But their cost is already higher.

Number of cylinders

Compressors come in 1-2-3 cylinder types. The performance of the device depends on the number and volume of cylinders. Compressors can also differ in in-line, V-shaped, W-shaped cylinder arrangement, but in this article we will not delve into these features.

Technical specifications

The 220V electric air compressor must meet the following basic technical characteristics:

Air Compressor Specifications

- power (1-1.5 kW is suitable for home use, but for industrial purposes you will need high performance and no network interruptions);

- voltage - not lower than 180 V, otherwise it may cause failures; It is recommended to install network filters;

- productivity - directly depends on the goals and objectives of operation: for domestic use - some indicators, for construction or industry - others, increased several times;

- maximum pressure is within 8-12 atmospheres.

So, for a mini-compressor intended for home use, the optimal technical characteristics will be the following:

- power – 2 kW;

- receiver volume – from 50 l;

- automation that protects against breakdowns and failures;

- cooling elements;

- belt drive and distributor valves.

Which brand of air compressor should you choose?

Electric air compressors are highly specialized equipment for specific tasks. Many companies are engaged in its production, but preference should only be given to proven ones, whose products have proven themselves in the market. Reliable manufacturers, in comparison with fly-by-night companies, regularly introduce new, proprietary technologies, ensure equipment maintenance and its full compliance with the declared parameters.

Our editors have prepared a brief overview of the five most popular brands that produce high-end compressor equipment:

- Fubag . The brand name is synonymous with the best quality at affordable prices. The company offers a choice of several lines of equipment of various layouts. Among Fubag compressors there are modifications of various classes - from household to professional.

- Denzel . When looking for durable and unpretentious equipment, experts recommend any compressors from this manufacturer. Even household models can easily cope with minor overloads and do not fail in difficult times.

- Wester . Despite production in the Celestial Empire, equipment from Wester fully complies with the specified parameters. Even low-power models are equipped with additional options, such as anti-vibration feet and overheating protection.

- FiAC . The brand combines Italian technologies and components and Belarusian production. It is this technique, according to customer reviews, that is reliable and stable from series to series.

- Kraton . The domestic brand offers users good quality and provides service and components.

One or two compressors in the refrigerator

It will depend on many parameters which refrigerator is better: with 1 or 2 compressors, because this part significantly affects its operation. First, let's look at the features of units operating on the same cold injection device. Even if the refrigerator model has two chambers, one pump is still used. During cooling of the freezer and refrigerator compartments, one compressor pumps air. However, it does not separate the functions of lowering the temperature in a specific chamber and constantly works in two sections.

A significant disadvantage of such refrigerator models is that it is not possible to separately turn on the cooling of a specific chamber or turn it off if unnecessary.

Advantages and disadvantages of single-compressor refrigerators

A single-compressor unit is often a refrigerator with a total volume of 100 liters with a small freezer or no freezer at all. One refrigerator compressor is enough to ensure stable and trouble-free operation of the cooling system. This option provides for setting the temperature simultaneously for both the freezer and the general cooling chamber.

The single-compressor type often does not provide for separate shutdown of the freezer compartment and the general refrigeration section. That is, if, for example, you need to turn off one of the compartments for a long trip or for cleaning, you will have to turn off the unit completely. This property cannot be considered as a minus, since it also has economic feasibility.

However, some models of single-compressor refrigerators have a special solenoid valve, thanks to which the refrigerant circulation can be adjusted. The function of this component is to block the access of refrigerant to the evaporator of the refrigeration compartment, as a result of which the cooling stops, but the freezer continues to operate.

Regardless of the type of refrigerator with a single compressor, not a single such unit has the ability to separate the freezer compartment separately from the refrigerator compartment.

Advantages and disadvantages of two-compressor refrigerators

When choosing which refrigerator to buy: with one or several compressors, you don’t need to spend a lot of time comparing. The buyer will be provided with the distinctive characteristics of the various models that he will be interested in in the store, but in any case he will have to face a rather large cost. It is not easy to compare quality and cost if you do not familiarize yourself with the main distinguishing characteristics.

An additional compressor increases the speed of the freezing function, while allowing you to increase the overall dimensions of both the freezer and refrigerator compartments. This factor can cause both purchase and refusal due to the redundancy of such equipment for one family. Often, a traditional model that copes with its main tasks of food storage is sufficient for a home.

Since the pros and cons of single-compressor units have already been presented above, it is advisable to familiarize yourself with the similar factors of refrigerators with two compressors. So, the advantages of this technique include the following:

- Thanks to the presence of a separate compressor in each compartment, freezing and refrigerating, the load is distributed across two systems, which ensures faster freezing of products.

