Microwave ovens are actively used in every home for cooking and heating food. However, the owners do not understand at all how exactly this equipment works. Therefore, when the device fails, repair difficulties arise. A magnetron for a microwave oven is a source of microwave waves, which, in fact, provide heating of food. Failure of this component is one of the most common types of microwave oven malfunctions. Now we will take a closer look at what a microwave magnetron consists of, how it works and methods for restoring this part.

Principle of operation and design of the magnetron

The word "magnetis" is literally translated from Greek as "magnet". The structure of a microwave oven magnetron looks like this:

- a copper part in the shape of a cylinder is an anode-resonator;

- the element inside which the filament is located - the cathode;

- The ring-shaped components located at the ends of the magnetron for a microwave oven are magnets.

The key principle of operation of a magnetron in a microwave oven is the inhibition of electron flows that intersect at an angle of 90 degrees. This process occurs in magnetic and electric fields. Ring magnets form a field. A special casing equipped with a flange acts as a conductor. It is with the help of this element that the part is attached to the waveguide.

Microwave waves appear as a result of the interaction of the electron flow formed by the emitted cathode and the magnetic field. A wire loop identifies these waves and then transmits them outward using a special antenna. This emitter is located inside a cylinder made of ceramic. Now you know what a magnetron is and how this component works.

As mentioned earlier, the antenna acts as a wave emitter - this is a small pipe, which is usually called a rod. The antenna also pumps air out of the lamp. A cap made of metal is securely fixed to this element. During operation, the magnetron in the microwave becomes unusually hot. The possibility of overheating is eliminated due to the special design.

The component in question is supplemented with a plate radiator. This element is constantly blown by a fan, which significantly reduces the temperature. Temperature fuses provide an additional level of protection against overheating. An integral component is also a high-frequency filter that prevents radiation penetration. This part is created using special capacitors and outputs.

Now you know how a magnetron works in a microwave. It is obvious that this is an electronic device with an unusually complex and multi-level design. Only an experienced craftsman can disassemble the part without damaging it. Therefore, after diagnosing the failure of a component, it is advisable to contact a service center to eliminate the possibility of aggravation of the malfunction.

However, the presence of special equipment and superficial knowledge of radio electronics allows you to repair a microwave oven yourself at home. There is only one condition - adhere to expert recommendations and act strictly in accordance with step-by-step instructions.

The plug has melted

This is what remains of the protection that protects the magnetron waveguide from drops of fat and water.

And this is on the back side of this plug.

I tried to clean it out and melt it back into its original shape, but I worked in vain. I decided to just throw it away. Instead, it is better to cut it out and put it.

Causes of magnetron malfunctions

Our service center offers its services for repairing household appliances at a competitive price. We repair any breakdowns of modern household appliances. Leave a request and get a 15% discount - Leave a request

Experts usually identify several main reasons for the failure of the magnetron of a microwave oven:

- Failure of the cap attached to the vacuum tube. Microwave oven owners can replace this component on their own. Find a similar cap on any other magnetron. The installation locations for this part have a standard configuration.

- The heater broke. The component may overheat and fail. This happens due to violation of the rules for operating equipment. For example, it is strictly forbidden to turn on an empty microwave oven. To check the functionality of the microwave, namely its filament, measure the resistance level between the capacitor elements. The serviceability of the component will be indicated by an indicator - from 5 to 7 Ohms.

- The feed-through capacitor is damaged. To diagnose this breakdown, use a tester. If it shows infinite contact resistance, then replace the capacitor immediately.

It is due to these reasons that the magnetron in the microwave stops working. Now let's take a closer look at how exactly this malfunction manifests itself.

Installing a new part

If you have an expensive microwave model, then it is wiser to replace the broken part rather than buy a new stove. Of course, it is best to contact a service center, but you can try to replace it yourself.

When buying a new magnetron, pay attention to the same power, contacts and mounting holes. Otherwise, you risk purchasing a useless part.

Connecting a new magnetron is not difficult, since it has only two main contacts. Detailed information about all symbols is on the diagram; the main thing is to check the compliance of the following parts of the device:

- The antenna must match the diameter of the factory one.

- Make sure that the new device is firmly attached to the waveguide.

