The devices responsible for ensuring that everything works smoothly are control elements represented by electronic units and sensors. One of the most important parts of any washing unit is the pressure switch.

If the water level sensor is faulty, the control module of the washing machine processes the signal incorrectly or does not receive it at all from this device. In such a situation, the water level in the tank is not controlled, and therefore underfilling or overflowing occurs. All signs of a malfunction of this sensor will be described below.

What is a pressure switch

When wondering what a water level sensor is, you need to understand that any process related to the supply of water to the washing unit must be strictly regulated by a given program. According to the principle of operation, the pressure switches of washing machines Lg, Samsung, Electrolux, Candy, Ariston or any other brands do not differ, but there may be differences in design, appearance and characteristics. This device looks like a small plastic piece, usually round in shape, with electrical wiring connected to it and a tube from the washing tub tank.

The pressure switch in a washing machine is a device that controls the water level in the tank, without which the operation of any unit is simply impossible. The element is small in size, and its replacement does not require major capital investments, but the importance of this part is enormous.

Hardware sensor test

Before repairing the pressure switch of a household washing machine, it is worth conducting a hardware check. Before you check the pressure switch in the washing machine yourself, you should purchase a multimeter and learn how to use it. Many owners of automatic washing devices are interested in how to check the pressure switch of a washing machine using a machine multimeter.

Below is an algorithm for working with Samsung, Ariston and Bosch models:

- Prepare a device for testing resistance;

- Place the multimeter probes on the contacts that correspond to the electrical circuit of the relay;

- Create pressure in the air tube until a certain contact of the controller is activated.

If the contact is triggered and the resistance value remains unchanged, this means that the sensor will have to be replaced. If the check shows that the machine is working properly, then you should check how the tube is attached to the relay and how tight it is. The elements located in the washing machine where the pressure switch is located must be treated with care. It is important to set the washing program.

Operating principle of the sensor

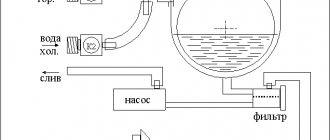

The operating principle of the water level switch of a washing machine is based on the effect of pressure on a special membrane (diaphragm). When water is drawn into the tank of the washing unit, water fills the compression chamber and pressure corresponding to the level of the collected water is injected into the sensor housing through a special tube.

The compression chamber is usually built into the drain pipe. The pipe itself is connected to the tank and the volute from the drain pump using special clamps. There are cameras soldered directly into the tank itself. It happens that these cameras become clogged with slurry and dirt over time!

When pressure is applied to the membrane, the contacts close and open, as a result of which a signal about incoming water is sent to the control module. There are several types of pressure switch: pneumatic (mechanical) or with an oscillating circuit (electronic), in this case the mechanical principle will be described. They are also divided into single-chamber and double-chamber.

Double-chamber pressure sensors are specially developed for washing machines with small and large loads. When the load is low, one membrane is activated and water is supplied in a minimum amount. When the drum is heavily loaded, the second membrane is activated, the contacts close and the control processor gives a command to supply the maximum amount of water.

As a rule, the membrane installed inside the sensor is made of rubber or elastic polymer and is designed for repeated on and off cycles. The operating principle of the pressure switch combines the sequential influence of air pressure on the mechanical part, above which the electrical contacts are located, and a direct electrical impulse on the control processor of the washing unit.

How does the sensor work?

A pressure switch is provided in any automatic machine. It is necessary to control the water level. The sensor sends a signal to the “brain” of the washing machine, notifying the controller about the degree of fullness of the tank. This information is used by the module to control the wash.

As the SMA tank fills, the pressure in the tube and air chamber of the pressure switch increases.

The sensor membrane is very sensitive. Under pressure, the rod rises and presses on the plate with the spring. When the water in the tank reaches the desired level, the circuit closes. The pressure switch notifies the module that there is enough water, and the controller starts the next “step” of the wash. At the draining stage, the pressure in the pressure switch tube decreases, the rod begins to descend along with the plate. The electrical circuit is broken.

