For several years now, there has been a debate about proper moonshine brewing among very experienced distillers with extensive work experience: some argue that a classic distiller with the addition of a steamer is quite enough to produce high-quality strong drinks, others advocate column-type products. So what is better in practice – a moonshine still with a steamer or the same product, but equipped with a distillation column?

There are quite a lot of differences in design and purpose, and in this article we will try to give the pros and cons of these devices, talk about their features and operating principle, so that potential users can decide which device they need to purchase to improve their distiller, which model is worth buying and why.

What is a dry steamer?

The main purpose of this product is to protect the distillate from splashes of mash during active boiling, because small drops are captured by alcohol-containing vapors and transferred through the pipeline to the cooler, thereby contaminating the final product.

This behavior is typical for all types and recipes of mash. In addition to protection, the steam chamber filters fusel oils, since the temperature in it is slightly lower than in the upper part of the distillation cube and the steam pipe. All fractions with a higher boiling point than alcohol are condensed in it, and alcohol-containing vapors are sent further to the refrigerator - this is the only similarity with column-type products.

There is no loss of strength in this device, and if you purchased a collapsible version, you can flavor the final product at your discretion, for example, with citrus zest, aromatic herbs or dry fruits and berries. The difference from alcohol infused with the same ingredients is huge: there is no color, as well as the bitterness that comes from lemon or orange zest.

Description and role in the distillation of dry steam

A dry steamer is a device that prevents fusel oils from getting into the final product. In addition, the main task of the designated device is that it prevents mash from entering the finished product, which can penetrate during its strong boiling. Thereby making the alcoholic drink transparent. It should also be noted that the steamer is a recommended additional element to the moonshine still, which, according to experienced distillers, allows:

- Refine moonshine, which can subsequently be used to make cognac, whiskey and gin at home.

- Improve the degree of purification, thereby eliminating harmful substances from the product.

- If you have a collapsible steamer, you can flavor the product being manufactured.

- The steamer is a removable part, so it can be used during the distillation process if desired.

Another advantage of the designated device is that it does not require special care; it will be enough to check the quality of the sealant.

Distillation column

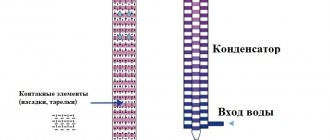

This complex design has special nozzles or plates inside; the mash column will begin to perform the functions of a rectification column only after being filled with nozzles to capture different fractions, so you should not confuse these two different functional design features.

The packings have a complex filling and greatly increase the internal surface of the column, where the main sedimentation of various fractions occurs. The boiling point of the alcohol is maintained in different areas of the product, so vapors pass through unhindered, and fusel oils and other harmful impurities fall into the condensate. Copper perfectly captures sulfur compounds, forming insoluble compounds, so distillation columns are made from it to distill mash from grapes or grain.

The product has a reflux condenser in the upper part - it is this that helps maintain a very strict temperature regime when selecting fractions, due to which the effective purification of alcohol-containing vapors occurs. The column can produce aromatization if the manufacturer has provided for the integration of additional blocks into the main structure - a special basket for putting aromas into it is purchased separately.

Their differences

The steam chamber is in contact with the environment, and in the column, due to the presence of a reflux condenser, temperature errors are eliminated, and the distillate is purified from harmful impurities to the maximum. Moonshine stills with a rectification column make it possible to obtain absolutely pure alcohol with a maximum strength of up to 96 degrees, while similar models with a steam chamber generally distill moonshine with a strength of 80-85 degrees.

Only experienced distillers, through careful adherence to technology, reach the highest limit of 900. The columns clearly select the so-called heads, and with the presence of a dry steamer, all fractions are more blurred, but you can get the final product with the smell and taste of the original raw material. On a column this is also possible, but only with less strict adherence to the temperature regime.

In terms of cost, they also differ significantly, but we will talk about this in detail in the following sections. The verdict so far is this: a distillation column is more expensive than a classic moonshine brewing apparatus, but it allows you to significantly expand the possibilities of home production of strong drinks.

Features of the device with a steam chamber

The steamer, as a part of a moonshine still, began to be actively used a dozen or two years ago. At first, it earned fame as a superfilter that could purify moonshine better than factory filters for vodka. But then they began to look at him more soberly. Using a practical method, a methodology for working with a dry steamer has been developed; reasonable restrictions have been clearly established on what the tone can and cannot do. One thing can be said with absolute certainty - without this evaporator filter, the moonshine turns out much worse, even with repeated distillation.

