Reasons for replacing the drive belt in a Samsung car

The following reasons push washing machine owners to replace parts:

- An uncharacteristic noise or rumble is heard during washing.

- Upon inspection, the surface of the part is rough (looks like dirt), and when rubbed, it rolls into balls.

- You have been using the machine for more than 6 years - this is usually the service life of the part.

If at least one of the above reasons is confirmed, you need to carry out a technical inspection of the machine - you may need to replace the part.

Next, we will look at how to change the belt on a Samsung washing machine.

Important! In the model range of this brand, the back panel cannot be removed, so repairs are somewhat more complicated.

How to put a belt on a Samsung washing machine. How to change the belt on a Samsung washing machine

It is difficult for a modern woman to imagine her life without household “gadgets”. The leading position in the ranking of home assistants is occupied by the washing machine. Any housewife today cannot imagine her life without it. Therefore, the breakdown of such an important assistant becomes a real tragedy. This is an expensive and complex household appliance. Not everyone can simply replace a broken machine with a new one.

Replacing a belt in a Samsung machine

To replace the drive belt, proceed as follows:

- Remove the back panel by unscrewing the fasteners.

- For models that do not have a removable back panel, you must remove the front panel. In this case, work is carried out from above.

To remove the front panel:

- Unscrew the lid.

- Take out the powder dispenser (it has a small button inside for easy removal).

- Remove the control panel and place it on top out of the way.

- Unscrew the bottom panel.

- Unscrew all the screws that secure the front cover and pull it towards you.

- Arm yourself with a slotted screwdriver - using it carefully, lightly hook the edge of the belt.

- Remove the belt from the grooves on the pulley by sliding it to the side.

- Rotate the pulley while holding the strap with your hand. After this, the belt should easily come off the pulley and you can safely remove it from the housing.

Important! If there is a “beard” and it is wrapped around the engine, be sure to untangle everything and remove it.

Reasons why the belt flies off or breaks from the drum of a washing machine

First of all, the reason must be looked for in the belt itself. This:

- Wear or stretching of the belt due to prolonged use.

- Self-installation of the wrong brand or type of belt, or incorrect installation of the belt.

- Drying of the belt in machines that have not been used for a long time (more typical for models with vertical loading). At the point of greatest bend, on the engine pulley, the belt loses its elasticity and “freezes” in this bent state. When you turn on the machine, this section straightens and a break occurs.

- Severe imbalance of laundry during spinning: if the machine is overloaded, the shock-absorbing systems may not cope and the washing machine will begin to vibrate too much, resulting in damage to the drive belt. The problem of imbalance is most acute for narrow washing machines: in them all the parts are extremely close to each other, and when the belt vibrates, it can touch bulges or screws on the back wall, which is why it jumps off or breaks.

In the latter case, the belt most often remains intact, but falls off the pulleys. There is no need to change such a belt, you just need to put it in place and in the future follow the operating rules of the washing machine without overloading it.

Unfortunately, the belt often falls off or breaks due to other types of malfunctions in the washing machine. These include:

- Wear and/or partial destruction of the bearing leads to play in the drum axis and increased vibrations during washing and, especially, spinning. As a result, the belt stretches and constantly flies off the pulleys or breaks.

- Violation of the geometry of the engine pulleys and drum, which can occur due to loosening of the motor fastenings, deformations of the pulley and / or shaft, damage to the cross, deformations of the tank (more typical for machines with vertical loading), violations of the pulley fastenings, etc. All this leads to excessive vibrations. As a result, the belt flies off or breaks.

That is why, if problems arise with the drive belt, we recommend contacting specialists! Only a complete diagnosis of the washing machine will allow you to determine the reason why the drive belt is slipping or breaking and correct the problem in a timely manner.

Installation work

Important! Buy a part with 5 streams (Megaden production is suitable). Buyers respond positively to it, praising the quality and especially the silicone inserts that extend service life.

Don't know how to tighten the belt in a Samsung washing machine? All the hardest parts are already behind you - all you have left are the final chords. Just a few steps separate you from using an updated machine:

- Place the new part on the pulley so that the grooves line up as specified by the manufacturer.

