Types of cast iron burners

For conventional enameled stoves, it is possible to use one of three types of cast iron burners:

- Express burners with increased power

Standard burners with medium power

And automatic burners

1. Express burners

. The express burners in the middle are indicated in red. Their use is recommended when rapid heating is required. It is enough to compare the statistics - in the case of setting the switch knob to maximum, the express burner heats up in seven minutes, while standard burners require ten minutes.

2. Standard burners.

Have average power

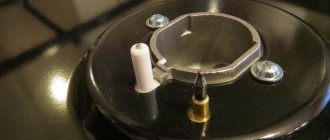

3. Automatic burners.

There is a white spot in the middle to indicate automatic burners. There is a built-in sensor in the center that allows you to determine the temperature of the dishes. The advantage of this burner is that there is no need to turn it on at maximum power and then switch to lower temperatures - for example, to boil water. The burner will be able to independently determine when the water is boiling in order to reset the power. In addition, when dishes are removed from this burner, they will not overheat and will not fail.

Comparison of measurement scales

Traditionally, gas stoves produced in the USSR, as well as neighboring countries (Czechoslovakia, Poland), used internal thermometer calibration divided into eight segments. Accordingly, the elements of the scale were designated from 1 to 8, and the question arises of how to determine the temperature in the oven using numbers. Since the maximum temperature in household ovens does not rise above 360 degrees Celsius (on average), you can try to calculate the temperature correspondence to the calibration yourself.

- It should only be noted that even with minimal heating (level 1) the heat usually reaches 150 degrees.

- Accordingly, the normal temperature for baking - 200-220 degrees - corresponds to marks 4-5, and acceptable for preparing biscuits - to mark 3.

- The minimum possible heating suitable for drying meringues or cooking dried fruits and berries is about 70−90 degrees Celsius and is achieved in conventional stoves only by controlling the gap between the door and the main part of the oven.

More accurate information can be obtained from the product passport, if it has been preserved. However, prolonged use may make adjustments to the actual heating level. So it is advisable to test it experimentally.

Disadvantages of cast iron burners

Any housewife who has worked with an electric stove knows that “pancakes” take a very long time to heat up and cool down. That is why many have already abandoned classic electric stoves. Nowadays, buyers are increasingly choosing glass ceramics or induction hobs. The advantages are obvious: economical energy consumption, quick heating and cooling of the surface, the surface is much easier to clean, and the materials are much more attractive.

Another point is the limited surface area of the burner. If you are planning to cook a dish in a duck pan, then this dish will not fit on a regular pancake. A large pan may suddenly tip over. But in the case of glass ceramics, this question disappears. The fact is that modern manufacturers make one burner for several types of cookware, depending on its diameter. There are several circles on the hob, which indicate the size of the container for cooking dishes. This allows heat to be distributed evenly and economically. Brew coffee in a Turk - place it on a small circle in the center of the burner, fry eggs - put it on a medium one, cook borscht in a large saucepan - choose the maximum diameter.

How to choose an electric stove with optimal parameters, functions and design

In old houses and most new buildings there are no gas pipelines, which are replaced by electric lines. Therefore, it is necessary to understand how to choose an electric stove for the kitchen - what functionality to choose, how to stylishly fit it into the interior of the room. First you need to decide between the classic options with an enamel or stainless steel surface and modern induction glass-ceramic models. In the first case, you get low cost and ease of maintenance, and in the second, fast heating, energy efficiency, and a stylish appearance. A number of other important factors also influence the choice.

Types of burners in glass-ceramic electric stoves

For stoves with glass-ceramic surfaces, it is possible to use rapid, halogen, Hi-Light and induction burners:

1. Rapid burners.

They work thanks to a heated built-in spiral. Heats up in 10-12 seconds

2. Halogen burners.

Halogen burners are equipped with halogen elements in addition to the spiral. A halogen element is a quartz tube filled with gas. The halogen element starts working after switching on. Warm up in about 1 second.

3. Hi-light burners.

They operate using a ribbon-type heating element. Ultra-fast heating. Reliable in use, easy to maintain. This type is widespread.

4. Induction burners.

They work thanks to the principle of induction. Induction burners heat the bottom of the cookware without heating the hob. True, you cannot use dishes made of copper, aluminum and heat-resistant glass.