A simple steamer from a can

The structure of the dry steam tank is very simple, even primitive. However, it works quite effectively. Its basis is a glass jar (consider the simplest example), closed with a sealed lid, preferably a metal screw one. There are two holes made in the cover into which sections of tube with a diameter of 8-10 mm (depending on the diameter of the main pipeline) are soldered or threaded.

Tubes of different lengths - the long one protrudes above the lid by 5-6 cm and falls down, not reaching the bottom of the vessel by 2-3 cm. The short one protrudes to the same height, but falls below the lid by only 2-3 cm. In working condition, the tubes are connected to the steam line. Steam is supplied along the long one and taken away along the short one. You cannot confuse them - this threatens depressurization, maybe even an explosion.

Where is a distillation column and steamer used?

First, a little history: rectification became known at the beginning of the 19th century; it is one of the most important technological processes in the alcohol and oil industries. Today it is used in various fields of chemical technology, where the isolation of fractions in their pure form is of particular importance.

Distillation columns are used not only in distillation processes - the same principle of heat exchange between vapor and liquid is used both in simple laboratory instruments and in rather complex industrial installations in oil refining, chemical, gas, brewing and many other industries. The diameter of industrial devices can reach 16 and the height 90 meters or more.

Unlike column-type devices, a steamer is used only in the process of moonshine brewing as an additional element between the container with mash and the coil. It separates harmful components, and alcohol-containing steam is sent further for cooling and collection in a container. It is used for more efficient filtration and additional flavoring of moonshine.

As a result of passing through the steamer, the drink turns out to be stronger, better purified, rich in the aroma and taste of the original product, for example, strong chacha has a persistent smell and taste of grapes. Each distiller makes his own decision about the advisability of using it, but experts believe that to obtain a strong and well-purified final product, this device will be useful.

Rectifier and its functionality

A rectification column is significantly different from a dry steam tank. This is a complex design that separates alcohol from various impurities. Its work is based on the evaporation of foreign liquids by manipulating their boiling point.

At the lower level of the column, the components that boil the fastest are removed. Alcohol will begin to evaporate only at the penultimate level, and at the top of the column this process will occur with water. Alcohol vapor passes through special channels into the refrigerator, where the substance is cooled and transformed into pure cold alcohol.

There are industrial versions of rectifiers that process several hundred liters per hour. But there are also household ones that work with small volumes. They are more expensive than other systems for the production of purified alcohol, but they are fully worth their cost. Cheaper equipment is usually not able to offer the owner a decent level of performance and long service life.

The rectifier and steamer are different devices. The latter is used to modify the previously obtained product, and the column is used for the production of alcohol.

What is better to choose

As a result of the comparison, we found out that the steam chamber and the distillation column are completely different products that are used in moonshine stills for specific purposes:

- The dry steamer is an additional module, and not an independent device, like a distillation column.

- This device is used to refine the resulting moonshine, and the column serves as a source of high purity of the resulting high-strength alcohol.

- Cost: the price of a dry steamer is in the range of 300-500 rubles, the most complex designs are sold for no more than 1.5 thousand rubles. Column-type rectifiers are much more expensive: the simplest product with a low column will cost the consumer at least 7 thousand rubles.

The conclusions from the above are as follows: buying a steamer is justified if you already have a reliable moonshine still and want to receive not only pure and strong alcohol, but also elite varieties, such as brandy or whiskey, as well as homemade liqueurs, for example, from black currant or chokeberry.

The rectification column is purchased by those distillers who need large volumes of pure alcohol, otherwise such a purchase will be unprofitable.

Rating of the best models

moonshine stills with steamer

Malinovka Shchukina

pros

- wide neck

- for all types of slabs

- 3 thermometers

- excellent quality of the resulting drink

- thermometer on the distillation tank

- two steamers

- easy to clean, disassemble and store

- The cube has comfortable wooden handles

Minuses

- valves on steam tanks require rewinding with FUM tape

From 8990 ₽

VIEW OFFER

Using the Malinovka moonshine still, you can obtain the best purified products, as well as flavor the drink directly during distillation. There are several models, differing only in the volume of the distillation tank (12, 20, 30 l). The tank of the device is made of stainless steel and has a reinforced bottom. The wide inlet opening of the cube (11 cm) greatly facilitates the maintenance of the device after distillation.

