Electric planers are an essential tool for modern carpenters, joiners, and all specialists involved in processing lumber. Their prevalence is due to practical efficiency and the presence of significant advantages of this equipment compared to manual analogues. To fully utilize the device's potential, electric planer blades must be pre-adjusted before processing wood. Also, the blades must be sharp. This, together with the correct adjustment of their position, will allow processing significant volumes of boards or beams without any special problems or effort on the part of the user.

Types of knives for electric planers

Knives on an electric planer are consumables. With their help, wood surfaces are processed.

Often knives come complete with power tools in the amount of 2 pieces.

Electric planer knives are classified according to the following criteria:

- opportunities for practical reuse;

- blade shape;

- knife blade sizes;

- cost.

When buying an electric planer, in addition to checking its performance and configuration, you should pay attention to the quality of the knives installed on the drum and their sharpening. The blades should be sharp, with a straight edge and no bends or gouges. Spare knives should also be checked. The final quality of lumber processing depends on the correct selection of cutting attachments.

Disposable knives

Knives intended for disposable use are made of steel-based hard alloys in the form of plates sharp on both sides. Such cutting parts cannot be sharpened. After the edge being used is completely worn out, the blade is turned over and placed on the drum with the other side. At the same time, the tool continues to work. If the second cutting edge becomes dull, then the blade is simply thrown away.

Disposable knives are intended only for performing work that does not require high precision and quality of workpiece processing. But they are convenient for practical use: during installation they do not need to be precisely adjusted and balanced.

The shapes of disposable products are:

- straight;

- wavy;

- straight, but rounded at the ends.

The first type of product has a straight cutting part. It is convenient to use such consumables to process parts that have a smaller width than the length of the installed blade, and to select quarters. Wavy knives are used when it is necessary to carry out rough processing of lumber. With their help, you can give a wooden surface a different texture, for example, to simulate “aging.” Straight cutting edges, rounded at the edges, are good because they do not leave marks (grooves, steps) on the surface of the wood being processed. This is a suitable option if you need to work with wide wooden pieces.

Disposable blades have a longer service life, but can break quite easily if they accidentally collide with metal (for example, a nail, bolt). They are the best option for attachments when it is necessary to work with hard wood workpieces.

Reusable cutting attachments

Products that are intended for reusable use differ in both their shape and size from disposable cutting attachments. They are made using high quality steel, which ensures ease and quality of processing of wooden surfaces.

Using reusable knives, you can achieve such a smooth surface of the workpiece that grinding is not required. They are marked HSS (fully High-Speed Steel, which translates as high-speed steel). These blades are considered professional. Their installation is accompanied by high-precision balancing and adjustment. The sharpening must also be of excellent quality. In this case, tool high-speed steel can be sharpened so that it is very sharp.

It is more profitable to buy reusable cutting attachments because they can be sharpened multiple times. But high-speed steel products do not allow processing hardwood (for example, larch or oak).

The working drums of most models of electric planes can be equipped with both disposable and reusable cutting attachments. But there are also devices that can only be equipped with blades that are not intended for sharpening. For this reason, when purchasing an electric planer, it is recommended to give preference to universal power tools.

Classification by size

Knives for electric planers can be standard or non-standard sizes. Products of the first type, called “plates,” have a length of 82 mm, a width of 5.5 mm, and a thickness of 1.2 mm. Such cutting attachments are suitable for most models of electric planes from foreign companies Makita, Skil, Bosch, Black&Dekker.

Straight knives for electric planers Bosch, SKIL

Non-standard cutting attachments with larger blade widths and thicknesses are typical for electric planers from Baikal and Interskol. Due to their parameters, they are stronger and better than standard plates. When they come into contact with metal, such knives do not break. They can be sharpened using sandpaper. The width of the nozzles is about 1 cm. The length can be 82 mm, 102 mm, and for products from the Rebir company it reaches 110 mm.

Straight knives for electric planer Rebir IE-5709

The price of the cutting attachment depends on the manufacturer. Also, this factor often determines the quality of the product. If you purchase knives from well-known companies (for example, Bosch), you can count on their long service life.

Some models of electric planers are equipped with cutting attachments of unusual shape and design. In order not to be mistaken with the dimensions, it is recommended to take the old blade with you for comparison before purchasing.

When do you need to adjust or replace electric planer knives?

The knives on an electric planer wear out over time. They need to be removed and sharpened or replaced altogether, and then installed back on the drum. Newly installed cutting attachments need to be adjusted in order to process lumber as efficiently as possible. The blades of new power tools also need to be pre-adjusted before use.

The following signs indicate that adjustment is necessary:

- change in sound when processing workpieces;

- vibration of the tool during operation;

- deterioration in the quality of planing lumber (formation of waves, chips, grooves, protruding fibers and other defects);

- increase in effort spent on work.

The change in sound is not typical for all models. This symptom may also indicate a number of other problems.

If, after adjusting the blade blades, the symptoms discussed above do not disappear, then more serious repairs to the power tool will be required.

