Looking at an old washing machine, any housewife dreams of quickly replacing it with a new assistant. The home craftsman, on the contrary, is in no hurry to throw the machine into scrap. He thinks about where this “wealth” can be used.

Answering the question of what can be made from a washing machine, let’s carefully consider it from all sides.

We will see that the design contains many useful components and assemblies that can receive a new life in the hands of a good craftsman.

Judge for yourself: a body and an engine, pulleys and a drum, a window with a sealed door, relays and switches - this is a list of components from which you can make many useful things and mechanisms in the household.

Let's explore together the most popular homemade options from old washing machines, both conventional and automatic.

Grinder

The first thing you should pay attention to after inspecting a used home washing machine is the engine. It has enough power and speed to make a homemade sharpener. No complex modifications are required here.

For the shaft you need to make an adapter attachment on which the grinding wheel will be attached. If we provide an additional “neck” for the cutting wheel at the seat, then together with the sharpener we will get a cutting machine. They can cut not only plastic pipes, but also metal (reinforcement, sheet or corner).

As you can see in the photo, the washing machine motor is attached to the frame using four brackets. The switch for it was removed from the same washing machine. A regular piece of thick board was used as the base. The option turned out to be quite acceptable, especially considering its mobility and ease of manufacture (no welding required).

Here is another similar option for using a motor to install a grinding and cutting wheel. Having placed them on a common adapter, they are clamped with a nut with a left-hand thread.

Emery from a washing machine motor

An emery machine is useful for almost any household. It can be made in a simple way - to do this, it is enough to prepare the engine from an automatic washing machine in working condition. When you attach the whetstone to the engine, some difficulties may arise - the hole in the stone may not coincide with the diameter of the shaft of the electric motor. In this case, you need to take an additional part that will need to be specially turned. This adapter is easily made by any turner; you just need to tell him the diameter of the shaft. In addition to the adapter, you need to have a special bolt, nut, and washer. The thread on the nut must be cut depending on which direction the motor will rotate. So that the motor rotates clockwise , a left-handed thread must be cut; for counterclockwise rotation, the thread must be right-handed. If you do the opposite, then during operation the stone will constantly unwind and fly off. It may be that you have a nut, but the direction of the thread is inappropriate. Then we change the direction of rotation. In this case, we swap the winding wires. We connect the working winding to a 200 V network, connect the starting pair to the working coil. We apply the other end to the winding terminal for a short time. The commutator electric motor will begin to move in one direction. When the locations of the starting winding terminals change, the direction of movement of the motor will change to the opposite. The direction of rotation of the motor can be changed without using a capacitor. Here, after connecting the working winding to 220 V, we sharply turn the stone in the desired direction. After this, the motor starts and the machine starts working.

Simple crafts from an old washing machine

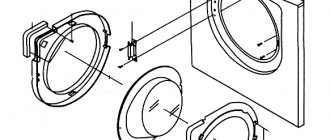

Not every person knows how to masterfully work with welding or a lathe. However, even in this case, you will be able to find a worthy use for the old washing machine. Look at the window that covers the drum. This is a masterpiece of engineering art and a godsend for design.

Without further ado, many use it for its intended purpose, but in an updated context. Cut out the washer door along with part of the body and you will get an excellent “marine” porthole. It will look original in any interior.

If you love your yard guard, then be sure to decorate his booth with this modern “facade”.

In addition to the original appearance, this option has practical significance: if necessary, the dog can be easily isolated from guests without fear for their legs and clothes.

Just don’t forget to make side ventilation holes in the booth (the window on the automatic washing machine is sealed!).

Furniture from spare parts

Those who do not need homemade equipment and utensils for cooking can be advised to use parts of a disassembled washing machine to make original furniture or storage areas. The body and drum are best suited for implementing design ideas. Read below to learn how you can refresh your interior using an old washing machine.

Coffee table

You can make an unusual high-tech coffee table from the drum of an old washing machine. Thanks to the characteristics of the source material, it will be very durable, but lightweight, and will serve you for many years.

We take the drum from an automatic washing machine as the basis of the table; To make the product look more impressive, we will add shine to it using a special cleaning agent. As a tabletop, take a piece of tempered glass of suitable diameter. We fix it on the drum using long fasteners. The table is ready!

A table can also be made using the body of a washing machine.

Drum poufs

Another interesting piece of furniture that can be made from the drum of a regular washing machine is a pouf that can simultaneously serve as a drawer for things. To make it we need: the drum itself, a thick foam pillow in a bright pillowcase, a sheet of chipboard, a construction stapler and a pair of furniture hinges.

