An electric stove is present in every modern kitchen - it is the heart of this room. Despite the reliability of modern solutions, sometimes electric stove breakdowns occur. Some of them are quite simple and can be repaired yourself. In the article below we will look at the main malfunctions of electric stoves and how to eliminate them.

Design and main components of an electric stove

The electric stove looks very impressive - it is a complex household appliance, but its design is quite simple, and all the main working elements are located in a special heat-resistant case, which is made of stainless steel.

The operating principle is similar to all electrical household appliances: current passing through heating elements (heating elements) heats them to a given temperature. The stove has several burners on the hob, and their number varies: a minimum of two, and the standard is 4 pieces.

The structure of the burners is quite diverse. The classics are burners on an enamel hob with heating elements inside, modern ones are solid ceramic surfaces with various types of heaters built into them. Let's look at the main types of burners.

- Old domestic versions are equipped with cast iron products; they heat up slowly and also cool down, creating a steam effect in the kitchen, but they are resistant to moisture and high temperatures.

- Tubular spirals - they are made of a hollow tube; when heated, such devices not only give off heat, but also promote the circulation of warm air inside their body, which significantly increases their efficiency. These products are very difficult to repair yourself.

- Ceramic burners are very simple in design, they are easy to repair at home - a nichrome spiral is placed in special cells in a circle and secured. Modern models increasingly use glass-ceramic solid plates - they are more durable and easy to clean.

- Halogen devices are special burners with a similar emitter that are installed in different places on the hob. A stove with such burners provides fast heating, in a second, and low energy consumption, so they are the most economical, but only professional craftsmen can carry out repairs.

All models of modern stoves use a special cross-section power wire to transmit current to the burners; in addition, they are connected to regulators and thermostats, ensuring their protection from overheating.

In different models, the heating level is controlled in different ways: by manually changing the cooking mode or by special timers and alarms that monitor.

Types of electric stoves

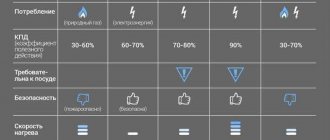

Despite the great variety, all electric stoves can be divided into groups, guided by such interdependent criteria as the type of burners used and the material from which the hob is made.

Burner type

Modern electric stoves are equipped with built-in heaters (burners) of various types. The standard quantity is 4 elements, but in some models there may be 6 heaters. The exception is some budget models that have 2 burners.

The following types of burners are produced by industry:

- tubular (heater);

- rapid (spiral);

- halogen (Halo-Light);

- tape (Hi-Light);

- induction

As a rule, heating elements are closed with cast iron “pancakes”, but can be operated without them (tabletop electric stove “Dream 010N Elna”, etc.). Rapid heaters are used to organize so-called expansion zones on modern hobs. In electric stoves of previous years, nichrome spirals were hidden inside cast iron “pancakes” or placed on an open ceramic base (rare tabletop electric stoves).

Important! Halogen, tape and induction types of heaters can only be called burners conditionally, since their elements are structurally separated, and on the hobs of electric stoves the zones in which it is necessary to install cookware are visually shown.

Hob material

In the manufacture of cooking surfaces for domestic and foreign electric stoves, the following are used:

- alloy steel, which is coated with durable anti-corrosion enamel, which is highly resistant to high temperatures;

- stainless steel;

- glass ceramics.

Ovens

Almost all household electric stoves, in addition to hobs with burners, have ovens, which can be:

- static, i.e. equipped with two heating elements (upper and lower), ensuring uniform heating of products from all sides;

- multifunctional, using the principle of convection for operation, while the uniform distribution of heated air throughout the entire volume of the oven is carried out by means of a fan.

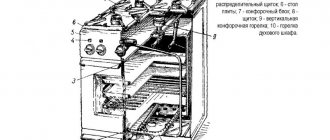

We disassemble the product

Models of slabs vary not only in external shape, but also in size and design - it is impossible to describe a disassembly algorithm that will fit all products. A common factor for all is the presence of a thermal insulation layer - you need to work with it with extreme caution. Users should be aware that asbestos dust from gaskets under the burners in older models is very harmful to health - take this fact into account when dismantling archaic stoves.