- The length of the faulty antenna must match the new one.

It’s best to unscrew the old part and take it to the service center so that the specialists can select the one you need.

Possible faults

We list the main breakdowns:

- During operation, sparks appear, indicating that the cap has burned out. Replacing this component will not be difficult, since all caps have the same configuration.

- The high-voltage diode has broken down.

- No voltage is supplied to the magnetron.

- There is no contact in the fuse that controls the temperature and heating level.

- The filaments have burned out.

- The magnetron for the microwave oven has depressurized due to complex overheating.

- The high voltage capacitor is not working or the fuse is blown.

Check the microwave magnetron to determine the type of problem. Absolutely all of the listed breakdowns can be repaired independently at home, except for depressurization. Now you know how to test a high voltage diode in a microwave. We remind you that repairs should only be carried out by those people who have at least a superficial understanding of radio electronics.

Microwave design

Although the design of a microwave oven contains a lot of elements, most of them do not play a special functional role. To repair this device, you only need to know the basic elements of the circuit that ensure its operation. Among them:

- Magnetron.

- Transformer.

- High voltage fuse.

- Rectifier diode.

- Capacitor.

- Control block.

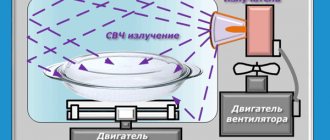

Arrangement of elements in the microwave

It is easy to distinguish them, because the external design is not very complicated. The magnetron is always installed in the middle, aimed at the food heating unit. The transformer is located under it, representing a massive box with a protruding coil. The capacitor, diode and fuse are located to the right of it, and the control unit is often located near the input panel.

When the device is turned on, a voltage of 220 V is supplied to the transformer. Passing through the primary and secondary windings, a current of 2 kV already flows at the output of the element. Next, the negative half-wave goes to the diode, and the positive half-wave charges the capacitor, which again leads to a doubling of the voltage. After which the generation of microwaves begins using a magnetron. The magnetron power is controlled by the control unit.

Therefore, in the event of a breakdown, it is worth paying attention to these elements. They bear the greatest load, so the problem often arises in them.

When disassembling the microwave, be sure to unplug it.

How to determine a breakdown

To determine the malfunction, turn off the power to the equipment by unplugging the power cable from the outlet. Start with a visual inspection of the inside of the microwave oven. How to check the magnetron and understand what is the source of the problem? Failure of this component is accompanied by the appearance of traces of combustion. This type of diagnostic will let you know if a fuse may have blown.

Before checking the magnetron in the microwave with a multimeter, be sure to do a visual inspection. After all, this is also an effective type of diagnosis.

However, it is impossible to identify hidden hardware faults without special equipment. Remember that you must first disconnect the component, and only then test its functionality. Be sure to follow the simple step-by-step instructions:

- Connect the multimeter probes to the terminals of the part. An infinite value on the tester screen indicates a component failure.

- Check the integrity of the printed circuit board, because many important elements are integrated into it: diodes, varistors and resistors. You don't have to solder all the parts, just test the board.

- Ring the fuse at room temperature. In such conditions, he must give an appropriate signal.

- Check the high voltage capacitor for possible breakdown. In working condition, it gives the multimeter an infinite value. If the part is broken, then almost zero resistance will appear on the screen.

- High voltage diode test. The main obstacle to diagnostics is the serial connection. Inspection is not possible and internal resistance is too high to measure. Therefore, make sure that there is no breakdown in this part using a megger.

Use these instructions and also monitor the appearance of characteristic symptoms in order to promptly detect equipment failure.

Disassembling a microwave oven yourself

If the above reasons are not confirmed, then you need to disassemble the device to troubleshoot. Before doing this, be sure to turn off the oven from the network and wait a couple of minutes.

Fuse

What should you look for when looking for breakdowns? There are several main elements that often fail:

- Circuit breakers.

- Capacitor.

- Diode.

- Transformer.

- Magnetron.

Microwave capacitor photo

These elements are directly involved in the operation of the device and were mentioned earlier. First you need to check the serviceability of the fuses. Their breakdown is immediately visible, because when burned, the conductor inside is destroyed. If this does not happen, then you should look further.