How to clean an electric stove

You can clean the burners of an electric stove using special modern cleaning products for electric stoves and ovens. You need to wait until the stove cools completely. Then apply the cleaning agent to the surface and wait about 10 minutes. After this, wipe the entire surface dry. It is advisable to use paper towels - they will help completely remove moisture. But you can do without expensive chemicals and use refined sugar. Lightly moisten a piece of sugar with water and rub the burners. Glass ceramics can be cleaned with regular detergent or special household chemicals. In general, glass ceramics are easier to clean than a classic electric stove with cast iron “pancakes”. For example, sauce will be difficult to wash off from cast iron, but on a glass-ceramic stove it can be easily removed with a damp cloth.

Important functions of electric stoves

It is difficult for an ordinary person to understand the abundance of functions that are present in the technical description of a product. That is why you need to know the basic terms that manufacturers use.

Protection against accidental activation

— blocking accidental activation of the hob. This function will be relevant for families with small children. They won't be able to turn on the electric stove.

Residual heat indicator

- if the hob (glass ceramic) has not yet cooled down, you will see the “H” indicator (English: “Hot” - hot). As a rule, the indicator lights up if the burner temperature is above 50°C. When it cools, the letter disappears.

Autofocus

— to save energy, special sensors monitor the heating zone. This function is called autofocus, i.e. the heat is “focused” on a specific surface area where the dishes are located. This function is used in glass ceramic panels.

Boil function

- this function is often displayed as a separate icon on the hob. If you activate it, the burner will operate at maximum power. Most often, this function is used to quickly boil water, hence the name. After some time, part of the power will be automatically turned off.

temperature sensor

— the burner always maintains one temperature selected by the user. It is thanks to the temperature sensor that the heating is always the same.

| It is difficult to imagine the interior of a modern kitchen without glass ceramic panel . But just a few years ago we could not even imagine such luxury. There were only bulky electric and gas stoves with many disadvantages. Glass-ceramic panels have made the work of housewives easier and have become a godsend for designers. The glass ceramic panel has a lot of advantages:

Hobs are made of glass ceramics, which has unique properties that are ideal for use in cooking: Disadvantages of cast iron burnersThe upward pressure is provided by a leaf spring 90, which is attached to a bracket 92, which is attached to the bottom wall 96 of the rough box. |

A few words about modes and configuration

Smeg electric stoves are perfectly suited for cooking. Cooking surfaces (both induction and Hi-Light) have expansion zones. This means you don’t have to think about changing dishes or giving up your favorite duck dish. Induction models have a convenient “Booster” function. With its help, you can temporarily increase the power of one burner at the expense of another that is not in use. If you need to cook a dish at a high temperature, this option will come in handy.

Most oven models have grill and convection. They can be combined with top and bottom heating, creating optimal conditions for cooking a wide variety of dishes. The grill comes with a spit, so you can cook the whole bird without having to turn it over by hand.

The set includes two baking sheets (deep and shallow), one or two racks and a removable spit. In larger cooking centers, each oven has its own set of trays. If you want to purchase additional accessories, it will not be difficult: the dimensions of the ovens in Smeg electric stoves are quite standard.

Order today and you will have reliable and convenient equipment for preparing your favorite dishes. Delivery times and other details can be clarified with the manager.

Burners in glass-ceramic hobs

A burner is a relative concept for a hob.

Only the markings of heating zones are visible on the panel. The “burner” is a flexible heating element hidden under glass ceramics, laid on an asbestos base in the form of a spiral. The following types of “burners” can be distinguished:

Thus, when the mounting screw 98 is tightened, the spring 90 tilts upward toward the reflector. Two contacts 100 and 102, shown on opposite sides of the surface block, are connected to the foil heater. The configuration of the foil heater 74 is not shown in but is typically of a spiral configuration, starting from the periphery of the heating means 64 until it reaches the center where it doubles back on itself and has a reverse spiral going in the opposite direction, in generally parallel to the first spiral, but terminating diametrically opposite to the side of the heating means.

They can be round in shape or have an extended heating zone. These burners allow you to cook in different sized containers.

The high-temperature coil heats up red-hot in 10-12 seconds. The heating power of a burner with a diameter of 210 mm is up to 2.1 kW, 145 mm is about 1.2 kW. The housewife will not have to worry that the food in a five-liter saucepan will heat up unevenly, or that the handles of a small saucepan will become so hot that it will be impossible to remove it from the stove.

This particular helical configuration is generally well known and is not part of the present invention. It is good to understand that the thickness of the foil heater 74 is increased at the terminals to reduce the operating temperature at the terminals. Push connectors 104 may be installed on the terminals for electrical connection thereto. Wire leads 106 are compressed toward connectors 104, as is standard in the art.