- If you work from above the CM, then help yourself with a strong thread or a piece of used belt. Tie the belt to an improvised “fishing rod” and lower it into the body. Hold it with one hand and put it on the engine with the other.

- Now stretch and place the part on the side grooves on the pulley.

- Continuing to create tension, rotate the pulley to the right and everything will fall into place.

If you have a Samsung S1021, S803J or S803J model, now you know how to remove and install the drive belt. For other SM models, the replacement process is similar.

We hope the installation goes smoothly and successfully. Good luck with your renovation!

How to avoid drive belt failure?

First of all, you should regularly inspect your washing machine and monitor its operation. This doesn't have to be done every day. But this way you can avoid costly repairs by preventing them.

- During operation, pay attention to the position of the drum. If you see a misalignment, immediately turn off the device and inspect the drive. The belt may already be so deformed that it cannot hold it in the desired position.

- When the washing mode starts, there is a strong noise and whistling sound. If you hear this, stop using it immediately. This is the final stage, after which a breakup is inevitable.

- The smell of burning. An unpleasant whistling sound may be accompanied by a burning smell. Don't panic. Unplug the machine and call a technician. In this case, the problem may be caused by more serious reasons than deformation of the drive belt.

- Periodic thuds. If you hear this sound, it may indicate that the belt has become misaligned. Try to eliminate the malfunction as soon as possible, otherwise it may lead to failure of the engine as a whole.

Don't forget these precautions and pay more attention to your washing machine. Any service center can offer you the services of a repair and maintenance specialist for this home assistant. The technician can regularly diagnose the device and carry out preventive maintenance. This will help extend the life of the washing machine.

Causes of belt failures

Belt wear

In narrow devices, all elements are located very close to each other and to the body. Therefore, at the moment of wear, such parts are free and rub against each other, causing severe wear.

Cracked drum pulley

There are several reasons: the pulley is cracked, the automatic machine was overloaded, the element is not tensioned correctly. A broken pulley cannot hold the belt, so it must be replaced.

The cause of the failure is wear of the bearings

Severe wear can lead to high vibrations of the spin unit and the device drive. When they reach their peak, the strap stretches, slips, or breaks. After which repairs are required.

Incorrect loading and operation of the washing machine

The belt can fly off if the drum is not loaded correctly and excessive vibration is caused. This element can dry out and become very thin if the equipment sits idle for a long time.

Very often, in side-loading machines, plastic parts exhibit fatigue deformation, which leads to a violation of the arrangement of the elements. After which the strap may fly off along with the pulley shifting. In such situations, it is better to buy a new device than to adjust the equipment.

Replacement algorithm

First, you need to disconnect the machine from the electrical network and communications in order to more conveniently position the equipment. The machine must be turned towards you with the back wall. Then follow the instructions:

Symptoms of a faulty belt

The belt in a Samsung washing machine is a weak point. It wears out after just three years of using the machine. This is because Samsung machines use a three-strand silicone belt, so its strength leaves much to be desired. You can tell that the belt is faulty by the following symptoms:

- The drum in the washing machine does not rotate, although you hear the motor humming;

- when the drum is lightly loaded, the engine cannot rotate it, you see how the drum jerks and does not start to rotate, this means that the belt has stretched;

- the drum stops rotating when fully loaded, but rotates well when the load is small;

- A belt malfunction can be detected by shuffling sounds, but this is the case when the belt has delaminated and touches the body of the machine. This is dangerous because parts of the belt can catch the electrical wiring and break it.

Thus, there is no need to delay replacing the belt. This type of problem must be corrected immediately. We hope that now you know how to change the belt in a Samsung machine, and the spare part can be bought at any store, and it will cost you about 1,500 rubles. For other malfunctions of cars of this brand, read the article

Fault diagnosis

Replacing the belt of a Samsung washing machine will require removing the back panel, disconnecting the device from electricity and the water supply network, so the first thing you need to do is make sure that the drive belt is the cause of the non-operation of the household appliance. This malfunction may have the following symptoms:

- The motor runs, but the drum does not rotate.

