How to replace the belt on a Samsung washing machine

Washing machines manufactured by Samsung have a cover located at the back that is not removable. This always makes it very difficult to eliminate unit breakdowns.

To fix the problem, you will need:

- The same belt - should be selected with markings identical to the failed one;

- A piece of electrical tape no more than 15 centimeters long;

- Half a meter of wire 0.5-0.8 millimeters thick;

- Wire cutters;

- A flashlight or any other device that can become a light source;

- Crosshead screwdriver.

Before starting repairs, inspect the gear and drum pulley. The gear has several compartments for the belt mates. It is installed from top to bottom. When installing a new belt in place of the old one, it is important to correctly get to where the failed element was previously. If it gets too close to the gear, it will not be clear how correctly it is installed. There is a possibility that in this case part of the belt will either sag or stand on the edge of the pulley and then the repair work will have to be repeated.

After the strap is put on the gear, it needs to be moved slightly to the side. It is important to choose a pulley position where it has support from turning the equipment, which, as a rule, constantly tries to move to the opposite side, on which it will stop thanks to the stop.

Use electrical tape to secure the strap. To protect it from damage, a wire is useful - place it on top of the electrical tape, forming about 10 turns and secure its edges by twisting them together. Rotate the pulley until the belt fits properly.

If the actions were performed correctly, you will hear a kind of click. You won't be able to turn the strap because it is securely fixed with the lock you made.

Now you should turn the gear in the opposite direction, and then remove the electrical tape and wire. The renovation is complete.

All actions, in general, take no more than a quarter of an hour, but only when they are performed strictly in accordance with the instructions. To check the result, rotate the pulley. The belt snaps into place and is aligned.

Choice to replace

How to properly install a belt on a washing machine? First you need to purchase a similar product that is suitable for your SMA.

Wedge type

Models with asynchronous motors use a wedge type. Its cross section is compared to a triangle or trapezoid. Due to the rigidity of the material, they rarely tear. You can determine their number and brand by the designation on the outside.

A feature of the installation of a wedge-like product is considered to be strong tension and a slight deflection in the middle part.

Poly V-type

For the SM commutator motor, poly-wedge products are used. Consists of several toothed wedges.

How to tension the drive belt in this case? The installation differs from the wedge one - it is not tensioned so much. However, in some models of narrow machines, this poly-wedge type can be put on very tightly. Therefore, you will need to use more force for installation.

To buy a belt in a specialized store, just name the make and model of the car, after which the seller will offer a suitable option.

How to change the belt on an Indesit washing machine

First, get a new strap. It is better if it comes from the manufacturer of the washing machine or a trusted seller. First remove the remnants of the failed belt from the machine and only then proceed to install a new one. The replacement belt purchased should be placed on the engine, pressing its upper part more tightly to the pulley. Now you need to simultaneously rotate the drum and install the element on the pulley.

The belt must be in the center of the pulley located on top. This can be achieved by moving it a couple of tracks on the pulley, which is located at the bottom of the equipment.

“Exposing” the drive mechanism

If on most washing machines to remove the back wall it is enough to unscrew a few screws and pull the body, but with Zanussi everything is different. To access the drive unit, you will have to halve the washing machine, which will require certain actions. First, you should prepare an awl, a flat-head screwdriver, a screwdriver and a 7 or 8 socket head. Then we proceed to disassembly, following the following instructions:

- disconnect equipment from the power supply and water supply;

- turn the washer body sideways;

- find the bolt in the center of the side wall;

- use an awl to pick up the “cap” and expose the bolt;

- with a 7 or 8 head, depending on the model of the Zanussi washing machine, unscrew the fasteners;

- repeat unscrewing the bolt from the other side;

Before any repair work, the washing machine must be de-energized and disconnected from the water supply!

- unscrew the screws securing the “back” at the bottom and top;

- remove the drain hose;

- remove the top cover by pushing it away from you;

- pay attention to the place where the power cord “enters” the washing machine;

- use a flat screwdriver to pry up the “tab” on the left side of the element holding the power cord and press it out;

- unscrew the four screws securing the metal strip under the top cover;

- Carefully remove the back panel.

All! Immediately behind the rear wall you will see the drum pulley, and on it there is a tensioned drive belt. If the rubber band breaks or falls off, the “wheel” will be empty, and the rim will be on the bottom. We will consider further how the condition of the belt is assessed and replaced.