Conductors 108 and 110 are shown greatly enlarged in the drawing; however, it should be readily apparent that the conductors 108 and 110 are only built to a thickness of 50 to 100 angstroms and thus do not form appreciable extension beyond the plane of the bottom side 109 that abuts the top surface 111 of the dielectric layer. The space between them as shown in the drawing is for clarity of illustration only. The ends of conductors 108 and 110 are made slightly thicker to accommodate suitable terminal blocks, which may be similar to terminals 100, and the lead wires from the terminal connections are in turn connected to a control circuit for controlling the application of power to the 68V heating block. response to a given change in the resistance of the glass-ceramic plate.

The rapid burner is the element most widely used by manufacturers.

The heating element is a snake-shaped tape made of a special alloy. Heat is distributed throughout the working area in 4-7 seconds. Heating of water on such a panel occurs much faster than on other types of panels. But, if a rapid burner consumes on average 1-1.5 kW per hour, the Hi Light element consumes much more - 1.5-2 kW per hour.

Thus, it is difficult to differentiate between the condition of a broken or exposed conductor and a cold hob. "Looking" at the conductors, the resistance measurement will be very high in both conditions. Accordingly, an integrity check is provided to monitor the condition of the conductors. For this purpose, each pair of strip conductors is terminated with a continuity resistor of approximately 50 kOhm. Advantageously, as will be described below, the ratio of the resistance of the end-of-line or shunt resistor to the resistance of the glass ceramic between the strip conductors at the operating temperature of the heated glass-ceramic plate is such that the shunt resistor has little effect on the operation of the sensing means.

The Hi Light element is used by manufacturers, as a rule, only for a few models.

The high-temperature coil is combined with a halogen lamp, which is a quartz tube filled with gas.

The lamp produces a large amount of heat, emitting a bright red glow. The element has high power. Heating is instant.

An additional safety feature can be enabled by enabling the peripheral strip ground wire, which serves as a glass break detector. The peripheral ground wire may be plated on the underside of the cooktop at the same time as the sensor conductors or in a separate deposition step. This strip may be the same metal as the sensors, but is preferably a cheaper metal, such as silver, that can be deposited on the bottom surface of a thin layer.

Each cooking zone has an area of maximum heat, indicated by a circular shape with dashed lines. Each cooking zone is coupled to this resistance-sensitive temperature sensor of the type described above comprising a pair of strip conductors 28 and 30 that extend from an area adjacent to the edge 36 of the cooktop plate 22 through a corresponding cooking zone 32 terminating in a cool region. Preferably, each strip ends with a resistance element 29 having a value of about 50 kOhm.

For preparing French fries, fried meat, and quickly boiling water, this panel is an ideal option.

This development is unique because it is based on changes in the electromagnetic field. An inductive coil and an electric generator are hidden under the working surface. The principle of heating food is that the atoms of the crystal lattice of the alloy from which the cookware is made vibrate under the influence of an electromagnetic field.

Terminals 1 and 6 serve as common ground terminals and are connected to one of the strip conductors of each pair by a metallized strip that surrounds the periphery of the glass. The circuit can be easily traced starting at terminal 1 where strip 120 is connected to sensor strip 28A. For convenience, the designation of an alphabetical culinary region may be applied to the reference character of the elements found in each region. The strip 120 extends across the adjacent lower edge 121 of the plate 22 as seen in the drawing and has a sharp turn at the corner of the plate 22 before continuing upward as at the adjacent edge 122.

The bottom of the pan heats up, while the panel itself remains cold. This element eliminates the possibility of food sticking to the work surface and saves time and energy due to direct heating.

Heating elements for electric stoves - advantages and disadvantages

The tubular electric heater is an invention that has been firmly established in the production of electric heating devices since 1859, increasing their convenience and safety. Mr. George B. Simpson, who patented this device, contributed to the introduction into our lives of comfortable electric stoves, water heaters and many other equipment that are used everywhere. The design of such a heating element is quite simple. This is a thin-walled metal tube, inside of which there is a heating coil. The space between the spiral and the tube is filled with a material that has high dielectric properties, but at the same time very high thermal conductivity. The end of the tube is separated by insulating material. This technology has made it possible to obtain a safe device that effectively converts electrical energy into heat. The use of insulating powder and tube reduction was patented by American companies, which prohibited use of the invention outside the United States for many years. It was only after World War II that this technology became known in many countries. Since 1955, machines producing heating elements were allowed to be sold abroad, and only to one company, Kantal. In 1980 the agreement ended. Now such machines can be purchased all over the world.

