A sewing machine is the main tool of a needlewoman. You need to choose it very carefully, having decided on the necessary functions. The appearance should be aesthetic, and the functionality should fully make you feel like a professional. But not only the quality of the device itself affects the service life; proper operation of the device is also important. In order for a sewing machine to serve for a long time, it is necessary to properly maintain it: change parts, clean and lubricate, and adjust mechanisms. This article will tell you how to lubricate a sewing machine, why lubricant is needed at all, and what lubricants are used for this.

Why do you need lubrication?

A sewing machine is a complex device. When creating a stitch, many mechanisms work simultaneously. If you do not clean and lubricate important components on time, the mechanisms will become clogged and fail. This will entail breaking threads, creaking, knocking and general noise. In the worst case scenario, the machine will not work and you will have to replace it.

How to sew a pencil case

Lubricants are needed for:

- Extending service life and improving overall quality of work;

- Easier needle movement;

- Reducing noise during operation;

- Prevent thread breakage and fabric damage;

- Easy and quick adjustment of mechanisms.

Old manual typewriter

Important! Old machines are lubricated every 90 days, while new ones require inspection every 6 months. If the work intensity is low, you can lubricate moving parts once a year.

With constant use, it will immediately become noticeable when new oil is needed.

Old unit Podolsk

Machines with rotating rotary shuttle

These are old VERITAS cars, modern BERNINA, PFAFF cars (limited number of models), they are installed in some models of cars from Chinese companies. The rotating shuttle is the most durable and high-quality, allowing you to sew at high speed. Therefore, they are installed in almost all models of industrial machines. It is enough to keep this shuttle clean (brush) and drip about 3 drops of oil between its movable and stationary parts.

In all sewing machines, the needle bar block and its adjacent hinges should be cleaned and lubricated. To do this, remove the left cover (where the light bulb is located), clean out the dust and dirt with a brush, and apply oil to the needle bar rod and adjacent hinges.

It is very useful to clean the dust between the teeth of the fabric conveyor (rack). In my practice, there have been cases of motor breakdowns (expensive replacement) due to uncleaning of sewing equipment - the mechanisms jam, then the motor *burns out*.

What you need for work

To lubricate the machine correctly, you should prepare everything necessary for this. And you may need:

- Machine oil. You can buy it at any hardware store. Even 100 grams of oil will be enough for your head;

- Medical syringe. It is convenient for them to lubricate those parts of the machine that are difficult to get to without disassembling it;

- Brush. A small brush will do a great job of removing dust, dirt and old oil;

You might be interested in Ready-made patterns and the order of sewing warriors with your own hands

Cleaning kit

- Screwdriver. Some things still have to be unscrewed. On some machines you need to disassemble the body, and on some - certain parts and covers;

- Napkin or cloth. Remains of new and old oil and dust can be safely removed with a napkin;

- Film for surface protection. If the machine has not been cleaned for a long time, there may be a lot of dirt on it, which will end up on the tablecloth or carpet.

Important! This is exactly the set you need to perform high-quality professional cleaning conscientiously.

Sewing machine Veritas

Lubrication Features

The biggest mistake is the idea that sewing machine oil needs to be applied in large quantities. In this situation, more does not mean better. During use, an impressive layer of dust accumulates on the internal parts of the device, which gets there along with the fabric. Over time, this may cause problems with the advancement of the canvas. In addition, deposits of dirt on moving elements create a serious load on the device drive. An excessive amount of oil, applied by the generous hand of an ignorant owner, accumulates tiny pieces of matter, scraps of thread, and dust. Falling into lumps, this mass accumulates in one place, causing problems with the sewing machine.

Which oil to choose

Oil for such purposes has a special viscosity indicator. If it is too viscous and stringy, then the deep parts will not be lubricated properly, but they bear almost all the load. A composition that is too fluid will also not be useful, since it will not have time to penetrate deeper and will simply drain. This means that the lubricant for the sewing machine should be moderately viscous. Usually this parameter is directly indicated on the box and is recognized upon purchase. When working on a high-quality production machine, lubrication may not be necessary, since such units have an automatic lubrication system.

Regular medium viscosity oil

The best oil will be the one that came with it. If it is not there, you need to choose a better quality lubricant. You can find recommendations for choosing on the website of the manufacturer of this machine. Under no circumstances should you use vegetable oil: this can lead to serious damage and rapid contamination.

Toyota Power Fabriq

Which components need to be lubricated?

It is necessary to determine which operating units of the device need lubrication. This is usually indicated in the instructions for the machine. If it is lost, you can find an electronic version on the Internet on the same official website of the manufacturer. You can do it even simpler: lubricate all the components where there are moving parts. For cleaning and lubricating, you will need a table from which you must remove all valuables in advance so as not to stain them with oil and dirt.

Lubricating the top

Sewing machine care. Cleaning the Fabric Feeder

Before cleaning the machine, unplug it so as not to injure your hands with a needle from accidentally pressing the pedal. Using a screwdriver, remove the needle plate, presser foot and, just in case, the needle. By the way, it wouldn’t hurt to replace it in any case.

Run your fingernail along the tip of the needle; if the tip is bent, you will feel it. Remove all frays using a stiff brush, especially carefully clean the teeth of the rack.

Sequence of disassembling and lubricating the machine

Disassembly of the machine is necessary before lubrication. By looking at it, you can immediately identify elements that can be removed and unscrewed. The general operating procedure is as follows:

- Remove the cover from the needle bar by unscrewing the screw and pulling out the cover;

- Turn the device over and unscrew all the bolts at the bottom;

- Pull back the speed selector knob and remove it;

- Remove the cover from the side without touching the flywheel;

- Unscrew all remaining screws;

- Remove the handle fasteners;

- Lower the presser foot handle down;

- Separate the remains of the plastic housing;

- Remove the shuttle from the holder.