We cut out a piece from a sheet of chipboard that will act as a hinged pouf lid. It can be either round or square, depending on the shape of the pillow. Then, using a stapler, we secure the pillow to the lid. Next, hang the lid on furniture hinges to the top of the drum. To make our ottoman look more aesthetically pleasing, you can paint it with acrylic paints.

Hatch door as a window

Another part of the washing machine that can be used in an unusual way is the hatch door. Many people use it as a window - but only in non-residential buildings. The fact is that the thick, durable glass of the hatch transmits light well, but it is difficult to see anything through it. Therefore, it is often placed in bathhouses, outdoor toilets, garages and even in doghouses. An additional plus is that such a window does not allow water to pass through and can be easily opened for ventilation.

Coffee table made from a washing machine

Your old automatic washing machine, or rather its drum, will help decorate the interior of your apartment. You can use it to make an original coffee table. Perforated stainless steel, complemented by colored lighting, looks great.

It is not difficult to make such an unusual piece of furniture in the high-tech style. You will need several steel rods that need to be attached to the washer drum. A round tabletop made of glass or MDF board is fixed on them.

Dismantling the machine

Many home craftsmen are trying to find new uses for outdated things. From individual parts of an old washing machine you can make a lot of useful things for your garden or home interior.

What kind of spare parts can be used:

- engine . If the engine is in working order, it can become the basis for various mechanisms for home use;

- drum . It is made of high quality stainless steel, since it bears the main load during washing. Since stainless steel is a very durable material, it can last for many years in any new form;

- housing and loading hatch . You can also make many useful things for your home from them;

- there will always be applications for heavy counterweights, powerful springs , and various small parts;

- an analog board can also be useful, since it contains many different elements necessary for repairing household electrical appliances.

Brazier

The body of the washing drum, made of durable and high-quality stainless steel, can withstand very high temperatures. Therefore, it can be used as a barbecue.

A few pipes, half an hour of welding and a convenient barbecue grill will appear on your estate. By making the supporting part of the structure collapsible, you can take it with you on country picnics.

Drums from front-loading machines, as well as from top-loading washing machines, are suitable for making barbecues. In this case, you will have to cut off one of the sides of the body with a grinder, and provide it with a stable support from below.

Where to put old washing equipment?

It often happens that it is easier to purchase a new washing machine than to repair an old one. Sometimes we want to update our household appliances, so we buy modern, improved products. Having installed a new device in the house, we have a question: what to do with the old one? It can be handed over for recycling, in which case you will have to pay additional funds for removal.

A car in working condition can be sent to a nursing home or donated to those in need. You can also apply to sell a used car and win a certain amount. Often, large shopping centers organize promotions where you can buy a new washing machine to replace the old one with an additional payment.

This is also a very convenient and practical option. However, in many cases, old equipment can find a second life on the farm. From the parts of the device, craftsmen make construction equipment, garden furniture and various devices for the garden, which simplify life. From a machine drum, for example, you can build an excellent outdoor shower or washbasin. It can also be used as a flowerpot. Housewives manage to use a container removed from an old barrel machine as a sterilizer or juicer. Also, using parts removed from the old apparatus, a potter's wheel is obtained, on which you can make a variety of clay crafts.

In general, a failed product can be disassembled into elements, which will subsequently become the basis for new useful devices used in the household. What parts can be used? This:

- Engine. Applies only if it remains operational.

- Drum. It is made of durable stainless metal and is quite a spacious container.

- Doors with impact-resistant glass. Used as an interior element. Provide reliable tight closure.

- Frame. It is also used to make many useful things for the home.

- Counterweights. They are usually made of cast iron. They can always be sold for scrap metal, but a more practical use is as a press for pickling cabbage.

- Wheels and legs. If necessary, they can be installed on a sofa and other pieces of furniture.

- Analog board. It contains many elements that are used to repair other household appliances.

- Other details. Springs, bearings, wires, and clamps are sure to come in handy in everyday life.

Mobile smokehouse

Why buy an expensive smoker for fish and meat when there is an old washing machine sitting idle on the farm? There are many options for using it in this capacity.

We will focus only on the mobile device. It can be made from a drum removed from a top-loading automatic washing machine.

To prevent smoke from escaping through the side perforated holes, they must be muffled with a thin steel sheet, wrapped and secured around the body. On top, as it should be in a real smokehouse, we make a hole for the chimney. We fix a smoking grate inside the drum (you can take it from an old gas stove).

Useful mechanisms

First of all, you can use spare parts from an old washing machine to make useful mechanisms for the household.