Signs of a malfunctioning pressure switch

As with any element of a washing unit, malfunctions can occur in the water level sensor, leading to malfunctions of the entire washing unit. This is expressed in the following signs:

- the washing process begins in the absence of water;

- water is supplied to the tank in too much or too little quantity;

- after the wash is completed, water is not removed from the tank;

- the laundry spinning program is not processed;

- There is a periodic pumping out of dirty water and supply of clean water in the rinsing mode, which is not typical for normal operation;

- malfunctions of the washing machine in all washing programs.

In addition, due to the lack of water in the tank and the heating element being turned on, smoke and a burning smell may appear. Typically, such inclusion ends with the replacement of the heating element. A faulty sensor can also lead to failure of the electric motor due to constant overload on it, since more water is often drawn into the tank than the required level.

How to prevent pressure switch failure

Blockages in the pressure tube, damage to the surface of hoses and valves, overheating and burning of sensor contacts are the main types of failure of the pressure switch. The source of these problems is the dirt accumulating inside the machine.

Experts recommend regularly cleaning the drain and at least 2 times a year running a preventive washing mode using special cleaning agents: Calgon, Alfagon, Luxus Professional and others.

Also, to avoid machine breakdown, you should pay attention to the following points.

- Do not allow the washing machine to idle. Before starting the wash, the machine must fill the tank with water.

- The optimal temperature for washing is no higher than 45 degrees. This is enough for high-quality washing of clothes.

A pressure switch is necessary for the entire SMA system. When it fails, it deprives you of the ability to wash, and can lead to various breakdowns. Replacing the pressure switch in an automatic washing machine is a troublesome, but not complicated process. Pay attention to the behavior of your machine, and you will be able to notice a malfunction in time.

Where is the pressure switch located?

In washing machines from most manufacturers, the sensor is installed on a bracket in the upper part of the body on the side wall, however, in each specific case, you can find out where this device is located only by removing the top cover or side trim of the unit. Very rarely, on vertical types of machines, the pressure switch is located at the bottom of the unit.

A distinctive feature that makes it easy to find the sensor is a small-diameter tube connected to it, usually made of rubber or polyvinyl chloride.

Checking for serviceability

If you suspect that the water level sensor is not functioning, do not rush to immediately replace it with a new one. First, check whether the pressure switch is actually faulty. To do this, remove the part from the machine, previously disconnected from the network. Usually this sensor is located on the side wall of the device closer to its top. So your first action should be to detach the top cover.

After unscrewing the bolts that hold it in place, slide the cover away from you and remove it. The sensor is secured with 1-2 bolts, which you will have to unscrew. You also need to disconnect the contacts and hose from the pressure switch by unscrewing its clamp using pliers.

After this, we check the sensor using a hose about 10 centimeters long, the diameter of which should be the same as that of the tube removed from the pressure switch. Place one end of this hose on the inlet fitting, and blow on the other end, applying the pressure switch to your ear. You should hear several clicks (one to three depending on your washing machine) indicating that the sensor is working. If there is silence inside the pressure switch, it means it is not working.

You can also use a multimeter to check the conductivity. For a working pressure switch, it will change as the air pressure increases.

Related article: Which tile to choose for a small bathroom - design features

You can clearly see the process of checking the pressure switch for functionality in the following video.

Replacing the pressure switch

If checking the water level switch shows that it is faulty, then replacing it in most cases does not cause any particular difficulties. Therefore, you can change this device yourself, without resorting to the help of specialists. Repairing the device itself is not only impractical, but also useless, since the case is non-separable, any attempt to get to the internal parts will lead to a violation of its integrity. Some types of water pressure sensors must be opened, but this is a rather lengthy process and requires some competence in this area.