How to put a belt on an LG washing machine

To replace the strap on LG equipment, unscrew the bolts located on the rear wall of the case and remove the cover secured by them. You can perform these manipulations using a Phillips screwdriver.

Remove the failed strap by pulling it to the side and turning the pulley in parallel. When rotating, the element may burst and fly apart. In this case, it is important to collect all its parts so that they do not damage the machine in the future.

Now we put a new belt on the engine, and after that on the pulley. To do this, pull the strap onto its circle and carefully turn it. Check that the belt is placed exactly where it should be and is firmly pressed into the groove. Rotate the pulley to ensure proper installation. After checking, put back the fixing panel and screw in the bolts.

As you can see, changing a faulty belt in a washing machine is not difficult. The main thing is to carry out all actions slowly and strictly adhere to the drawn up action plan.

How to remove and replace?

If the belt comes off on its own, it is simply pulled out of the washer. But if it is still on the pulley, it must be removed by turning the wheel by hand . If the part has weak tension on the pulley, it becomes ineffective, in which case it may spin. As a result, the drum does not receive proper movement, and the washing process does not complete.

Putting a new belt on a pulley can be quite difficult. The best option is to ask someone to help. One person can make sure that the belt does not come off the motor, while another person will pull it onto the large pulley.

How to put on a belt:

- The new part is first put on the Bosch motor pulley.

- Slowly, turning the pulley wheel on the drum, pull the rubber belt onto it. At the same time, you should check that it does not jump off the motor.

- Check for correct placement.

- Rotate the drum pulley several times.

If after installation, at the stage of turning the pulley, you feel the belt tension, then the work was done correctly.

Next you need:

- Install the back panel.

- Secure the back panel with screws.

- Return the washing machine to its original place.

- Connect all communications.

After repair work, a test run should be performed. This will ensure that the installation is correct.

How to remove the belt - on video:

What kind of belts can there be in a washing machine?

V-belt

Most often, such belts are used for asynchronous motors. They are made from high quality material and special strength.

This element, installed in the machine, must be tensioned so that its deflection does not exceed 5 millimeters when pressed with a finger. The tension is produced by moving the motor, with the fasteners pre-unscrewed. If the engine movement is not sufficient to create the required tension, then such an element must be replaced. Its installation is carried out starting with the motor pulley. Next, the strap is inserted into the groove of the drum pulley. Then, holding it in it, they turn the pulley until it is completely in the desired place. Once the strap is in the right place, its installation can be considered complete.

V-ribbed belt

Used for placement in commutator motors. It has a jagged shape. It can have a variety of characteristics regarding its size and shape, as well as have a different number of wedges.

Replacing a post-wedge strap is completely identical to changing a wedge strap. There is only one difference in installation - the poly-V-element should be located in the center of the counter pulley, both on the drum of the washing machine and on the engine.

The tension level of this belt is slightly lower than that of the previous model. It is produced by turning it completely. If the belt tension during repair is too strong, you should be extremely careful not to injure your hands.

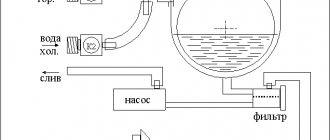

Is it really the belt?

It is impossible to determine at first glance that the drive belt has come off - it is “hidden” behind the back wall of the machine, and to confirm your guess, you will have to use a screwdriver. However, sometimes it is possible to identify that the reason for the equipment stopping was problems with the drive, based on certain “symptoms”.

Firstly, modern washing machines can themselves indicate to the user the reason. Direct confirmation will be the signal sent by the fault self-diagnosis system. Washing machines with a display will display a specific error code on the screen. The user will only have to look at the instructions for the equipment and decipher the designation. Automatic machines that are not equipped with a display will indicate a breakdown by flashing the display on the control panel.

It happens that the internal self-diagnosis system simply does not notice a broken belt. Then the owner of the equipment can independently guess what’s wrong by analyzing the general “symptoms”. You can think about problems with the drive in the following cases:

- The machine has started the specified program, filled the tank with water, the engine is running, but the drum does not start spinning:

- The washing machine hums, then suddenly quiets down and stops working. The motor states change at regular intervals;

- the washing cycle begins, the engine runs continuously, but the SMA “freezes” and does not respond to user-specified commands;

- The drum of the automatic machine rotates easily by hand, but the engine does not make any sounds.

You cannot operate a washing machine whose drive belt has fallen off; this will lead to overheating of the electric motor and its failure.

