A washing machine, like any technical device, is a complex device, the “heart” of which is the power unit. It is this that ensures the rotation of the drum, converting electric current into mechanical movements. Any asynchronous type power unit has brushes in its structure, which often fail. Replacing the motor brushes of a washing machine is not such a complicated process; it can be done independently.

What are they needed for

So, as it became clear, brushes are required for normal operation of an electric motor. This is a small but necessary part, which ensures the transfer of electrical energy to the rotor winding of the power unit, due to which, in fact, it rotates.

Brushes wear out over time, so they need to be replaced from time to time. And if you delay this, the problem may turn out to be much worse and the power unit itself will have to be changed.

Purpose of brushes in a washing machine motor

The operation of an AC asynchronous motor is based on the rotation of a magnetic field, which drives the rotor of the device. It is the rotor that is connected through a belt drive (shaft and pulley) to the drum, ensuring its rotation. Most often, compact electric motors are used, with the ability to adjust the rotation speed.

Currently, most of all household devices are equipped with commutator motors, consisting of a stationary stator, a commutator rotor, a tachogenerator and at least a pair of graphite electric brushes, through which electricity is transmitted to the motor armature.

The commutator motor has a small size, good starting torque, is not tied to current frequency and is easy to control. All these qualities were the reason for their installation in washing units from almost all well-known global manufacturers. It is the presence of quickly wearing and noisy brushes for the electric motor that is noted as a disadvantage of commutator motors.

Types of parts

The main difference between all brushes is their pressing element, which can be:

- copper-graphite;

- carbon-graphite;

- electrographitized.

Washing machines often use carbon types, which are not so expensive, but quite reliable.

Motor brushes

The main purpose

Brushes are one of the main special parts in an automatic machine responsible for contact. During their operation, electric brushes transfer energy from an external circuit to the motor of the structure.

Thus, the drum rotates, and due to this the machine itself works.

All brushes for washing machines are equipped with steel springs and a copper contact, but there are also different elements, for example, a pressure part.

Electric motor brushes come in three types:

Carbon-graphite;- Copper-graphite;

- Electrographitized.

According to reviews and opinions of experts, it is recommended to buy special (original) parts from such manufacturers as:

- Bosch

- Whirlpool

- Zanussi

- Beko

Interchangeability

There are cases when electric brushes from one manufacturer can fit machines of completely different brands. Here's an example:

Universal brushes are cheaper than the original ones, but the price also affects the quality and characteristics - the brushes may not fit in size, may be of poor quality and wear out quickly.

Of course, it is better to buy original parts so as not to end up with more serious money in the future.

Based on surveys conducted among washing machine owners and service center employees, it was revealed that the main problems and breakdowns among washing machines are models from the manufacturers Indesit and Ariston.

33% of washing machines were sent for repair due to a large number of different types of problems.

When to replace

There are several signs by which you can definitely recognize brush wear:

- Unexpected cessation of operation of the electric power unit, for example stopping during washing. If this is not accompanied by a voltage surge or mechanical damage, then the reason is precisely the wear of the brushes.

- During washing, a crackling or other unknown noise appeared.

- Significant reduction in power of the electric power unit.

- The smell of burnt wiring and burning from the washing machine.

- An error code appears on the display.

These are just the most basic reasons for brush abrasion, but there may be others that only a specialist can recognize.

Replacing brushes will not present any difficulties even for those people who have never encountered this problem before, but the process must be approached as responsibly as possible.

What happens when brushes wear out?

If you use an automatic machine a couple of times a week, then the need to replace graphite tips will arise 7-8 years after purchasing the equipment. With active, almost daily use of the washing machine, electric brushes can wear out in 3-5 years. The “home assistant” will notify the owner that the rods have worn out and the motor is not operating at full capacity. Signs of wear on electric brushes may include the following:

- the washing machine freezes during the cycle, and the power cord of the machine is not pinched or damaged, there are no power outages;

- a hum and grinding noise is heard as the drum rotates;

- the machine does not spin clothes well (which is not surprising, because the engine speed decreases);

- the machine smells burnt;

- An error code is displayed on the display of the washing machine, indicating a malfunction of the electric motor.