First, the hob is dismantled - it is attached with screws; if you unscrew them, it can be easily removed. Under it there are burners, leading wires to them and mechanical temperature controllers, which are located on the front panel.

All this must be dismantled in order to get to the lower part, where the oven heating elements are located.

For a modern electric stove with a glass-ceramic hob, disassembling the housing for repairs will be different - in order to get inside, you just need to remove the top panel.

Advice from the experts

- When unscrewing the nut from the pin, apply a small amount of oil to the pin for ease of movement.

- When disconnecting the wires with spring tips from the faulty burner, attach pieces of paper with information about which wiring belongs to which connector.

- Entrust the replacement of parts of an electric stove with a glass-ceramic hob to the specialists from the service center. For other types of slabs, it is possible to use improvised materials for repairs, but branded components are better.

- The burners in the old stove are replaced with more modern ones: this simplifies the search for new parts.

- Before disassembling, the plate is first inspected to determine the cause of the malfunction, for example, remaining wire, carbon accumulation on the contacts, etc.

The plate is subject to both mechanical damage and wear of parts, which leads to breakdowns. Most often, repairs are carried out by a specialist, but there are breakdowns that can be repaired independently. You can find out how to repair a gas stove, its oven and glass, as well as learn about common causes of breakdowns of induction stoves and their repair on our website.

To avoid possible breakdowns, a preventive inspection of the technical condition of the household unit is carried out annually. Following safety rules, possessing the basics of electrical engineering, and armed with the necessary tools, they repair components and parts of electric stoves.

Why did the electric stove stop working?

In a good half of cases, the problem lies in the electrical circuit. The device stops responding to controls, the display turns off, the burners do not heat up, and the oven does not work. There are a number of reasons that can lead to equipment failure:

- faulty socket;

- the heating element is burnt out;

- terminals are disconnected;

- contacts have oxidized;

- fuses or circuit breaker are knocked out;

- damaged network cable.

Power regulation

A heating element alone is not enough to get a working burner: its power must be varied, from weak to strong, in order to cook different dishes. Some require low heat, others require fast fire. How to do this?

Two designs are usually used: a set of several heating coils in one burner, or a thermostat. In the first case, the burner consists of two or three spirals of different power, which can be turned on simultaneously or one by one. The fire control for such a burner is discrete (stepped) and can occupy one of four or six positions. Here is an example of the design of such a burner with 4 heater positions:

- The burner has 3 spirals: two with low power, and one with high power.

- Position 1: one of the low power coils is on;

- Position 2: two low power coils are on;

- Position 3: high power coil is on;

- Position 4: all coils are on at the same time.

A stove with a thermostat is designed differently; the power regulator on it is smooth, and there is only one heating element in the burner. A thermostat is a relay that activates at a certain temperature and turns off the heating. In this way, a strictly specified heat output is achieved. Stoves with thermostats on the burners are rare, but ovens are almost always equipped with this device.

Ovens come in two main types of design: simple and convection. A simple oven is heated by two large electric heaters: an upper and a lower one. This oven has two regulators, one of which sets the temperature, and the other turns the upper and lower heaters on or off. A convection oven usually has only one heater and an air supply system that works similar to a commercial hair dryer.

Diagnosis of problems

Important! Before starting any work, you must first completely turn off the power to the equipment by unplugging the plug from the socket.

Diagnostics of faults includes testing the circuits with a multimeter, where each connection is checked: heating elements, burners, indication, control unit, thermostat, fuses, etc.

As a rule, the operating instructions are accompanied by a detailed diagram of the electric stove, as well as technical recommendations. But in order to carry out diagnostics, you need to have a clear understanding of the essence of electrical connections. Otherwise, it is better to contact a specialist.

