What can be done from an old pump?

A homemade water pump will replace manual labor - with a little tinkering, you will create an electromechanical device that will free you from the need to carry watering cans and buckets. However, it is not suitable for a large plot - the pump power is too small, but in a small garden it will be very useful. It is also suitable for supplying water to a fountain and for creating a backup water source so that your flowers are not left without watering if the main pump breaks down.

What pumps are suitable?

To water the area, it is better to use pumps from old Soviet machines - only they are capable of dispensing up to 30 liters of water per hour. The pumps of new machines are not even capable of such a volume.

How to make an irrigation system?

Before connecting the pump from the washing machine, you need to check the condition of the contacts on the relay and the electric pump. This is done with a multimeter, the probes of which are applied to the wires in turn. After this, the relay and pump wires are connected.

The further algorithm of actions is as follows:

- a container is being prepared from plastic material, from which a protective casing will be made in case of rainy weather;

- holes are made in it for the output of wires, a relay is placed inside;

- the pump from the washing machine is connected to the electrical network and checked for functionality;

- a tee is mounted at the outlet of the pump, on the reverse sides of which hoses are attached;

- all connections are fixed with clamps.

To ensure that the pump is secured comfortably, you can do the following. We take a plate of metal or duralumin and drill six holes. Using four of them, the pump will be installed, the remaining two are intended to fix the plate itself.

Now we take a steel strip 1.5 by 80 cm, the thickness of which is 6 mm. We drill a couple of holes in the pin for fastenings. We attach the pump to the plate, then screw it to the pin using bolts. The pin is stuck into the ground and performs not only the functions of support, but also grounding.

What do you need for homemade?

To build a mini-pumping “station”, you will need an arsenal of materials and tools. The pressure will be very modest, but it will be enough for flowers or washing a car. Before connecting the pumping device to the tank, you need to prepare the tools. Stock up:

- Wire cutters;

- Pliers;

- Screwdrivers;

- Soldering iron;

- Keys - sliding and open-end;

- Multimeter tester;

- With a knife.

You will also need a lot of parts and components:

- A short hose - pour water into the tank;

- Long hose - for supplying water to the beds;

- Plastic casing;

- 24 V relay - it can be removed from some old electrical appliance;

- Copper wires, with insulation;

- Cord for connecting to the network - you can use a cord from an old washing machine;

- Tee;

- Several clamps;

- Insulating tape;

- Water tank.

What can be made from a pump?

From an old or broken washing machine, you can take a valuable part that may well be useful in everyday life. This is a water pump, or pump. In most models it is installed at the bottom, under the drum. The direct purpose of the part is to pump liquid from the device into the sewer system.

Important! The pump is directly connected to an alternating network with parameters of 220 V and 50 Hz. Its power is 30 W.

The drain pump includes a solenoid coil and a sealed assembly with a motor core and impeller. One of the options for using a pump is making a submersible pump for watering plants in a summer cottage . The pump pressure is not enough to pump water out of a well or borehole. And in order to pump water out of a barrel or a larger tank installed on the ground, it is enough.

Step-by-step instructions - how to make a pump with your own hands?

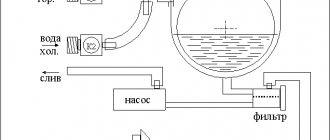

Before starting work, check the contacts of the electric pump and relay for compliance. This is done using a tester, one by one applying its probes to the wires. If everything is in order, the wires can be connected. Further procedure:

- We make a protective casing. Any plastic container, such as a jar, is suitable for this purpose. After making a hole in it to bring the wiring through it, place the relay inside the container. Here it will be safe - the plastic will protect the device from precipitation.

- We connect the pump to the power supply. Let's check its work.

- We install a tee at the pump outlet. We screw the hoses to it and secure the connections with metal clamps.

- Take a metal or duralumin plate. After drilling 6 holes in it for a 6 mm thread, secure the device. 4 holes - for attaching the pump, 2 - for attaching the plate.

- Make 2 holes in a 15x800 mm steel pin, 6 mm thick. Mount the pump on the plate, and connect it to the pin using two bolts. Stick the pin into the ground - now it is both a support and grounding.

- Check the work of the homemade product. Immerse the end of the short hose in a container filled with water. If you used a closed container instead of a barrel, make a hole in it for the hose. Seal the hole with sealant.

They also make a “house” for the pump itself - a plastic box is suitable for this purpose. Holes for the wires are made in advance. Using this homemade product, you can water your garden using a hose or organize convenient drip irrigation.

Please note that the old machine pump is not designed for long-term operation without interruptions. Don't leave it on for long. Such watering can be perceived as auxiliary. A mini-pump, created using spare parts from a washing machine, cannot cope with heavy loads.

Video:

Drain pump device

The drain pump for a washing machine has the following technical characteristics:

- power consumption - usually from 25 to 40 W;

- type of fastening to the volute - screw or fastening with latches;

- contact arrangement - paired or separate;

ATTENTION! When choosing a new pump, be sure to pay attention to the type and technical characteristics of the old pump, since the new one may not be suitable for some of the above parameters.

The pump in the washing machine differs not only in appearance, but also in the type of “snail” filter installed inside them. Very often the filter becomes clogged, and in this case the water is not completely drained from the chamber, then the dirty liquid stagnates and an unpleasant odor appears inside the drainage system. In this case, it is necessary to check the condition of the filter. You will need some tools, since the device cannot be removed with bare hands. The filter can be cleaned and the problem may be resolved.