You may only notice one of the signs of wear listed above. Sometimes they are observed in combination. In any case, you will have to check the condition of the electric brushes.

You can replace the brushes of the commutator motor yourself, without the help of a specialist.

To get to the electric brushes, you will have to partially disassemble the body of the automatic machine. To be more precise, remove the top cover and back panel. The work is classified as light, so there will be no problems with replacing tips.

Preliminary manipulations with the machine

First you need to disassemble the washing machine:

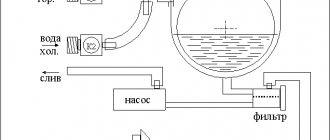

- Disconnect the device from the power supply and water supply/discharge system.

- Remove the rear protective cover.

- Remove the belt from the pulley.

- We disconnect the motor from the power supply.

- We remove the engine itself.

It is worth understanding that the disassembly process may be slightly different, based on the specific manufacturer and model of the machine.

What will you need?

To replace the motor carbon brushes you will need standard tools:

- flat and Phillips screwdrivers;

- 8 mm wrench;

- marker.

To replace, you must first find brushes that match your unit model. During the disassembly of the unit, if other faulty or worn parts are found, they will also need to be replaced with new ones.

To choose the right carbon brushes, it is recommended to initially remove the old ones and take them with you to the store to check the article number and size. Different models provide the following types of parts:

- in a plastic casing;

- dismountable components from three components;

- standard, including a spring and a graphite rod.

If during the inspection you determine that only one brush is worn out, in any case it is necessary to replace both to prevent distortions and displacements of the motor.

Replacement process

The entire replacement process will be shown using the Gorenye brand as an example, but it is actually suitable for other brands:

- The power unit is laid on its side and the mounting bolts are removed from the brushes, after which the latter are removed.

- On the other side of the engine, identical manipulations are performed.

- Brushes that have exhausted their working supply have a rod length of no more than 1.5 cm (if the brushes are longer, then the problem is not with them).

- The power unit manifold is being cleaned.

- New parts are mounted and secured with screws.

Attention! The brushes must be replaced in pairs.

Next, you need to put the engine in place and do all other manipulations in reverse order. Once everything is connected, be sure to check the quality of its operation. If it works a little better or even louder, most likely everything was done correctly. If there is an unpleasant or unusual sound, the problem is most likely not solved.

Attention! It is not recommended to overload the drum for the first 10 washes after replacement.

Do you need a lot of tools?

To change graphite rods, you will need a minimal set of tools. First of all, you need to purchase new components, focusing on the model and serial number of the washing machine. Even if only one brush is worn out, they must be replaced in pairs. In addition, the following will be useful for repairs:

- screwdrivers: Phillips and slotted;

- pencil or marker;

- TORX key (size – 8 mm).

You should prepare for repairs. Be sure to turn off the power to the washing equipment and turn off the tap on the pipe responsible for the water supply. After this, unhook the drain hose from the body.

The final stage of preparation is draining the remaining water from the system. To do this, cover the floor under the machine with rags, place a small container at the location of the garbage filter and unscrew it. All the liquid in the pipes will flow out of the hole into the basin. Next, all that remains is to move the machine away from the wall and begin replacing the brushes.

How to replace?

After the motor is removed from the washing machine body, access is opened for a detailed inspection of the brushes. These are two protruding plates located on the engine housing .

To disconnect them, first remove the fasteners holding the part (use a Phillips screwdriver), after which the wires are disconnected with pliers.

You can visually assess the wear of parts. If the plate protrudes from the housing by less than 1 cm, it must be replaced.

Depending on your existing experience in repair work, you can replace the brushes in the Indesit washing machine in two ways.

Fully

Algorithm of actions:

- Use a rag moistened with alcohol to wipe the engine, contact chips, and motor slats.

- Using sandpaper with the finest grain fraction (“zero”), wipe the collector (this is how graphite chips are removed from the surface).

- A new part is installed in place of the previously dismantled brush. To do this, a graphite tip is inserted into the socket. The spring is compressed and also inserted into the socket.

The contacts are connected last. To avoid mistakes, during the connection process you need to check with previously taken photos or videos.

