Household gas equipment poses a high risk. Often the open fire of ovens and stoves may go out due to a draft or gas supply being cut off. To prevent leakage and gas supply, thermocouples are installed on the plates. Next, the topic will be covered: what is a thermocouple for a gas stove, the principle of operation, the main malfunctions and testing of this equipment. A description of how to do it yourself will also be given.

Device

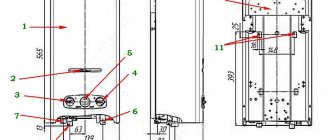

The thermocouple for the oven and gas stove is designed according to the Seebeck principle. The scientist has found a way to produce a small fraction of electric current by heating various metals. The thermocouple consists of the following elements:

- Working tip with 2 types of metals inside. It is this part that is in direct contact with the open flame.

- Contact tube up to 1.5 meters long. This is the electrically conductive contact from the tip to the bolt mechanism.

- Solenoid valve. A mechanism that opens and shuts off the gas supply to the burners and oven. The valve is metal. Raised by magnetic attraction.

There are 2 main types of this device:

- Ungrounded. This type of pair has a split-coated tip. This approach made it possible to reduce susceptibility to external electromagnetic vibrations. The disadvantage is the connection method. Often the two halves are joined together by soldering or crimping. Both options lose their tightness with frequent and prolonged heating, due to an increase in volume.

- Grounded. A more common type of device. The tip is not separated by an insulating coating. This affected the sensitivity of the tip to electromagnetic vibrations from extraneous sources. Microwave ovens must not be installed near the oven. The electromagnetic field can cause the valve to open. Despite this, grounded thermocouples are the most reliable.

The shell with metal rods is fixed to the tube using: welding, soldering, crimping. The mounting depends on the purpose of the thermocouple and at what temperature fluctuations it will operate in the future. The most reliable connection is welding. This connection is not disrupted by the expanding surfaces of the housing. The chemical composition of the rods inside the housing also depends on the temperature. The rods are:

- Chromel is aluminum. Operates at temperatures - −200 ÷ +1000 °C. Denoted by the letter "K".

- Copel - chromel. −200 ÷ +800 °С. Refers to the most sensitive elements. Denoted as "L".

- Chromel - constant. −40 ÷ +900 °C. Has increased sensitivity. Designated "E".

- Copper is constant. – −250 ÷ +300 °C. Denoted by "T".

- Iron is constant. −100 ÷ +1200 °C. They are among the cheapest devices. Designated "J".

- Tungsten - rhenium. Operates at temperatures above +1800 degrees. Used in heating boilers. Designated "A".

- Nichrosil - nisil. −200 ÷ +1300 °C. Denoted as "N". Used on high-precision heating devices.

- Double platinum rhodium. +100 ÷ +1800 °C. Designated "B".

- Platinum - platinum rhodium. There are 2 types. Operates at temperatures up to + 1700 °C. Designation "S" or "R".

Knowing the composition of the internal rods, it is easy to select a suitable element to replace the faulty one.

The thermocouple kit also includes a tube and a valve. The tube has a conductive element inside. Often a wire enclosed in a fireproof sheath. The solenoid valve is necessary to open and close the gas.

Household natural gas and rules for handling it

Everyone knows that flammable gas mixed in a certain proportion with air is explosive. But, oddly enough, it comes to an explosion when working with gas for a different reason.

For the sake of safety, a tiny amount of an odorant, mercaptan, is added to household gas. This is an extremely smelly chemical compound and, in theory, if there is a leak long before the concentration reaches a dangerous level, the unbearable stench will spread throughout the entire area and someone will dial 104. But if the gas is coming from an open pipe, a different situation is possible.

Most of natural gas consists of saturated hydrocarbons – propane, butane. However, unsaturated ones are always present in some quantity - ethylene, propylene

They have a psychotropic effect: sensations are dulled, and a person stops paying attention to the hissing of gas and the smell of the fragrance. Mental disorders and inappropriate actions are also possible, for example, trying to light a cigarette in a gas-saturated atmosphere

To protect yourself and your home when working with gas, you must strictly comply with the following requirements:

- completely de-energize the apartment by unscrewing the plugs or turning off the main circuit breaker;

- remove all self-powered mobile devices from the apartment, completely turn off the computer UPS (uninterruptible power supply);

- open doors and windows throughout the entire room;

- before starting work, close the shut-off valve on the descent from the gas riser to the stove and unplug the stove's power supply from the socket;

- use only special consumables, components and tools for gas fittings;

- prepare a plug in advance from a wet rag, and under the 1/2″ supply pipe - from an old wine cork;

- any open pipe should be plugged immediately, and only after that continue work;

- work quickly, confidently, with full knowledge of the matter;

- After reassembling any connection, supply gas by opening the shut-off valve and check it with a soap solution. The slightest bubble - immediately close the valve and make it completely sealed;

- If a hissing or smell of gas appears for an unknown reason, immediately close the shut-off valve and call 104 an emergency gas service specialist.