Some problems are visible to the naked eye. For example, if the glow intensity of heated heating elements decreases or dark areas begin to appear on the spirals, then it is time to change the heating element. Let's look at common faults with electric stoves.

Preventive actions

It is possible to ensure long-term uninterrupted operation of a household appliance by observing proper care and following the requirements set out in the operating instructions.

- The glass surfaces of the electric stove are maintained without the use of abrasive materials.

- Every time after cooking, clean the stove with soapy water and wipe dry.

- Do not leave the stove turned on unattended for a long time to avoid igniting objects located nearby.

- Use cookware with a diameter that matches the size of the burner.

- Inspect the stove and components in a timely manner for damage and possible malfunctions, and carry out repairs in a timely manner.

- Do not place cold dishes on a hot burner.

- Avoid getting liquid, salt and sugar on the glass-ceramic hob, otherwise it will quickly become unusable.

- When starting repairs, the stove is first de-energized, and the contacts are checked for residual current with a multimeter.

- Protect the stove from mechanical damage.

- Before using for the first time, carefully read the operating instructions.

- Do not use household appliances for purposes other than their intended purpose.

Burners do not work after turning on the oven

More often this happens due to problems within the circuit: closed or, on the contrary, broken contacts. The latter are concentrated in the distribution box, which is located on the back side of most models.

It is necessary to inspect the wires for physical damage and oxidation of contacts. If the end of the cable is charred, you can try to clean it by cutting off the problem area. The terminals and contact points also need to be treated with sandpaper to get rid of any oxide that has appeared.

Troubleshooting algorithm

An electric stove is a rather complex device, which generally includes:

- electric burners;

- temperature sensor;

- oven with heating elements (heating elements) and fan;

- control Panel;

- terminal box;

- power cord, etc.

Despite the high reliability of electric stoves, they, like all household appliances, can break down from time to time. In cases where the electronic components that control the operation of the electric stove fail, only a person with deep knowledge in the field of electrical engineering and microelectronics can repair them independently. In addition, he must have on hand a number of measuring instruments necessary for diagnosing and subsequent adjustment of these components.

However, you can try to fix simple malfunctions that often arise during the constant operation of the electric stove yourself. To do this, it is enough to have knowledge of safety requirements and basic electrical engineering, as well as a set of simple tools .

Required Tools

When starting to repair an electric stove with your own hands, you need to prepare a multimeter, a set of Phillips and flat-head screwdrivers, pliers and wire cutters (side cutters). You will also need heat shrink tubing with a mounting knife and fine-grained sandpaper. The most important thing is to take a voltage tester, a set of wrenches, a flashlight, tweezers and a hammer.

Step 1

Before starting diagnostics, you must make sure that the malfunctions were not caused by violations of the operating rules of the electric stove. In general, such failures include:

- lack of power supply voltage;

- weakening or oxidation of contact connections;

- failure of the operating mode switch;

- heater malfunctions;

- broken electrical wiring, etc.

In any case, diagnostics and repair of electric stoves begin with checking the presence of voltage in the power outlet and visually inspecting the power cord. The voltage is checked using a multimeter or test light. Only after making sure that the outlet is in working order and the power cord has no external damage can you begin to disassemble the electric stove.

Attention! To safely disassemble the electric stove, you must first remove the plug from the electrical outlet.

Step 2

Next, you need to remove the hob. Structurally, electric stoves differ from each other, however, the hob of many modern electric stoves (Gefest, Beko, etc.) is secured with screws located in the corners of the body. Having unscrewed them, the surface is carefully lifted and moved to the side. This will open access to the internal parts of the electric stove.

Advice! To avoid damaging the hob, it must be disconnected from the body. To do this, remove all the wires coming from the burners and switches.

Step3

The next step is to check the presence of voltage at the contacts of the terminal box, where the wires from almost all elements of the circuit (burners, switches, etc.) are connected. Having reached it, measure each contact with a multimeter. If voltage is present everywhere, then troubleshooting continues further. And if it is not present on some contact (broken wire, oxidation of terminals, etc.), then the defects are eliminated and only then (if necessary) work continues.