A few words about the physical properties of heating elements and how they affect the performance characteristics of the device. The material from which the tubes are made is stainless steel or steel 10. Chemical or electrochemical coating can be applied to the metal - tinning, nickel plating, fluoroplastic. The use of double-thick steel increases the durability of the device. In addition, the larger the diameter of the heating element, the greater the maximum available power. For example, for TEN-85 (the expanded length of the shell is encrypted in the marking), the maximum available heating power for casting molds for a diameter of 8-10 mm is 1.25 kW, and for 13 mm - 1.6 kW. If the power exceeds the maximum permissible for the heating element, it quickly fails. The temperature of the coil inside the heating element is often more than 1000°C. At the same time, in places where the backfill filling the tube has a weaker contact with the metal, the temperature is even higher, reducing the durability of the electric heating device. But the wider the surface of the heating element, the less heat is removed from it.

The oldest and most common use of heating elements is their use in electric stoves. In industrial and household electric stoves, narrow, wide (tape) heating elements and pancakes are used. The main operational indicators of electric burners are permissible power, size, heating speed and temperature, cooking duration, efficiency, electricity consumption and warranty period.

The device of a pancake heating element - a nichrome spiral thread is located inside the heating element. The heating element is filled with cast iron. Pancakes have their benefits. Those who have used a pancake heating element know that such a surface heats up more evenly and retains heat longer. However, these burners are prone to warping. A flat burner requires the use of dishes with a perfectly flat bottom, otherwise their contact area will be very small, which significantly reduces efficiency. The service life of pancake heating elements is on average 2 years. Unfortunately, such burners are not repairable. Once they fail, they require complete replacement. At the same time, you cannot do without the help of a specialist. And, the most unpleasant property of pancakes is the long heating and cooling time. At the same time, what is more pleasant, energy consumption is low. In general, if you have a lot of free time, are ready to remove the pan when it boils until the burner cools down to the desired temperature, but at the same time save on electricity, cast iron pancakes are your choice. The surface temperature can be 350°C-450°C.

The advantages of spiral heating elements over pancakes are higher efficiency. The surface of the spirals heats up more quickly. If the spiral fails, it is quite easy to replace it yourself in compliance with safety requirements.

The biggest advantage of narrow spirals is fast heating. But also the biggest disadvantages are fragility and not very high resistance to deformation. Considering the above about the physical properties of heating elements, it is clear why a narrow spiral heating element expects faster burnout. But if the most important thing for you when choosing a tile is to cook food quickly, and you are ready for a short change of equipment, this is your option. A thick spiral will significantly improve the performance of the slab.

A wide spiral heating element has average performance characteristics between the two above. It is not as slow as a pancake, and more durable than a narrow spiral one. The average time of use of a wide heating element is about 10,000 hours. The surface is heated to 400°C-800°C. A wide spiral heating element is the choice for those who are looking for the most optimal balance of comfort and quality. Today it is widely used in the production of electric stoves.

Functions and equipment of glass-ceramic panels

The panels can be combined: three gas burners + one electric (or two gas + two electric).

If you experience power outages, it is advisable to purchase just such a model. Not all manufacturers produce such panels, and their price is slightly higher than others, but you will have a guarantee that you will not be left without hot food in the event of a power outage. According to their functions, burners can be divided into:

The strip runs along the peripheral edge 126 of the plate 122 as it 127 and in the form of an internal turning angle, continuing on 128 adjacent edges 129 to the end. However, it should be apparent that any other suitable geometric arrangement for the sensors may be used as long as they intersect the maximum temperature region defined by the circle.

There is a separate control circuit for each heated area or "burner" of the cooktop, but for convenience only one control is described and illustrated. The second input of the temperature comparator means 142 is derived from the reference temperature means 144, and the second input of the continuity comparator means 143 is derived from the continuity of the reference means.

Thermostatic

Equipped with a thermostat – temperature sensor. This allows you to maintain the temperature set from the control panel. This function is very convenient for preparing dishes that require long-term cooking at a constant temperature.

With variable heating zone

When using round utensils, contours of either larger or smaller diameter are activated; If it is necessary to use oval-shaped cookware, an additional heating segment is activated. Such burners are convenient for cooking in patches and roasting pans.