The rag must be wet to ensure a gas-tight seal. Household gas is supplied at low pressure - from 100 to 300 mm. water column (for comparison: 1 atm = 10.5 m of water column) - and will not squeeze moisture out of the pores of the rag.

The cork from the narrow end, compressed by the neck of the bottle, is cut into a cone with a sharp knife and processed with sandpaper. Insert tightly into the pipe, turning slightly back and forth. If it gets stuck, remove it with a corkscrew.

There is no need to prepare a soap solution with distilled water. A children's set for blowing soap bubbles is very suitable: with a ring on a stick it is convenient to check the reliability of the shut-off valve. Another way is to add 5-10 drops of any liquid dishwashing detergent to a glass of water.

Principle of operation

A thermocouple is a fairly simple device. The working principle of a thermocouple can be explained as follows:

- The tip is located near an open flame.

- As soon as the gas stove or oven is turned on, the metal rods heat up and create an electric current.

- Current flows through the tube and enters the temperature sensor.

- An electromagnetic field is created in the sensor, which lifts the valve, opening the flow of gas to the burners.

If the flame goes out without human control, the thermocouple cools and the electrical voltage disappears. The electromagnetic field also disappears, thereby closing the valve. The flow of gas into the system is blocked.

Thermocouples are most often installed inside ovens. This is necessary due to the lack of visual control of the flame. This gas monitoring device has a number of advantages:

- High accuracy.

- Long working period.

- Easy to install, replace, maintain.

The gas supply control device is reliable and durable. But it also has its service life.

Prevention is better than repair

Regular maintenance of your gas stove will extend its service life. Keep both the outside and inside of the stove clean. Regularly remove dirt from work surfaces.

Regular maintenance of your gas stove will extend its service life and avoid breakdowns.

Important! To avoid getting burned while cleaning, wait until the stove and burners have cooled completely.

Repairing a gas stove is simple. Keeping it in good working order and preventing breakdowns is even easier.

Malfunctions

Determining a malfunction of a gas control element is quite simple. A faulty sensor has the following symptoms:

- When the burner is turned on, the flame does not light up. The reason is the gas supply valve has not opened. If the stove is equipped with a push-button switch, the button will press back immediately after pressing.

- After switching on, the flame burns for a short time and goes out again. The reason is the same. On plates with push-button control, shutdown will occur immediately after pressing.

So, there are only two reasons and both lead to the valve. Subsequent testing is necessary to determine the problem.

Examination

Checking the thermocouple for functionality is quite simple. To do this, you must first dismantle the element. You can clean it before dismantling. It is performed as follows:

- It is necessary to clean the tip body using sandpaper. Accumulated carbon deposits do not allow heat to pass through, which leads to prolonged heating of the thermoelement.

- You also need to check all electrical contact connections. Often, when several burners are turned on, the temperature rises, which melts the insulation of the wires. Uninsulated wires may touch the stove body, creating a short circuit.

- It is worth paying attention to the rigidity of the shrinkage of the terminals. Heating the copper tips can reduce contact with the conductor, causing the valve to simply not receive voltage to create a magnetic field.

- After cleaning, you need to turn on the stove again. If the problem remains the same, the thermocouple must be removed.

Often, one stove has thermocouples installed on all burners and inside the cabinet. If cleaning does not lead to the desired result, you will have to dismantle and check all the elements.

- Close the main gas supply valve.

- Understand the top panel of the slab.

- If the device is located inside the oven, remove the door.

- Find the solenoid valve.

- Using a wrench, disconnect the element from the valve body. Gas regulators have different connections, simple fitting or in the form of terminals. The terminals must be disconnected carefully so as not to break the protruding tip. It will not be possible to restore it.

Next, you just need to inspect the surface of the element. If it is damaged, no inspection will be required. The part will have to be replaced. It is impossible to repair a melted pair. If the case is intact, you will need to check with a multimeter:

- Set the multimeter to the mode for measuring the minimum constant electrical voltage.

- The tube has a conductive contact; you need to connect the “+” probe of the multimeter to it.

- Connect the minus probe to the element body.

- Heat the tip over an open flame.

When heated, a working thermoelement should produce a fraction of the electric current of 17–25 mV. If the voltage is absent or below these values, the part requires replacement. It is not recommended to test the part for resistance. Such a check will only show the integrity of the case. A non-functional thermocouple must not be disassembled for repair purposes. It will not be possible to restore the heating elements, since it is impossible to find replacement parts.

If the thermocouple is working, the solenoid valve will require checking. It is difficult to repair; if it malfunctions, it is better to replace it with a new one. To check, the valve must be removed after first shutting off the gas supply. This procedure cannot be performed on working stoves. Further:

- Check the part for contamination.

- Remove and clean the filter; on the latest models it is located on the inlet side.

Next you will need a battery or power supply. The “+” contact from the battery must be connected to the only terminal of the device, the “minus” contact is supplied to the housing using a piece of wire. Within a minute, a click should sound, indicating that the locking device has opened. After disconnecting the battery from the terminal, the click should repeat, indicating that the shutter is closing. If the valve does not respond to the supply of voltage, it must be replaced strictly with an analogue one. If it closes while voltage is applied, the valve is also considered unusable.

Replacement

Replacing the thermocouple in a gas stove should only be performed at a specialized center. But it is quite easy to do it yourself, subject to strict safety measures. Before replacing the gas stove thermocouple, you must purchase it. The element body is marked with an English letter. It is this marking that indicates the chemical composition of the rods inside the housing. Installing an element with a different composition may affect the valve opening or closing time and the overall sensitivity of the part. Also, parts with different markings may have connecting parts, thickness and length of the tube that differ from the original. You need to purchase a complete analogue. Next you need:

- Unplug the stove from the electrical outlet.

- Turn off the gas supply at the main valve.

- Remove the top panel of the gas stove.

- Disconnect the thermocouple from the mount. The tip is constantly at high temperature and may be difficult to unscrew. Before dismantling, it is better to use a rust remover. It is strictly prohibited to bend or break the fastener.

- Replace the faulty part with a new one.

- Reassemble the plate in reverse order.

- Connect the oven to electricity.

- Open the gas supply.

- Check the operation of the device.

Before changing the thermocouple, be sure to protect yourself from gas leaks and electric shock.

When purchasing a new part to replace an old one, you need to pay attention to the length of the conductive tube. It must be identical to the factory counterpart. When installing on a gas stove, it is necessary to install the tube at the mounting points; it should not dangle, sag, or be located near the flame.

Also, when installing the thermocouple tip, you must maintain the distance between it and the burner. A close location will significantly reduce the service life of the part; if the location exceeds 1 cm, this can lead to problems with gas ignition.

Why does a gas stove need a thermocouple?

The gas in the stove burner is ignited with matches, a manual piezo lighter or a built-in electric ignition. Then the flame should burn on its own without human intervention until the fuel is turned off by the valve.

However, often the fire on a gas hob or oven goes out as a result of a gust of wind or a splash of water from a boiling pan. And then, if there is no one nearby in the kitchen, methane (or propane) begins to flow into the room. As a result, when a certain concentration of gas is reached, a bang occurs with fire and destruction.

The working function of a thermocouple is to control the presence of a flame. While the gas is burning, the temperature at the tip of the control device reaches 800–1000 0 C, and often higher. As a result, an EMF arises, which keeps the gas solenoid valve on the nozzle to the burner open. The burner is working.

However, when the open flame disappears, the thermocouple stops producing EMF to the electromagnet. The valve and fuel supply are shut off. As a result, the gas does not enter the kitchen without accumulating in it, which eliminates the possibility of a fire from such an emergency situation.

A thermocouple is a simple temperature sensor without any electronic devices inside. There is nothing to break in it. It can only burn out from prolonged use.

The following article, which is entirely devoted to this interesting issue, will introduce you to a complete set of sensors designed to control and safety the operation of a gas water heater.

Among the advantages of thermocouples:

- simplicity of the device and the absence of breaking mechanical or burned out electrical elements;

- the device is cheap - about 800–1500 rubles, depending on the model of the gas stove;

- long service life;

- high efficiency of flame temperature control;

- quick gas shut-off;

- ease of replacement, which you can do yourself.

The thermocouple has only one significant drawback - the difficulty of repairing the device. If the thermocouple sensor is faulty, it is easier to replace it with a new one.

To repair such a device, it is necessary to weld or solder two different metals at high temperature (about 1,300 0 C). It is extremely difficult to achieve such conditions in everyday life at home. It is much easier to buy a new control unit for a gas stove as a replacement.

Adviсe

Operation and subsequent repair of the thermocouple must be carried out in compliance with safety precautions.

- It is necessary to respond promptly to a gas leak. Even new gas protection may not work. This happens due to debris getting into the bolt seat. Debris appears in the gas supply system due to poor quality pipe repairs.

- Do not cool the thermocouple with water. A sudden change in temperature can destroy the rods that form the current.

- It is prohibited to operate thermocouples with adhered food or carbon deposits. Foreign coatings retain high temperatures. After turning off the stove, the shutter mechanism will not work, which will lead to a gas leak.

- After replacing the element, you need to monitor its operation for several days.

- It is prohibited to purchase parts from unknown manufacturers or low-quality counterfeits. For a new pair, it is better to contact a specialized store or service center of the gas stove manufacturer.

- If you have doubts that you will be able to check or replace the thermocouple yourself, it is better to entrust this to specialists and take the stove to a service center.

Replacing a thermocouple is an easy but very responsible process. Do not neglect simple safety rules.

Classification of sensors by material of manufacture

Today there is a wide range of thermocouples on sale, which differ in the following characteristics: resistance to vibrations, operating temperature range, chemicals, durability, emf, device compatibility, as well as material of manufacture.

Remember, the main criterion for choosing sensors for a kitchen stove is the thermal range.

Let's consider the main types of converters made of base metals

- Type XA, THA, K (nickel-alumel/nickel-chrome). This type of thermocouple is the most common, its advantages are: low cost, durability, high accuracy (measurement error does not exceed 0.4%), large operating temperature range - from -270 to 1260°C.

- Type L, THC (chromel / copel), the distinctive characteristics of these units are considered to be a long service life and good noise immunity.

- Type A-1, A-2, A-, TVR (tungsten-rhenium), the advantages of such thermocouples are affordable cost, heating stability, as well as a good linear relationship between electromotive force and temperature.

- Type J (iron / constantan), this type of sensors ranks second in popularity after nickel-aluminum and nickel-chrome elements. The advantages of such devices are their high thermal resistance, as well as the possibility of use at high temperatures (from -280 to 760°C). The main disadvantage of this type of thermocouple is the short operating time.

- Type T (copper/constantan) are highly specialized devices designed to operate at extremely low temperatures (from -270 to 370°C) or with a lack/slight excess of oxygen in the atmosphere.

- Type E (nickel-chromium / constantan), are characterized by high sensitivity, high measurement accuracy, thermoelectric homogeneity, and the devices have a strong signal. Despite their undeniable advantages, such sensors have a narrow temperature range, which varies from 270 to 870°C.

- Type N (nikrosil / nisil), the measurement accuracy of these devices is several times higher than that of K-devices. The recommended operating temperature range for such devices is from -210 to 480°C.

Currently, in addition to the above types of thermocouples, “premium” class converters made of noble metals are on sale. Their distinctive characteristics are a high level of measurement accuracy, durability, oxidation resistance, and the ability to operate in wide temperature ranges.

The only drawback of such devices is the high cost, which significantly reduces the demand for these products.

Let's consider the most popular types of thermocouples made of noble metals

- Type S (platinum-rhodium-platinum). As a rule, this type of device is designed to operate at high temperatures, their operating range is from -50 to 1350°C

- Type B (platinum-rhodium-platinum-rhodium). A distinctive feature of such parts is the ability to accurately measure very high temperatures, which reach 1700°C.

- Type R (platinum-rhodium-platinum). They have identical properties as an element of type S.

Despite the excellent characteristics of thermocouples of types S, B and R, it is absolutely impractical to use them to equip a gas stove. Often, the scope of application of such devices is the production of vacuum furnaces, hydrogen, as well as automation of industrial processes.