Purpose and types of temperature sensors

The task of this element of the washing machine circuit is to control the temperature of the water in the tank. The sensor measures parameters in real time, transmits information to the control module, which in turn analyzes the data and, if necessary, gives the command to turn on the heating element.

Modern washing machines can be equipped with three types of sensors. Each of them has its own characteristics, advantages and disadvantages. These are: a bimetallic element, a gas-filled temperature sensor and an electronic thermistor sensor.

Bimetallic element

This is a purely mechanical device. The moving element of the sensor is a plate made of two metals, one of which has a significantly higher coefficient of thermal expansion. When the set temperature is reached, the plate bends and closes or opens the contacts.

Exactly the same element is used in irons, cheap convectors and other heating equipment with a temperature measurement function. The sensor is simple and fairly reliable, but has low accuracy and often fails due to oxidation of the contacts.

Gas-filled sensor

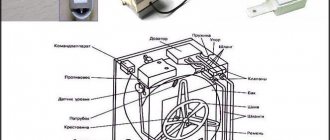

A temperature sensor of this type consists of a sensor itself with a sealed tube filled with gas, a temperature controller and a conductor that connects them. The sensor is installed in the tank; when the temperature changes, pressure arises, which acts on the membrane, closes and opens the contacts, turning the heating element on and off. Such temperature sensors are found in older Indesit washing machines.

This temperature sensor is distinguished by a fairly high accuracy of temperature measurement, but it is difficult to manufacture and prone to breakdowns. The slightest damage to the tube leads to a complete loss of functionality and the need to replace the sensor.

Thermistor

Unlike previous types, this is a completely electronic element. In modern washing machines, it has almost completely replaced mechanical parts. Found in almost all washing machines Samsung, Bosch and others. The temperature sensor is easy to change (it is installed directly next to the heating element). Structurally, it is a metal cylinder with a diameter of about 10 mm. There is a connection block for connecting to the wiring.

The operation of a temperature sensor is based on the effect of reducing its resistance when the ambient temperature changes. The absence of moving elements ensures a long service life, and electronic filling guarantees high accuracy of indicators.

Types of temperature sensors

Water temperature sensors (thermal sensors) are installed in all washing machines, but their operating principle and design differ.

Thermostat is a temperature sensor in washing units with electromechanical control.

Thermostats are:

- bimetallic,

- gas-filled.

Thermistor electronically washing units . Most modern washing machines have thermistors.

Both the thermostat and thermistor measure the temperature of the water in the washing machine. The water is heated by a heating element (tubular electric heater).

When the water has heated to a certain temperature, the thermistor transmits a signal to the electronic module. The module, in turn, sends a signal to the heating element relay to stop heating the water.

The thermostat itself turns off the heating element relay and water heating stops.

Thermistors are in many ways better , more reliable and durable than thermostats. If they do fail, another “plus” is discovered - this part can be replaced with a new one yourself.

Not every owner of a washing machine can repair or replace a bimetallic and gas-filled thermostat with a new one.

This is interesting: Why the sound on the TV does not work: what to do?

Symptoms of a faulty temperature sensor

Most automatic washing machines from renowned manufacturers, for example, Bosch, can themselves detect a malfunction of the temperature sensor. If it breaks down, a code is displayed on the display, which allows you to accurately identify the source of the malfunction. In addition, the following symptoms indicate sensor failure.

- When performing any program, the water temperature rises to almost boiling.

- Body parts get hot, and in some cases steam appears in the area of the loading hatch.

- The heating element does not turn on, the washing machine does not heat the water at all.

The appearance of an error code on the screen, as well as any of the signs of failure described above, is a reason to start repairs. You should not delay, since a violation of the temperature regime entails not only damaged laundry, but also damage to a number of parts of the washing machine.

Possible problems due to malfunction

Many people turn to specialists due to problems that arise during the operation of the washing machine. A malfunction of the temperature sensor will be indicated by:

- Washing clothes in boiled or cold water, regardless of the selected mode.

- Excessive heating of external panels.

- Washing process is too fast or spontaneous.

Temperature sensor (thermistor)

If you turn on a unit with a faulty sensor, this can lead to:

- damage to linen;

- rapid wear of the rubber bands on the device doors;

- excessive load on the control panel;

- failure of other components, which will completely stop the operation of the washing machine.

