Which walk-behind tractor is better? How not to make a mistake in choosing this technique? Let's find out in this article.

Country life attracts many, in addition to clean air, with the opportunity to get a plot of land at their disposal for growing crops. However, high-quality cultivation of the land is always very difficult work associated with considerable physical effort. Using only “trusty assistants”: a shovel, a rake, a hoe, it is extremely difficult to achieve serious results, especially if the area is not the size of a “handkerchief”. Moreover, modern people have also learned to value time - not everyone likes to dedicate the entire daylight hours to working in the garden.

Which walk-behind tractor is better - choosing a reliable assistant for agricultural work

What to do? From time to time, driving real heavy agricultural machinery onto your plot for a fee can be economically unprofitable, and often completely impossible. But there is a way out - a walk-behind tractor will help in cultivating the land.

The emergence and widespread dissemination of such mechanisms, without much exaggeration, can be called a kind of revolution in individual agricultural activities. But in order for the technology not to let you down and to fully justify the money invested in it, it must be chosen correctly. Therefore, it makes sense to highlight the question - which is the best walk-behind tractor to purchase for specific operating conditions.

What is a walk-behind tractor? Types of equipment by drive type

First of all, what is meant by the term “motoblock”.

A walk-behind tractor is a self-propelled agricultural machine on a single-axle chassis, equipped with a mechanical drive that creates draft and working force. The walk-behind tractor is equipped with passive (working only from movement) or active (implying rotation of the working mechanism) type equipment of various functionality. The number of possible agricultural functions depends on the class of the walk-behind tractor and the degree of its equipment.

Prices for popular walk-behind tractors

In a word, it can, with some degree of convention, be considered a mini-tractor that allows you to carry out agricultural work in conditions where the use of large equipment is unprofitable, unproductive, or completely impossible.

A high-quality walk-behind tractor with a good set of mounted and trailed equipment greatly simplifies the performance of labor-intensive agricultural and even general economic work.

The working or draft force is created on the walk-behind tractor using the installed engine.

They are not particularly widespread, but walk-behind tractors with an electric motor are still available for sale. It would be more accurate to call them cultivators, since their functionality is small and is limited to surface tillage and weed control. However, for small areas located in close proximity to the house, they are quite suitable. Moreover, it is difficult for those involved in greenhouse farming to do without them. Using a walk-behind tractor with an internal combustion engine indoors, that is, with the exhaust of fuel combustion products, is still far from the most reasonable option.

The electric cultivator “DAEWOO DAT2500E” will be a good helper for work, for example, in a greenhouse.

Naturally, to work with such equipment it is necessary to provide a connection to the electrical network. The power cord trailing behind the unit presents a lot of inconvenience to the worker, especially since it is “adjacent” to sharp rotating cutters. This drawback is eliminated in models of electric cultivators equipped with a battery-powered motor.

Cordless electric cultivator "GreenWorks G40TL 27087" - high maneuverability, increased operating safety, but severely limited operating time on a single charge

No words - very convenient. However, the functionality is low, limited only to surface tillage in a very small area. And the operating time on a single charge is very limited - usually no more than an hour. That is, such units are still not worth considering as a serious agricultural machine.

Expert opinion: Afanasyev E.V.

Chief editor of the Stroyday.ru project. Engineer.

The most common and popular consumers are walk-behind tractors with gasoline engines.

Light equipment for this purpose is often equipped with two-stroke engines that require special fuel preparation (mixing in a certain proportion with motor oil).

Lightweight cultivator with compact two-stroke petrol engine

The advantages of two-stroke engines can be considered their compactness, simplicity of design, and unpretentiousness. But they are still not designed for long-term heavy loads. This predetermines the limited functions of walk-behind tractors with a similar drive.

Four-stroke engines are used in mid- and heavy-duty walk-behind tractors that allow the use of attachments that require power take-off. A more complex device, a separate lubrication system, a significantly higher price. But on the other hand, there is also the possibility of developing considerable efforts, completely different indicators in terms of permissible duration and variety of operations performed.

A walk-behind tractor with a four-stroke gasoline engine is usually a powerful multifunctional machine.

It is walk-behind tractors with a four-stroke gasoline engine that can be called the most popular among land owners.