For further checking, you need to take a multimeter, because externally it is extremely difficult to find a breakdown on the remaining parts. To check the capacitor, you need to switch the device to ohmmeter mode and then connect it to the part. If there is no resistance, the part must be replaced.

High voltage diode

It is impossible to check a high-voltage diode with a tester. It is recommended to replace it if other parts break, because often it also gets hit. It can be checked using a slightly different method - by connecting it to the network on the way to the light bulb. If the light is dim or blinking, then the part is working properly. If it lights up brightly or does not turn on at all, then the diode must be replaced.

Read also: Installation and installation of electric meters

Next, the transformer is checked.

Photo of microwave transformer

It is important to follow safety precautions, because

Photo of microwave magnetron

This element is able to hold a charge for a long time. It will take several minutes to discharge a working transformer, and much longer if the discharge resistor breaks down. It is worth discharging it on the body or not touching it at all if you have no experience working with such equipment.

Next, the transformer windings are checked. You need to remove the terminals and check the device terminals one by one with an ohmmeter. First, the primary winding is checked, for which the norm varies from 2 to 4.5 Ohms. For the secondary winding, the limits are 140 and 350 Ohms. It is also worth checking the filament winding by connecting the terminals leading to the magnetron to a multimeter. The norm here varies from 3.5 to 8 ohms.

All previous tests have failed, then the problem may lie in the magnetron.

To test the magnetron, simply connect the tester to its power terminals. The tester switches to ohmmeter mode. If the resistance is 2-3 Ohms, then this means the device is broken. The same situation occurs if the tester shows infinity. In both cases, the device must be replaced.

The listed elements are the most common culprits of microwave oven failure. However, device failure is often associated with other problems, such as problems with the electronic control unit, timer and other electronic parts. Here simple checks with a multimeter will not help; the help of a qualified technician is required. Although it is much easier to simply replace the part if you are sure it is broken.

Magnetron repair

Some hardware components cannot be restored. If the magnetron burns out in the microwave, it will have to be replaced. This component cannot be repaired. The cost of original spare parts for a microwave oven is unusually high. Sometimes it is more profitable to buy new equipment. Therefore, it is extremely important to thoroughly check the magnetron with a tester by measuring the voltage.

Next, we’ll look at how to test a magnetron in a microwave using special measuring instruments. We will provide detailed step-by-step instructions. It is possible that only individual elements of the component are damaged, which makes it possible to carry out repairs without major capital investments.

Anyone who has at least a little knowledge of radio electronics and also has access to a regular tester and megger can handle hardware repairs. If you doubt your abilities, then it is better to seek help from a service center staffed by experienced professionals.

Control unit diagnostics

Microwave oven testing will vary depending on the design of the device. It is customary to distinguish several main types of control units:

- mechanical;

- electronic;

- sensory.

The magnetron for a microwave oven is checked with a multimeter. Diagnostics of the control unit is carried out in a similar way. Using this tool, make sure that voltage is supplied to the transformer. If you turn on the timer, having previously selected the operating mode, but there is no voltage, this indicates a failure of the control unit.

The easiest way to repair models is those equipped with a mechanical timer and manual operating mode controls. Start with a visual inspection, and then use a tester to measure the current level at the switch contacts. Such diagnostics allows you to determine: burnt contacts, failed parts, oxidized cables. Replace defective parts.

A microwave with an electronic control unit is more difficult to repair. Perform an initial inspection using the display. If a malfunction occurs, the display will show incorrect information. If the screen does not light up at all, then be sure to make sure that the built-in fuse is intact.

The good thing about the electronic control unit is that each user can start the automatic diagnostic process. Check the detected error code with the values indicated in the special table. This is enough to obtain the necessary information. No multimeter connection required.

The control unit is a radio-electronic module with a rather complex structure. To restore the functionality of this unit, special measuring instruments will be required. If you do not have access to them, contact an authorized service center in Moscow or any other city.

Checking the radio wave emission system

Incorrect operation of hardware components, including the control unit, as well as the magnetron for the microwave oven, indicates the need to check the condition of the elements of the microwave radiation system. It includes a high-voltage transformer as well as voltage shift circuit components. Modern furnaces are equipped with high-voltage MOT transformers. Their design includes three levels of winding:

- primary – 220 V;

- step down – 3 V;

- boost - 2 kV.

