Difficulties in disassembly during repairs

People buy top-loading washing machines much less frequently than front-loading ones - that’s a fact.

- The tightness of the machine components creates difficulties during disassembly

- Increased vibration during spin cycle

- On some machines it is not possible to adjust the level of the rear legs

- Corrosion of the top cover from moisture

- Spontaneous opening of the drum flaps due to imbalance

- Narrow and deep, perfect for tight bath spaces, closets or kitchens

- No need to bend over to fold laundry

- Possibility to interrupt the program and add laundry

- Child safety. Control panel location.

Features and nuances for self-repair of verticals:

The device contains the same elements (pressure switch, water intake valve, drum, tank, control board, pump, and so on). The drum axis is structurally made on two bearings; a self-positioning sensor is sometimes located on the tank (the drum is fixed with the flaps up).

We will show the dismantling of components using the example of Electrolux:

1. Using a screwdriver, release the control panel from the sides 2. Pull the plastic panel up and slide it towards you 3. Tilt it at a slight angle towards you to remove the wires from the board connectors 4. Remove the panel

To remove the electronic control module, disconnect the remaining wires and unscrew the screws shown in the figure. For quick and correct assembly, take photographs of the connection points of the wire loops. To remove the water fill valve, disconnect the rubber hoses from the clamps and dismantle them. Unplug the wires and press on the holes from the outside to press out the valve.

To remove the side panels, unscrew several screws; do not forget to save the washers for grounding the case. Bend the wall from below with your hand and slide it down.

After removing the two sides, access to the screws for removing the front panel appeared. Unscrew them.

To remove the NTC sensors and position the DSP drum itself, it is enough to remove the right wall and dismantle them.

- Frequent malfunction - there is no way to change the program:

Example - Hotpoint Ariston ARTL 1047.

Many “craftsmen” sin that the control module is to blame for everything. But no!

It is enough to unscrew two bolts from the back and remove the control panel.

This very cracked handle is the culprit. Use a metal ring (antenna plug for example).

By squeezing the plastic handle, the ring will prevent programs from skipping.

- Exploded top of the Indesit, Ariston vertical:

001 - control knob 002 – white on/off/reset buttons 003 - white control panel 004 – bitron switch 005 – function keys 007 – display 008 – cover handle 010 – dispenser release lever 011 – dispenser hook spring 012 – dispenser release button 016 – cover support 018 – partition with shock absorber 021 – door locking device 022 – white dispenser 023 – siphon cover 026 – control panel wiring 027 – 8-pos.

potentiometer There is an opinion that two drum supports instead of one are good.

This is not so, and in the case of the “vertical” it is simply a forced engineering decision. The service life of the drum bearings does not increase even by a minute.

If the screws are difficult to unscrew, heat them with a blowtorch.

Use special lubricant for oil seals - Litol-24, CIATIM-221, CV joints-4M, etc.

On the Kandy, in order to change the bearings, you need to disassemble the entire machine down to the screw! And what about the wild cramped conditions in the depths of the “verticals”. Sometimes you have to do everything literally by touch.

Preparatory work

We remove one by one the top cover, the back panel, the powder tray, unscrew the control panel, and remove the front panel. Then we get to the back of the machine and turn off the engine and remove the drive belt. The engine is secured with two bolts. After unscrewing them, remove the engine. Let's move on to the heating element, which is fixed below. We turn off the power from it. The location of the wires needs to be remembered, or better yet, sketched or photographed. Unscrew and remove the upper and lower counterweights one by one. Disconnect the filler pipe from the tank, then all the wires that lead to the tank. All that remains is to disconnect the shock absorbers and remove the tank from the springs. Now the tank can be removed from the machine body. To do this, you need to lift it a little and pull it towards you.

Source

How to disassemble a Hotpoint-Ariston washing machine?

Like any complex technical device, Ariston brand washing machines also tend to break down. Certain types of faults can be eliminated solely by almost completely disassembling the unit into its component parts. Since the majority of such malfunctions of the Hotpoint-Ariston washing machine can be completely corrected on your own, the independent disassembly procedure should not be confusing. We will look at how to put this into practice in this publication.