The common advantages of all gasoline engines include unpretentious operation in all weather conditions, including at subzero air temperatures.

Expert opinion: Afanasyev E.V.

Chief editor of the Stroyday.ru project. Engineer.

The most powerful, and at the same time, demonstrating the highest efficiency indicators in operation, are walk-behind tractors with diesel engines installed on them.

Diesel walk-behind tractors – excellent performance indicators, high engine life. But this is against the backdrop of the complexity of service and the price is not affordable for everyone

This technique is distinguished by very impressive performance indicators. No other walk-behind tractor can compare with a diesel one in terms of fuel efficiency, that is, in terms of work done, calculated per unit of energy carrier.

The unique ability of diesel engines is the possibility of stable operation at low speeds with the development of high draft force, which is especially important when processing “heavy” soils. As a rule, such walk-behind tractors are monofunctional machines with a power take-off system and the ability to install a variety of equipment for various purposes.

The disadvantages of diesel drives are the difficulty of maintenance, which requires an exclusively qualified approach. A well-known problem with diesel engines is the difficulty of starting at low temperatures. But the main thing that limits their widespread use is their high cost. That is, the purchase of such a walk-behind tractor should be completely justified economically, and will make sense when constantly cultivating large plots of land. In fact, such units can already be classified as mini-tractors.

Types of walk-behind tractors by engine type

What kind of clutch is there?

The clutch configuration largely depends on what task the unit will perform. In the classification of walk-behind tractors, there are several types of clutch.

- Friction type clutch. The most common clutch among summer residents and gardeners. Very easy to maintain in field conditions. Spare parts can be found in any relevant store, and the service life and payload indicators that this clutch can withstand are much above average.

- Centrifugal clutch type. Judging by numerous user reviews, this type of clutch can slip in loose soil, resulting in fairly rapid wear of the surfaces with which it comes into contact. Not the most popular type of clutch.

- Hydraulics. As soon as you press the accelerator pedal, a piston in the hydraulic clutch begins to move, which leads to the movement of fluid through the central channel. The pressure that appears in the system causes the connecting rod to move. It returns to its original position using a spring system.

- Belt type clutch. The low popularity of this type of clutch is due to the fact that it wears out quite quickly. Belt breaks often occur when operating at high loads. The more powerful the engine installed on the model, the faster the belt clutch wears out.

- Disc type clutch. Disc clutch devices differ in the number of parts. There are single-disc and multi-disc clutch types. The principle of operation remains the same, the difference lies in the increased comfort and reliability of the device. The disc clutch is one of the most reliable; devices with such a device boast the softest control, as well as smooth and trouble-free starting of the power unit. The downside is expensive maintenance.

Differences may also depend on the ignition system installed on the power unit. Here clutches are divided into permanently closed type and non-permanently closed type.

Conditional classification of walk-behind tractors by purpose

The range of walk-behind tractors offered to consumers is very wide. Diversity can be seen in everything - dimensions, weight, power and type of engine, the availability of existing functions and the possibility of expanding them, cost, etc. And if the owners of a land plot have come to the idea of the need to purchase such equipment, then it is necessary to quite clearly outline the planned range of its “responsibilities” in advance.

There is a conditional division of walk-behind tractors into several classes, which determine the scope of their application.

The “bottom stage” is occupied by ultra-light walk-behind tractors. Although, of course, in terms of operational capabilities, it would be more correct to classify them only as motor cultivators, since the very concept of “block” implies the presence of wide functionality.

Ultra-light motor cultivator - light weight, narrow processing range, limited capabilities, but, nevertheless, quite noticeable help when processing small areas.

Such machines usually do not exceed 15-20 kg in weight and are equipped with two-stroke engines with a power of up to 3 horsepower. The usual “weapons” for them are cutters for shallow (no more than 80-100 mm) surface treatment of the soil - loosening, weeding. The cutters are installed coaxially with the wheels. However, many models of this class do not have wheel travel at all. As a rule, there is no speed switching, that is, they operate in the same mode.

The processing width of such cultivators is about 200-300 mm, which allows for good work between the beds.

Such units are quite compact, which allows you to even transport them on public transport, that is, take them with you to a suburban area as needed. Prices are in an affordable range, but the service life is not long. That is, it’s a good assistant for an amateur gardener, but you shouldn’t expect any miracles or real help from it, for example, with spring plowing.