Grinding and cutting machine

Giving a second life to the electric motor of household appliances is quite simple - its power is quite enough to make a sharpening machine. There are no particular difficulties for the home craftsman: attach the motor housing to a strong wooden base (a piece of board will do), connect the start and stop button, make an adapter attachment on the shaft where the grinding or cutting wheel will be attached. You can see other homemade products made from a washing machine engine here.

Smokehouse

Many people dream of having their own smokehouse to surprise friends with smoked meats, but in a city apartment there is no place to install it. We offer a mobile analogue - it is made from the drum of a top-loading washing machine. We fix a thin sheet of steel in a circle so that the smoke does not escape through the perforations, and insert a special grate in the middle where fish and meat will be laid out for smoking.

A hole is made on top for the pipe, where the smoke will come out; under the grate we lay out wood blocks or chips from oak, alder, cherry or apple tree. The main task is not to overdo it, the volume of the smokehouse turned out to be small, so you don’t need to put a lot. It is better to find out the norm in advance using an empirical method, from smallest to largest. Experts in this field assure that five small bars or dry branches are quite enough.

Feather removal machine

For those who are engaged in breeding poultry for subsequent sale in city markets, this improvement will be to their liking. We mean assembling the feather removal machine on your own. It works in the same way as the factory analogue, only it looks less aesthetically pleasing, but is many times cheaper.

The operating principle is not particularly complicated:

- The fairly capacious tank is studded with special rubber pins (beaters) with a threaded connection at the end for a tight and reliable connection to the body.

- The bottom rotates at high speed and is also studded with rubber beaters.

- A poultry carcass scalded with boiling water is placed in the tank: chicken, goose, duck or broiler.

- When turned on, the bottom rotates, the beaters force the carcass to quickly move throughout the entire internal space, as a result of which the feathers fly off in different directions.

- In 2 minutes the carcass is cleaned, leaving only minor residues in the area of the inside of the wings, tail and paws.

Using the example of some farms, up to 30 carcasses can be plucked in this way in an hour.

Amateurs believe that mechanical plucking causes damage to carcasses, but in practice their presentation is 100% preserved.

The tank is positioned horizontally and water is supplied as shown in the photograph. An outlet is made at the bottom to remove water and feathers, so the bottom is slightly smaller than the diameter of the drum. The supply of water has a beneficial effect on the entire process of mechanical plucking.

The most expensive part is the purchase of pins made of durable rubber: the cost of one is at least 1.5 dollars, and you need at least 120 of them, but the costs will quickly pay off.

Concrete mixer

This is a rather complex device, which, in addition to mixing concrete, must ensure its unloading. Therefore, when planning to make a concrete mixer out of an old washing machine, first weigh your plumbing skills and knowledge.

The easiest way to turn a barrel washer into a device for mixing concrete is to replace the standard activator with two U-shaped blades. They can be made from a thick 4-5 mm steel strip. To do this, you need to cut it to size, then bend the two blades and rotate them 90 degrees relative to each other.

After this, they need to be welded to a shaft passed through the hole for the remote activator.

The drain hole, which is in every barrel washing machine, must be plugged. Next we proceed depending on how much concrete will need to be mixed. If we are talking about 1 bucket, then you can leave the old single-phase motor.

If you need to prepare a large volume of concrete, then in place of the old motor you will have to install a more powerful one (0.75-1.2 kW) with low speeds (1300-1500 per minute).

In addition, the “original” belt drive must be replaced with a gearbox that reduces the speed (from 1300 to 25-30) and increases the torque on the mixer blades.

Note that the best mixing quality is obtained when it is not the shaft with the activator that rotates, but the concrete mixer body itself with the blades fixedly fixed in it. However, to create such a design, a deeper and more complex modification of the washer is required.

Types of washing machine engines

Before you start inventing new designs, you should study what the components are - parts removed from old devices. The main mechanism of any washing machine is the engine; without it, operating an electrical appliance is unthinkable. The washing unit is equipped mainly with the following types of motors.

Asynchronous

There are two types of such devices. Two-phase motors are found in older car models. More modern copies are equipped with three-phase asynchronous motors. The design of motors of this type is simple; they reach speeds of up to 2800 rpm and operate almost silently. The motor removed from the old unit can be reused. It is enough just to lubricate the bearings.

Collector

Present in most equipment models. Its main feature is that it allows you to adjust the number of revolutions. However, compared to the previous model, it is noisier. The product operates on both AC and DC current and is compact in size. The disadvantages of this design include rapid abrasion of the brushes. However, if necessary, they can be easily replaced. It can also heat up and even spark.