Important! The voltage measurement at the terminal box contacts is carried out with the power cord connected to the network. To avoid serious injuries that may result from accidental contact with live parts, it is recommended that work be carried out in the presence of an assistant. His task will be to be near the outlet during the procedure and, if necessary, instantly turn off the power to the disassembled electric stove.

After such a check, you can immediately draw some conclusions.

- If there is voltage on at least one contact of the terminal box, then there is no need to check the power cord and socket.

- If there is no supply voltage in the terminal box contacts, then the fault should be looked for either in the power plug or in the power cord. The reason for the lack of voltage may also be broken wires or poor contact.

Next, they begin to search for faulty components installed inside the electric stove housing.

Socket, plug

The problem may not be with the stove itself, but with the socket or plug. The first can be checked by connecting another electrical appliance, for example, a kettle. When choosing a socket, you should pay attention to the rated current. If it differs from that indicated on the machine, the wiring may melt or even catch fire. For a single-phase network, a classic 32-amp outlet is more than enough.

The chrome elements of the fork should be clean and free of any signs of burning. If there are any, then it must be cleaned, and in difficult cases, replaced. The same rule applies here: buy a plug with an eye on the rated current of the machine.

Burner malfunctions

A burner malfunction can be detected during diagnostics if a live test shows that voltage is properly supplied to the burner, but it does not heat up.

If the burner on your stove has a stepped power control and consists of several spirals, then most likely only one spiral will be faulty, and the burner will work too weakly in one position. If the burner has continuous regulation and is equipped with a thermostat, then it will not work at all. Both options are a sign of a broken nichrome thread. You can verify this by checking the resistance of each thread using a tester. Infinite resistance clearly indicates a broken thread.

This is usually repaired by replacing the burner with a similar spare one. Find a burner of the same design in any store or online spare parts store and install it in place of the damaged one.

If you have an induction or halogen stove, then instead of classic burners on heating elements there will be inductor coils or lamp-shaped burners. The same applies to them: a breakdown can be diagnosed by the absence of an effect in the presence of supplied voltage, and it is corrected by replacing the failed element.

If the burner has an open spiral design, then it can be repaired without replacement. This is the advantage of an open spiral: a rupture or burnout in it can be detected by a simple visual inspection of the spiral. It is not the entire heating element that will have to be replaced, but only the specific damaged thread; other threads can be left as is.

Checking other nodes

Modern technology is provided with more reliable protection, unlike models of older generations. If the heating element malfunctions, the operation of the electric stove may be completely blocked. To rule out a problem with the burner, you should check several main components.

Circuit breakers

One of the most common problems - power surges - lead to blown fuses. They look different. Most often this is a small part with a glass or ceramic body with thick contacts at the ends.

Thermal fuse for Hansa cooker

You can check their performance using a multimeter: if the resistance is barely visible, then everything is in order, otherwise we replace them with new ones. Fortunately, they are inexpensive and are sold in any electronics and household appliances store.

It is very important to select the correct fuse. If the element is less sensitive than necessary, it will burn constantly. And overestimated indicators can cause burnout of the main elements of the electric stove.

The ideal option is to take the old fuse with you when going for a new one.

Machine

If the machine in the control panel constantly knocks out when you turn on the stove, then the whole point is a short circuit. The wires could melt and become twisted together. You should inspect the electrical wiring of the stove, test suspicious areas with a multimeter and eliminate the fault.

Sometimes the problem lies in the machine itself. For example, if there was a replacement with an option with a lower load power. In this case, you need to do the same as with a fuse: take it with you to the store and buy a solution with similar characteristics.

Power switch

Next, you need to inspect the power switch. If it is mechanical, then some physical damage will be immediately noticeable. We unscrew the fasteners on the panel, disconnect the fixing shaft and remove the switch. Inside you can see several springs: we take them out and inspect the structure.