How to replace brushes on an Indesit washing machine, video instructions:

Partially

To replace only the worn brush plates (the spring remains old), you need to disconnect the plates from the motor housing and bite off the springs with pliers . A new plate is soldered in place of the disconnected part.

It is important to observe the bevel angle at which the contact is connected to the capsule. Otherwise, there is a high risk of sparks occurring during engine operation.

Life time

The service life of these elements depends on the following factors:

- Correct use of the device,

- How often is washing done?

- Build quality,

- Machine drum load.

Washing machine motor brushes usually last quite a long time. Their service life is more than 5 years, and in some cases more than 10 years. It should be noted that replacement is performed infrequently. Much more often something more fundamental breaks down, which leads to the purchase of a new washing machine.

Despite the high wear and tear, they are worn out or broken during the operation of the machine very rarely.

Replacing a brush for a washing machine with your own hands

Brushes are a part that is considered consumable due to wear and tear, so it needs to be replaced in a timely manner. In a large number of washing machines of different models and brands, it is enough to remove only the back panel to replace the brushes, but there are also models that require complete disassembly.

There are also designs in which it is impossible to get close to the motor even after complete disassembly, so you need to take your machine to a service center, where they will disassemble the engine and replace the electric brushes. Prepare your tools in advance before disassembling the washing machine and installing new brushes.

Separating the motor from the drum

The main task is to disconnect the motor from the drum. You need to disconnect the machine from the network, disconnect the contacts and start working on the motor. First make sure that the problem is in the brushes; their wear can be easily detected.

Replacement is due to uneven wear of the rods. It may also be that the rods will wear out faster, so replacement will need to be done after a few weeks.

Distribute all your work in stages in advance, and write it down, or sketch it, or maybe take a picture. This will help you assemble your design correctly, without missing anything, and without mixing up the parts.

We photograph the sequence of work

Before replacing the brushes, first remember their location and in which direction the bevel is located. If they are installed incorrectly, the motor may spark.

You can remove the brushes using screwdrivers, then inspect the motor commutator.

If various types of defects are detected, such as scratches or just dust, they need to be eliminated.

Scratches can be removed with fine-grained sandpaper, and dust can be cleaned with a brush. After this, you can install new electric brushes (preferably original ones), attaching them with self-tapping screws.

If you recorded the progress of your work, then reassembling it will not be difficult for you. After installing the brushes, put the motor in place, securing it, install the electrical wires and cover it with the back panel.

Testing

Once you have installed the brushes and motor, you need to test them to ensure they are working properly and allow the new brushes to settle into place. You can test in the following ways:

- – turn on the machine in spin mode;

- – set and run the fastest washing program.

Check and change the brushes in the motor in a timely manner and do not forget that your checks should be regular. Lubricate parts and carry out structural maintenance.

If you follow these rules and use the washing machine according to the instructions, then your unit will serve you long and reliably. And if you don't do this, you will cause serious damage to your car, and it will be very difficult to fix them.

When to replace motor brushes

Dust particles getting between the carbon brushes and the formation of a spark, combined with the rotation of the engine rotor, leads to their natural wear. This is expressed in a simple change in shape in the form of erased contacts and linear dimensions of the element. As a result of wear, the operation of the electric motor, and as a consequence of the entire washing unit, is disrupted. You can determine brush wear by the following signs:

- noise and crackling noises are emitted from the motor installation location during operation, caused by direct contact of the pressure spring to the rotor commutator;

- insufficient power of the electric motor when the laundry remains wet even at high speeds during spinning;

- sudden stop of washing;

- the appearance of smoke, sparking and a specific burning smell;

- displaying an error code (typical engine malfunction).

In recent years, more and more models of washing machines are equipped with self-diagnosis systems, which allow, without interfering with operation or disassembly, to determine most of the reasons why certain working units fail.

The error codes that appear on the displays of washing machines are different for all manufacturers and are indicated in the technical documentation. For example, for German Bosch washing machines, the designation E or F21 means a problem with the motor, but not always with the brushes. No matter how “smart” the washing machine is, the actual condition of the brushes and commutator can only be determined visually, and this cannot be done without disassembling and removing the engine.