Washing machines of the Samsung brand are widely represented on the domestic market. Their popularity is associated with high reliability and the use of innovative technologies.

But even such equipment is not immune from possible breakdowns. One option is the need to replace the belt. This type of work is a moderately complex repair, and you can even do it yourself.

We will tell you in the article how to change the belt on a Samsung washing machine (remove the old one, put on a new one).

Signs that a part requires replacement

The need to replace a belt is not a common problem. Worn parts can become noticeable during prolonged or improper use of the washing machine.

The average service life of a washing machine belt is 6 years. The need for replacement during longer use is a normal situation.

with regular violation of the rules, for example, overloading laundry, can accelerate the wear of a part

In some cases, a problem with the drive belt may be indicated by a complete stop of the washing machine and the display of code E4, , UB. On machines not equipped with a display, all mode lights blink and the second temperature indicator from the top lights up.

A problem with the drive belt does not always cause an error code to appear.

It is necessary to pay attention to the following failure situations:

- when water is filled into the drum and the motor is running, the drum does not rotate;

- the engine runs intermittently;

- after the start of the work cycle, despite the engine running, a freeze occurs;

- free rotation of the drum when the engine is not running.

- Uncharacteristic noise when washing.

If the part itself has a rough surface, pellets have formed on the surface and on the elements that are in contact with the belt, or delamination, then replacement is definitely needed. But this can only be determined through direct access.

If problems with the drive belt occur frequently, professional diagnostics of the machine by a specialist is necessary.

Why does the belt drive fall off?

Thanks to the belt drive, the drum pulley rotates. Like any mechanical transmission, it can be damaged. If the strap comes off once, no problem - below we will tell you how to install the strap yourself, without calling a technician. But it happens that the drive belt has to be returned to its place over and over again. Causes of the problem:

- Wear. During operation, the strap stretches, which is why it comes off the wheel. Having weakened, it also makes a characteristic noise - whistling. The element may be damaged and even torn. To inspect and determine the degree of wear, open the back panel.

- Pulley fastening is broken. Check the fastening and tighten if necessary.

- Poor motor mounting. Check and, if necessary, strengthen the fasteners.

- Deformation of the pulley and shaft. These elements can bend due to an unsuccessful belt. A defect is also possible - then the SMA is returned in accordance with the warranty obligations. Deformed parts require replacement.

- Damage to the crosspiece. The tank and the shaft are connected by a cross - if it bursts or weakens, the balance is upset. Fastenings need to be changed or tightened.

- Incorrect installation of the belt drive. When installing on your own, mistakes are often made. It is better to call a specialist to fix the problem.

- Spare parts do not fit. If a pulley or belt was replaced with new ones purchased in a store, they may not fit.

- Bearings are worn out. Because of this, the drum skews when rotating, and a knocking sound is also heard during the spin cycle.

Preparation for the process

Replacing the drive belt is carried out by partially disassembling the structure of the washing machine. Therefore, you need to prepare:

If there is water in the washing machine, it must be drained and the laundry must be removed from the drum.- Disconnect the device from all communications. You should not only turn off the machine with the button, but also remove the plug from the socket.

- Move the machine so that you can access the back wall.

- Prepare tools - a set of screwdrivers.

If the part has flown off for the first time and has no visual damage, it can simply be returned to its place without replacement.

Two belt access options

The belt can be accessed from the back wall of the washing machine, if it is removable, or through the top.

Since many Samsung models do not have access to the elements of the washing machine from the rear wall, the job of replacing the belt becomes much more complicated.

Procedure for machines with a removable back panel:

- Unscrew all the screws that hold this cover in place.

- Remove the cover. This allows you to get a good overview and convenience when replacing parts.

Otherwise, you will have to work through the top of the machine. For this, the steps will be as follows:

- unscrew the screws that hold the top cover;

- lightly push the cover towards the back wall so that it is removed from the grooves;

- remove the cover.

The immediate procedure for replacing the belt does not depend on the method of access to the part.

How to call a specialist

You can call a RemBytTech specialist in any convenient way - by filling out the form on the website or by phone from 8.00 to 22.00:

READ MORE: Stretch ceiling: glossy or matte. My baby is the main one

When contacting, please inform the manager:

- The brand of the washing machine, if you only need to install the belt (if it has fallen off or if you have already bought a new part yourself). If you need to replace a drive belt that has become unusable, please also tell us the model of the unit. For example, Samsung S821, Electrolux EWS 1105 or LG WD-8012C. The exact number can be found on the body of the washing machine on a special tag or in the operating instructions. This information will allow the technician to take with him the “original” belt installed on your unit by the manufacturer for replacement work.

- The day and time of arrival of the master that suits you.

- Contact information – your last name, first name, address and telephone number.

On the selected day, the technician will call you again to confirm a time convenient for you to replace the belt.

How to install a new one?

In order to replace the belt, you must first dismantle the old part and then install the new part. First you need to determine whether it is on the drum pulley. If it's not there, it's probably torn or fallen off completely and fallen to the bottom.

How to tension a new belt? Procedure for machines with a non-removable back side:

The car must be tilted towards itself so that the tank sag towards the hatch, and the gap between it and the rear wall becomes larger.- The old part must be pryed off with a screwdriver and removed from the pulley by sliding it.

- While holding the belt, you need to rotate the pulley. This will help release the rubber or polyurethane part.

- Use a flashlight to illuminate the area where you are working to see if any parts of the belt remain un-removed if it has become frayed due to wear. If they are detected, it is necessary to remove all fragments so that they do not interfere with normal operation in the future.

- Place the new part onto the engine pulley. If you have to work through the top of the machine, you can use the help of a second person to grab the belt through the bottom. Or help yourself hook it by lowering it on a wire loop.