If at least one of the listed “symptoms” is noted, you should immediately end the cycle and see if the belt is in place. To do this you will need a screwdriver. Let us analyze the basic algorithm of actions that should be followed when conducting diagnostics.

Causes of belt problems

Wear

Characteristic of compact models of washing machines, in which the parts are located extremely close to each other. While the unit is operating, they can rub against each other, thereby wearing out much faster than they should.

Cracked drum pulley

There can be many reasons for the formation of a crack, from overloading the machine to incorrect belt tension. One way or another, the occurrence of this breakdown requires replacement of the pulley.

Bearing wear

A high degree of wear can lead to strong vibrations of the spin unit and the unit drive. This causes the strap to stretch. Over time, it may slip or tear.

Incorrect use of the washing machine

When placing a large volume of laundry into the drum, the machine may vibrate strongly. The belt can easily fly off from such vibration. Or if the machine is not used for a long time, its strap may dry out and become thinner.

In side-loading units, one can often observe such a malfunction as fatigue deformation of parts made of plastic. This, in turn, leads to displacement of the machine elements and slipping of the belt. If this type of breakdown occurs, it is recommended not to waste money on useless repairs, but to purchase a new washing machine.

Household appliances Washing machine

Signs and causes of malfunction with the drive element in the SMA

If the equipment is overloaded with laundry, the drum may spin more and the strap may fall off.

Main symptoms of a problem

The following factors indicate that the drive belt has fallen off in an automatic washing machine:

- lack of rotation of the drum with the engine running when starting the program;

- there is no scrolling of the drum assembly, although the engine works with noticeable effort;

- spinning a drum with only a few things inside;

- no torsion when loading a large batch of laundry;

- extraneous sounds - grinding and friction;

- launching the program and then the machine freezes.

Important! The main failures of a part are breaks, delamination, and stretching.

Why does the belt come off on a washing machine?

Before fixing the problem, you should fully understand why the belt on your washing machine is falling off.

- Problems with the pulley fastening. Loose and loose fasteners lead to belt breaks and jumping off, as well as drum jamming.

- Unreliable motor mounting . If the fasteners are loosened, the belt will not tension well and may slip off. The breakdown is eliminated by tightening all fasteners.

- Natural wear of the part. If the machine is used for more than 10 years, the belt will stretch. This is indicated by whistles when scrolling and problems with spinning.

Important! Due to the stretching of the belt, the machine stops executing programs.

- The failure of their bearings. When the bearings of the machine wear out, a strong noise is heard from the vibration of the part itself and the drum pulley. With each wash, the load on the part increases. Operating the machine with faulty bearings leads to stretching, flying and breaking of the belt.

Important! A breakdown caused by a broken strap can lead to broken wiring and damage to electronic sensors.

- Deformation of the pulley or shaft. The geometry of the parts is disrupted when the motor fasteners are loosened, the shape of the shaft and pulley changes, or the crosspiece breaks. Strong vibration during operation leads to the strap slipping and breaking, as well as to breakage of complex parts of the SMA.

- The belt is loose. If the element is not selected in size or tensioned incorrectly, it will fall off.

- Rare launch of household appliances. When the machine is used infrequently, the drive belt loses its elastic properties - it dries out in a bent state. The rigid element may crack, break or stretch when the drum rotates.

- Loosening of the drum cross. When the drive belt quickly falls off the working drum of a household washing machine, you need to check the balancing of the cross.

- Deformation of the plastic tank. With prolonged use of the equipment, deformed sections of the tank create pressure on the drum pulley. Changing its position relative to the motor one leads to the belt falling off.

Important! Breakage is typical only for top-loading models.

- Setting the intensive wash program. When the machine is overloaded with laundry and its daily use in intensive mode (5-10 hours) leads to the belt falling off. The part needs to be put in place.

Interesting to know! Belts of narrow models wear out more often due to the compact arrangement of components and increased friction.

We localize the breakdown

There are quite a lot of signs indicating that a drive element of an automatic machine has failed. Firstly, this is the error code displayed by the unit, which is shown on the electronic display, and if it is absent, it is displayed by certain indicators.

The next obvious sign indicating a breakdown of this kind will be a drum that does not rotate during the washing process, or a situation where its rotation occurs very slowly and is accompanied by scraping sounds.

Important! This breakdown is quite serious, since when the belt breaks, the power wires may break or damage any sensors.

Why does the Indesit washing machine belt break? There can be quite a few reasons.