Preparation

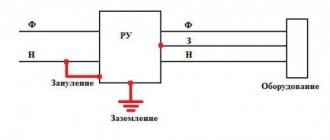

First of all, you need to disconnect the washing machine from all communications:

- disconnect from the power supply;

- unscrew the inlet hose;

- We disconnect the drain hose from the sewer (if it is permanently connected).

It is advisable to drain the remaining water from the tank in advance using a drain filter or a tube near it. Next, you should prepare free space for the location of the washing unit itself and the components and components removed from it.

We prepare the required tools. To disassemble the Ariston washing machine we will need:

- screwdrivers (phillips, flat, hex) or screwdriver with a set of bits of various types;

- open-end wrenches 8 mm and 10 mm;

- knob with heads 7, 8, 12, 14 mm;

- pliers;

- wire cutters;

- hammer and block of wood;

- A puller for bearings will not be superfluous (when disassembling the washing machine is carried out in order to replace them);

- hacksaw with blade for metal.

Step-by-step instruction

Having completed the preparatory work, we proceed to disassemble the Hotpoint-Ariston washing machine.

Washing machine top cover

Without dismantling the top, there is no way to remove the other walls of the unit. Therefore, unscrew the fastening screws from the back, move the cover back and remove it from its place.

On top there is a large block that equalizes the position of the washing machine (counterweight, balancer), which blocks access to the tank, drum and certain sensors, however, it is quite possible to get to the noise filter and control panel. Remove its bolts and move the balancer to the side.

Rear and front panels

From the rear wall, use a Phillips screwdriver to unscrew several screws holding the back wall. By removing the back panel, many components and parts become available to us: a drum pulley, a drive belt, a motor, a thermoelectric heater (TEH) and a temperature sensor.

Carefully place the washing machine on its left side. If your modification has a bottom, then remove it; if there is no bottom, then this makes the task easier. Through the bottom we can get to the drain pipe, filter, pump, electric motor and dampers.

Now we dismantle the front panel. We unscrew the 2 screws located under the top cover of the machine body in the front right and front left corners. We unscrew the screws located under the tray of the washing unit, and after that we take hold of the control panel and drag it upward - the panel will come off freely.

Moving elements

A pulley with a belt is fixed to the back of the tank. Carefully remove the belt from the motor pulley first, and then from the large pulley.

First steps

The main thing is to remember that a full guarantee for correcting existing breakdowns can only be given by a certified technician working at an enterprise that also has a license to carry out work. Independent actions do not always, but often lead to the deterioration of the equipment.

But, if you decide to carry out the repair yourself, the first step should be a detailed study of the instructions.

Where should you start?

In the case of Ariston washing machines, it is permissible to connect drain hoses using two schemes: through an outlet near the sewer pipes, or to an outlet near the sink siphon. Disabling should not cause problems in either situation.

After this, they move on to preparing the tools.

We will need the following devices:

What do we do next?

The process of disassembling the washing machine continues after preparing the tools.

Do-it-yourself bearing replacement in an Ariston washing machine

Today, bearings are used in almost all mechanical devices, including automatic washing machines (hereinafter also referred to as SM, ASM). The main task of the bearing is to minimize friction between the surfaces of the shaft and sleeve moving relative to each other during rotation. According to their design, modern bearings are divided into several varieties. In modern SM drums rotate on ball bearings, as well as on their roller “counterparts”. We will tell you about replacing the bearing in an Ariston washing machine in our article.

Causes and symptoms of bearing wear in washing machines

Ball bearings are designed for a long service life, on average up to 10 years. In order for the devices to work for a long time, their parts are well adjusted and generously lubricated with special substances. To prevent water from entering the mechanisms, the bearings are hermetically sealed with seals made of special types of rubber or caoutchouc.

During washing and spinning, the drum rotates inside the tank on ball bearings mounted on the shaft. Replacing bearings in an Ariston washing machine, as well as other well-known brands, is inevitable after water gets into mechanical parts. This occurs due to damage to the seals, which lose their elasticity over time. The reason is exposure to an external aggressive environment: water and detergents. Water accelerates wear of parts by washing away lubricant.