- If necessary, you can turn off any branch separately. This function is especially useful in case of a long trip or if you need to defrost the main compartment.

- When freezing, less load is placed on individual compressors.

- The failure of one compressor does not affect the operation of another.

In addition to the positive aspects, like any type of equipment, two-compressor refrigerators also have some disadvantages:

- Consume more electricity. But this minus sometimes allows you to correct the correctly selected climate class of the refrigerator, its location, etc.

- The operation of two compressors produces more noise, although this is mainly influenced by the compressors themselves.

- Compared to the single-compressor type, the two-compressor type is slightly more expensive.

Choosing between single-compressor and double-compressor refrigerators

Which refrigerator is better and how not to make a mistake in choosing? To do this, it is useful to make a list of needs. Without a detailed list, there is a risk of overpaying for the latest model, which in fact cannot boast of any of the necessary advantages. To avoid this, it is recommended to answer the question for yourself: how much food will need to be stored in the refrigerator?

A model with two compressors will not justify the money spent if you want to buy an impressively sized unit “in reserve”, but in fact store few products in it. If you calculate, on average, thanks to separate cooling of the chambers, the savings will be imperceptible (up to 50 rubles). Thus, it will not be possible to recoup the funds spent on the second compressor in the near future.

Two compressors are useful if the refrigerator is intended to store large quantities of food. Under such circumstances, this type will perform its tasks well, and economically.

This is explained by the fact that an overloaded freezer will increase operating power, thereby accelerating equipment wear, increasing power consumption and increasing noise. And thanks to separate compartments, the cold will be saved, which means that the units will not be forced to work at full capacity.

To summarize, I would like to note that with proper operation (which mainly determines the selected climate class of the refrigerator, placement location, product location and frequency of door opening), a two-compressor refrigerator will work much more economically and energy efficiently than a unit with a single compressor.

Selecting a compressor for the garage

A couple of examples on compressor selection.

If you have a garage and you service your car, your wife’s car, or constantly use: an inflator gun, a blow gun, a grinder, a wrench or a paint sprayer.

Another situation: renovations are planned in a private house and you plan to use a pneumatic stapler to repair the roof. You will need a drill, an angle grinder and possibly a paint sprayer.

| Tool type | Working pressure, Bar (P) | Average air flow (l/min), (Qn) |

| Air blowing gun | 4 | 170 |

| Painting gun (spray gun) | 3-4 | 141 |

| Polishing and grinding machine | 6 | 140 |

| Impact wrench | 6 | 226 |

| Tire inflation gun | 6 | 140 |

Table 4 – Table of parameters of pneumatic tools

The most voracious is the impact wrench, which means the compressor will be calculated based on it as follows: 226 l/min + 20% = 271.2 l/min – the required performance for pneumatic tools.

Since the compressor is planned to be used intensively, it is better to take a belt compressor. Previously it was stated that the efficiency for belt compressors = 0.75.

This means the inlet capacity should be: 271.2 ÷ 0.75 = 361.6 l/min

The required pressure for the tool is 6 bar, which means the compressor pressure must be at least 8 bar. Productivity – no less than 361 l/min. Pressure – at least 8 bar. The most suitable compressor is a belt compressor. The VCF/100 CM3 model is perfect.

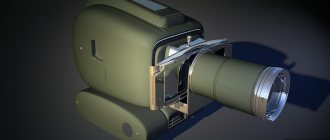

Belt compressor VCF/100 CM3

The best inexpensive compressors (household)

Household air compressors are used for minor repairs, maintenance of cars or various pneumatic tools. Distinctive features of equipment “for the garden and garage” are low productivity, compact dimensions and light weight. They are rarely designed to connect serious devices, for example, anticorrosion devices. The maximum volume of the receiver of a household unit is up to 50 liters.

Important: According to experts, “home” equipment is suitable not only for private use, but also for rare work in industrial conditions.

Below are four of the best air compressor models that you can safely take for your personal needs. The quality of workmanship and reliability are guaranteed by the manufacturers and have been tested by craftsmen more than once. If you are wondering which one is better, pay attention to their characteristics and scope of use.

Denzel PC 50-260, 50 l, 1.8 kW

One of the best household compressors in terms of reliability was developed by Denzel. This is an example of high-quality equipment at a low cost. Thanks to good assembly, the equipment works stably in domestic conditions and can be used in small workshops. All structural parts are tightly joined, the oil sump is protected by a special gasket, which eliminates unwanted leaks. Additionally, the unit is equipped with an overheating protection function and a second, by the way, very accurate pressure gauge.