To determine a burnt element, you need to sequentially check each winding with a tester. The lowest level of resistance is precisely the step-down winding, which provides heat to the magnetron for the microwave oven. The highest resistance is the high-voltage winding. If a breakdown of the microwave oven is detected, and the user has determined that one or more layers of the winding are broken, replace the transformer.

In no case can we exclude an interturn short circuit, which is observed in the high-voltage winding. A sign of this malfunction will be a low temperature level. The noise may increase significantly during operation of the microwave oven. A conventional multimeter cannot measure the voltage at the output terminals of a given winding. Therefore, you will have to use professional measuring tools. If the fears are confirmed and a short circuit is detected, change the transformer.

Be sure to check all the parts that make up the voltage multiplier system. The magnetron for a microwave oven is a key element of this circuit, but it is far from the only one. It also includes capacitors and diodes. The internal resistance level of a high-voltage diode is very high, and its breakdown cannot be measured with a multimeter. Therefore, you will have to use the megger again. If the part is faulty, then install a new diode.

Be sure to check the capacitor for breakdown. A working component will show resistance close to zero. It will increase significantly in just a few seconds. The resistance of faulty capacitors does not change sharply, since there is no contact with the cover.

It is likely that the oven began to heat food noticeably weaker due to the appearance of a leak between the plates. You can also determine the source of the leak using a megger. Faulty radio elements should be replaced.

Magnetron replacement

If the user is sure that the microwave magnetron is broken, replace this element. This procedure is mainly carried out by qualified specialists. However, everything can be done with your own hands. The main thing is to understand a little about radio electronics, and also know how current voltage is measured.

The replacement procedure in a microwave oven requires that the user first purchases a new component. To make your choice successful, you need to follow a few simple recommendations:

- The power level of the magnetron for a microwave oven fully corresponds to that of a broken device. All necessary information is specified in the technical passport.

- The new part has identical mounting holes, and all contacts match.

- The dimensions of the broken component fully correspond to the dimensions of the new spare part.

Installing a new magnetron for a microwave oven is not difficult. However, the user must achieve the tightest possible fit of the component to the waveguide. Don't forget to check the capacitor.

How to check the magnetron of a microwave oven for serviceability

To correctly determine a microwave malfunction, you need to disassemble the device and conduct a thorough diagnosis. Some hardware components are extremely expensive, so to avoid unnecessary financial waste, pay close attention to the initial inspection. Everyone can figure out how to connect a magnetron to a microwave; repairing this part is much more difficult, since it is impossible. The only way out is to replace the component.

Diagnosis is carried out as follows:

- Turn off the power to the microwave oven by unplugging the power cable from the socket.

- Remove the protective casing of the device.

- Find the broken part, and then remove the terminals from the component's terminals.

- Use a multimeter to measure the voltage of the magnetron, namely its contacts. It should be insignificant. If the indicator is too high, then this indicates a burnt-out filament.

- Measure the voltage between the terminal and the device body.

This completes the check. Now you know how to act.

How to make a magnetron cap

I was given the task of quickly and cheaply repairing a magnetron and microwave oven . After reading the opinions of those experienced in this matter once again, I decided to rummage through the defective radio elements to find similar cap sizes. And I found one! Found an old swollen electrolytic. The diameter was correct by eye.

I carefully gutted the capacitor. To do this, I needed narrow-nose pliers, with which I pulled out the rubber plug and capacitor plates, folded in a spiral.

Next, it was necessary to trim the edges of such a cap with a file and drill a hole. Having tried a drill with a diameter of 3 mm on an old cap, I found it suitable for this undertaking. At low speeds, I drilled a hole in the center of the cap and went through it again with a fine file. Having given the cap a slightly oval shape, I pressed it tightly into the desired place. In the end it should look like .

Or you can just buy it.

Then we collect everything to the heap in reverse order. It is interesting that a hole appeared on the inner wall of the microwave oven just opposite the location of the emitter . There was a lot of soot around this hole.

