A blender is a common small household appliance that almost every modern housewife has in the kitchen. With its help, you can easily grind fruits and vegetables into puree, grind minced meat or beat fluffy biscuit dough. Unfortunately, over time, all equipment breaks down and begins to need repair. In order to handle the repair yourself without damaging the equipment further, you need to find out in advance how to disassemble your particular blender.

How does a blender work?

There are three types of these small appliances on the market today: the handheld, the stationary, and the food processor companion. Each type is driven by an electric motor, which activates the working elements of the mechanism. After connecting to a direct source of electricity and turning on the “Start” button, the knife begins to rotate, chopping the product in the bowl along one closed path.

During operation, the electric motor, bypassing the output shaft and spindle, transmits torque to the blade. As a result, you can adjust the speed of chopping fruits, vegetables or meat by controlling the grind. A circulation is formed inside the bowl - the crushed food moves to the background, and the front moves towards the blades.

This phenomenon is characteristic of powerful technology that is properly designed. Budget models do not always allow you to easily and quickly grind food to the desired consistency. A circulation is not formed, as a result of which the knives rotate through the air without touching the product. This feature is not always the cause of breakdowns - most likely, the power of your model is not enough to cope with the task.

If you are going to repair the blender yourself, we recommend that you take into account its operating principle. This will make it easier to identify the source of the malfunction, as well as disassemble, repair and reassemble the equipment without damaging other elements of the mechanism.

Types of blenders

Today there are three types of blenders available:

- Stationary

- Submersible

- As an option in a food processor.

In all types of blenders, the main component is the electric motor.

But the principles of operation of a household appliance are somewhat different. Stationary blenders are almost identical in their characteristics to food processors. They consist of two main components: an electric motor and a utensil with a knife placed inside it. See also:

How to use a blender correctly

Types of blenders and their design

This is a necessary technique that allows you to replace many devices. A mixer, meat grinder, shaker will no longer take up space in your home, because this invention has all the required attachments. Each housewife can choose any convenient variation for herself: stationary or submersible. Each of them has its own individual design and advantages.

Submersible

Visually, this model resembles a cane to which an attachment is attached. Most often, manufacturers include several functional components that allow you to quickly beat, mix or grind products. The peculiarity of this model is the need for constant monitoring, since it will not be able to work without your help.

Our service center offers its services for repairing household appliances at a competitive price. We repair any breakdowns of modern household appliances. Leave a request and get a 15% discount - Leave a request

The submersible view has a simple design:

- engine;

- spindle;

- Control block.

With their help, products crushed in a bowl can turn into a puree or emulsion with small pieces in just a couple of minutes. It will also be convenient to whip egg whites or mix ingredients using special attachments.

It is worth noting that immersion-type models are not suitable for chopping, whipping or mixing large volumes of products. They go on sale with low power, which is enough for domestic use. If you neglect this point, your model will quickly break.

Stationary

Unlike a manual one, a stationary one can work independently. You can load the products you need for chopping into it, press the “Start” button and continue doing other things. The classic model of this type consists of a main body and a bowl, which is attached to the top. If necessary, you can independently install the required attachments, which are included in the basic package by the manufacturer.

Stationary consists of the following parts:

- bowls, which are hermetically sealed with a lid;

- engine;

- spindle;

- knife;

- drive shaft;

- blocker;

- switch;

- wires.

Since the structure is more bulky and multi-component, it will be more difficult to repair.

Free hands are the main advantage of stationary models, but using them for chopping, mixing or whipping small amounts of food is irrational. This technique does not perform its duties well if it is not fully loaded.

Blender: what is it?

First you need to understand what a blender is. To describe the device in a simplified way, it is a motor with an attachment (immersion blender) or with a bowl (stationary). The device is very easy to use; it can have a speed controller, several power levels, many attachments and other functionality. Basically, a blender is used to grind food, turn it into puree, slurry, and also for making cocktails.

Symptoms of breakdowns

Before repairing an immersion or stationary blender, it is important to correctly diagnose the breakdown. Any deviation from stable operation signals the occurrence of problems, but there can be many reasons why they appeared. If the whisk of a blender breaks, fixing the problem will not be difficult, because you can see exactly what you are dealing with. But if the problem is hidden deep inside the mechanism, it will not be possible to immediately determine the source. Repairing a submersible with your own hands is possible, but it is best to carefully study the manual for a specific model in advance. In turn, stationary ones need a more professional approach to troubleshooting faults of any complexity, since the mechanism is more complex.