The continuity comparator means 143 may take the form of an operational amplifier voltage comparator that performs a fail-safe function and prevents the load relay control means 146 from turning on 147 if the continuity resistor means indicates an open or discontinuity in the sensor, i.e. control 146 is only allowed to be activated if the sensor resistance is below a minimum value.

It will be appreciated that many different circuits may be designed for use with the sensors of the present invention. The sensor resistor 150 and the continuity resistor 151 are shown connected in parallel with the dotted lines representing the surface of the cooking surface. Sensor resistor 150 corresponds to the resistance between strip conductors 28, and to this end, junctions 158 and 159 are connected through the AC terminals of transformer secondary winding 160 via conductors 161 and 162, respectively.

Equipment

:

Burner indicator lights

Residual heat indicator

Control system

Assistive devices

The best models of electric stoves with prices

There are a huge number of hobs of various configurations on the market. Most often, consumers purchase practical models from the middle price segment. Simple appliances for country houses and small kitchens are also in demand. Based on these consumer preferences, a rating of the best electric stoves in 2021 was compiled:

- In 5th position is the budget two-burner Russian-made model Darina S EM 521 404W . Affordability, compactness and a spacious oven are the advantages of this unit. Cons: modest functionality and slow warm-up. The cost of the product is from 7,000 rubles.

- The 4th position is occupied by an electric stove with a stainless steel surface Hansa FCEX 58210 . The functionality of the unit is quite wide. The appliance is equipped with 4 burners and a spacious oven. The main advantages of this model are the presence of cabinet lighting, baking trays and racks as standard, and low energy consumption. Among the shortcomings, buyers note the strong heating of the case. The cost of Hansa FCEX 58210 is 22,500 rubles.

- 3rd place goes to the premium model from the well-known company Electrolux . The EKS 954901 X oven supports 11 modes for preparing various dishes. The top panel is equipped with 4 burners: 2 of them are single-circuit, 2 with an expansion zone. The disadvantages of the stove are considered to be a slightly inflated price (49,500 rubles) and the lack of a catalytic coating.

- In 2nd place is the unit VEKO CSE 57300 GA . Its main advantage is its multifunctional oven. The basic package includes 2 baking sheets and a wire rack. The model has a very modern and stylish design due to the cabinet door made of tempered glass. The VEKO CSE 57300 GA stove heats up quickly. This model is also equipped with a residual heat indicator. This feature reduces the risk of accidental burns. The price of the product is 19,000–20,000 rubles.

- The leader of the rating was the glass-ceramic stove Gorenje E5121 WH-B from Slovenian manufacturers of household appliances. The model has a stylish classic design. 4 burners with a metal lid to protect the cooking table and an oven with pyrolytic panels greatly simplify the maintenance of the unit. The disadvantages of this model are the lack of convection in the oven. This disadvantage is partially compensated by simultaneously turning on the lower and upper heating. The cost of Gorenje E5121 WH-B is from 17,000 rubles.

Types of auxiliary devices

Infrared sensor

Measures the temperature of the dishes and regulates it by increasing or decreasing the heating power.

Automatic boiling

This device makes it possible to turn on the burner at full power, and after a specified time, part of the power will automatically turn off.

Connection 173 is coupled to anode terminal diode 174 such that only positive sensor control signal pulses are supplied to the negative input terminal of operational amplifier 172 through the conductor. In operation, operational amplifier 172 is biased such that its output is low when the amplifier is set to sense a given differential input through connections 169 and 173 through connections 169 and 173 through rectifiers 170 and the output of amplifier 172 is supplied through rectifier 175 and conductor 176 through capacitor .

The relay control circuit means may comprise an optical control device of a known type including, for example, a transistor control element 167 that has its control gate electrode coupled to a connection of resistors 178, and a collector of the transistor 167 connected via a resistor 180 to a positive line 181 to obtain a suitable supply voltage. The emitter of transistor 167 is connected to the anode terminal of light emitting diode 182, which has its cathode terminal returned to a common neutral bus.

Safety system

Installed to prevent accidental switching on of the stove. This feature is very useful if there are small children in the house.

Automatic cooking

The initial mass of the product and the program number are set - and the food is prepared independently, without your participation. Half an hour before cooking, the heating element turns off, and the food arrives with residual heat. The electronic timer gives a signal notifying you of the end of the process. Cooktops give consumers the chance to create a kitchen workspace with maximum convenience. When developing a design project, you should take into account that the hob and oven can be placed independently of each other. There are dependent and independent panels.