Partial disassembly of the washing machine

The temperature sensor measures the temperature of the water in the tank, therefore, it is attached to its body. To gain access to it, you will need to partially disassemble the washing machine. The easiest way to work is with new models in which the sensor is a thermistor; to check and replace it, just remove the back panel.

Before starting work, you must unplug the washing machine from the socket. Next, disconnect the inlet and outlet hoses. They need to be handled with care; there is probably some water left inside that could spill onto the floor.

The washing machine is moved away from the wall; it is better to place it in the middle of the room. The work is performed according to the following algorithm:

- Unscrew the screws holding the back wall;

- remove the panel, put it aside;

- loosen the screw holding the heating element;

- remove the temperature sensor.

This instruction is relevant in the case of a washing machine with a thermistor, these are new models Samsung, Ariston, Indesit and others. Finding and retrieving sensors in older washing machines has its own characteristics, which will be discussed below.

Where is the thermostat located and how does it work?

In most models of washing machines, the thermistor is located in the heating element and has a cylindrical shape with a circumference of 10 mm.

In some washing machines, the thermistor can be installed separately from the heater directly in the tank in a place provided by the design, and have the shape of a tablet with a diameter of 25-30 mm.

It directly contacts one part with the water in the tank to obtain an indication of the existing temperature of the liquid. Wires are connected to the second, outer part of the sensor, transmitting readings from the electronic component to the electronic unit.

Electronic temperature sensors transmit data to the control unit in the form of resistance readings, which change depending on the level of water heating. The processor converts sensor resistance readings into temperature parameters and controls the timely shutdown of the heater.

Older machines were equipped with gas thermostats. They were made in the form of a thin metal tube with gas, on one side of which there was a tip in contact with water, and on the other a temperature regulator.

The power supply to the heating element in such a sensor was turned off due to a change in pressure when the water was heated. These thermostats had a rather complex design and were subsequently replaced by their electronic counterparts, which had a simple design and the lowest cost.

Thermistor check

The electronic temperature sensor changes resistance when the ambient temperature changes, this is exactly what you should make sure of. You need a multimeter to work. You need to do the following:

- disconnect the wires from the sensor;

- remove it from the socket;

- switch the device to the resistor testing position;

- check the resistance with a multimeter (the normal value at room temperature will be about 6 kOhm);

- lower the thermistor into hot water;

- re-measure.

At approximately 50 degrees, the thermistor resistance should be below 1.5 kOhm. If the value is constant or if the device shows a “gap”, the sensor is changed. Installation is carried out in the reverse order, the back wall of the washing machine is attached last.

If a breakdown is not detected, the cause of the malfunction may be a burnt heating element.

Removing and checking the gas-filled temperature sensor

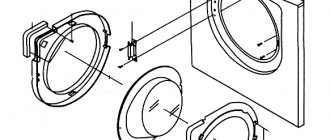

Owners of an older Indesit or LG washing machine may encounter another type of sensor, the working part of which is a tube filled with gas. To remove and check such a temperature sensor, you will first have to dismantle the front panel of the machine and disconnect the regulator.

Further, along the wires coming from the regulator, it is easy to detect the sensor itself. It is mounted on the drum, but the exact installation location depends on the manufacturer and model; before starting work, you should read the disassembly manual for your specific washing machine.

To check this temperature sensor, you also need a multimeter. It is transferred to the “ringing” mode. Set the temperature switch to 45-50 degrees. The sensor is immersed in hot water and the moment of contact activation is recorded.

The faulty temperature sensor is replaced. Sensors and kits that also include a regulator are sold separately. It is better to change the pair, this will guarantee a long service life of the washing machine and protect against unscheduled repairs.

Checking the bimetallic element

Sometimes you can encounter mechanical type temperature sensors; the procedure for checking them is similar to the procedure for working with gas-filled sensors, but the difficulty lies in finding and removing the element itself.

Exactly as in the previous case, the sensor is removed, tested for contact, and then immersed in hot water. By the way, a bimetallic temperature sensor can be checked without a multimeter. Due to its design, it clicks quite loudly when triggered, however, it is better to use the device; often the sensor does not trigger due to oxidation of the contacts, this cannot be determined by ear.

Despite the obvious complexity of a modern automatic washing machine, most of its breakdowns can be fixed independently. Replacing the temperature sensor is no exception. It is easy to check and replace if necessary. It is important only to buy original replacement sensors; an attempt to save money may become a reason for repeated repairs.