Accelerated wear is caused not only by damage to the seals, but also by improper operation of washing machines. If you often load a large amount of laundry into the AFM and spin it at maximum drum speed, high loads lead to the following symptoms:

- strong vibrations and hum while spinning clothes;

- play of the drum when it rocks, which can be felt with your hands;

- slow rotation or jamming of the drum during washing and spinning.

If signs of a defect are evident, replacing the bearings yourself requires preliminary preparation.

Preparing to replace the bearing

To get started, you need to have a set of tools for disassembling the unit:

- pliers and platypuses;

- a set of slotted and Phillips screwdrivers;

- adjustable wrench and set of open-end wrenches;

- metal rod;

- removable device for bearings (preferably, but not required);

- sealant and WD-40 fluid;

- hammer.

It should be noted that bearings are quite easy to change in models of the Margarita 2000 series - such as AVSL 109 and others, with metal and plastic tanks that can be disassembled. But there are other models of machines with a non-removable tank made of plastic. In these cases, you will have to purchase and replace the entire expensive unit.

Some craftsmen manage to cut a non-separable plastic tank, change the bearings and oil seal, and then glue it together with sealant and fasten it with self-tapping screws. But the consequences of such repairs are unpredictable - the tank can leak at any time, as it experiences heavy loads during spinning.

Before you change the bearings on your Hotpoint Ariston washing machine, you need to purchase the same new ones. The markings can be found in online stores that sell spare parts for ACM. New seals for ball bearings also need to be purchased. In the place where the repairs will be carried out, you need to free up a free space of at least 3–4 m2. A free perimeter around the machine is necessary for access to all its components.

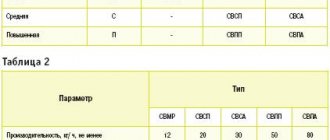

Characteristics and parameters of popular models of Hotpoint-Ariston washing machines: review and prices

For a large family, it is worth choosing washing machines with sufficient capacity. Agree, when there are children in the house, it is better to buy models with a load of dry laundry of at least 5 kg. This makes it possible to wash clothes faster. Our experts have prepared for you a detailed review of washing machines that are best suited for a large family.

| Model | Characteristic | Price |

| Hotpoint-Ariston RSM 601 W |

| 16 000 |

| Hotpoint-Ariston VMUF 501 B |

| 15 000 |

| Hotpoint-Ariston VML 7023 B |

| 20 000 |

| Hotpoint-Ariston CAWD 129 |

| 33 000 |

| Hotpoint-Ariston WMTL 601 |

| 25 000 |

Some Ariston washing machines have a backlit mode switch. This is a very convenient addition to the main options of the device.

Washing machines are able to independently control the amount of foam in the drum, so an emergency spin or rinse mode can be started.

How to unlock

If you need to open the washing machine immediately, even if it’s an emergency, you can use one of the known methods. Manufacturers indicate them in the instructions - the procedure depends on the specific model. However, there are several basic techniques for unlocking a lock.

Before you begin repairing your washing machine yourself, you should familiarize yourself with the following recommendations:

- Before any manipulations with a locked door, you need to unplug the machine from the outlet.

- Make sure there is no water in the drum. If necessary, drain it through the filter.

- If the indicator shows the presence of water in the tank, and the wash is completed, you need to click on “Drain water”.

- If an unfamiliar code appears on the indicator, you need to find the instructions and look at its designation.

- If the board or any control element is burnt out, you do not need to figure it out yourself. Only an experienced technician will be able to get the device working.

- If the pump works even in the absence of water, you just need to unplug the washing machine and call a technician.

Using a rope

If the door does not open using the on/off switch, you can try to unlock it yourself. Before doing this, you need to turn off the power to the washing machine and arm yourself with a rubber spatula and a thin rope. Its length should exceed the circumference of the door rim by 20-30 cm. Between the hatch and the door there is a small gap where you need to insert one end of the rope. Use a putty knife or flat-tip screwdriver to push it further. Then pull out the other end and pull both at the same time - the door should swing open. This method is designed to pry up the latch when the door breaks.