Light motor cultivators weigh up to 40 kilograms, and the power of their gasoline drive can reach up to 4 horsepower.

Light motor cultivators - a wider range of processing, but still only superficial soil cultivation, albeit to a greater depth.

The functionality of such units is also not particularly outstanding. Nevertheless, the depth of soil processing can already reach up to 150 mm, and the width in one pass can be from 400 to 600 mm. On soft soils, this even allows for digging before spring planting of vegetable crops, effectively and without requiring much effort to fight weeds. That is, such a cultivator is already becoming a very effective assistant on a well-groomed plot of several hundred square meters.

Often units of this class already have wheels, which in some cases allows the use of trailed equipment. For example, it could be a hiller or a small plowshare for cutting furrows.

Light walk-behind tractors may already have several gears, although, as a rule, there is no reverse (reverse gear). This is compensated by the presence of a front handle, allowing the worker to move the cultivator back if necessary.

The motor life of the engines is short - usually within 300 hours. However, two-stroke gasoline engines are quite easy to repair by replacing the main parts. The gearbox can be considered a weaker point. For many models, it has a non-separable design with plain bearings, and cannot withstand heavy loads for a long time. In this regard, collapsible gearboxes perform better, which allow for regular maintenance - lubrication of rolling bearings, replacement of boots and seals. The durability of such units can be significantly longer - three to four times.

But it is still difficult to consider such equipment as a serious help for those who are either professionally engaged in agriculture or devote most of their free time to work on the plot.

Middle-class walk-behind tractors can already be considered as fully functional equipment capable of performing a variety of agricultural operations. The weight of such machines is up to 100 kg, and the drive power (most often gasoline, although diesel models are also found) reaches 6-7 horsepower.

Mid-class walk-behind tractors are fully functional units capable of long-term and productive work.

Thanks to their considerable weight and solid drive power, the cutters of such walk-behind tractors are capable of cultivating soil to a depth of 250-300 mm, capturing a strip of 800-900 mm in one go. Vibration during operation is no longer as sensitive as in light class machines. Naturally, their power transmission, the gearbox, is much more reliable.

Most often, such walk-behind tractors already have several speeds for moving forward and reverse. The presence of a powerful frame and pneumatic wheels with a characteristic tractor tread allows you to perform work on loose soil and use trailed passive equipment - a plow, hiller, potato digger, harrow, etc. Most models provide an additional geared power take-off mechanism (most often through a belt drive). This makes it possible to use some types of removable equipment that require torque to operate - for example, seeders, mowers, etc.

Such walk-behind tractors are quite suitable for those owners who are seriously engaged in agricultural work on quite decent plots of several tens of acres.

In terms of their functionality, heavy walk-behind tractors can already be seriously considered as professional equipment, a kind of mini-tractors capable of performing a large volume of work over a long period of time.

Without much exaggeration, heavy walk-behind tractors can already be classified as mini-tractors in terms of their functionality and expected motor life.

The mass of such units exceeds 100 kg, which is of decisive importance for agricultural machinery. Naturally, such weight characteristics require an appropriate drive. Thus, the power of internal combustion engines (diesel or four-stroke gasoline) is at least 8-10, and sometimes reaches 16 or more horsepower. The width of one pass during plowing or cultivation can exceed 1000 mm.

Additional trailed equipment allowing for full plowing of the site

The powerful frame of the walk-behind tractor is always equipped with a reliable tow hitch. This makes it possible to use heavy trailed mechanisms for deep cultivation of the land - plowshare or disk plows, harrows, potato diggers. The use of a special trolley allows you to turn the walk-behind tractor into a vehicle for transporting quite substantial loads.

Delivering seeds or fertilizers to the field, bringing out the harvested crop - no problem if the landowner has a heavy-duty walk-behind tractor at his disposal

High drive power is combined with the presence of several forward and reverse speeds. This allows you to choose the most economical and productive operating mode, depending on the condition of the soil and the operation being performed. The mandatory presence of a power take-off ensures the versatility of the walk-behind tractor, which can be used, in addition to purely agricultural functions, as a sweeper, motor pump, sprayer, snow blower with a moldboard bucket or rotary mechanism, garden shredder and even a wood splitter.