Two steam chambers guarantee 100% purification of the finished drink from foreign impurities and oils, and a silicone gasket on the neck of the cube prevents the appearance of an unpleasant odor in the apartment. In addition to the cleaning function, one of the steamers plays the role of a “gin basket”, that is, it is used to add flavoring components to the drink: aromatic herbs, berries, pine needles, zest, nuts.

The temperature control of the process is carried out using three thermometers: two electronic and one analog. The device is characterized by high productivity and efficiency. So, on average, in an hour you can get 3 liters of the finished drink, and you can brew moonshine on any type of stove, including induction. With the help of additional equipment (tsar and reflux condenser), the owner of this device has the opportunity to prepare a product with a strength of up to 96%.

Double distillation moonshine still 20/35/t with drawers

pros

- strength of all parts

- normal design

- high quality final product

Minuses

- the design of the drawer is not thought out

From 9790 ₽

Probably, the quality of production at the plant is poor, because the flaring of the cooler pipes is poor, the drawers are made in such a way that, for example, it is impossible to pull out the Panchenkov nozzle for washing without damaging it. You have to work only with a stainless steel analogue, and its efficiency is much worse than copper or combined, but you can wash it together.

MAGARYCH Magarych Mashkovsky Export 20

pros

- build quality

- original leather inserts with logo

- excellent compactness

Minuses

- very low performance

From 8090 ₽

Phoenix Folk 20 liters

pros

- modern design

- quality steel

Minuses

- weak side seams - leaked after a year

- in the steam tank there are iron inserts that rusted after two weeks

- small coil - poor cooling

From 8000 ₽

MAGARYCH Magarych Mashkovsky Export 12

pros

- great design

- quality of all details

- You can add a drawer to improve quality

Minuses

- narrow neck

- low productivity

From 6330 ₽

Phoenix Miner 12 liters

pros

- sufficiently compact

- thermometer built into the tank

- collapsible glass steamer

- high performance

Minuses

- not found

From 5500 ₽

distillation columns with steam steamer

Dobry Zhar Universal system Source 25 liters

pros

- high reliability

- build quality

- heating on any heat source

- three degrees of purification

- full set

Minuses

- not found

From 20540 ₽

Cuprum & Steel Star Plus 40 liters

pros

- copper + steel AISI 430

- steam steamer of the latest design

- Works also on induction hobs

- PVC hoses for water

- for collecting distillate - a hose made of medical silicone

Minuses

- not found

From 25900 ₽

THERMOSPHERE Ararat-7 20 liters

pros

- triple distillation in one go

- three degrees of purification

- bubble steamer - removes 98% of impurities

Minuses

- not found

From 15490 ₽

The domestic plant Thermosphere, Balashikha, Moscow region, is the only enterprise operating using German technologies and equipment from Germany. Ararat-7 was developed jointly with German specialists, and in 2021 it was recognized as the best product of the year. Based on popularity, it was awarded the People's Mark award.

Dobry Zhar Universal system Flagship 50 liters

pros

- tubular refrigerator

- high degree of purification

- argon welding guarantees tightness

- Digital Thermometer

- complete with hoses for water and distillate

Minuses

- not found

From 29250 ₽

Cuprum & Steel Star Plus 30 liters

pros

- copper column

- steamer with drain valve

- powerful flow-type refrigerator

- low water consumption

- suitable for all types of slabs

Minuses

- not found

From 24150 ₽

How to choose a moonshine still!?

Hamsters welcome you, friends!

Today's post will be devoted to the subtle science in the field of choosing moonshine stills. If during the distillation or rectification process you have flakes in the selection, and throughout the distillation the moonshine has an unpleasant smell and taste, then you have hooked hands, or you have fallen for an advertising company of unscrupulous manufacturers. Today we will find out what structural components you should pay attention to first, what kind of steel should be in these shaitan machines and what kind of thermal controller should be installed in the distillation cube. I am sure this post will be useful not only for beginners, but also for professionals in this difficult craft.

This issue should have started like this: a beautiful moonshine still. The mash column is all made of stainless steel. Clamp connections that allow you to quickly assemble and disassemble the apparatus, modifying it structurally for various types of distillations. In general, in appearance these pieces of iron look like a whole adult construction set. This was a gift to myself for the New Year, since everyone has long known that rivers of beer and tons of liters of strong drinks flow inside every normal person.