Replacing the pressure switch in a washing machine begins with disconnecting the vacuum tube and electrical contacts. By loosening or unscrewing the mounting bolts, remove the sensor. Reinstallation of the device is carried out in the reverse order of dismantling. Although the vast majority of sensors are similar in appearance, it must be taken into account that this element is configured for a specific model and brand of washing unit.

When carrying out all types of work, safety measures must be strictly observed. Before starting work, it is imperative to disconnect the plug of the washing unit from the power outlet.

Where can I buy?

You can buy the sensor in specialized stores selling household appliances and service centers.

You can order a water level switch online on websites that sell parts from washing machines and other household appliances. Pressostats are also available for sale on Ozone, Yandex.Market and other large marketplaces.

The cost of the device is from 500 rubles. depending on the manufacturer and quality of the product. The most budget options can be found on AliExpress (from 400 rubles). The average price for online stores is 700-800 rubles.

How to check the pressure switch yourself

The water level sensor in the washing machine tank can be checked for functionality at home. To do this, it must be dismantled. Carefully inspect the pressure switch housing and vacuum tube for mechanical damage (cracks, chips, abrasions). Carefully check the tube and inlet fitting for blockages, and if there are any, clean them with a plastic stick or soft wire.

The pressure switch can be checked for functionality by blowing air into its housing using a small hose identical in diameter to the standard one. To do this, attach the hose to the inlet fitting and blow lightly into it several times. In connection with the pressure force, characteristic clicks should be heard inside the housing. The number of clicks depends on how many water levels a particular model of washing unit provides. Their absence indicates a malfunction.

The second way to check the water level sensor is to measure it with a multimeter. This method allows you to be almost one hundred percent sure that the pressure switch is faulty. By connecting the device to the pressure switch, you need to measure the resistance. If the resistance does not change when air is blown into the device body, you can safely send the faulty element for scrap.

In order to avoid undesirable consequences for the entire washing unit as a whole, it is necessary to carefully monitor its operation, and if the slightest malfunction is detected, take the necessary measures. By replacing a relatively inexpensive pressure switch in advance, you can extend the life of the entire washing machine for a long time.

Before opening the pressure switch

After detecting a malfunction in the system, it is necessary to understand whether the pressure switch was really the cause. Carefully inspect the filling system, examine the hose and fitting of the water intake sensor, its transition chamber. The inspected elements should not contain:

- abrasions, tears;

- deposits from laundry detergents.

If you find dried detergent on the parts, be sure to rinse the components and try to start the machine again. Perhaps these measures will help restore the functionality of the pressure switch.

Next, you should check the stability of the connection of the power supply wiring to the sensor. Perhaps a wire has become frayed or bent. If a defect is found, fix it and check the washer for functionality.

And finally, it is necessary to inspect the contacts of the pressure switch; if they are dirty, they should be cleaned. Then start checking the water intake sensor. For diagnostics, you will need a tube with a diameter similar to the permanent sensor hose. One end of the tube will have to be put on the inlet fitting of the device, and lightly blow into the free second hole. When the sensor is working properly, it makes a clicking sound. If after such a check no problems were found, it is necessary to disassemble the pressure switch.

Setting the washing machine pressure switch

Along with the serviceability of all elements of the sensor, its precise adjustment is also of utmost importance. It must operate clearly at certain pressure levels, sending the necessary signals to the central control processor. The amount of water supplied to the tank depends on this, which is different at each stage of washing.

Accurate calibration of pressure switches is carried out at the manufacturer's factory using special ohmmeter devices, and under normal conditions no additional adjustment is required. Washing machine repair technicians not only do not recommend, but also categorically deny the possibility of adjusting the pressure sensor at home.

On the adjusting bolt of almost any pressure switch there is a seal, the integrity of which must not be violated. Even if you simply insert a screwdriver and turn the bolt half a turn, and then turn it the same half a turn in the opposite direction, the fine adjustment will be lost. In this case, no one can guarantee the normal operation of the washing unit.