Relay coil 190 is operatively coupled to it by a pair of normally closed contacts 192 connected in series with the heating element. Continuity comparator means 143 also sets the sensitivity of the differential input through a pair of voltage dividers. Bus 204 applies to it an output voltage output from the AC output terminals of power transformer secondary winding 160 after the output voltage has been rectified by series diodes 205 and a smoothing capacitor.

The positive or non-inverting input of amplifier 200 is connected to a voltage divider including sensor resistors 150 and 151 via diode 174 such that the voltage of the positive input of amplifier 200 is a function of the positive pulse power waveform. Diode 174 effectively blocks negative pulses. A small positive voltage of about 100 millivolts is output from a resistive voltage divider containing resistors 208 and 209 connected through a smoothing capacitor.

In dependent panels, the controls for the oven and burners are located side by side (on the oven body).

In independent panels, the oven and hob have different controls.

If you choose independent panels, you can give free rein to your imagination. For example, if the oven is installed at chest level, it will be more convenient to remove hot baking sheets from it, and if the hob is located next to the cutting table, this will save a lot of time. Some people prefer to install the hob in the center of the cutting table. Everyone can achieve a level of maximum comfort for themselves.

The junction of resistors 208 and 209 is connected to the anode terminal of diode 210, the cathode terminal of which is connected to the positive input terminal of the amplifier. The output terminal of the diode 210 is also connected to the inverting input terminal of the amplifier 172, and the resistive element 211 is connected between the cathode terminal and ground.

Thus, to distinguish between an open circuit, which could lead to hazardous operating conditions and adversely affect the cooktop, and a cold condition, a continuity resistor 151 is provided. Resistor 151, which has a value of approximately 50K ohms, effectively bypasses strip sensor resistance element 150 when the cooktop surface is cold. On the other hand, as the hob surface approaches its temperature limit, its value decreases to the order of 1 kOhm or less and effectively bypasses the continuity control, which nevertheless continues to provide its protective function in the form of cycles of the hob surface temperature about the temperature limit and prevents it from working when the sensor is opened.

To operate the burners and oven, you can choose either standard electromechanical rotary switches or control using a touch field.

Precautions for use

— Do not subject glass ceramics to strong sharp impacts.

No matter how durable the material is, if treated barbarously, it can burst. Do not use the hob as a cutting board. Scratches from a knife can soon leave the coating in a state that is unable to maintain the functionality of the panel.

During startup operation, when the cooktop surface 22 is cold and the coil heater 193 is warm, both amplifiers 172 and 200 have a low voltage output. The inverting input terminal of amplifier 172 is biased slightly higher than the non-inverting input or positive input, so that the amplifier is biased slightly negatively.

If the sensor wires are open or broken, the positive input of the amplifier will rise to maximum voltage to turn on the amplifier. This causes a charge or voltage to build up on capacitor 177, which rises to the firing voltage of the transistor.

Choose the right cookware. Avoid aluminum and copper cookware; they leave a metallic sheen on the panel that cannot be removed. To avoid heat loss during cooking, choose cookware with a perfectly smooth bottom. The best choice is high-quality stainless steel cookware. The bottom of such dishes is weighted and somewhat concave. When heated, expansion occurs and the bottom straightens.

If your hob is not equipped with an infrared sensor, do not leave cooking unattended. The glass-ceramic panel does not have sides, and the liquid that “escaps” from the pan will spill onto the floor and, most dangerously, get onto the adjacent burners and can lead to cracking of the ceramic-metal.

Use special ceramic compounds and scrapers to clean the panels. Usually scrapers are included with the slab. If you don't have a scraper, you can use a disposable razor. Window cleaning liquid can be used as a detergent. The main thing is that after washing the surface, a layer remains on it that rejects fat.

Manufacturers and price of slabs

- BOSCH

- ELECTROLUX

- SIEMENS

- ARISTON (Italy)

- VIKING (USA)

- ARDO

- ZANUSSI

- GAGGENAU

- MIELE

- GORENJE (Slovenia)

- BAUKNECHT

- FAGOR

The cost of glass-ceramic stoves ranges from $300 to $2000.

Prices for glass-ceramic stoves, like any other product, largely depend on the popularity of the manufacturer’s name. The more famous the name, the higher the level of assembly and reliability, and the wider the range of services. Happy shopping!