Before purchasing a mash column, naturally, hundreds of videos on this topic were reviewed. The principle of operation here is to finely regulate the amount of water supplied to the reflux condenser - a kind of refrigerator that allows you to control the amount of alcohol vapor passed through it. This system requires a precise precision needle tap. To adjust the selection speed, you have to turn the tap literally a fraction of a millimeter. The heating power here should be constant and not change throughout the entire process. These subtle points should ensure maximum separation ability of alcohol fractions inside the column and increase the quality of the selected product.

With an increase in the amount of supplied water, the amount of steam passed through the reflux condenser decreases, the amount of reflux returned to the tank increases, and the reflux number accordingly increases and the strength increases due to repeated evaporation of alcohol. And then there’s whole physics, a bunch of variables that depend only on the design of your device.

In general, immediately after purchasing and unpacking the mash column, I encountered the first problems. When sending, the manufacturer forgot to include a water seal with a lid. This is a device that releases carbon dioxide during the life of yeast and prevents various bacteria from getting into the tank from the air. This is mainly needed for fruit and grain mash, where it can deteriorate during long fermentation. In the case of sugar mash, the water seal allows you to determine the fermentation activity by the number of bubbles emerging.

Why is my distillation cube inconvenient for infusing mash? After the yeast turns the sugars into alcohol and forms a sediment, the mash must be poured into a bucket, the sediment must be cleaned from the cube, and then the mash must be poured from the bucket back into the cube. Trying to get into the hole without getting anything dirty. Men are familiar with this situation! Fortunately, this problem does not apply to the manufacturers of such tanks, I’m a handyman and that’s normal.

For such cases, there are more thoughtful cube designs. They have a full-fledged lid with latches, a drain valve for mash, markings with the displacement inside, and so on. In general, in this pan you can cook a huge portion of borscht for the whole family.

Braga. Let’s immediately make a reservation that during the experiments we will use exclusively the classic one - sugar. Using turbo yeast, which allows you to process all the sugars in a fairly short period of time of a few days.

During the first distillation of the mash into raw alcohol, it was noticed that the moonshine still had some inconsistencies in the configuration. There were clearly differences between what was written on the website and what actually arrived.

When purchasing, a cube with an electrical box and a 2 kW heating element was selected. The website says that the electrical box allows you to control the temperature using a dimmer, which maintains the same temperature in the cube throughout the entire distillation. It looks something like this in the picture: a dimmer in a stainless box, a heating element and a good long wire that has a plug combined with a switch.

The wire, which turned out to be in fact, was no more than one meter long and could hardly reach the outlet. My Euro plug does not include any switches in its design. With the temperature controller, everything turned out to be much more interesting than one might expect. During the distillation process, I had to step away for a minute and turn off the heat! But upon returning, turning it back on using the adjustment knob simply did not work. Curious!

For unknown reasons, the thermostat had a fairly large time inertia between turning on and off. After waiting for the heating to stop at the set temperature, I began to observe, while simultaneously starting the stopwatch on my phone. 10 minutes passed - no progress. Closer to the 12th minute, something inside the cube clicked and the heating element hissed, as if hinting that the heating process had begun. The trick of this thermostat is that as soon as the heating of the cube stops, the selection of alcohol also stops. Take a little while the cube heats up, then rest for 12 minutes and so on. You can completely forget about fractional distillation with this mode; here it will be impossible to stabilize the column and select the so-called “heads”, which contain acetone and other nasty things that need to be gotten rid of during the distillation process.

Having unscrewed the front bolt and looked inside the electrical box, an interesting picture appeared there. Have you ever seen what a thermostat looks like in a Soviet refrigerator?! Well, this is the same thing, this masterpiece is called “Capillary thermostat”. Reliable as a Swiss watch, it can work continuously for a hundred years. It is based on the principle of expansion of liquid inside a capillary tube, which, at a certain pressure, mechanically closes and opens contacts. Inertia here depends on the time of year, the volume of the cube and the position of the stars in the sky. A dimmer works on a different principle; it allows you to regulate the power at the load by cutting off some part of the half-wave of the mains voltage. It turns out that something wrong was clearly placed inside the box for the mash column.

