If the washing machine malfunctions when filling or draining water, the cause may be a broken pump. You can replace or repair a broken washing machine pump yourself. Let's look at the causes of the breakdown, questions about self-repair, and tips for keeping the machine in working condition.

The article is relevant for the following brands and models: Ardo / Ardo, Beko / Beko / Veko; Bosch Logixx, Maxx / Bosch Logixx, Max; Brandt / Brandt, Candy Grand, Holiday / Kandy Grand, Holiday; Daewoo / Daewoo, Electrolux EWS, EWT / Electrolux; Gorenje / Gorenje, Haier / Hayer, Hansa / Hansa, Hotpoint Ariston Aqualtis / Hotpoint Ariston Aqualtis; Indesit / Indesit, LG / LG/LV; Panasonic / Panasonic, Samsung Diamond / Samsung Diamond; Whirlpool / Whirlpool, Zanussi / Zanussi, Atlant, Vyatka, Fairy, Ocean and others, including automatic models (SMA), with vertical loading and direct drive.

Signs and causes of breakdowns

You can tell whether the pump is broken or not by these signs:

- the washing machine does not work according to the program set when washing began;

- The machine turns off completely when filling with water;

- when filling or draining water, humming or extraneous sounds appear - for example, something is buzzing;

- The water level in the drum is less than it should be.

Reasons for failure:

- lack of voltage on the pump due to engine malfunction;

- Damage to the seal (rubber or plastic) due to scale and dirt settling on the impeller;

- destruction of the impeller and the appearance of extraneous sounds during startup;

- constant operation of the pump due to incorrect connection or breakdown of the water level sensor;

- The filter is clogged, which makes it impossible to drain water.

Also read what to do if the machine does not drain water.

DIY washing machine pump repair

Under heavy loads, the pump is protected by fuses that are located on the winding of the part and are switched off. When the temperature normalizes, the contacts are restored.

First you need to disconnect the pump from the cochlea . In general, there are two types of fastening: simply with screws and without screws (you only need to turn the pump counterclockwise). At this stage, you can find out whether the impeller rotates on the shaft. Normally, it should spin with small delays, so-called jumps. This is due to the action of a magnet rotating in a coil. If it is difficult to turn and there is no debris, then you will have to completely disassemble the part and see if it is possible to repair the washing machine pump impeller.

The motor housing has a latch on both sides that needs to be unhooked with a screwdriver. This is if your car has a collapsible motor, but there are non-separable types. At first glance it is impossible to make out, but if you know some of the nuances, you can.

A construction hair dryer will help by heating the long part of the part, the so-called shank at a low temperature. After heating the shank, the crosspiece with the magnet is removed from the housing. Usually dirt accumulates on the magnet and in the place where it was pulled out. After cleaning, the magnet itself is removed. Next you will see the bearing, which is also cleaned and lubricated. After these procedures, the part is reassembled. There is a ring under the blades that should fit tightly into place. The seal may need to be replaced.

Bearing wear

Because of this, friction appears between the volute and the impeller, which causes problems and repairs of washing equipment pumps. The problem can be solved by replacing the bearings. In an emergency, when it is not possible to buy a new part, and washing cannot wait, only shortening the blade by no more than 2 mm will save you. This is done with a sharp knife.

After repair, the housing is installed in the coil and fixed. This concludes troubleshooting the pump on your own.

A little theory

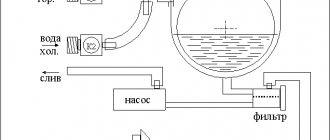

A washing machine drain pump or pump is a mechanism that pumps water and detergent out of the tank. A special electric motor starts the pump. It can have a power from 30 to 120 W and a frequency of up to 3000 rpm. The pump takes part in almost all washing modes - this ensures water circulation in the machine and better removal of dirt from things.

Principle of operation. Draining dirty water occurs like this: water enters through a rubber pipe, which is connected to the tank and volute using special clamps. The liquid enters the pump through a special filter located in the volute - it protects the pump impeller from foreign objects. The water then comes out through a drain hose connected to the volute.

About details

A pump is an internal pump in a washing machine that pumps waste water out of the tank. It works during the initial spinning of the laundry or when rinsing it. Pumping out water without a pump is impossible.

There are two types of pumps - drain and recirculation. The first one works only for draining. The second can operate in drain mode or be connected at the stage of rinsing clothes, passing water in a circle.

Usually the pump is an intermediate link between the drain channel and the snail in which the filter is located. It is located at the bottom of the machine. This simplifies its diagnosis and maintenance. The pump itself consists of a plastic casing, a motor and an external impeller, which pumps dirty water out of the washing machine.