- Drum pulley malfunction. This is caused by incorrect loading of laundry, exceeding the permissible weight of things placed in the machine, the occurrence of an imbalance, etc. Under the influence of these factors, the belt may come off, break, or weaken.

- Natural wear and tear. Any thing can wear out over time, and, often, only a few parts function properly throughout its entire service life. Premature wear of the drive belt can be caused by the daily use of the machine, as well as its design (in narrow SMAs, the belt wears out faster than in standard models).

- Incorrect loading of laundry. Exceeding the weight of loaded laundry allowed by the manufacturer leads to an imbalance in the drum - things shift to one side. During the spin process, which occurs at high speeds, the drum may accidentally hit the tank, which will cause the drive belt to jump off.

- Failure of the bearings necessary for uniform, correct rotation of the drum. Problems with bearings will lead to increased vibration of the pulley, which can cause the drive element to tear or fly off.

- Very rare use of the washing machine. It would seem that the less you use the machine, the more durable it will be. This is not entirely true. As for the belt, with infrequent use, parts of it shrink. During subsequent washing cycles they are erased, which entails stretching and breaking of the drive element.

If it was still not possible to prevent the root cause of the breakdown, the problem should be eliminated as soon as possible. Let's talk about how to replace the drive element in Indesit washing machines.

How can you tell if your washing machine drive belt needs to be replaced?

If the drive belt is broken or damaged, the washing machine will not operate correctly.

- If the belt falls off or breaks

, the machine will stop rotating the drum. At the same time, you can hear how the program is being executed: the motor is running, the relay is switching, etc. But the drum remains motionless. You can check your guesses by removing the cover and inspecting the drive belt. - If the belt is stretched and slips

, the machine will not work properly. Most often this is noticeable during the spin cycle: the washing machine either spins or doesn’t. Some models may generate drum axle load imbalance errors. You can check that the belt has stretched by removing the washer cover and inspecting the part. If the belt has visible damage, significant cord separation, grooves, if the belt is loosely tensioned on the pulleys, then the part requires replacement.

How to be?

Since installing or replacing a belt has its own nuances and is quite complicated, if the need for such an operation arises, it is recommended to seek professional help. A qualified specialist will perform repairs quickly and efficiently, ensuring reliable operation of the washing machine.

Our team has been successfully solving people’s everyday problems for many years, saving them time and money. Therefore, we will be happy to help you if you have problems with your washing machine or other equipment. Call right now by phone in Kyiv 383 90 60 and call a repairman directly to your home!

© Any reprinting of this article, as well as partial or complete use of materials (information) from it in any form is permitted only if a direct link to our website is provided

Instructions

Turn off the power to the washing machine and turn off the water.

Take a Phillips screwdriver and remove the two mounting screws. These screws are located on the back of the washing machine

and attach the top panel to the casing.

Lift the back of the machine

and slide the cover towards the rear wall.

Remove the lid of the washing machine

when you feel it is unhooked.

Unscrew the fastening screws located on the back cover of the washing machine

, and remove the back panel.

Tilt the washing machine back slightly to allow easy access to the bottom.

Using pliers, remove the spring supporting the washing unit.

Remove the old belt

turning it on a pulley.

Loosen the motor mount and move it towards increasing the belt length.

Tighten the fastener. Put on your belt

, first, on the engine pulley and only after that - on the drum.

If the design of your machine

does not provide tension for the drive belt, then you need to replace it with a new one.

Get a new belt

drive.

It is very important that the new belt

matches the model of your washing

machine

. To make sure of this, carefully study the markings of the old belt. The first four digits of the marking indicate the length of the belt. The letter following them indicates the shape of the tracks. The last digit of the marking indicates the number of tracks. All markings on the old and new belts must match.

Tie a small, strong thread to the new belt.

Skip the belt

through the top.

Place the belt

on the engine with one hand.

The second hand, at the same time, should pull the belt

up by the tied thread, preventing it from jumping off the pulley.

Place the washing machine in its original position.

Hook the edge of the belt onto the drum pulley. Very carefully, but with force, while rotating the drum clockwise, insert the entire belt

.

Check the quality of your work. Spin the drum. The absence of distortions and extraneous noise when the drum rotates indicates correct installation of the belt.

Assemble the washing machine.

note

If the drive belt breaks, it can damage sensors, electrical wires and other elements located in the rear of the washing machine. During the process of replacing the belt, it is advisable to diagnose and, if necessary, eliminate these faults.