A similar motor is present in almost all modern automatic machines. These are reliable, durable, practically unbreakable units. They can be used in devices subject to excessive loads. They are small in size and weight, so they are used for making small-sized homemade products. The products have high efficiency and are effective in operation. The design does not provide for the use of quickly wearing out or breaking parts. The rotation speed can be changed.

Having determined the type of motor, you can figure out where to reuse it. However, before that, let’s take care of disassembling the equipment. We carry out all manipulations extremely carefully, without undue haste. After a long period of work, there may be some deposits on the parts of the device, which must be carefully cleaned off.

Sterilizer for preservation

Another homemade product from an old barrel washing machine will be useful for the dacha and farmstead. This is a sterilizer in which you can install a dozen jars for heat treatment.

The only point that needs to be taken into account: such a device is suitable for sterilizing fruits and vegetables. To process meat, a higher temperature is needed (above + 100C).

The rework sequence looks like this:

- A plug is placed on the activator hole;

- A thick wire mesh for cans is mounted on the bottom;

- You need to place a support under the mesh;

- A hole is drilled in the housing for installation of a 2 kW electric boiler.

1. Activator plug; 2. Water level; 3. Washing machine tank; 4. Cover; 5. Drain hose; 6. Cans with preservation; 7. Wire mesh; 8. Electric boiler (heater) 2 kW; 9. Electrical cable.

DIY vibration table

Using the motor from a washing machine, we can make a vibrating table for paving slabs.

Equipment of this type is constructed in a fairly simple way. A homemade vibrating table is made in the form of a plate, which is the upper part of the device, attached to a metal base using a movable connection, with a motor with an eccentric from a washing machine. When the slab vibrates, air bubbles come out of the concrete that is poured into the molds on this slab and voids disappear. Thanks to this, the finished products are characterized by high strength and quality.

Juicer

There are two options here:

- Using an old machine with a centrifuge and a washing compartment;

- Remaking a conventional barrel washing machine.

Let’s say right away that the first option is better, since it allows, with minimal modifications, to implement two processes in one device: chopping fruit and squeezing it. To do this, you will need a washing machine in which the activator is located on the bottom, and not on the side wall. Replacing it with three homemade strip steel knives, we get a fruit slicer.

Knife installation diagram: 1. Knife, 2. Shaft; 3. Clamping nut; 4. Washer; 5. Tank bottom; 6. Bearing assembly with oil seal; 7. Activator pulley; 8. Locking screw.

Knife group design

The drain hole of the washing tank must be plugged.

There are few additional treatments for the second unit - the centrifuge. You need to install a stainless steel mesh in it (mesh size 1.5 mm, wire thickness 0.2 mm) so that it covers the side surface of the centrifuge.

After thoroughly rinsing the centrifuge, washing tank, hoses and pump with baking soda, you can make the first load.

The operating principle of this juicer is very simple. The fruits are washed and loaded in small portions (1/2 -1 bucket) into the washing tank (knives must be turned on). After 15-20 minutes of cutting, the engine is turned off and the crushed mass is transferred to a centrifuge (in portions of 3-4 liters). Turn on the centrifuge and squeeze out the juice.

Making a juicer from a barrel washing machine or automatic machine is much more difficult. In a barrel, a homemade centrifuge can become a “stumbling block”. Making it is half the battle; the main thing is to achieve perfectly accurate alignment. Without this, at high speeds it begins to vibrate strongly and it will be impossible to squeeze out the juice.

Here is a drawing of a working sample. The master had to work hard to reduce the runout of the centrifuge (the motor is suspended from the washing machine body on 6 springs). Of these, 3 balance the engine in a horizontal plane, and the other 3 push it upward. The body itself rests on an old car tire, which dampens vibration.

Feather removal machine

The body of an old washing machine is suitable for assembling a device that can be used to remove feathers from poultry carcasses. To make it, you need to install a steel disk 3 mm thick and with a diameter slightly smaller than the diameter of the tank at the bottom of the tank.

Holes are drilled in it and special rubber fingers are placed in them. They are the most expensive elements of the future design (1.5-2 dollars per piece). On average, you need 120-140 pieces. The diameter of the fingers depends on the type of bird being plucked. Please keep this in mind when you place your order.

All other components of the washing machine, including the motor, do not need to be changed. Holes are drilled in the side walls of the case for installing pen-removing (punch) fingers. To do this, you need to step back 15 cm from the bottom of the tank.

The distance between the holes for the fingers is chosen within 3-4 cm. The lower disk is mounted on the drive shaft.

There is no need to plug the drain hole here. It will be needed to drain water that drains from the carcasses. After scalding the bird in boiling water, it is placed in a tank and the engine is turned on. Rubber fingers remove the pen quickly and cleanly.