Advantages:

- reliable assembly;

- fast air injection;

- good technical parameters - pressure 10 bar and flow rate 260 l/min;

- rubber anti-vibration stops;

- The compressor is lightweight and small-sized for its class.

What to look for when choosing a compressor

To choose a 220 V air compressor, you need to take into account that, in addition to differences in price, the models differ from each other in a number of ways. These characteristics largely determine the efficiency and operating life of the compressor. It is therefore important that electrical equipment has:

- mobility and compactness, which will simplify its movement;

- light weight - so as not to waste extra effort on transportation and management;

- power - the higher this indicator, the longer uninterrupted operation will be ensured.

Technical characteristics of different compressors

Also, before choosing a 220 V electric air compressor, it is important to pay attention to the following characteristics:

- presence of a cooling system;

- belt drive, maintaining efficiency and increasing reliability;

- asynchronous motor, characterized by a simple and durable design;

- the presence of an automatic shutdown that prevents breakage and damage to parts;

- minimalism of additional structures that complicate the operation of the compressor;

- the volume of the receiver, large indicators of which indicate long-term operation without stopping.

The optimal choice for domestic needs is a 220 V electric piston air compressor.

The best air compressors combination of price and quality

The optimal combination of price and quality is affordable semi-professional class equipment. The equipment does not have the disadvantages inherent in household compressor models, has increased performance and higher build quality. The area of use is wider than that of “household” ones, in addition to blowing and servicing cars, they are suitable for painting cars, applying light plasters, and various types of tools. This type of equipment is more comfortable to operate, the compressors operate more stable and quieter, and there is no need for regular maintenance and “adjustment” of parts.

AURORA GALE-50

The best compressor in terms of power. The specifications indicate a figure of 412 l per minute. However, at the output it can drop to 288, which is the average parameter in this range. More buyers use the device, since it has the necessary characteristics that make it possible to successfully use it for painting a car in a service station. In addition, the product is noted for its reliability - it was purchased several years ago, and throughout this period it functioned without failures.

The device is equipped with an air filter to protect components from dust, the seams of the receiver, the casting of the cylinders and the engine are made of extremely high quality. Externally, the device looks quite bright - there are no gaps in the elements, no backlash. The design provides universal outputs like “rapid” to simultaneously connect 2 consumers. The product in question cannot be called light or compact, but it has a handle and 2 wheels, which will greatly facilitate transportation.

Pros:

- functioning without failures;

- possibility of transportation;

- presentable appearance;

- 2 outputs for equipment.

Minuses:

- significant mass.

ABAC MONTECARLO L25P

At the end of the last century, compressors from an Italian manufacturer made a splash on the domestic market - unlike Russian devices from Soviet times, they are quite light, compact and productive. Today the situation has changed, but the leading places in the ranking, as before, are occupied by the products of this company.

The compressor is designed to operate with variable pressure, which will fully satisfy a larger number of compressed air needs. The device is equipped with a 50-liter receiver, 1-phase electric motor, 2 pressure gauges, large wheels and a handle for transportation.

Manufacturers used the latest technologies in the design of the piston head: for optimal cooling, aluminum alloys were used, the cooling fins were enlarged, the piston was equipped with graphite-Teflon rings, which are characterized by low friction and increased wear resistance. Thanks to this, the service life of the device has significantly increased, in particular during cold starts.

Pros:

- well-designed piston head;

- high blood pressure.

Minuses:

- not installed.

QUATTRO ELEMENTI KM 50-380

For large-scale car painting, a compressor with higher performance is required; among the budget variations, this product can be distinguished. Its marking encodes the parameters: 50 l is the air collector, 380 l is the input capacity. The output power is less and is approximately 270 l/minute - enough to create good working pressure. At the same time, the performance of the electric motor and energy consumption are not very different from the power of other expensive compressors.

The developer increased the service life of the device by installing cast iron cylinders instead of similar ones made of aluminum. A drain valve is installed on the bottom of the receiver, which allows condensation to be eliminated in the shortest possible time; the receiver itself is coated with dye to prevent corrosion. The weight of the device is approximately 40 kg, for its transportation there is a handle and 2 wheels. According to the characteristics of buyers, it turns on infrequently, pumping is fast, and therefore long-term operation. Disadvantages include inconvenient oil changes and the short length of the power cord.

Pros:

- optimal ratio of power and energy consumption;

- 2-cylinder group;

- adequate cost;

- silent operation.

Minuses:

- high starting current;

- short wire.