You might be interested in Sewing a mattress for a newborn stroller yourself

The device is disassembled

No further disassembly steps need to be taken. All elements can be reached with your hands or a syringe. The further procedure for lubricating the components is as follows:

- Place the machine in a position as if it were going to be used for sewing;

- Fill the syringe with lubricant;

- Slowly turn the flywheel counterclockwise;

- Drop oil onto all existing parts and their joints, which will begin translational and rotational movements;

Digging from above

- Under no circumstances should you touch plastic parts and gears that have already been lubricated with a special compound, this may damage them;

- Lubricate the needle bar parts at friction points;

- Remove excess grease with a napkin or rag;

- Check the progress of the nodes by connecting the power;

- Assemble the machine and give it a couple of hours so that the joints of the parts are saturated with oil;

- Run for a couple of minutes with the presser foot raised.

Digging from above

How to lubricate a Janome sewing machine

Janome are popular machines, so the question is relevant. As with any device, they require constant prevention of breakdowns and lubrication. You need to process at least the main components that set the device in motion.

Before work, it is important to read the cleaning and operating instructions and review all explanatory drawings. You need to remove the cover of the device and pour lubricant into the special holes, and also apply it to the rubbing elements.

Janome Sewist 780D

Brother machine lubrication

No less popular brand of cars. It has its own instructions, but if it is lost, it is important to remind you that a couple of drops of oil are enough for processing. They should only be applied to metal surfaces, avoiding smearing plastic.

Important! The brazer especially needs high-quality wiping of excess oil after processing, as well as idle operation to consume the mechanisms.

Removing the shuttle from the Brother

Singer

High-quality Singer machines require lubrication much less frequently, but still require maintenance. You need to start cleaning them from the needle plate. To do this, the screws are unscrewed and cleaning is performed. Next, the shuttle is cleaned: the cap is removed, and the latches are moved apart. The shuttle parts are removed and cleaned of dust. The same is done with the rotation device itself.

Astralux

To service Astralux you need:

- Remove the needle plate by turning the handwheel until the needle is in the highest position;

- Clean the lower fabric feeder. To do this, take out the bobbin cap and clean the conveyor with a brush;

- Clean the mechanisms and lubricate them. Remove the bobbin and cap and fold the two holders to the sides. When this is done, the shuttle will come out freely and the device can be lubricated;

- Reinstall the bobbin and cap by rotating the handwheel.

You might be interested in this Master class on sewing skirts from old jeans

Astralux needs roller lubrication

Vertical shuttle machines

They especially need lubrication, even imported ones. The steps are the same: remove the bobbin and move the clamps apart, take out the shuttle parts and wipe them thoroughly. Put everything back. In such machines it is important that the needle bar is in the upper position.

Machines with horizontal shuttle

Most of these machines have a lube-free shuttle, but this is a ploy to sell new equipment when the old one breaks due to improper use. Any moving mechanism needs lubrication.

Electric Brother Artwork with horizontal shuttle

Machines with rotating rotary shuttle

This type of shuttle is the most reliable and lasts the longest. Another advantage is its high sewing speed. This is due to its popularity in industrial machines. For long-lasting operation, you need to clean it and add three drops of oil.

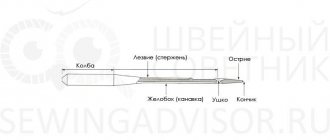

Bobbin case device. Cleaning the bobbin compartment

1-Bobbin case. 2-Hook fastening levers. 3-Central rod for fixing the bobbin case latch. 5-Shuttle. 6-Shuttle guide. 7-Protrusion of the shuttle.

The bobbin compartment becomes dirty with fabric frays and thread fragments, which sometimes penetrate the bobbin case and are pressed onto its walls, interfering with the free movement of the bobbin. You should inspect it before installing it back and, if necessary, clean the walls from fringes with a stiff brush. In addition, it is necessary to disassemble the shuttle itself, as shown in the diagram. Be sure to lubricate the shuttle movement grooves with a small amount of oil.

In general, try not to waste too much oil in the shuttle compartment. Oil can get in as the thread moves upward and stain your product, even after a long time. If your machine has a horizontal shuttle, the grooves do not need to be lubricated. The shuttle is made of plastic and does not require lubrication. But the swinging shuttles are completely metal, so a little lubrication will do the trick.

When installing the hook back, position it as shown in the figure so that the hook guide 6 forms a crescent moon on the left side of the sewing machine. Holding the shuttle 5 by the central rod 3, position it so that it forms a crescent on the right side. Protrusion 7 shown in the figure will be at the bottom. Place bobbin plate 4 on top. Return levers 3 to their original position until they click.

How often should you clean and lubricate?

If the sewing machine is new, then at first you need to lubricate it once every six months. When the device ages, lubrication is carried out every three months. This largely depends on the intensity of the work.

Hook lubrication

If a person uses a machine every day for several hours, it is necessary to constantly listen to it. If suddenly there are extraneous noises, knocking, creaking or rustling, this is a reason to disassemble it and clean it thoroughly, additionally applying a new portion of lubricants. This will prevent breakdowns and sudden failure of the sewing unit.

In addition to oil and a napkin, you will need a screwdriver

In conclusion, we can say that a sewing machine, no matter how high-quality it is, needs repair and maintenance. In order not to repair a broken component of an expensive product, you need to follow simple rules and periodically inspect the device, listen to the sound of its operation, and lubricate it in a timely manner.