An example of the variety of attachments and trailed equipment for heavy walk-behind tractors

The only drawback of heavy walk-behind tractors is their high cost. The purchase will be justified if cultivation of the land is the main occupation of the owners and is carried out over a fairly large area - from a hectare or more. But in such areas it is simply unrealistic to achieve anything serious manually, so it is impossible to do without such equipment. In addition, such machines are widely used in public utilities.

Criteria for selecting a walk-behind tractor for individual use

When choosing a walk-behind tractor, the future owner must be able to evaluate his purchase based on certain criteria.

It is clear that first you need to decide on the class of the walk-behind tractor:

- If you intend to process a very small area right next to your house or dacha, about a few hundred square meters, then there is no point in purchasing an expensive, powerful unit. An ultra-light model with a processing width of up to 300 mm and a power of a couple of “horses” will be sufficient. This will allow you to easily maneuver between beds, carrying out surface cultivation or weeding. And spring or autumn digging of a small area can be done manually. Multiple speeds are not required.

- For plots of up to 20 acres, it would be more advisable to purchase a lightweight cultivator capable of cultivating a strip of up to 600 mm per pass, with a power of up to 3-3.5 horsepower.

- An area of up to 60 acres will require a walk-behind tractor with higher capabilities - about 4 hp. power and 800 mm processing strip. Such units are already characterized by the presence of several speeds when moving in the forward direction and reverse.

- To cultivate a plot of land up to a hectare, a middle-class walk-behind tractor with a power of up to 6-7 hp and a processing width of up to 900 mm is sufficient. Insufficient weight when working on loose soil or when deep plowing is necessary can be compensated by installing metal wheels with lugs or using special weights.

The plowing capabilities of a mid-class walk-behind tractor can be increased, if necessary, by installing metal wheels with lugs and special weights. - Finally, when professionally cultivating land on an area of more than a hectare, it will be difficult to do without a really heavy walk-behind tractor - a mini-tractor.

The engine displacement is, of course, directly related to its power and the force developed on the processing tools used. There are models on sale with a volume from 50 to 450 cm³. and the transmitted force increases with increasing volume. Thus, engines with 130 “cubes” can create a torque force of about 6 Nm, and if the engine has a volume of about 300 cm³, then this force increases to 20 Nm, which is a very significant value that allows processing of dense soils over a large area.

Engine starting system. in light-duty walk-behind tractors there are usually no options, that is, a manual starter with a pull cord. Medium and heavy-duty units often have an electric starter with a start button on the control handle. Convenient, of course, especially when frequent stops are required, and especially necessary for diesel engines.

The walk-behind tractor engine can be started using a manual or electric starter.

But the presence of an electric starter also requires the presence of a charged battery, and often also a generator for recharging. All this complicates the design and makes it more expensive. However, there are models with a manual starter, which optionally include the installation of an electric one, so you can take it, as they say, “for the future.”

An important selection parameter is the type of transmission, that is, the mechanism for transmitting torque from the engine to the working parts of the walk-behind tractor.

- On light class units, a gear-worm design is most often used. Essentially, these are two combined gearboxes, with the higher transmission of rotation from the engine being a gear, and the lower transmission to the cutters or wheels being a worm. The clutch system, as a rule, is made on the principle of a centrifugal clutch, which is activated when the engine speed increases, that is, in fact, it is not controlled by anything else.

- Mid-class walk-behind tractors are usually equipped with belt, gear or chain drives (combinations of these are possible). The circuit is quite reliable and productive, available for adjustment, maintenance and repair. The clutch system may be a belt drive with a pressure roller.

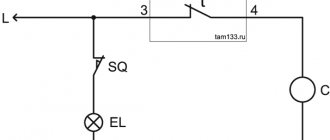

An example of a walk-behind tractor belt drive with a clutch system with pressure rollers - Finally, for heavy walk-behind tractors, either a chain or even a purely gear transmission system is used, which can withstand maximum torque forces. And the clutch system is often almost completely similar to a car’s - that is, with a release clutch and discs.

Powerful heavy walk-behind tractors are characterized by transmission systems of chain, gear or combined type.

In any case, the optimal choice would be a transmission that can be repaired. Non-separable gearboxes, which are installed on some models, are, alas, not very reliable, and can become a significant problem and an unnecessary loss of a lot of money.