Fubag DC 320/50 CM2.5, 50 l, 1.8 kW

Inexpensive but good compressor with increased productivity of 320 l/min. Suitable for connecting any pneumatic tool. Together with a 50-liter tank, the unit copes with even complex tasks: facade or finishing work, car repairs, as well as finishing metal structures. The compressor consistently supplies compressed air, and the enlarged oil sump provides high-quality lubrication. Fubag is reliable, equipped with overheating protection and a durable filter.

Advantages:

- low noise and ease of use;

- high performance with average power consumption;

- good protection of the mechanism from construction dust;

- anti-corrosion coating of the receiver.

Flaws:

- demanding of voltage;

- hard plastic casing.

Compressor units for business

Distinctive features of this equipment are large dimensions, complexity of design and high productivity. Only qualified personnel can service and repair such installations.

Reveza SB4 F-500 – from 89,990 rubles

A two-cylinder stationary model of an oil compressor with a belt drive from a 5.5-kilowatt electric motor.

A 2-cylinder block is used here, where air is compressed sequentially in each piston group, up to 15 bar. Thanks to this, the 500-liter receiver holds 7,500 liters of air, and the 5.5-kilowatt engine has time to cool well while consumers are dismantling the impressive supply. The compressor is equipped with a direct outlet - a valve through which all the pressure is supplied to the outlet line; and an adjustable gearbox - for distributing air at a given pressure.

The disadvantage is the lack of a non-stop work cycle.

Such installations have no other disadvantages - because stationary equipment is designed for universal use, and the necessary air preparation systems are calculated at the place of its installation. A good option for starting a tire or auto repair business. Technical characteristics of SB4 F-500

| Characteristic | Meaning |

| Type (number of working cylinders/compression stages) | Piston (2 / 2) |

| Receiver volume, l / maximum pressure, bar (capacity, l/min) | 500 / 15 (850) |

| Drive (unit / power, kW / rotation speed, rpm) | Belt (electric motor / 5.5 / 1195) |

| Weight, kg | 250 |

Video review of the REMEZA AB850 model:

ZIF-PV-12/0.7 – from 1,019,000 rubles

Screw compressor with direct drive from a diesel engine, on a chassis.

Reliable tractor diesel works better in such equipment than in any self-propelled equipment. There is pre-heating for stable starting from -25 0C. A full tank is enough for 6.5 hours of autonomous operation, subject to 100% load - 6.8 bar at a flow rate of 12 m3/min. There are no restrictions for use as an emergency source for stationary pneumatic networks of industrial enterprises.

Minsk diesel engines, which are installed on version 12/0.7, received a lot of negative feedback from those who operated them on Bychki, Zubryaty and Paziki. None of these ratings should be used as a guide when studying the capabilities of a compressor. If only because 2,200 rpm here is the normal operating mode, and cargo-passenger vehicles have a snail’s pace (with their gearbox, 3,000 rpm is optimal, but the D-245 engine is not able to withstand such loads for a long time).

The compressor meets the needs of construction groups of industrial organizations and structures from the housing and communal services sector, road construction.

Technical characteristics of ZIF-PV-12/0.7

| Characteristic | Meaning |

| Type | Screw |

| Maximum pressure, bar (capacity, m3/min) | 6.8 (12) |

| Drive (unit / power, hp / rotation speed, rpm) | Direct (diesel / 104 / 2,200) |

| Weight, kg | 1577 |

Video review of the specified compressor:

Powerful compressors

The more powerful the electric tool, the more kWh it generates during operation. The purchase of such a device must be justified from a financial and practical perspective, because it is not cheap. This section shows the best 2 devices with optimal price-quality ratio.

Denzel PC 3/100-504

pros

- 3 kW

- 3 compression levels

- 100 l receiver

- 3 year warranty

- 10 bar

Minuses

- without protective cover

From 26,500 ₽

The oil compressor is suitable for an equipped workshop, since its operating voltage is 380 V. Ventilation is also important, because the device does not have a dust cover. Now about the positives. The performance of this beast is amazing: 504 l/min, with 3 stages of compression and pressure adjustment. Protection systems in place.

Dimensions and design features

In addition to technical and operational indicators, it is important to take into account such characteristics as mobility and size. For example, if you plan to work with a spray gun to paint a fence, then you should turn to lightweight and ergonomic devices. Even if they provide a minimum level of performance, it is more likely to be sufficient for simple operations. Such models, in particular, include a coaxial compressor for pneumatic tools. The choice in this direction can also be oriented towards oil-free equipment, which does not have a receiver at all, but benefits from compactness. If you need a powerful and productive compressor with a massive body, then it is recommended to purchase models equipped with comfortable handles and wheels.