- The drum rotates jerkily, and the smell of burnt rubber is felt in the air.

- Extraneous sounds are heard when the drum rotates.

This important part of the washing machine does not always fail so much that the household appliance stops working. In the early stages of wear of this part, problems can only occur when the washing machine is fully loaded. If in such a situation the drum begins to jam, then you should not wait for the situation when the engine jams or a loose belt breaks the internal wiring wires. If you suspect such a problem, you should immediately begin troubleshooting the problem.

Before you begin repairing a household appliance, it should be disconnected from the electrical network and communications. If it is not possible to remove the back panel of the washing machine without changing its location, then the device extends in such a way that during operation it is as convenient as possible to replace the belt. Then you should prepare a slotted and Phillips screwdriver. Replacing the drive belt is carried out in the following sequence:

- Unscrew the screws holding the back cover and carefully remove the panel.

- Using a slotted screwdriver, you need to pry the part, bend it to the side and remove it from the pulley, turning it slightly clockwise.

- A new belt is installed in place of the worn part. To do this, first place it under the lower pulley, and then, placing the belt on one side on the grooves of the pulley, turn it half a turn.

- Rotate the upper pulley 1 - 2 turns to check the belt drive.

- Assemble the washing machine.

After all communications are connected, the washing machine should be started in test mode to ensure its functionality.

Some models of washing machines do not have the ability to remove the back cover, so many craftsmen are interested in the question of how to tighten the belt in a Samsung washing machine. In this case, the actual process of replacing the part becomes much more complicated. To carry out such an operation, you will need to open access to the internal parts of the household appliance from below or from above.

The second option is more preferable, because to remove the top panel it is enough to unscrew two screws. Then the cover is moved back and up a little, after which access to the belt drive will be opened. Before proceeding with this operation, you must also disconnect the device from the electrical and water supply networks.

To remove the old belt, it will be enough, as described above, to pry it with a sharp object and turn the pulley to remove it from the household appliance. Installation of a new part, in this case, will require the use of auxiliary tools. The engine pulley located at the bottom is located at a considerable distance, so it is not possible to hook it from above with a belt.

In order for the part to fit into the recesses of the pulley, you should take a piece of thick wire, bend it into a U shape, hang a new belt on it and lower it down, hook it to the lower pulley. Then you should install it on the upper pulley of a larger diameter and turn clockwise to complete the process of installing the new part.

Once the belt is in place, you need to replace the top cover of the device and connect the washing machine to electricity and water supply. Before using the household appliance, you need to test run the washing machine.

READ MORE: The water heater plug is heating up - Technical Forum

Briefly about belts in a washing machine

Types of belts

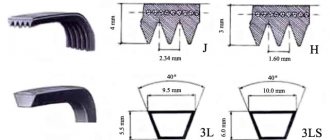

There are two types of belts for washing machines. They differ from each other only in the tension force and additional control.

In most cases, such a belt is used for asynchronous motors. It is made of high quality and especially durable materials. The wedge element must be very tightly pulled onto the washing machine equipment with a slight deflection of up to 5 mm when pressed with a finger.

Tension is carried out by moving the motor. To do this, you need to unscrew the fasteners in advance. If there is not enough engine adjustment to ensure proper tension, the belt must be replaced.

The installation of the wedge element begins with the motor pulley, and then this element is installed in the groove of the washing machine drum pulley. You need to hold the belt in the groove with one hand and turn the pulley with the other until this element is completely in place.

V-ribbed belt

This element is perfect for commutator motors. It has a jagged shape. Belts can vary in length, width, shape and number of wedges.

Repair and replacement are exactly the same as for the wedge element. The only difference is that the serpentine belt is located in the middle of the counter pulley, as on the drum and motor.

The tension of this element is slightly lower than that of the other model. Therefore, tension must be done by rotating 360 degrees. If the belt is too tight during repairs, be careful as your hands may be injured.