Buzzing sound when turned on, but no action occurs

If you start using it, but instead of stable operation the device hums, but does not grind, there may be several reasons for this problem:

- The blender attachment is broken. In most cases, the working mechanism jams, resulting in a buzzing sound, but no grinding occurs. To eliminate this problem, you need to carefully press the “Start” button after removing the bowl.

- The motor winding is broken. If deactivating the “Start” button did not help return the device to working condition, it is most likely burned out. This problem can be identified by the specific burning smell that appears immediately after switching on. You can fix this problem yourself, but only if you need to replace the brushes. Other reasons may turn out to be expensive in terms of cost, which is irrational, because it will be cheaper to buy new equipment.

If you are not sure that you can fix the problem yourself, we recommend not to tempt fate. Contact the service center, where professional technicians will fix problems of any complexity correctly and efficiently.

No buzzing sound when turned on

When nothing happens when you press the Start button, the absence of a buzzing sound is not always a reason to panic. There may be several reasons why the equipment does not work:

The malfunction may not be hidden in the device itself, but in the outlet. Before you start panicking, check if it works.

If used for a long time or improperly stored, it may happen that the cord may break down. This happens like this: in one or more places it bends and does not allow electricity to pass to the working mechanism. To diagnose a breakdown, you need to open the case, find the power block and the cable screwed to it. In this unit you need to check the presence or absence of current using a special screwdriver. If electricity is supplied, it means the cord is working.

Some models may have fuses that burn out after a while, blocking the operation of the device. The problem can be solved by replacing them with new ones.

If nothing happens when you turn it on, and the above points are fully operational, the engine is most likely burned out. You can diagnose a breakdown by checking the board for visual defects. If it is swollen or the tracks are interrupted, the device cannot be repaired, since the cost of this part will be more expensive than buying new equipment.

Doesn't shred

If the device turns on, but the blade mechanism does not spin, it is most likely jammed or the motor is faulty. The problem can be resolved by replacing or rechecking the correct installation of parts. In some cases, the problem lies in the low power of the blender, which is not enough to grind the product to the desired consistency.

Blender repair in Moscow can be carried out by many service centers. If you don’t know how to restore stable operation of your equipment, contact a specialist. It will help you fix breakdowns of any complexity easily and quickly.

Doesn't spin

What to do if the blade in the blender does not spin? You should not sound the alarm bell, since the reason may be a simple jamming of the mechanism. To correct the situation, you need to remove the bowl and check the knife for malfunctions. You can repair a Philips blender or another brand yourself.

Does not work

If at a certain moment the blender stops working, at best your motor winding has failed. You can fix it yourself or take the equipment to a service center. If basic diagnostics do not produce results, repair of a Bosch or other brand blender is at risk. The source of the breakdown may lie in the board, the repair of which will be expensive. Visual defects on its surface may be the answer to the question why the blender does not work.

Speed controller repair

A breakdown of the speed controller on an immersion blender is one of the most common problems. If this is the case, then the blender is definitely in danger of being disassembled. The functionality of this unit can only be fully checked in a workshop where the necessary equipment is available. If you have the necessary electrical knowledge, you can “ring” this part yourself. You will be able to determine if this is the problem. The regulator is removed from the blender and it is checked in all positions. For normal operation, the regulator contacts are normally closed in each position.

But before disassembling the household appliance, it is worth listening to whether the rotation speed of the knife changes when switching gears.

It should be remembered that in most models, the blender cannot be turned on if the bowl is not connected to it. This option is classic, because since the invention of the blender, its creator emphasized that the equipment will not turn on if the bowl is not installed.

Advice:

Minor faults

In most cases, the stable operation of equipment can be blocked by minor faults. Diagnosing and eliminating them is not difficult, but in some situations a complete repair of the blender may be required.

Issues such as repairing a blender attachment or bowl have no rational solution. In such cases, you need to replace the old part with a new one. Also, before disassembling an immersion blender, read its manual in advance. Some models have a molded plastic body that cannot be repaired.

Blender blade repair

The problem of knives not rotating is a common occurrence that occurs due to improper use. You won't be able to sharpen the blades yourself, but replacing them won't be difficult. If the blender does not turn the knife in the bowl, use the following algorithm:

- remove the bowl;

- remove the knife;

- replace the old knife with a new one.

In some cases, it may be necessary to disassemble the blender, namely the bowl. When carrying out this process, immediately replace the seals, otherwise after a while you will need to return to repairs again.

Cleaning required

When Kenwood does not turn on, repairs are inevitable, but in some cases cleaning can help. It should be carried out only after the blender is disconnected from the network, using the following algorithm:

- remove the bowl from the body;

- remove the ring nut;

- free the cutting mechanism from the object that blocks its operation;

- check the knife for defects;

- wash the parts with warm water using detergent;

- let the parts dry;

- assemble and run the equipment in test mode.