DIY repair

How to remove the pump

To repair the pump yourself, you need to know where it is and how to get to it. In different washing machines it can be located behind the back wall, behind the front panel or at the bottom of the machine:

- for Zanussi and Electrolux the pump is located on the back of the machine, behind the rear panel;

- for AEG, Bosch, Siemens models - on the front side, behind the front panel;

- in Indesit, Samsung, Beko, Ardo, Whirpool, Candy, LG, Hotpoint Ariston machines - under the drum from the bottom of the machine (the bottom, which may be absent in some models or may be removable).

Let's consider the procedure depending on the location of the pump.

Under the centrifuge

- check the presence of water in the powder compartment;

- put the car on its side;

- if there is a bottom panel, unscrew the screws and remove it; if not, skip this step;

- loosen the pipe clamps and disconnect them from the pump body;

- disconnect all wiring;

- unscrew the fastening screws;

- get the pump;

- separate the panel that covers the drain filter.

Behind the front panel

- Unscrew the two screws from the back and slide the cover in the opposite direction from you;

- remove the top cover from the machine body;

- by pressing the latch in the center of the powder compartment, remove it;

- unscrew the screws behind the dispenser and on the opposite side;

- loosen the latches;

- remove the control panel;

- remove the bottom panel under the door;

- open the tank door and unscrew the two screws holding the door lock;

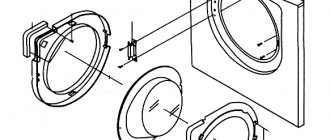

- remove the cuff clamp;

- Unscrew the screws around the perimeter of the panel and remove it from the body;

- loosen the pipe clamps and disconnect them from the body;

- disconnect all wiring;

- unscrew the fastening screws;

- get the pump.

Help: It is not necessary to completely disconnect the control module wires; it is enough to place the panel on the top of the machine body.

Behind the back panel

- disconnect the water supply hose to the machine from the body;

- Unscrew the screws from the back cover;

- loosen the ring that secures the pipe;

- Unscrew the screws that hold the pump, disconnect the power wires;

- remove the pump from the housing.

To start

IMPORTANT! Before starting self-repair, you must turn off the power to the washing appliance, turn off the water supply tap and drain all the water remaining in the machine.

For self-repair you will need:

- drain pump assembly;

- impeller;

- pulley;

- axis;

- contacts;

- pad;

- cuff;

- sensor.

Required tools for repair:

- wrench;

- screwdrivers;

- bucket for draining liquid

- multimeter (to check electrical functionality).

Removing the blockage

To remove the blockage, it is necessary to disassemble and clean the pump. Parsing order:

- remove the snail by unscrewing several screws;

- inspect the snail and pump with impeller;

- clean the impeller and volute from foreign objects;

- assemble the pump and install it in its original place.

To check, run the washing program, make sure that the machine does not make noise and pumps out water.

Repair parts

Remove the pump and inspect it for external damage. If they are not there, disassemble the part and check its insides. Most often, the impeller breaks: it flies off the axis. The pump turns on and makes sounds, but does not pump water. The impeller will have to be replaced. Next, inspect the rubber seals and moving parts of the pump, including the pulley. All spare parts must be replaced if there is the slightest sign of wear.

Features of some models

The Samsung, Elgie, Ardo, Indesit and Hotpoint Ariston machines do not have a panel that covers the bottom, so they have an easier way to access the pump.

In German brands - Bosch, Siemens, AEG - you can install universal Askoll type pumps or square ones with a latch. They are the most difficult to repair, since the bottom is closed and it is impossible to get to the bottom. You will need to remove the front wall.

Where is the pump located

Models of washing machines Candy, LG, Whirpool, Ariston, Beko, Samsung are equipped with a pump located at the bottom. To get to it, the washing machine is laid on its side and the bottom panel is removed. The snail with the filter is attached with screws that can be unscrewed and the required part is in your hands.

If we talk about Zanussi and Electrolux models, their pump is located behind the back cover, which will need to be removed.

The most difficult models to disassemble are Bosch, AEG, Siemens. They will have to dismantle the entire front panel.

Question answer

How to understand when it's time to repair

When you start the wash, the water does not drain, there is a cracking sound during draining, or the drain sometimes drains and sometimes not. It is possible that a foreign object has entered the pump or the rod (shaft) has worn out.

The pump makes a lot of noise when spinning

Most often, noise occurs due to blockage, broken parts, clogged drain pipe, water drain hose or drain filter.

Help: The pump is especially noisy between rinsing and spinning the laundry.