The company's technical support answered this question simply: these are constructive improvements that a whole group of technologists are working on. Despite this, the manufacturer replaced the thermostat with a normal one without any questions. But he didn’t suit me either for personal reasons. What was missing here was a power supply indicator and a good cooling system, since the cube during operation heats up to hundreds of degrees.

Power indication could be implemented in two ways. The first is to add two back-to-back diodes to the capacitor charging circuit in the dimmer circuit, and the second option is to introduce a neon in parallel with the power contacts of the triac. The neon light turned out to be a less universal solution, since at maximum power it stopped shining during the adjustment process. The LED shines constantly. Having decided on the most suitable circuit, a board was laid out with thick power traces, terminals for clamping and soldering of wires. The most important thing is that there is a compact 12-volt power supply that will power the fan and thereby cool the triac during operation. The most convenient way to order the production of printed circuit boards is through the world-famous PCBWay service

Two weeks after the order, the courier knocked on the window of the 4th floor and pushed through a bag with 10 circuit boards. I don’t know how he came back down later, but the fees were excellent! We place the elements on the board according to the indicated locations. On the side we place a miniature Hi-Link 12 volt power supply. It looks like a fairly compact design. We connect 220 volts and check how everything works.

The wires inside the electrical box were soldered directly into the mounting holes on the board to minimize losses, bypassing the clamping blocks. The end result looks like this: a radiator, a fan, and a board screwed on at an angle. Elon Musk’s senior officers are probably assembling the same “Kulibins”. The main thing is that nothing exploded during the tests and the power adjustment works like a clock with a power indicator and good airflow.

We connect the heating element to the electrical box. The ideal version of the cube is when the heating element sits on the clamp and is not screwed into it through a thread, as in my case. Take this moment into account!

During operation, the infrared camera clearly shows how the temperature of the tank and the electrical box differ. To date, about 10 stages have passed, the temperature control scheme is pleasing. The only point that should be taken into account is the load capacity of the wiring in your apartment. Under load, the voltage in the network drops by 6 volts, therefore, instead of the required 2 kW, the heating element produces 1.8 kW!

A more universal device for finely adjusting the heating of the cube can be used digital dimmers from China. Here the power can be changed in increments of one percent, the load capacity is up to 10 kW, and there is a voltmeter on top, which you can use to see what voltage is coming to the heating element or any other device.

Let's return to the mash column. In the process of adjusting the water supply with needle taps on the reflux condenser, for some reason I couldn’t shake the feeling that this tap was about to break off and “Golden Rain” would begin to flow from the neighbors below. The quick releases are held on by slippery pins and there is no additional fixation. To understand, in normal devices, quick releases are installed on threaded connections, and when it comes to electricity, water and flammable materials, safety precautions should be paramount.

I also advise you to pay attention to the thickness of the hoses that come with the kit. On the mash column it was only 8 mm, but a normal apparatus should have 10 mm. Of course, the thicker the better, since there is a possibility that in thin tubes at high temperatures on the reflux condenser, an air lock will form and the entire distillation will go down the drain. Quick releases are the most ingenious way to connect hoses today!

At the stage of distilling the mash from raw alcohol, for unknown reasons, some flakes of a white, incomprehensible substance began to fall into the selection at a certain strength. The first thing that came to mind was the poorly washed components of the column structure. After thoroughly washing the apparatus and re-distilling, the situation did not change. It was difficult to imagine that alcohol vapor rising from the cube would take with it dirt particles.

The first distillation is such a thing, it doesn’t matter what cockroaches are pouring from the column. On the second fractional stage, things were much more interesting. All the resulting alcohol had an unpleasant taste and a strange smell throughout the entire run. Suspicion fell on the fact that the column had poor separating ability, since a regular Panchenkov nozzle was used inside the drawer, and the drawer itself, which came complete with the mash column, was only 39 centimeters long. This is very little! Another drawer with a height of 70 cm and a more efficient spiral-prismatic nozzle made of stainless steel were ordered. Now, in theory, the separating ability of the column should be sufficient to make candy out of stinking alcohol.

But that was not the case, the same alcohol was distilled 2 times, but the result was the same, a strange smell and taste throughout the entire run. For a long time, wondering what the problem could be, I had no choice but to accept the fact that I was probably violating the rules somewhere. the distillation process and I’m doing something wrong!