The internal structure looks something like this:

The pump rotor is a permanent magnet in the form of a cylinder, which is located in a plastic casing. When the system starts up, the rotor first turns on, then the impeller, located on the shaft at an angle of 180 degrees, begins to move. The impeller relative to the armature should have a small stroke; this is necessary for normal engine starting, since there is a load due to water.

The rod, or otherwise the magnetic core, has two insulating windings that are connected to each other. The whole design is similar to an asynchronous motor, where there is also a moving and a stationary part. The moving part is a rotor in the form of a cylinder, and the stationary part is a magnetic core with windings.

This is how a simple washing machine pump works.

For example, if the impeller of the impeller falls off from the pump, this will inevitably lead to the need to replace the pump, since it cannot be repaired.

The washing machine's circular pump only allows liquid to flow in one direction.

For example, in the pump of a Samsung washing machine, a sealing collar is used to block the independent entry of liquid. This is necessary to prevent water from leaking into the bearing. Also, such mechanisms are equipped with a rotor shaft, which passes through a central collar bushing, which is crimped in the form of a spring ring.

Before the cuff is secured in the desired bushing, it must be lubricated with a special technical lubricant. The product is applied in a thick layer so that when starting work it gets into all the necessary gaps. This action has a positive effect on the operation of the mechanism and significantly increases its service life.

Design #13 – Shukhov wick pump

The Russian inventor Shukhov became famous for many buildings, including the radio tower in Moscow. Below we will discuss another of his inventions - a water pump.

Pulleys are made composite. The depth of the groove should be slightly less than the swollen rope

The pump uses a special rope to operate. This rope consists of woven cotton threads with a total thickness of 5-6 mm, enclosed in a sheath. The thread is passed through the pulleys.

When movement occurs, the rope gets wet and wraps around the pulleys. The pulley (5) with the help of a spring (4) presses the rope against the pulley (3) with force. The squeezed water flows into the tray (7). Figure “c” shows sections of pulleys (3) and (5), respectively.

To operate the entire system, an electric motor of only 5-10 watts is required. Typically, such engines have 1500 rpm.

To reduce speed and increase force, you can use a worm gear, shown in figure “c”. It is quite possible to make it by hand. To do this, you need to find a suitable gear and make a worm from wire. Small forces on the shaft allow manufacturing inaccuracies.

With your own hands you can assemble not only a pump that pumps water for domestic needs, but also a device that can be successfully used in landscaping a site. The following article will present successful options for homemade fountain pumps.

Design #5 – deep-well piston pump

The difference from a conventional piston pump is that the pump sleeve must be installed at the depth of the well. In this case, the length of the rod is more than 10 meters.

The sleeve of such a pump can serve as a wellbore, and the role of a spring can be played by a suspended load (+)

There are two ways to solve this problem:

- Make the rod from a lighter material, for example, aluminum pipe.

- Make a rod from a chain.

The second option requires some explanation. In this case, the rod is not rigid. The bottom of the liner is connected to the bottom of the piston by a return spring.

How to use an old pump in a garden fountain?

Many people dream of a small fountain in their dacha. You don't have to do anything particularly complicated. The main thing you need for a fountain is a pump and a water tank. A closed water supply system is also necessary - the liquid must circulate non-stop. If you have all of the above, you can get to work.

The most difficult thing is to organize water pumping. Requires a centrifugal motor. An old car engine is quite suitable for this purpose. It has a wheel with blades that spin the water in the tank - it will become a source of centrifugal force that will push the water up to the exit. Old machine motors consume 220 V, which is convenient for the average user. But you should remember safety measures - all contacts and the housing must be carefully insulated and protected from moisture.

A pump from a washing machine will not solve the problem of global watering of large country and garden areas, but for small areas it will do just fine. If you have an old washing machine lying around in your garage, you can make a lot of useful things out of it - from a concrete mixer to a garden fountain.

Design #6 – American or spiral type

The spiral pump uses the energy of the river flow. To operate, the minimum requirements must be met: depth - at least 30 cm, flow speed - at least 1.5 m/s.

Option 1

Necessary materials:

- flexible hose d.50mm;

- several clamps according to the diameter of the hose;

- intake – PVC pipe 150mm;

- wheel;

- pipe reducer.

The main difficulty in such a pump is the pipe reducer. This can be found in decommissioned sewer trucks or obtained from factory equipment.

For greater efficiency, an impeller is attached to the pump

The flexible hose is attached to the wheel in a spiral using clamps. An intake made of PVC pipe 150mm is connected to one end. The second end of the hose is put on the pipe reducer.

Water is taken in by the water intake and moves in a spiral, creating the necessary pressure in the system. The lifting height depends on the flow speed and the immersion depth of the intake.

Option 2

Necessary materials:

- flexible hose d.12mm (5);

- plastic barrel d.50cm, length 90cm (7);

- polystyrene foam (4);

- impeller (3);

- sleeve coupling (2);

We cut an intake hole in the bottom of the barrel. Inside the barrel, it is necessary to lay the hose tightly in a spiral and connect it to the sleeve coupling.

Inside the barrel, the hose is laid tightly, pressed against the walls with a strip. The barrel can be metal with foam floats

To impart buoyancy, foam floats must be glued inside the barrel. Finally, screw on the impeller.

For this design option, the drain hose must be 25 mm. in diameter.