The pump is leaking

The pump may leak due to severe wear. Remove it, inspect it and replace it if holes or tears are found.

The reason for the slippage is wear of the seat. Repairing a part on your own does not give an effective result. Therefore, it is recommended to completely replace the old pump with a new one.

How to find out if the pump is broken?

If the machine starts to work incorrectly, the following signs may indicate a pump malfunction:

- The machine starts the draining program, as a result, the water is not drained, but remains in the tank;

- When water is drained, a characteristic sound is heard;

- Water is pumped out slowly, not completely;

- The machine turns off until the water is completely drained;

- The control module freezes;

- The pump motor hums, but the water does not drain.

If you notice one or more of the listed signs, then in most cases this is due to a pump failure. To make sure of this, you should also check the drain hose and filter. Debris can accumulate here, obstructing the flow of water.

Tips and tricks

To avoid damage, we recommend:

- Before washing, check pockets for items;

- wash clothes with small elements and decor in special mesh bags;

- use water filters and special powder for automatic machines;

- clean the drain system: clean and change the strainer located on the fill valve;

- use special products to prevent scale.

If you still have to buy a new one, we recommend taking the dismantled elements and going to the store with them.

Useful video

A couple of removal methods:

Do-it-yourself circulation pump repair - step-by-step instructions

DIY circulation pump repair

Circulation pumping devices are very popular among owners of private houses and summer residents. The range of pumping equipment is quite wide, but the general principles of the device are the same. Such equipment can stop due to minor breakdowns, for example: the pressure switch of the pumping station does not work, what should I do?

READ MORE: Ardo washing machine - operating instructions in Russian | RemBytTech

Mechanical check

For a mechanical check, remove the snail. In this case, the movement of the impeller and the wear of the bushings are checked. Let's turn the impeller manually. In a normal state, its rotation occurs intermittently, as if in jerks. This is due to the rotor made of a permanent magnet. Next: shake the impeller from side to side across the axis. If there is significant play, it is time to replace the drain pump. If all the signs are normal, the last check is to connect the motor directly to the network using a pre-prepared wire with two terminals and a plug. The motor should start without any extraneous noise.

Prevention and Maintenance

Long service life and trouble-free operation are possible only if proper operating conditions and regular maintenance of the pump are observed. Maintenance means periodic inspection and cleaning of the pump. Inspection for abnormalities in operation should be carried out at least once a quarter, that is, twice during the heating season. It is advisable to perform cleaning every two to three years, depending on the quality of the water and the conditions in which the pump operates.

During the entire period of operation, it is advisable to periodically check the operation of the pump:

- Connections are checked for leaks. If identified, gaskets and seals (tow, FUM tape, etc.) are replaced.

- The presence and condition of grounding is visually checked.

- The sound of a running engine should not be accompanied by clangs, knocks, or extraneous sounds.

- The engine should not vibrate much.

- The pressure in the line is checked and its compliance with the nominal one.

- The housing must be clean and dry. If this is not the case, then you should carry out external cleaning, check the electronic unit for flooding and eliminate the reason why the pump is wet.

Approximately every two to three years, it is advisable to clean the pump, including all its elements. This only applies to models that can be disassembled. There are pumps with a pressed or solid, welded casing that does not require repair or disassembly. Such units fail and are then replaced with a new assembly. It is advisable to entrust this work to a service center. However, if you have the skills and tools, you can do everything yourself

- hex wrench;

- slotted screwdriver (flat) 4 and 8 mm;

- Phillips screwdriver.

Before disassembling the pump, drain the water from the system or drain a separate area in which the pump is involved, dismantle it and then begin disassembly.

- Using a hex wrench or Phillips screwdriver, unscrew 4-6 bolts around the perimeter of the engine housing at the junction with the shell of the pump part.

- Remove the shell, leaving the impeller on the rotor shaft along with the engine.

- Locate four drainage holes around the perimeter. Using a narrow slotted screwdriver, pry the jacket of the engine compartment under the impeller little by little around the perimeter. As a result, the shaft with the rotor and impeller will come out of the grooves and stator shell. You can help yourself by unscrewing the protective plug on the outside of the pump, inserting a screwdriver into the slot at the end of the shaft and lightly knocking the shaft out of the support bearing.

The analysis is now complete. Now you should clean the surface of the rotor, impeller and the inner surface of the shell from plaque and scale, if any, without damaging the surface of the parts. It is not permissible to use a coarse abrasive. It is better to use a brush with hard polymer bristles. Cleaning products containing a weak solution of hydrochloric acid can help. As a last resort, the finest sandpaper is used - “zero”.