The answers to all questions were clearly visible from the very beginning of the purchase. The first thing that confused me when working with the column was the poorly processed internal joints of the clamp and a piece of pipe. This made it difficult to properly insert the Panchenkov net into the drawer. I am not a proud person, I can handle everything myself. Then, after a while, go ahead and check the steel for quality. I once had experience working with low-quality stainless steel, although I didn’t have to run alcohol through it.

In general, all the cards were revealed by the Antik H180M etching paste, which contains nitrate and fluoride acids. In simple terms, it is an acid gel that is used to clean weld seams after welding. And then everything fell into place. It turned out that the clamp in the design of the lid for the tank was made of normal stainless steel, and the rest of the pipe was made of technical grade. This reacting swamp stinks, indescribably! The same situation was with the 39 centimeter drawer. The clamp insert is good, but the pipe welded to it is crap.

The further task was to coat everything that was possible and not possible with this paste. As a result of acid treatments, an interesting picture emerged. The entire apparatus is randomly made from different stainless steels. If, for example, the drawer reacted, then there would be no 90-degree turns. The main refrigerator reacted with all the different tubes inside, but the reflux condenser did not. This moonshine still comes out, a hodgepodge of different stainless steels, ordered from different manufacturers, at different factories at different times of the year. No matter how good the alcohol you pour into the cube, after interacting with the steel of the refrigerator it will be spoiled.

But that is not all. I also ordered a parrot, which can be used to check the strength of alcohol in the stream. And its quality turned out to be even better than the entire mash column taken together. I don’t know, maybe the manufacturer doesn’t know that the purchasing department at his factory has staged a sabotage. Anything can happen, but this parrot is not cheap. What can we say about the prices, for example, a diopter here costs $68, but on the Internet you can find it 3 times cheaper. Business and nothing personal. A diopter is the very first thing that you need to purchase for your device so that you can do fractional distillations in the pre-distillation mode, where the separation of raw alcohol fractions will be best.

Checking the quality of steel with a magnet is absolutely useless. For example, both good and bad drawers do not have magnetic properties. Steel turned 90 degrees, although good, is perfectly magnetic!

Today, every manufacturer of moonshine stills can find some irregularities in the production cycle. These are parts from a distillation column purchased a little later. As in the case described above, all parts of the structure were coated with etching paste for stainless steel. In 30 minutes, the only thing that reacted was the fitting on the needle valve, and this reaction was within the normal range. But, despite the good steel, a small problem was still able to come out after several rectifications.

The internal seams of Dimroth's refrigerator began to rust. The manufacturer answered this simply: the master forgot to coat the seam with etching paste after welding, and offered to send the refrigerator at his own expense to the factory and fix everything. This is fine! Because indeed, after the etching paste, there were no further darkenings and I’m sure the manufacturer will monitor this point.

Looking ahead, I will say that the cost of a distillation column turned out to be almost comparable to a mash column, and what is the point of buying mash columns today is generally unclear, they are obsolete in their design and have difficulties in operation. It's like a car with a manual transmission, in which you constantly need to tighten the taps and make sure that the water pressure through the dephlegmator does not drop. Working with a distillation column will be shown in the next post, since in this post we are just looking at what you need to pay attention to when buying a moonshine still.

Let's look at a simple part that comes with many moonshine stills. Tap fitting for the cooling system. What should I do with him!? It doesn't fit under the kitchen faucet. A way out of the situation was found in the bathroom, since the faucet there was old and the first run was done with a dozen hoses lying on the floor from the bathtub to the kitchen.

To avoid such a misunderstanding, you need to buy a diverter - this is a thing that switches the water pressure in different directions. If you want to wash the dishes, if you want to make moonshine.

Now let's see what a nipple for installing a thermometer can be like. As you can see, in the cube it is implemented in the form of a welded tube into which the thermometer probe is inserted. The disadvantage of this design is inertia and deterioration in measurement accuracy. It is better when the probe is placed inside the point being measured - directly, through the clamp nipple. This one was independently welded into the drawer.

In general, after all that was seen, a letter was written to the manufacturer’s plant with a request to return the money for the low-quality product. We agreed that I keep the cube for myself, and the top of the cube is digested using normal stainless steel and for the time spent I will be compensated for two packs of wasted translated good American yeast, costing $15

A week later, the lid under the clamp was overcooked. No questions. But in the process of returning the money, an interesting point emerged regarding the cost of the cube. The price on the website is indicated without the lid, and its cost is, of course, calculated separately. Plus the price of the electrical box, and plus the price for the ferrimagnetic bottom if you want to work with an induction cooker, and the total amount ends up being a pretty penny. I learned about the ferromagnetic bottom when I started working with the distillation column; I wanted to increase the heating power, but of course it didn’t work out.