Power off

If we consider a blocked door as a “freeze”, it is logical to come to a solution in the form of a reboot. To do this, you need to unplug the machine from the outlet and turn it on again after 1-2 minutes. Then wait a little more time and try to open the door. The fact is that at the moment of switching on, the control module checks the condition of the door. If a failure occurs in the blocker, it will return to normal. Otherwise, you will have to start a new washing program and catch the moment when the door unlocks. This can happen in a matter of seconds - it’s better not to leave the washing machine.

Causes

The first thing you should not do if the washing machine does not open after washing is to use physical force. In this case, the hatch will be damaged, and the door is unlikely to yield to efforts. Before contacting a technician, you should exclude obvious factors that influence why the hatch is jammed.

Water in tank

The main purpose of the locking mechanism is to protect against water pouring out of the washing machine drum. That is why the hatch is securely closed at all stages of washing. If the drainage system does not work well, water will remain in the tank. In this case, it is necessary to lure the pump (pump), this problem may arise due to a blockage or an initial defect. Pump wear is affected by water hardness, powder quality and washing frequency.

Sometimes water may not drain due to a breakdown of the pressure switch - the water level sensor. The machine believes that the tank is empty, the drain does not occur - the door remains locked. New washing machine models have a separate “water drain” function. This problem is especially common in Samsung models.

Timed out

The machine immediately signals the end of the wash, but the door may remain closed for some time. A few minutes after washing are allotted to complete all processes correctly. After 2-3 minutes, the door will unlock automatically. Of course, on some models the hatch opens immediately after the signal, but it won’t hurt to wait at least 30-40 seconds.

If you urgently need to stop work, but there is no need to remove or put in laundry, you can simply click on “Pause”. This will pause the operation; you will not have to open the door with physical force. Then, by clicking on the same button, you can resume the process.

Lack of light

An annoying situation familiar to many: there were only a few minutes left before the wash was completed when the electricity went out. It will not be possible to open the washing machine door until it is resumed - the locking mechanism is broken. If the light is expected soon, it is better to just wait.

In case of long-term power loss, you should not leave laundry in the machine drum. However, you cannot pull it out simply by pulling a special cable. In this case, water from the drum will pour onto the floor, and the threat of flooding the neighbors will become quite real. Before taking out the laundry, you need to drain the water: unscrew the lower facade, pour the water into the basins through the filter. The volume of liquid can be 10-15 liters, this must be taken into account. After the drum is completely empty, the door may open in response to the draining of water. Otherwise, you will have to follow the instructions for the machine.

Stopping the program

If the washing machine door does not open, even though the operating time has expired, and the timer shows the opposite, you need to understand the reasons. The program could stop as a result of the following problems:

- water does not enter the tank;

- the liquid did not drain out after washing;

- heating element failure;

- accidental pressing of buttons after starting the wash.

How to avoid the problem

Often the cause of a broken door lock is careless handling of the washing machine. You need to choose the right operating modes, correctly calculate the weight of the laundry and use high-quality powder. Before turning it on for the first time, be sure to read the instructions and start the washing machine only according to it.

The washing machine door locking after finishing washing is a common problem. The reasons for it are varied, from a jammed latch to burnt electronics. Self-repair and diagnostics are only permissible in case of mechanical problems. In this case, you can try different methods by first studying the instructions for a specific model.

Receive one of the most read articles by email once a day. Join us on Facebook and VKontakte.

As long as the washing machine is in washing mode, its door will be locked. This option is provided by manufacturers of washing equipment intentionally and is necessary in order to avoid various unpleasant accidents with spilling a large amount of water on the floor and subsequent failure of the entire drum of the washing machine. The hatch unlocks automatically when the selected washing program ends. Of course, there are situations when the wash is completed, but the hatch remains blocked for one reason or another.

It is important to understand that when the machine ends a washing program, it does not end the program. First, the device goes into diagnostic mode, which takes 3-5 minutes. Only after its completion the “automatic machine” gives the corresponding sound signal, and with it a command to open the door. The door may not open automatically due to a power outage, water not draining from the drum, a broken locking device, or a broken handle. It is best to call a professional in such a situation, but there are some things you can do yourself.