When cleaning, do not use metal or sharp objects, as they can harm the equipment./blockquote>

Replacing the blender blade

Unfortunately, not everyone can sharpen such a knife at home. Therefore, you should not experiment; it is better to purchase a new cutting tool for your blender. In the store you may encounter the following developments:

- You have purchased a new blender blade. In this case, you need to remove the old one and put a new knife in its place. You can disassemble the blender with your own hands; to do this, unplug the blender and remove the bowl from it. We take a clean towel so as not to get hurt on the sharp edge and begin to unscrew the knife from the motor spindle. The threaded connection here is not standard, but left-handed, so we unscrew it in the opposite direction. Sometimes the knife is connected using nuts. In this case, wrenches and pliers will come to your aid.

- There are models in which you need to disassemble the blender bowl to replace the blade. There is no problem in this, but here do not forget to replace the oil seal with a new one.

- And finally, the most inconvenient option is when the bowl cannot be disassembled. In this case, you will have to purchase the entire unit: a bowl and a knife.

Mechanical damage and ways to eliminate it

Knowing how to fix a hand or stationary blender, you can save a lot, because most problems do not require large investments. In some cases, mechanical damage can block the operation of equipment. For diagnostics, you can use different methods, such as: disassembling the blender bowl or body.

Leaking engine gasket and bowl

If during operation a leak develops between the body and the bowl, do not hesitate to repair it. To do this, apply the following algorithm:

- remove the bowl from the body;

- unscrew the spindle;

- replace the old gasket with a new one.

When repairing a Scarlett blender with your own hands or another brand, please note that the spindle has a left-hand thread.

Damage to the lid latch mechanism or attachment

If the lid latches or attachments break during operation, they cannot be repaired. The problem can only be solved by purchasing a new component.

Please note that not every manufacturer offers replacement parts for their models. Take this point into account when choosing equipment, otherwise, after the bowl, lid or nozzle fails, you will have to buy new equipment.

Damage to the blender body

If the blender body is damaged during operation, it cannot be repaired. The problem can only be solved by purchasing new equipment.

Damage to the blender jar

Due to careless use, the bowl latches, which not only hold the container, but also operate the device, may fail. There is no point in trying to repair it, since it cannot be returned to its previous state. The problem can only be solved by purchasing a new bowl.

Leg repair

Most models, including the ELENBERG BL-3205 G blender, are equipped with a leg that cannot be restored. If it is made of metal, you can try to bend it manually. Even after returning to its previous shape, the leg will no longer work as well as before.

Please note that the monolithic leg cannot be restored. If it breaks, you will need to buy a new one that is compatible specifically with your device model.

Gearbox repair

Repairing a blender gearbox is a problem that you may encounter in cases where the equipment operates beyond its capabilities. This problem occurs due to overheating: the heated shaft melts the gear seats, which leads to its jumping off. To eliminate the breakdown, the device must be disassembled and visually inspected. If the gear is intact and just slipped off, it needs to be put back by replacing the fasteners or using superglue.

If during the repair you find that the gear is broken, you need to purchase the same one. No analogues or similar models will fit.

Reliable blenders from SMEG

The SMEG range includes powerful stationary and compact immersion blenders. The body of the device itself and the additional containers that come with it are made of metal and durable safe Tritan, and the sharp knives are made of high-quality stainless steel. Professional sharpening and a reliable 800 W motor allow you to work with any ingredients: from juicy berries to nuts, from meat to ice cubes. For grinding products, four speed and one pulse modes are provided.

The manufacturer also took care of safety: when the jug is removed, the rotation of the knives stops automatically. If the user works with the device for too long, an automatic protective shutdown will protect the powerful motor from overheating.

An important advantage of SMEG blenders is their unique retro design in the style of the 50s of the last century. Elegant rounded shapes and a wide color palette make it possible to choose a model that will fit perfectly into the classic kitchen setting and at the same time can become a bright contrasting spot in modern design. When purchasing a SMEG tabletop blender, you can choose a blue, red, cream, pink, green, silver, white or black model, and if you want something special, a limited edition BLF01DGEU with a Sicilian pattern, created in collaboration with the Dolce&Gabbana design bureau.

Electrical faults and troubleshooting methods

Identifying electrical faults is much easier than any other. When repairing a faulty blender yourself, you can use special devices to quickly find the source of the problem. A voltmeter or a special screwdriver will help you.