For wet rotor pumps, it is important to check the cleanliness of the channel inside the shaft and the drainage holes located in the protective jacket separating the area of the pump part and the motor. The fluid enters the rotor precisely through these holes and then returns through the internal channel; if they are clogged, engine cooling suffers.

For pumps with a dry rotor, waterproofing the support bearing is important. If a leak is detected from the pump block to the stator block, then all gaskets and seals inside the device should be completely replaced.

READ MORE: If you've lost your dishwasher manual: general usage tips | Dishwashers | Blog | DNS Club

The condition of the bearings on which the shaft rests is checked. If they are already quite broken, they will need to be replaced, which is extremely difficult to do at home; you will have to contact a service center.

All seals and gaskets inside the pump should be checked for wear and replaced with new ones if necessary. Once all elements have been cleaned and checked, reassembly is carried out in reverse order.

Circulation pump needs cleaning

Leakage at the pump housing or volute

If during diagnostics it turns out that the machine is leaking from below, then the pump is faulty. You need to get to the pump and start repairs. First of all, the drain pipe is inspected for damage, reliability of fixation and blockages. Sometimes it is enough to clean the hose, but more often a replacement is required. Next we proceed like this:

- disconnect the wiring connected to the pump;

- loosen the fasteners;

- take the pump out of the machine;

- We inspect the impeller.

Most pumps are dismountable: the cover can be removed by unscrewing the retaining bolts. Afterwards the snail is removed, and the device itself is checked for leaks. Be sure to test the pump with a multimeter in ohmmeter mode.

Impeller dismantling process

If you decide to remove the impeller from the pump with your own hands, we will help you with this. Let us present a detailed algorithm for dismantling a plastic part. So, after the drain pump is removed from the washer body, perform the following manipulations:

- cut off the plastic part located at the end of the impeller with a hacksaw;

- forcefully pull out the prefabricated base together with the impeller from the water pump;

- insert the removed structure into a vice and securely fix it in it;

- Take 2 flathead screwdrivers and, placing them on the bottom of the plastic screw, gently press upward on the impeller with upward movements.

At this stage, the main thing is not to overdo it and not to break the fastening of the drain pump impeller.

After lifting and pulling the impeller up, it should fly off the mount. When the plastic impeller is removed, you will see the shaft that powers it.

Now you need to remove the metal shaft from the overall structure. To do this, unscrew the vice from the tabletop, turn it over and reinstall it so that the compression bars are on the bottom. After this, the element to be disassembled is clamped in a vice in the area of the metal shaft.

Then you need to take a screwdriver, install its end into the upper hole of the shaft (it is important to choose a screwdriver of a size that matches the diameter of the hole) and carefully tap it from above with a hammer. The shaft should remain in the vice, and the structure remaining in the hands should be free to understand.

It is possible that the problem with the impeller was caused by abrasion of the rubber in the shaft area. Therefore, carefully inspect it and, if necessary, replace the rubber ring with a new one. The process of dismantling the impeller with your own hands is completed; you need to proceed to reassembling the element.

Installing the impeller in place

If you cannot quickly purchase a new drain pump, you can use a simpler, but at the same time not very reliable option - try to put the impeller in place using waterproof glue or sealant. If you fasten a plastic part in this way, you can correct the situation, but just for a few wash cycles. It will not be possible to operate the machine for a long time, since the impeller will soon fall off and the waste liquid drainage system will fail again.

So, if the impeller is broken, and there is no time to fully replace the pump, you can do the following:

- gain access to the impeller mounting point;

- thoroughly dry the shaft on which the plastic part “stands”;

- degrease the shaft with a special product;

- apply anaerobic sealant or moisture-resistant glue to the seat;

- “plant” the pump impeller on the shaft.

Please note that this method will not eliminate the problem, but will only help to temporarily cope with it. Try to replace the faulty drain pump with a new one as soon as possible. This way you can forget about the problem of draining water for many years.

[custom_ads_shortcode1]

How to choose a drain pump

For more information about the drain pump: where it is located in the washing machine, its operating principle and structure, you can read in this article: what is a water pump for a washing machine

When replacing a drain pump, you must choose a complete analogue in terms of design and technical parameters. All drainage devices differ both in power and performance, and in the method of fastening. You should only choose from proven and reputable manufacturers. Sometimes it happens that the connection of electrical wires to both the drain pump and the circulation pump may have a different location than those that have failed. This nuance usually does not matter and does not affect the installation of the element in its normal place. All replacement operations are carried out in the reverse order of dismantling, with mandatory quality checks of all fasteners and connections.