Experiments with adjusting the water level sensor, as a rule, lead to failure of the heating element or the entire unit as a whole. If the cause of malfunctions in the washing machine is indeed the pressure switch, it is replaced entirely, and it is best if this operation is carried out by a service center technician, followed by high-quality diagnostics.

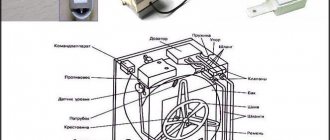

Operating principle and choice of relay for a washing machine

The pressure switch is made in the form of a round tablet. It is located under the top cover of the washing machine. A tube extends from the body of the part into the tank. The more water the machine takes in, the higher the pressure in the tube rises. As a result, one of the contacts closes and the module sends a signal to turn off the intake valve.

You can select the correct sensor based on the serial number or model of the SMA. The series numbers are indicated on the pressure switch itself, so it’s easier for you to dismantle it and go to the store. There, show the part to the consultant, and he will suggest a suitable replacement.

Signs of a pressure sensor failure are failures in the water filling and draining system:

- The liquid is collected until an overflow or leak occurs.

- The waste liquid does not leave the tank.

- The wash cycle runs normally, but does not go into rinse.

- The display shows a fault code.

- The cycle begins even though the water has not reached a certain level.

All these “quirks” are associated with incorrect operation of the pressure switch. To carry out additional diagnostics and replacement, the element must be dismantled.

How to replace a relay?

All you need is a screwdriver and a short tube. Unplug the machine by unplugging the plug from the socket. Close the water inlet valve. Unscrew the screws securing the top cover. Slide the panel back and remove it from the body.

You will see a pressure sensor on the side wall. How to remove the part:

- In some SM models, the pressure switch is bolted. In others - on latches. In the first case, unscrew the fixing screw. In the second, turn the part clockwise to release the latches.

- Disconnect the wiring connectors.

Disconnect the hose. Check it for blockages. Often it becomes clogged with debris that comes from the main line. Therefore, the relay may give incorrect readings.

Before replacing the level sensor, perform diagnostics. Connect a hose of the same diameter in place of the pressure tube. Blow lightly into it. When the contacts close, clicks should be heard. If you don't hear anything, it means the contacts are not working and the part is broken.

Another way to check for serviceability is with a multimeter. Set its toggle switch to resistance measurement mode. Connect the probes to the relay contacts. Blow into the tube and watch the readings on the screen. If nothing has changed, the sensor is faulty.

Prepare a new pressure switch. Reinstall it and secure the mounting bolts. Connect the wires. Put the hose in place and secure it with a clamp.

Without replacing the lid, run the wash cycle on a short cycle. Does water flow in and out normally? This means that the SM repair was carried out correctly.

During operation, it is recommended to clean the inlet hose and filter from debris and rust. Install cleaning filters to prevent small debris from the water supply from clogging tubes, hoses and other equipment parts. The video shows the stages of work:

https://youtube.com/watch?v=T4WqANQOZ9s

Bad 1

Interesting

Super

Principle of operation

A pressure switch, also known as a pressure or water level switch, is a small round element made of plastic. Several insulated wires and a tube or hose clamped with clamps are connected to it. There are several types of devices:

- mechanical;

- electronic;

- single-chamber;

- two-chamber.

A rubber membrane is built into the sealed housing, which moves under the influence of air pressure, closing or opening electrical contacts. The device has a return spring that returns the diaphragm to its original position. From the outside it looks like a click inside the washing machine body.

A rubber hose runs from the bottom fitting of the tank to the sensor. When you turn on the washing machine, water begins to fill the tank, which puts pressure on the air in the hose. When the pressure reaches a certain value, the membrane will compress the spring, the contacts will open, and the water supply will stop.

The pressure and volume of water are adjusted by a screw that acts on a spring (but not all models are adjustable). A mechanical pressure switch is designed and operates on this principle. An electronic relay has an inductor (choke) instead of contacts, which controls the operation of the device.