Sources:

- how to replace a belt on a washing machine

- Replacing the timing belt VAZ 2110, 2111, 2112 16 valves

Video on the topic

Sources:

- how to replace a washing machine drum in 2017

The technical regulations for carrying out work related to engine maintenance provide for checking the condition of the timing belt after driving every fifteen thousand kilometers. As a result of the control inspection, a decision is made on it (replacement or tightening).

You will need

- - household steelyard,

- - caliper,

- — a key for tightening the timing belt.

Instructions

Before you start checking the degree of belt tension, the steelyard hook is attached with electrical tape to the handle of the crank from a set of socket heads. And a metal ruler is placed on the edge of the camshaft drive pulleys.

Next, pressing the belt

Using a crank in the middle between the pulleys with a force of 10 kgf, the amount of its deflection is measured, which should not exceed 5.4 mm. Otherwise, the specified parameter is brought to the standard by moving the tension roller.

Video on the topic

Helpful advice

If the goal is to routinely check the integrity and degree of tension of the camshaft drive belt of a VAZ 2112 car engine, a plug is removed from the front cover of the engine, allowing access for visual inspection of the specified part.

When choosing this method, it is necessary to take into account that the amount of deflection can only be measured from the edge of the front cover. Therefore, determine in advance the distance from the edge to the belt, and then make adjustments during the described test.

Sources:

- how to tighten the timing belt of a VAZ in 2017

The service network provides services for replacing and tightening the drive belt of a washing machine with both horizontal and vertical loading in Moscow and the Moscow region. Thanks to the presence of craftsmen in all districts of Moscow and most cities in the Moscow region, we complete orders in the shortest possible time. Within 24 hours after your request, a RemBytTech specialist will come to your home and:

- will put on the belt if it has come off the drum pulley;

- will replace it with a new original one if the belt is broken.

The new belt and the work of the technician to replace it are covered by

9-month

warranty .

The belt “jumped” again

If the belt falls off regularly, even after installing a new one, you should think about it. There is probably some problem with the washing machine. Diagnostics of a Bosch automatic washing machine is necessary if the drive rubber flies off more than twice in 6 months. A permanent “failure” of an element can occur for the following reasons:

- wear of the part. The drive belt is subject to stretching. If traces of wear, creases, cracks are detected on its surface, as well as an elongation of the diameter by more than 2 cm, you need to purchase a new rubber band. The old one has completely used up its resource and can no longer perform the functions assigned to it;

- drum pulley play. In this situation, it's not about the belt. The problem can be solved by tightening the drum wheel mounting screw. In isolated cases, the pulley will need to be replaced;

- poor fixation of the electric motor. Initially, during assembly, the motor is securely mounted in the housing. Over time, when the equipment is used for a long time, the engine may become loose. So, due to constant vibrations, the bolts are unscrewed, which leads to disruption of the drive system. You need to tighten the screws and the elastic band will stop falling off;

- deformation of the shaft or “wheel”. This may be the result of unsuccessful repairs. You can meet craftsmen who, when replacing some parts, manage to damage others. If the drum pulley has been bent, you can try to straighten it, but the best solution would still be to replace the wheel;

- cross defect. Very rarely, but owners of Bosch washing machines may still encounter this problem. The part must be changed; it cannot be corrected. If you do not install a new crosspiece, you can cause the drum to become unbalanced, and these are other repair costs;

- bearing damage. Deformed elements can lead to “distortion” in the system, which will result in the drive belt falling. In this case, in order to improve the operation of the washing machine, you will have to change the bearings and seal.

The drive belt can break off again if it is not installed correctly - when the elastic band is not fully secured in the grooves.

Also, the belt periodically flies off if it is not suitable for your washing machine, that is, its characteristics differ from the factory element. Therefore, when buying a new rubber band, it is important to select an analogue that matches the specific Bosch model.

Thus, if the belt becomes loose and falls out of place, there is no need to panic and call the service center (the exception is when the washing machine is still under warranty). Putting the elastic band back in place is within the power of a housewife, the main thing is to strictly follow the instructions for action and be patient.

If after a short period of time the belt drive is broken again, you will have to undertake in-depth diagnostics of the Bosch washing machine. Perhaps the problem can be solved by “tightening” the drum pulley or the motor fasteners. In some cases, more serious repairs will be required - replacing the bearings or “wheel” of the drum.