- After the part is draped over the engine, you need to pull it onto the pulley grooves. This must be done by holding the belt itself taut and turning the pulley clockwise.

- To make sure that the belt is “sat” in place, rotate the pulley.

- Reassemble the washing machine in reverse order.

- Run a test wash.

What kind of belts can there be in a washing machine?

V-belt

Most often, such belts are used for asynchronous motors. They are made of high quality material and are especially durable.

This element, which is installed in the washing machine, must be stretched so that when you press it with your finger, the deflection is less than 5 millimeters. Tension is produced by moving the motor with pre-unscrewed fasteners. If the motor movement is not enough to create the necessary tension, then this element must be replaced. Its installation is carried out starting from the motor pulley. Next, the bar is inserted into the groove of the drum pulley. Then, holding it there, the pulley is rotated until it is fully seated in the desired location. Once the strap is in the right place, its installation can be considered complete.

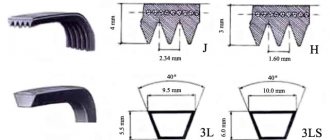

V-ribbed belt

Used for placement in commutator motors. It has a jagged shape. It can have a variety of characteristics regarding its size and shape, as well as have a different number of wedges.

Replacing a post-wedge strap is completely identical to changing a wedge strap. The difference in installation is this: the poly-V-element should be located in the center of the counter pulley, both on the drum of the washing machine and on the engine.

The tension level of this belt is slightly lower than that of the previous model. It is produced by turning it completely. If the belt tension during repair is too strong, you should be extremely careful not to injure your hands.

How to choose, how much to pay and where to buy?

The best option is to replace the belt with an original one that fully matches all the parameters of the washing machine. You should choose a part taking into account the characteristics of your washing machine, so you can simply remove the worn one and buy exactly the same one .

Poly V-belts, which are not smooth on the inside and have a textured surface of several wedges, have proven themselves to work well.

An important parameter for poly-V belts is the distance between the wedges. For Samsung, the “J” type works well, which means a distance of 2.34 mm. This parameter is indicated on the part itself.

Near the letter on the surface itself the number of wedges is indicated . There can be up to 5 of them. J3 is suitable for narrow Samsung devices, and J5 for wide ones.

The length of the belt is also indicated directly on it. This is an important parameter that cannot be ignored, because otherwise the part will not fit the machine.

For Samsung cars - 1270. Thus, the marking 1270 J3 indicates a poly-V-ribbed three-ribbed belt with J-type wedges and a total length of 1270.

Belts are made from rubber and polyurethane. It is even possible to determine the type of material visually: rubber ones are black, polyurethane ones are light . The former have a longer service life.

A good three-ribbed belt 127 cm Megadyne (made in Italy) costs from 420 rubles. One of the cheaper options is also suitable, which can be ordered, for example, on Yandex.Market or bought in a specialized store.

Prices for simpler product options start from 200 rubles. They are inferior in quality and less durable, but gain in price. A wider belt has better grip and is less likely to slip.

Calling a specialist: the price of the issue

If it is impossible to replace the drive belt yourself, you must call a technician from a company that repairs household appliances. You can find a company on the Internet. A professional technician will do all the work, conduct diagnostics and give recommendations .

On average, the cost of replacing a belt will be up to 1,000 rubles. The new part itself is paid separately.

When calling a specialist to replace a belt, you must indicate the make of the machine, as well as whether a new part is available or the technician needs to bring it with him. If the technician additionally has to fix other faults, the amount will be higher.

For machines that are still under warranty, you should call a specialist only from the service center . All information about such companies must be in the documents for the washing machine.

Contacting specialists through private advertisements can be dangerous, since there is a significant chance of ending up with unscrupulous workers, weak specialists or simply scammers. Contacting a company that has been in the service provision market for a long time will help eliminate the risk.

All the most important and useful information about repairing Samsung washing machines is in this section.

What are the reasons for wear of a part?

There are not many reasons why the cuff stops performing its functions. Moreover, most of them occur when the rules for using household appliances are not followed.

The main ones are the following:

- mechanical damage from rough objects;

- strong vibration of the drum during spinning;

- exposure to aggressive agents;

- mold on rubber;

- inaccurate loading of dirty items or removal of already washed items;

- natural wear and tear.

Damage from objects occurs when rough items are often washed in the machine, for example, sneakers, outerwear with hard “snakes,” etc. Metal products (nails, keys) and plastic that have fallen into the drum due to user carelessness can also cause the formation of significant defects on the rubber.

Cracks, cuts and tears in the rubber part can appear either as a result of a malfunction of the washing unit or due to the carelessness of users. Before loading clothes into the machine, be sure to check pockets for rough or sharp objects. They can easily damage the cuffThe washing machine drum tends to vibrate strongly if the machine is not installed correctly. Accordingly, the cuff attached to it suffers. The use of bleaching agents frequently and in high concentrations causes the rubber to become rougher. And the loss of elasticity, as is known, is fraught with the rapid appearance of defects.

The acids and alkalis used to clean the machine act in the same way. But again, if they are used incorrectly. For example, some users believe that the higher the concentration of the product, the more effective the cleaning. At the same time, they do not take into account the aggressive influence on the parts available for processing.

Mold is microscopic fungi that live in colonies. Having settled on soft rubber, the mycelium of these tiny creatures is able to germinate deeply. If the damage is severe, dark gray spots that emit an unpleasant odor cannot be removed with anything. In this situation, only replacing the cuff with a new one will save you.

The washing machine does not last forever. Even if you handle it very carefully, the parts gradually wear out. The rubber seal is no exception. It constantly experiences friction from the rotating drum of the washing machine and laundry, temperature changes, and exposure to detergents. All these factors make rubber brittle and brittle over time.