If a walk-behind tractor is purchased with an eye toward using attached active equipment, then special attention should be paid to the power take-off system. Essentially, there are two main varieties.

- Power take-off is carried out through a special pulley, on which there is a free dedicated handle for installing a belt drive.

A walk-behind tractor with a potato digger installed, with a belt transmission of torque through a pulley - The power take-off system through the gearbox shaft is considered more advanced and safer to operate.

The transmission of torque to attachments is carried out through the power take-off shaft.

Naturally, all equipment must correspond to the transmission system. That is, to have either a “reciprocal” belt drive pulley, or a connection system with the shaft, directly or through a cardan.

By the way, the diameter of the shaft is also very important. Thus, models of both walk-behind tractors themselves and attachments with diameters of 25 and 30 mm are produced.

- The purchase of attachments is a separate “song”, and is carried out in accordance with the planned agrotechnical or general economic operations. But if you already have certain ideas in this regard, then when choosing a walk-behind tractor, you should immediately clarify whether it is possible to use the appropriate units with it.

- It is worth paying attention to the diameter and thickness of the wheel treads. This will be of particular importance if work is planned to be carried out on loose soil. The wider the wheels, the less the unit itself will “self-burrow” into the ground. It never hurts to have a pair of metal wheels with lugs in stock.

- You should evaluate the ease of working with the walk-behind tractor - the location of the controls (starter, accelerator, gear shift, etc.), accessibility to them during operation. It is very good if it is possible to adjust the control handles - in height (for precise adjustment to the height of the worker), and laterally, if the operations involve the operator moving to the left or right.

- It should be correctly understood that working with walk-behind tractors is not an easy walk across the field, and it still requires a certain physical readiness of the worker. For example, sometimes it takes a lot of effort to turn or turn a car, to “pull it out” if it suddenly begins to “sink” in the ground. This means that, if possible, you should choose models with several speeds in forward motion, and at least one in reverse. A very good addition for medium and heavy walk-behind tractors is the differential unlocking system. That is, when changing direction, it is possible to block the left or right wheel to facilitate a turn or turn.

- High-quality walk-behind tractors are equipped with “self-defense” systems, for example, emergency engine shutdown in case of insufficient oil level or overheating.

- Surely, a thoughtful buyer will be interested in the warranty for the chosen equipment, the availability or accessibility of spare parts, and the development of the service system in the region.

- An ambiguous question is what is better, domestic or imported models. Motoblocks from well-known Western manufacturers are famous for their good build quality and reliable mechanics. But they may become “capricious” about the quality of fuel. In addition, their price is significantly higher.

Domestic-made walk-behind tractors are less demanding when it comes to the quality of gasoline or diesel fuel and are more affordable. But the service life may already be lower, however, this is often paid off by the availability of components and the low complexity of repair and restoration work. Models under the brands “Neva” (St. Petersburg) and “Salut” (Moscow) are very popular. The Belarusian technology is completely trustworthy.

By the way, domestic walk-behind tractors with installed high-quality foreign engines, “Lifan”, “Hitachi”, “B&S” are in good demand.

Some foreign partners organized the production of walk-behind tractors in Russia, adapting the model range as much as possible to the specifics of our conditions. In particular, walk-behind tractors of the famous German brand “Sun Garden” are produced in Voronezh, and they work in Dzerzhinsk.

How to store a walk-behind tractor in winter

Walk-behind tractors and walk-behind cultivators: what's the difference?

Working on the ground requires considerable effort. Modern technology can significantly simplify this difficult work. For example, walk-behind tractors and walk-behind cultivators will make plowing, weeding, hilling and some other operations easier. The main difference between a motor cultivator and a walk-behind tractor is the power and the number of operations they can perform.

They are similar in purpose, but differ in power, number of operations performed, and depth of tillage.

Motor cultivators are small, lightweight devices with a capacity of 3-6 horsepower. The main purpose is to loosen the soil using a milling cutter. Other operations and work with other implements are possible, but not on all models and not with all soils.

Walk-behind tractors are more powerful devices - from 7 hp. - with a wide range of functions. They can cope with plowing (working with a plow), loosening (milling cutter), hilling, mowing grass, etc. As an additional function - the ability to transport goods or move a small trailer.