Broken wire

If the blender does not turn on, do not immediately worry and go to the store to buy a new one. In most cases, the source of the breakdown is not in the mechanism itself, but in the wire. To check it, apply the following algorithm:

- disconnect the device from the power supply;

- check the wire using a special tester;

- disassemble the blender body;

- find the power block where the wire is screwed;

- check for electricity using a special screwdriver;

- if there is no electricity, replace the old wire with a new one.

If you carried out the replacement process correctly, after the repair procedure is completed, your equipment will work again.

It's a fuse issue

If your blender burns out, you shouldn’t immediately resort to radical measures: buying a new one or trying to repair the board. In some cases, a blown fuse may prevent operation. To diagnose and repair it, you need to apply the same algorithm of actions as in the case of a broken wire.

Blender motor repair

The first sign of problems with the motor winding is the presence of a buzzing sound when the working part itself is not working. To make sure of this completely, you need to disassemble the housing, find the engine and check its condition.

It is not advisable to disassemble Vitek equipment to repair the engine, since the cost of repair will cost you more than buying a new blender.

Failure of the speed controller

This type of failure is common in household blenders. The malfunction can be identified by alternately switching speed modes with the regulator. If the mechanism operates at one speed constantly, the speed switch is broken.

To check it, you need to unsolder the regulator from the blender, then check all positions. When changing speed, a short circuit should form. If the current does not flow in one of the positions, this is where the source of the breakdown is located. The regulator can be repaired or bought a new one.

Before repairing a Polaris blender or equipment from another manufacturer, read the instructions for use in advance. Some models are equipped with a safety lock that does not start the operating mechanism until the bowl is installed.

The most common causes of breakdown

Among the breakdowns in the blender that occur most often are:

- Failure of the gearbox;

- Dull or broken knife;

- Leakage in the bowl;

- Failure of the speed switch or start button.

Stationary and immersion blenders have the same operating principle, but they have a different design. Devices of different types are susceptible to various breakdowns. To determine the cause of the malfunction, you need to at least carry out visual diagnostics. It may be necessary to disassemble the product to assess the condition of its internal components. On submersible models, the rod with the chopper most often fails. This breakdown can be easily fixed even at home.

Important! To carry out high-quality repairs, you should use only original spare parts from the manufacturer.

Replacing the knife

If the blender continues to work (the sound of the motor is heard and the rotation of the main elements of the product is visible), then first of all you need to check the condition of the knife. In stationary models, to remove the knife from the device, you must perform the following steps:

- Disassemble the bowl.

- Unscrew the fastening element. These could be nuts or a latch.

- Remove the knife.

On submersible models, the knife is always accessible. The nozzle is simply detached from the head part, after which the knife is unscrewed.

You must first purchase a new part. You should purchase only original knives so as not to encounter operational problems. On some blenders, the bowl for chopping products is non-separable. In this case, the entire container will need to be replaced. You can find a new bowl with a knife in almost any specialty store. When purchasing new spare parts, special attention should be paid to compatibility. When purchasing spare parts for a submersible device, you should carefully inspect the rod with knives. The metal nozzle should be seamlessly connected to the head part.

Speed switch malfunction

Repairing the speed switch of a blender at home is extremely problematic. You can suspect a breakdown if, after plugging in, the blender does not start or starts only at a certain speed. If the switch fails, you must either resolder the contacts or use a new spare part.

In some cases, if the blender does not respond to pressure, this may be due to a blockage. The lock prevents the head unit from starting if it is not connected to the bowl. You should carefully examine the reliability of the connection. Also, lack of response to the speed switch sometimes indicates that the motor has failed.

Engine failure

If there are no reactions when you try to start the device, then most likely the blender has burned out. To check the condition of the engine, it is necessary to completely disassemble the product. Self-repairs must be carried out at your own peril and risk. In most cases, during repairs, the burnt out engine is completely replaced. You can determine a burnt out motor in a blender using a tester. Also, in some cases, smoke and blackening are visible on the motor and its elements.

It is worth diagnosing the device. It is necessary to check whether power is supplied to the motor. For this, a tester is used, which is applied to the power connector and fuses. In some cases, engine failure is not due to its breakdown, but to a violation of the integrity of the power cable. In this case, you will need to replace the wire with a new one.

A blender motor can cost as much as a new unit. If after diagnostics it turns out that expensive repairs are required, then it is much more advisable to purchase a new shredder.

Important! When using the tester, you must follow electrical safety regulations. The voltage supply is detected after pressing the power button.

Leakage in the bowl

If the bowl leaks during operation of the blender, then the reasons for this are:

- The occurrence of mechanical damage and cracks (the bowl is broken);

- Oil seal leakage;

- Blender overload.