In general, this whole business with moonshine stills is not cheap and you always need to be on your guard, since most of the funds can be spent on additional consumables, which will cost three times as much from most similar manufacturers.

Let's take another look at the cube. You may notice that the lid is clamped here through the wings, and unscrewing them is a rather lazy task. Now imagine that your entire moonshine still is assembled on such lambs, can you imagine!? There are also such units, you spend half a day assembling it, and then disassembling it the same way, no pleasure. Today, the best clamps are clamps; they take more than two seconds to put on and take off, I recommend them.

As for the two packs of yeast that they promised to compensate me for, the manufacturer kept its promise and sent two packs of Pakmaya yeast. It’s very touching on their part, since this is not an alcoholic strain of yeast and on the back it says how much flour should be mixed with this pack. I don't think I'm doing any baking here :)

In general, there are no words, only emotions. And the problem is not that the manufacturer saves on everything possible, but that you won’t even be able to tell anyone about it, since comments on YouTube can be disabled. Fortunately, there are third-party services where you can leave a review and write what you didn’t like when working with a particular product.

This post should have started like this: Table. Correctly set light. There are a lot of wonderful pieces of hardware lying around for what you love. A beautiful representation of the technical process of producing alcohol. But in fact, what? A beautiful presentation has nothing to do with the real world and unfortunately the post turned out the way it did.

Looking ahead, I will say that if you pour low-quality alcohol diluted with water into an oak barrel to obtain cognac or brandy, you will simply ruin it. The barrel will absorb the contents into the wood, and then give off unpleasant aromas the second time it is filled. During this film, we had to distill the same alcohol 3 times on a mash column, in different temperature conditions and with different techniques for supplying water to the reflux condenser. But the result was the same, alcohol with an off taste. The situation was changed by the distillation column. At the very beginning of the film it was said that throughout all the experiments we would use exclusively classic sugar mashes.

These are not apples for Calvados, not grapes for chacha, nor jam from which you can get pleasant notes of raw materials in the organoleptic taste. And sugar, there is not a single note in it that remains after distillation. Although village moonshine is famous for this, there are heads and smelly tails in the selection, acetone and acetaldehyde with fusel oils and many people like it. But not for me.

I’m already silent about primitive moonshine stills with steamers or double distillation; the product obtained by these antediluvian stills is cleaned with coal, eggs, potassium permanganate, and intermediate cleaning is carried out. If the moonshine is of poor quality, then even coal is not able to correct the problem, except that a little less fusel will be felt in the organoleptic taste. It varies in quality and in this frame, it’s clearly visible! The right sample of activated coconut charcoal turned out to be more activated than the left one.

My old people, for example, made exclusively tinctures with moonshine, since it was simply impossible to drink the raw materials that stank of horseradish. I don’t rule out that I have no taste, but distilling sugar mash is not a rewarding task, it only requires rectification.

Distillation apparatuses can be called columns with good strengthening, but pure alcohol without foreign impurities cannot be obtained on it. The distillation column is more universal in its design and is intended for high-quality separation of liquid mixtures in raw alcohol. You can already get the purest alcohol from it, just like in a pharmacy. If you reduce the height of the drawer, you can also obtain aromatic distillates from apples and other good-smelling crap from your garden.

We will talk about working with a distillation column in one of the following issues, since we cannot show everything in one post. There we will see how much alcohol can be obtained from one kilogram of sugar, which hydrometers are best to use, the main differences between thermometers and much more. Let's make a bunch of tinctures and conduct experiments with an ultrasonic bath.

This whole craft turned out to be quite expensive, labor-intensive, time-consuming, but I like it, it can be called a new type of hobby in which every day you learn something new and interesting, while getting drunk little by little.

For reference. This issue was planned as a manual on distilling sugar mash into alcohol, which can be infused in a barrel, made into tinctures, used as an antiseptic, and much more. But during the filming process, something clearly went wrong and the footage turned out to be more than 11 hours. In the next issues there will be rough mathematics, during which we will get an excellent alcohol with a strength of 96.8 degrees. But that’s all later! And for today, I think that's enough.

Archive with useful things

Full video of the project on YouTube

Our Instagram