A common cause of switch failure is melted contacts. We remove large deposits with a sharp object, and clean off the remaining residue with sandpaper. If necessary, replace wires and terminals. Next, assemble the switch in reverse order. If the unit is digital, then it is better to leave the repair to a specialist.

A heating element

The burner may not turn on due to a burnt-out coil. On many models you can replace the heating element yourself. The procedure should be described in detail in the operating instructions for the device. To replace the spiral, you will need to either remove the entire top panel or a separate burner cap.

Thermostat

If the temperature regulator fails, then after the stove is turned off, the heating elements continue to work until they burn out or the user completely cuts off the power to the equipment . The thermostat is a small, rather complex, but inexpensive part. Therefore, repairs as such are not practical here. It is much more practical to buy a new regulator and simply replace it.

Thermostat

Oven failures

Often, only the oven in the electric stove does not work. The most common malfunction is that there is no backlight inside the device; as a rule, there are two reasons.

- There is no contact between the supply wire and the lighting system - check the button responsible for turning on the backlight, and if it breaks, replace it.

- A light bulb has burned out - the lampshade protects it from high temperatures, but the way they are designed is that they very often burn out from the slightest voltage drop.

When a short circuit occurs in the electrical system of the stove, the lamps in the oven burn out first.

Oven fan

To better distribute the heat in the oven over the entire area, the designers installed a powerful fan, which sometimes may not function correctly: it rotates continuously or does not turn on at all. This type of breakdown is associated with the control unit, so it is useless to carry out repairs yourself - you need appropriate diagnostic equipment to accurately install or change the fan or the unit itself.

No heating element

When the oven of an electric stove heats up weakly, the main reason lies in the serviceability of the heating element. These products, like the heating elements of the hob burners, cannot be repaired - they must be replaced. Sometimes, which happens very rarely, the thermostat that regulates the temperature inside the device may burn out - it is dismantled and a new one is installed.

Very rarely, such a malfunction occurs: the housewife turns on the oven, and the product immediately turns off completely. When checking the circuit breaker on the electrical panel, it turns out that it has turned off the power supply to the product - perhaps a short circuit has occurred, the heating element needs to be changed.

Why choose us

Service you trust!

Our center employs household appliance repair technicians with more than 9 years of experience.

The visit of a specialist to your home is absolutely free.

The master gives a guarantee of up to 24 months for all work carried out.

The technician arrives very quickly - literally within 15 minutes from the moment of the call.

Found prices lower than ours? We will repair equipment 10% cheaper than our competitor.

We work seven days a week throughout the district and region.

Do you want to express your gratitude to the master or still have questions about the quality of the repair?

The quality control service is always happy to listen to you.

Other faults

The considered algorithms make it possible to correct most slab failures. But there are other minor faults. A short list of possible breakdowns will be given here.

- The smell of burnt fat when the burner is turned on: there is no malfunction, but the stove needs to be cleaned of dirt.

- The smell of burning rubber or plastic when you turn on the burner: this is an ominous signal that indicates an impending wire burnout. Turn off the stove, open it and conduct a visual inspection of the wires and terminals for melted or burnt insulation

- The stove knocks out plugs when turned on. This is a sign of a short circuit. Turn off the stove, open it and conduct a visual inspection of the wires and terminals for melted areas. This will allow the short circuit to be localized and eliminated.

- The oven light does not work. The light bulb has probably burnt out: unscrew it and carry out a visual inspection. If the light bulb is working, it is necessary to carefully check the power supplied to the light bulb using the method already discussed.

Signs of breakdown

An obvious sign of a malfunction is the lack of heating of the burners or oven. But there are other equally common problems:

- The electric stove does not heat well.

- One of the burners does not work or its heating does not correspond to the selected mode.

- There is no heat in the oven.

The lack of lighting in the oven also indicates irregularities in the operation of the appliance. The complexity of the repair, its cost and the ability to fix the problem yourself depend on the cause of the problem.