If the bowl starts to leak, then first of all you need to check whether too many products are loaded inside. When overloaded, leaks occur, as well as malfunctions of the device.

The container leaks when the integrity of the seal is damaged or worn. The solution to the problem in this case is a complete replacement. An immersion blender often comes with several different bowls. If the container leaks a lot, you can use another bowl from the set to perform the necessary kitchen work.

Gearbox failure

The gearbox is a part through which energy is transferred from the engine to the nozzle. If the gearbox fails, the motor works, but the blender itself cannot cope with its task. The cutting elements rotate slowly or do not rotate at all. These manifestations may indicate that the gearbox is broken.

Very often this breakdown occurs on budget models on which the gearbox is made of plastic. In most cases, a complete replacement of the part is required. Sometimes it can be repaired by returning it to its original shape. If a gearbox falls out of a stationary blender, you should carefully assess its condition, and then decide on replacement or repair. Removing the gearbox from the blender is extremely simple. It can be unscrewed or disconnected without using a specialized tool.

Mechanical damage

Mechanical damage usually includes:

- Hull defects;

- Damage to the bowl;

- Gearbox failure;

- Damage to the lid latch mechanism;

- Breakage of the submersible leg.

Unfortunately, most mechanical damage cannot be repaired, so you will need to either look for a replacement part or purchase a new device. To prevent the blender from breaking during operation, you should use it correctly in accordance with the instructions.

If any damage to the body or bowl does not affect performance, you can continue to use the blender. It is worth remembering that the crack may begin to grow and damage the device, so at least minimal repairs should be carried out.

Electrical breakdowns

Among the breakdowns that relate to the malfunction of electrical components include:

- Damage to the power cable;

- Engine failure;

- Fuse blown;

- Damage to the speed controller.

Some electrical faults can be repaired yourself. For example, by replacing the power cord, you can completely restore the blender's functionality. Also, without any particular difficulties, it is possible to restore the operation of the speed controller in case of mechanical damage to the buttons. Replacing a motor in a device is considered a more complex procedure, since it requires soldering and forming a reliable connection with other elements.

Disassembling a Brown brand blender

If during use you encounter a problem that the Brown brand blender does not work, you can try to fix it yourself or take it to a service center. When deciding to troubleshoot problems yourself, use this disassembly algorithm:

- Using pliers, remove the cartridge, also known as a holder for attachments.

- Using a thin screwdriver or knife, knock out the weld seam by inserting the blades between the body and the casing. These steps must be repeated until the engine moves freely.

- Bending the clamps, remove the engine.

- Together with the motor, you can easily remove the board, using pliers as necessary.

- There are latches inside the back cover that need to be bent. This will release the back section.

- Using a screwdriver, pry up the speed controller and bend the power cable holder. Next, you can begin diagnosing and repairing faults.

Be very careful when handling the board as it is very fragile. If you damage it, the equipment being repaired can be thrown away.

Tips for working with blenders

- Do not remove the cover until the rotation of the nozzle has completely stopped.

- Do not operate the blender with an empty container.

- Do not spill water on the motor housing.

- Do not place the blender on or near a hot surface.

- Make sure the plug is connected correctly and the fuse rating is correct.

- Disassembling the engine casing may interfere with the safety interlock mechanism.

- Check the condition of the cord regularly.

Originally posted 2019-05-05 06:58:09. Republished by Blog Post Promoter

Other small equipment

Our store catalog presents a wide range of modern, reliable, functional and stylish SMEG kitchen appliances. Here you will find ergonomic hobs, spacious ovens, universal cookers, reliable refrigerators, powerful hoods, as well as dishwashers, microwaves, coffee machines and many other indispensable household appliances.

Large appliances in your kitchen can be complemented by compact assistants. Among them are coffee grinders, juicers, mixers, kettles and toasters. To make the food preparation area even more functional, built-in wow factorers are designed to extend the freshness of any product, as well as cabinets for heating dishes, taking care of the correct serving of food while preserving its texture, taste, color and aroma.

Principle of operation

Before repairing a device, it is worth familiarizing yourself with the principles of its operation.

And in this vein, three types of devices can be distinguished:

- manual;

- stationary;

- as part of a food processor.

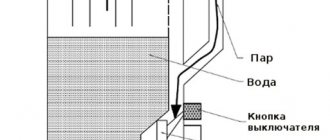

A knife rotates at the bottom of the bowl, and the products necessary for chopping are placed into it. The shape of the knife looks like a propeller. It effectively chops food thanks to its high rotation speed. As a result of circular movements, a mass is formed that moves up the thicket. Then, when it reaches the lid, it falls onto the knife. The process takes place at high speed.