As we know, carbon deposits in the form of fine coal dust - a product of combustion of any substance (in this case, paint) conduct electricity quite well, so we clean off such carbon deposits in all places with sandpaper .

The good news is, of course, you need to paint the area where the paint is peeling off and install protective plastic or a mica plate. But a different decision was made. A friend finally bought a microwave cover without installing a mica plate. Thus, the result was a cheap and cheerful repair of the magnetron of the LG microwave oven Daewoo .

Connection diagram for a magnetron in a microwave oven

In a microwave oven, the magnetron is connected to the output windings of the transformer. It is on its secondary coils that the following are transformed:

- 4V to power the cathode heating circuit;

- 2000V, which is supplied to a voltage multiplier assembled on capacitor C1 and diode VD1.

The heating circuit is a thick wire that is designed for a constant load of 10A. The high-voltage coil and its wires are characterized by high insulating properties.

The transformer, in turn, is connected to the household power supply network.

This is interesting:

What to do if the microwave oven stops turning on

Disassembling a microwave oven - how to do it correctly

Why does the microwave spin but not heat?

Some tips for replacement

If it becomes clear that the cause of the breakdown is precisely the magnetron or its individual parts, which cannot be replaced, then the magnetron can be replaced. It is not necessary to take a part from the same manufacturer as a new one. It is enough to make sure that the new and old parts are the same size, and that the connection points are located similarly. The magnetron is connected using two contacts.

Before installation, check 3 points:

- The length of the replacement unit is similar to the length of the old one.

- Both mechanisms have antennas of the same diameter.

- After connection, the magnetron is tightly adjacent to the waveguide; if this is not the case, the radiation will be uneven and some of the power will be lost, in other words, the microwave will not work properly.

Purpose and device

Heating and cooking food in the microwave is carried out due to the radiation emitted by the magnetron.

Reference . A magnetron is an electron tube that uses a magnetic field and electrons to generate microwaves.

The speed of cooking depends on the power that a given lamp can produce. The higher its power, the higher the speed will increase. In other words, the magnetron is the main element, the serviceability of which ensures the functionality of the entire microwave oven .

How the device works

The following components are distinguished in the design of an important microwave part.

- Antenna for emitting microwaves.

- Cylinder for antenna insulation.

- Magnetic core that distributes the magnetic field.

- Magnets for flux distribution.

- Radiator that protects the element from overheating.

- Filter.

Like any part, a magnetron may periodically fail due to frequent use. We’ll talk about the main factors for stopping work and popular verification methods below.

Possible transformer malfunctions and their symptoms

Checking the microwave transformer should be done when this household appliance is not functioning well, or when it is not functioning at all. Signs of a malfunction of the transforming device are:

- a fairly strong hum (noise) begins to emanate from the equipment after switching on;

- dishes placed on the platform are not heated at all or only slightly heated;

- During operation there is a smell of burnt insulation.

If such signs appear, it is better not to use the device until it is repaired. In the latter case, it must be disconnected from the network immediately to avoid even greater damage.

It must be remembered that breakdowns with electrical appliances occur during power surges. If this happened, then if the slightest hint of a malfunction appears, repairs should be started, during which a manufacturing defect may also be discovered.

The above manifestations in most cases are caused by a number of reasons:

- a break in the wire of the primary or secondary (boost) windings, in both at the same time (a rare case);

- a short circuit between the turns in one of them, or in two at once;

- a break or short circuit in the winding of the magnetron filament circuit.

Signs of a microwave oven breakdown

Most often, external signs of a microwave oven malfunctioning are the appearance of sparks, puffs of smoke, the plate stopping from rotating, and the lack of heating of food placed in the oven. Or the microwave simply won’t turn on. In this case, it is dangerous to plug it into the network! There are three main reasons for electrical appliance failure:

- Fuses blown;

- Magnetron malfunction;

- Burnout of the mica plate.

In case of this type of breakdown, you can repair the stove if you follow the instructions strictly. First, consider the functional diagram of a microwave oven. We take the functional diagram because It makes it easier to understand the operating principle of a microwave oven, it is universal, regardless of the brand of the oven, it is simpler compared to the circuit diagram of a microwave oven.

And the location of the microwave elements can be seen in this figure: