Purpose

The jigsaw is omnivorous, because it can be used to cut various sheet materials. This is due to the wide range of characteristics of the produced files, which allow sawing the following types of materials.

- Wood of different species;

- Wood panels (chipboard, fibreboard, MDF, OSB, laminate, etc.);

- Metal;

- Various polymer materials (plastics);

- Glass and ceramics.

Our separate article is devoted to the selection of jigsaw files.

Recommendations for use

To make it easy to work with the tool and maximize its service life, you must follow simple rules:

- When cutting any material, you do not need to put pressure on the saw blade, thereby “helping” it move faster. This way you will only speed up the process of its heating and failure;

- Change the saw blade more often to minimize the load on the engine, which increases significantly when working with a blunt tool;

- When cutting metals, you can lubricate the blade with machine oil. This will make the tool easier to operate, and the saw will remain sharp longer;

- To avoid excessive vibration when cutting thin sheet metal, place a sheet of plywood under it. This will make the cut more accurate;

- Periodically give the tool a rest, especially if you work at low speeds. In this mode, the engine is not cooled sufficiently;

- Do not store the tool if it is dirty. After work, clean it every time from chips and lubricate it;

- Do not place the tool in such a way that it rests on the cutting blade. This can lead, at best, to its curvature, at worst, to the straightness of the cut being lost;

- Store the tool in a special case to protect it from dust and accidental impacts;

- Do not operate the tool while wearing gloves. This will significantly reduce the reliability of fixing the jigsaw in your hand, which can lead to its fall, injury to you, or damage to the workpiece being processed;

- Be sure to wear safety glasses and a respirator to protect yourself.

Classification

The range of characteristics and parameters of jigsaws is very wide and it allows us to distinguish certain groups. Thus, the following classification of all jigsaws can be made.

Tool class

- For home use (household);

- Professional;

- Industrial.

The tool for home use does not have a high price, but has a short service life and a relatively small range of functionality. A professional tool, on the contrary, is adapted for long-term work, heavy loads, and accordingly has an increased service life, high technical characteristics and expanded functionality. Naturally, with such a set of positive parameters, the price of a professional tool is significantly higher than for home use.

Industrial jigsaws have an even greater reserve of power and resource, but have less functionality compared to professional tools. This is due to the fact that in production, basically all technological operations are quite standard and do not require unique capabilities and needs, since specialized industrial solutions are used.

By type of power supply

Jigsaws can be classified according to the type of power supply:

Wired

Corded jigsaws include models that receive power from a standard household power supply - 200V AC. Advantages - continuous operation (if there is electricity in the network), Disadvantage - the need to have an electrical outlet within reach.

Wireless

Cordless jigsaws include models that run on portable batteries. Advantages - the ability to carry out work without the need to have an electrical outlet within reach. The disadvantage is limited operating time and low power.

What is a jigsaw: scope of application of power tools

An electric jigsaw is a device with which shaped blanks are cut from wood, chipboard, fiberboard and even metal for various purposes. Similar equipment is used in furniture production, the production of figured decorations, and for household purposes (as an auxiliary tool). After all, if you have an even piece of wood, you can ideally cut boards, PVC or NDF panels. The angle of inclination is also adjustable, which allows you to chamfer or unravel the fiberboard lengthwise at the desired angle. He can even do garden work like removing dried tree branches.

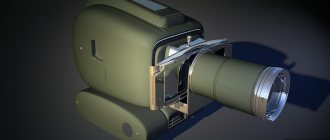

Device

To make the right choice of a jigsaw, you need to understand how it works, what elements it has, and what is their difference. Below is a schematic cross-sectional image.

| Number | Description |

| 1 | Start button |

| 2 | Adjusting the motor speed |

| 3 | Stock |

| 4 | Gearbox |

| 5 | File clamp |

| 6 | Support roller |

| 7 | Electric motor |

| 8 | Brushes |

| 9 | Support bearing |

| 10 | Chip drain pipe |

Let's look at the purpose of each element:

- Start button. Closes the electrical circuit and turns on the electric motor. Many jigsaws are equipped with a soft start system, which allows you to adjust the engine speed by the degree to which you press the start button.

- Adjusting the electric motor speed. Using this regulator, you can determine the maximum number of revolutions of the electric motor when the start button is fully pressed.

- Stock. A metal rod that determines the forward movement of the jigsaw saw blade.

- Gearbox. A mechanical device that converts the rotational motion of an electric motor into the pendulum motion of a rod.

- File clamp. A device that allows the saw blade to be rigidly attached to the rod. There are different fastening standards and, accordingly, types of saw blade shanks.

- Support roller. The roller on which the saw rests while moving.

- Electric motor. An electric motor is the basis of a power tool, and in the case of a jigsaw, it drives the rotating parts of the gearbox, which in due course transmits the translational movement of the rod.

- Brushes. Graphite brushes transmit electricity from stationary current-carrying wires to the rotating elements of the electric motor. They are not durable, so over time they wear out and the engine, not receiving electricity, stops working. In this case, you just need to replace the brushes. This is one of the common malfunctions of any power tool.

- Support bearing. Despite its apparent insignificance, the support bearing has a very important role - it is the support of the electric motor. It is this that often fails in the cheapest models of jigsaws. This is due to the fact that the bearing is fixed in a plastic housing and when the jigsaw is operated for a long time under load, it heats up to temperatures at which the surrounding plastic begins to melt, which leads to deformation of its seat and displacement of the electric motor and further jamming.

- Chip removal pipe (dust collector). The jigsaw is equipped with a system for removing dust and chips from the sawing zone in the form of a special pipe, which must be connected to the vacuum cleaner hose. During operation, a large amount of sawing products (dust and shavings) is formed, which are recommended to be removed.

- Support platform (or "sole"). It is not indicated in this diagram, but it will be discussed separately below.

The main components of a jigsaw are discussed above, but various functional parts that may optionally be present on various models are not touched upon. These include:

- The flashlight acts as a backlight for the sawing area;

- Laser level allows you to make cuts more accurately;

- The chip blowing system allows a directed air flow to remove sawing products (dust and chips) from the cutting area for a better overview of the sawing site.

and etc.

How to choose a good jigsaw for use in your home workshop?

When choosing a tool for a home workshop, the main thing is functionality and technical characteristics. The price is important, but not decisive, because material assets are produced in the workshop, the tool pays for itself.

The worst choice for a workshop is cheap, unreliable jigsaws, because you will have to buy 2-3 of them instead of one quality one. And instead of saving, there will be unnecessary overpayments and problems during work.

An example of a good jigsaw for a workshop is the Makita 4351FCT 720 W.

This is a Japanese development, which already guarantees quality, despite the country of assembly (Eastern Europe or China). All the necessary modern functions are present:

- workspace lighting,

- smooth start,

- speed adjustment,

- speed support under load,

- powerful motor, cuts wood up to 135 mm thick and steel up to 20 mm.

- saw stroke 26 mm,

- weight 2.5 kg, which is not much for such power,

- the presence of a pendulum stroke,

- long cord – 2.5 m.

Makita 4351FCT operates almost without noise and vibration, which indicates high-quality performance and assembly of all parts.

Service center technicians report that this model very rarely gets repaired during the warranty period; there are practically no defective copies. A new solution in the layout, the tool is easy to use and fits well in the hands. Supplied in a suitcase (case).

Parameters, features and technical characteristics influencing the choice of a jigsaw

The problem of choosing a power tool is a difficult task, since at the moment there is a wide variety of models and choosing the right option that will be optimal in terms of functionality, technical characteristics and price is not so easy. We will try to understand all the nuances.

Type of support platform (“Sole”)

The support platform is a very important part in the design of a jigsaw, since it is the one that comes into contact with the workpiece and, in many respects, the ease of use and various functionality depends on it. Let's look at possible options for the support platform.

Classification by manufacturing methodology

We present a table from which the options and their features will be clear.

| Support platform type | Preparation method | Advantages | Flaws |

| Stamped | made of sheet metal, thickness from 0.5 mm to 3 mm |

|

|

| Cast | all-metal, cast with subsequent milling of planes |

|

|

Stamped jigsaw sole

Cast jigsaw sole

Adjusting the tilt angle of the support platform

The ability to adjust the angle of inclination of the support platform significantly expands the capabilities of the jigsaw, since it becomes possible to make cuts at an angle to the sawing plane, and not just at 90°. It should be noted that inexpensive models have only two positions: 90° and 45°, while more expensive models (usually professional) have the ability to discretize the angle by 15°, that is: 90°, 75°, 60° and 45°.

The fixing mechanism for the angle of rotation of the support platform can be made in two versions:

- clamp with screws;

- special quick-release mechanism.

Clamping the sole with a screw

Obviously, fixing the sole with screws is a more labor-intensive process and, in addition to time, also requires the presence of a tool (screwdriver or special key), while changing the position of the platform with a special quick-release mechanism does not require a tool and is done in a few seconds. Accordingly, the quick-clamping mechanism increases the cost of the tool.

File fastening standard

At the moment, there are several standards for attaching a saw blade to a jigsaw rod, but only one is the main one, it is the most popular and, in fact, is now replacing all others. In addition, the fastening standard also determines the type of file shank that is attached to the jigsaw. That is, when choosing a jigsaw, you need to understand exactly what fastening standard is used. This will determine the types of saw blade shanks that will need to be purchased for it in the future.

However, let's look at all the options. There are three types of clamps:

- Screw

- Shoe

- Quick-release

Screw

This is the simplest method of fastening, in which the shank of the file is clamped with one single screw on the side.

Shoe

With this method of fastening the file, it is clamped into a special block with a slot, in which it is fixed with two screws located frontally. The advantage of such a standard is its versatility, that is, a saw blade with any shank can be clamped into such a holder, but the disadvantage is that if the screws are unevenly clamped, the saw blade can become skewed and, as a result, the saw cut can be crooked.

Quick-release

This is the most common method of fixation, since it does not require additional tools (screwdrivers or special keys) - the clamping is done using a special clamping mechanism, and changing the file takes a few seconds. The mount is quite reliable. The disadvantage is the lack of versatility, that is, you can install a saw blade only with a certain type of shank; others will not fit. In addition, very thick files may not be suitable.

Shank types

T-shaped

There are several types of shanks available today, but the most common is the T-shank. It was developed thanks to a successful design first proposed by Bosch. In this regard, this type of shank is also called “Boshevsky”. Now it is essentially a standard as it has been “adopted” by many eminent manufacturers.

U-shaped

The second most common is the U-shank. It is less common and is considered an American standard, so it can already be considered obsolete. Previously, this type of saw blade shank was very popular and was used for jigsaws with block and screw clamps.

Proprietary Shank Types

Makita shank

Bosch shank

They are now almost never used because they are not widely used due to their proprietary nature (unique belonging to a specific brand protected by copyright). These types of shanks were used by saws (and jigsaws) from Bosch, Makita, DeWalt and others.

Power

Engine power is a very important parameter, as it characterizes the jigsaw’s ability to work under load, and, accordingly, the ability to cut thicker workpieces. Even if you are not going to work at maximum loads, it is still very useful to have a so-called power reserve in the tool and, as a result, a service life. The standard power range for jigsaws ranges from 350W to 100W. Accordingly, the most optimal choice may be the “golden mean” – 600-700W. Let's give some conditional table of the relationship between the power of a jigsaw and the thickness of the workpiece being cut.

| Jigsaw power | Workpiece thickness (wood) | Workpiece thickness (metal) |

| 400 W | 60-65 mm | 4-6 mm |

| 600 W | 80-85 mm | 6-8 mm |

| 800 W | 100-105 mm | 8-10 mm |

This table is very arbitrary, since a lot depends on what kind of saw blade is installed, and what kind of wood (linden, pine, birch, oak, etc....), and what specific brand of steel is being sawn, and what efforts the master makes and the concept itself “saws” or “does not saw” is different for different masters.

It is important to note that power is directly proportional to the weight of the jigsaw, and if at the time of choosing a tool this does not seem to be a very important parameter, then when working with a jigsaw for a long time, this parameter becomes significant. This is due to the fact that your hand gets tired, and the quality of the cut directly depends on how firmly and firmly you hold the tool in your hands. So it turns out that the quality of long-term operation directly depends on weight and, as a result, power.

Blade stroke frequency

The frequency of movement of the jigsaw rod is an important parameter. The quality of the saw largely depends on it. Let's figure it out - the electric motor transmits rotational movement to the gearbox, which in turn converts it into translational movement of the rod. Accordingly, the frequency of movement of the rod directly depends on the number of engine revolutions, as well as on the gear ratio. It is important to understand that if the gear ratio is large, then the number of translational movements of the rod per revolution of the electric motor shaft will be large, and the power of rod movement (force during movement) will be lower, and vice versa. Thus, the number of saw blade strokes is directly proportional to the number of engine revolutions, taking into account the gear ratio.

The range of stroke frequencies for a jigsaw is from 1500 to 3500 strokes per minute, however, most jigsaws have this parameter from 2500 to 3200 strokes per minute. This is the optimal operating mode.

Speed adjustment and soft start

Soft start is a function that allows the engine to smoothly pick up speed, otherwise a microshock occurs during start-up, which negatively affects the entire design of the power tool. The jigsaw is not designed for shock loads.

Adjusting the speed of the electric motor is directly related to the speed of the electric saw and allows you to change them within a given range. Adjusting the saw stroke frequency can be done in two ways (of course, not for all models):

- The start key, which, as it is pressed and released, accelerates and slows down the speed of the electric motor (see the picture in the “Device” section - No. 1).

- A special regulator for the number of engine speeds (see the picture in the “Device” section – No. 2). It sets the maximum number of revolutions when the start button is fully pressed and is set before starting work.

The need to adjust the number of revolutions is related to the density of the workpiece being cut - the higher the density, the fewer the number of strokes of the saw blade (lower the motor speed). So, for example, soft wood (linden, pine) can be sawed at maximum speed, but when sawing metal you need to reduce the speed to a minimum. This is due to the fact that when sawing dense material, the load on the jigsaw itself increases sharply, and the saw blade (file) begins to heat up very much, which leads to its premature failure. And the jigsaw itself experiences unreasonably high loads.

Pendulum stroke

This is probably a standard feature at the moment, although it is a relatively new feature. The bottom line is that the jigsaw saw blade, in addition to vertical reciprocating movements, also makes oscillatory movements back and forth. This trajectory is possible due to the pendulum movement of the support roller (see the picture in the “Device” section - No. 6). The amplitude of the pendulum stroke is adjusted using a special switch, which usually has 3 or 4 positions - from “no stroke” to maximum.

The pendulum stroke of the saw allows you to significantly increase the speed of work and increase the service life of the saw blade. True, the negative side is the deterioration in the quality of the saw. Thus, if you need to do rough work and the quality of the saw is not important, then you can set the maximum amplitude of the pendulum stroke of the saw, and if necessary, get a clean cut - remove it completely. If a radius or figured cut is required, then the pendulum stroke must be turned off, otherwise the file may become deformed and jam.

Depth (thickness) of cut

This parameter is indicated in the characteristics of the jigsaw and can be used as some criterion for selection. The documentation usually gives three indicators: for wood, for steel and aluminum. You need to understand that this is a very conditional parameter, since even under the word “wood” there may be hidden the most delicate balsa or iron wood, comparable in density to some metals. By and large, this is a derived indicator from the engine power of the tool, although it can be assumed that some design features of the jigsaw itself can increase or decrease these indicators. Let's give a few values.

| Parameter | Household tools | Professional tool |

| Tree | 50-120 mm | 150-160 |

| Aluminum | 5-10 mm | 30-35 |

Maintaining constant speed under load

This is a function of the jigsaw electronics that analyzes the position of the controls responsible for the speed of the electric motor with the actual engine speed. With a significant load on the jigsaw, the engine becomes difficult to operate and a natural decrease in speed occurs. The electronics records this fact and corrects the speed by supplying additional electricity. Thus, over the entire range of permissible loads on the jigsaw, engine speed is maintained at a constant level. This function is very useful for the tool itself, since excess load and, as a result, slowing down the rotation of the motor, will lead to increased currents in the motor winding and its overheating. In addition, maintaining constant speed is good for the master, since the frequency of movement of the saw directly affects the quality of the cut, and accordingly, a constant frequency is the key to the quality of work.

Backlight and laser pointer

Some jigsaw models have lighting for the sawing area or a laser pointer. Backlighting can be very convenient for working in low-light areas, although even where there is good lighting, there may be natural shadows or areas of poor visibility, so backlighting is a very useful feature.

The laser pointer is used to improve cutting accuracy, as it is a kind of direction indicator that helps the master accurately guide the jigsaw along the marking line.

Weight

The importance of the weight of a jigsaw was mentioned above, but we repeat that during long-term work, when the hand of the master holding the tool gets tired naturally. Therefore, the quality of the cut decreases. If the jigsaw is heavy, your hand will get tired faster.

Equipment

This is not a parameter or characteristic of the jigsaw itself, but the composition of the kit being sold. Often the package includes a case (plastic box), which is optimized specifically for this tool and its components. If there is no case, then the kit comes in a cardboard box, which over time will lose its shape and is not convenient to carry.

In addition, the kit often includes branded saw blades for various purposes, this is also a positive point, since for the first time the master will be provided with saw blades. And also in the kit, in addition to standard components (instructions, special keys, etc.), there may be additional accessories - see the next section.

Additional accessories

As mentioned above, sometimes additional accessories are included with a jigsaw.

Compass stop

This is a special device that allows you to make concentric cuts along a given radius.

Rip fence

This is a special device that allows you to make cuts parallel to the edge of the workpiece.

Anti-splinter liner

This is a special pad that surrounds the sawing area. Its use reduces the number of possible chips of the saw material, and accordingly improves the quality of the cut.

Removable sole pad

This is a special cover made of metal or plastic that is installed on the support platform. It improves sliding, which reduces friction and, as a result, makes work easier, and also prevents scratches on the workpiece.

Which electric jigsaw should you choose for your home and garden?

The most popular jigsaws for household use are models from well-known brands with a good reputation, average power and cost. With their help, you can solve almost all tasks that such a tool can perform. At the same time, they are quite reliable, which is why they have gained popularity. These are the following models.

Makita 4329 450 W

This is a Japanese brand. Regardless of the country of manufacture, the design is distinguished by its traditional Japanese product compactness, ease of use, light weight and relatively low price - about 4,000 rubles. It has additional ventilation holes, so it can work for a long time without overheating the electric motor.

- The frequency of saw strokes is from 500 to 3100 rpm.

- The saw stroke amplitude is 16 mm.

- Cutting depth is 65 mm for wood and 6 mm for steel.

- Pendulum stroke adjustable in 4 steps.

- Adjusting engine speed.

- Weight 1.9 kg.

BOSCH PST 700 E 500 W

A model from a German brand, popular among professional builders and woodworkers. Can be produced in EU countries or China.

Thanks to the carefully thought out shape of the handle and layout, it fits comfortably in the hand. Features: the use of the “Low Vibration” system reduces vibrations to a minimum, which distinguishes the model from others. There is a system for blowing sawdust from the working area. Supplied in a hard case.

- The frequency of saw strokes is from 500 to 3100 rpm.

- The saw stroke amplitude is 16 mm.

- Cutting depth is 70 mm for wood and 4 mm for steel.

- There is no saw blade pendulum mode.

- Weight 1.7 kg.

- Cost – 4.5-5 thousand rubles.

DeWALT DWE349 650 W

A more powerful option for household and professional work. The long cable (4 m) allows you to do without an extension cord for many jobs. There is a function for blowing sawdust out of the working area. The saw blade clamp is keyless.

- The frequency of saw strokes is from 500 to 3200 rpm.

- The saw stroke amplitude is 20 mm.

- Cutting depth is 85 mm for wood and 10 mm for steel.

- There is a pendulum mode for the saw.

- Weight 2.66 kg.

- Cost – about 6 thousand rubles.

BISON L-400 400 W

Russian brand, country of assembly: Russia or China. One of the lightest, simplest and inexpensive jigsaws. A suitable option for rare auxiliary work.

- The frequency of sawing strokes is up to 3000 rpm.

- The saw stroke amplitude is 18 mm.

- Cutting depth is 55 mm for wood and 10 mm for steel.

- There is no pendulum stroke.

- Weight 1.4 kg.

- Cost – about 2.5-3 thousand rubles.

Interskol MP-55/500E 500 W

The Russian brand has already become famous and has gained a good reputation for the quality of its products. The country of assembly is formerly the Russian Federation, today mainly China, under the control of Russian designers and engineers. The product comes with a good 2-year warranty.

Can be used for any work.

- The frequency of sawing strokes is from 800 to 3000 per minute.

- The saw stroke amplitude is 18 mm.

- Cutting depth is 55 mm for wood and 10 mm for steel.

- There is a pendulum stroke with adjustment in 4 steps.

- Weight 1.6 kg.

- Cost - 2.1-2.7 thousand rubles.

TOP 5 jigsaws

Now let’s try to apply the information described above in practice and try to compare the TOP 5 most popular models of jigsaws, comparing their characteristics, parameters and configurations.

Comparison table of characteristics of jigsaws

| Manufacturer | Hitachi | Bosch | DeWALT | Makita | Metabo |

| Model | CJ110MV | PST 900 PEL | DW349 | 4350 FCT | STEB 70+ case |

| Price | 6,990 rub. | RUB 5,190 | RUB 4,379 | RUR 9,790 | RUB 5,499 |

| Manufacturer's warranty | 3 years | 1 year | 3 years | 1 year | 3 years |

| Saw stroke, mm | 26 | 23 | 20 | 26 | 22 |

| Pendulum stroke | Eat | Eat | Eat | Eat | Eat |

| Power, W | 720 | 620 | 500 | 720 | 570 |

| Max cutting thickness (wood), mm | 110 | 90 | 75 | 135 | 70 |

| Max cutting thickness (metal), mm | 10 | 8 | 15 | 10 | 20 |

| Speed adjustment, | There is | There is | There is | There is | There is |

| Number of strokes, stroke/min | 850-3000 | 500-3100 | 0-3200 | 800-2800 | 900-3300 |

| Availability is fast. deputy files, | There is | There is | There is | There is | There is |

| Availability of backlight | There is | There is | There is | There is | No |

| Adjustment of the inclination of the sole without tools, | No | No | There is | No | No |

| Availability of laser | No | No | No | No | No |

| Availability of soft start, | No | No | No | There is | No |

| Maintaining constant speed under load, | No | No | No | There is | No |

| Molded sole, | No | No | There is | There is | There is |

| Equipment, | case | case | box | case | case |

| Weight, kg | 2,20 | 2,10 | 2,50 | 2,50 | 2,00 |

Additional functions

- Laser pointer. The laser beam acts as a guide line. There is no need for it if you are used to making markings before cutting the material;

- Possibility of connection to a vacuum cleaner or dust collector. A useful feature that allows you to keep your workplace in order;

- Automatic sawdust blowing allows you to see the marking line as clearly as possible;

- Illumination is important to create maximum visibility of the cutting line, regardless of the position of the device and the operator;

Jigsaw with light - Adjusting the sole is a very useful feature that allows you to cut material at a strictly defined angle. Depending on the class of the tool, the angle of inclination of the support platform can vary by 15, 30 and 45°;

- A soft start ensures a gradual increase in speed by the electric motor. As a result of this, the starting current is reduced, and as a result, the load on the electrical network. In addition, this option is necessary in cases where high cutting accuracy is important;

- Blade replacement system. The saw blade is replaced without keys or screwdrivers;

- The holding mechanism is operated by a plastic lever;

- Maintaining speed under load. This useful option will help maintain the speed and quality of the cut, and also protect the motor from overload.

Household or professional

Like other power tools, jigsaws are divided into household and professional according to their capabilities. Jigsaws intended for home craftsmen are the most inexpensive, but they have relatively low power and a limited resource.

When choosing a professional tool, you need to forget about saving for a while, and think first of all about reliability, because such a jigsaw will have to work uninterruptedly for several hours a day. Decent technical characteristics and the presence of all the necessary functionality - this is what a professional will pay attention to when buying a tool for everyday work.

There are also industrial jigsaws, the safety factor of which is designed for long-term operation in a small woodworking enterprise. Essentially, these are mini-machines for straight and curved cutting.

Next, we will try to focus on how to choose a jigsaw specifically for the home. It is assumed that professionals are quite well versed in the issue at hand, but among amateurs there are inexperienced beginners.