Setting the correct position of the cutting attachments is carried out according to the following parameters:

- the height of the part of the blade that protrudes above the sole of the power tool;

- the size of the side protrusion of the knife intended for picking out quarters.

By correctly adjusting the position of the knife blades on the drum, high final quality of lumber processing is achieved.

How to make a sharpening device?

If necessary, you can make the required device for sharpening plane knives yourself. This version is characterized by the following features:

- Low cost.

- Possibility of application in a wide variety of cases.

- Versatility.

- Long service life.

The only drawback is that you cannot change the sharpening angle. That is why the functionality of the device is significantly reduced.

How to properly adjust knives

Adjusting the knives on the drum yourself is not a big problem. To set the position of the tool blades before work, you will need:

- hex wrench included with the plane;

- metal ruler or piece of glass of suitable size.

The setup is carried out by performing all operations in this sequence.

- Turn the electric planer over, placing it upside down on a table or workbench.

- If necessary, remove resin deposits from the nozzles using a solvent.

- Set the front part of the sole to a position that provides the minimum planing depth.

- Rotate any blade, placing it in the slot between the plates.

- A ruler is placed on the surface of the base plate.

- If the cutting edge does not touch it, then the knife bar is raised to the desired level, loosening (slightly) the fastening bolts using a hexagon.

- After alignment, tighten the fasteners.

- The procedure is repeated with all attachments, while setting gaps of the same size to prevent imbalance of the drum and vibration of the power tool during operation.

- By turning the drum by hand, determine the ease of its rotation.

- Check the correctness of the settings on the unnecessary workpiece.

In the considered sequence, the working position of the cutting edges is adjusted for models of electric planers with one, two or three knives.

It should be taken into account that the working parts of straight-shaped knives should protrude by approximately 0.5 mm, and rounded ones by 1 mm or more.

If the adjustment is carried out correctly, the cutting edges on the drum should be parallel to the sole of the power tool without distortion. A number of new models contain adjustment screws that simply need to be tightened to set the blades in the desired position. To set up the tool, it must be disconnected from the power supply, and in cordless models, the battery must be removed. This will ensure that the power tool does not start spontaneously.

Sharpening knives for hand planes

The working edge of the knife is an edge, which still has a slight radius of curvature. Before sharpening, visually check the integrity of the edge: there should be no local metal tears on it. If they are present, the planer knives will have to be shortened.

To minimize the radius of curvature on the edge, sharpening is recommended to be carried out in two stages. First, primary sharpening is carried out: the dull knife from the chamfer side is brought to the periphery of the sharpening wheel and pressed firmly. The speed of the sharpener should not exceed 600...700 min-1, otherwise the metal removal will be significant. It is important not to overdo it with the pressing force, since blue-violet tarnish may appear on the steel - an unpleasant sign of tempering of the metal. In this case, the hardness of the plane knife will decrease, and it will be necessary to restore the strength characteristics of the material through rather complex heat treatment (annealing + hardening + tempering).

If there is no sharpener, proceed as follows. Sharpening a knife for a hand plane is done with a coarse-grained sharpening stone, which must be fixed on a workbench (both hands must remain free). Sharpening is performed by circular movements of the chamfer along the surface of the block. In this case, it is advisable to periodically moisten the knife with water or soap solution. This not only cleans the sharpened surface from the smallest particles of the knife metal, but also allows the tool to be cooled evenly.

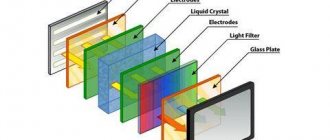

The appearance of a thin burr on the blade along its entire length is a sign of transition to the second stage of sharpening. Here the tool is sharpened using a finer-grained stone that will remove the burr. The generally accepted gradation of bars according to their grain size is as follows:

- High grain size (30...180 microns): whetstones/sharpening stones made of silicon carbide or corundum. Used to remove large defects on knives, change the chamfer angle, etc.

- Medium grain size (7...20 microns): whetstones/sharpening stones made of electrocorundum or chromium dioxide. Suitable for pre-sharpening.

- Fine grain size (3...5 µm). The materials are the same, the tool is used for final sharpening of knives.

After sharpening is completed, the knife blade is passed along a piece of hardwood, which will finally remove the burr fragments.

Algorithm for replacing knives on an electric planer

To remove the knives from the electric planer and replace them with new ones (or properly sharpened ones), you will need a set of wrenches, and also, in some cases, a screwdriver. There is no need to completely assemble and disassemble the electric plane to change working attachments. Replacement is performed in the following sequence:

- rotate the drum, placing it in such a position to gain access to the knife mounting bolts;

- loosen, but not completely, these bolt clamps;

- remove the working attachment manually or using a flat screwdriver;

- the rest of the blades are treated in a similar way;

- place new knives in the sockets, securing them with bolts;

- put them in the correct position.

The main point is the need to place the blades exactly in the sockets and securely fix them so that they do not fall out while using the tool. Due to the fact that different models of electric planers may have different attachments for working attachments, it is recommended that you first read the operating instructions for the equipment you are using.

On sale you can find knives whose blades rotate. This is very convenient because it is enough to simply turn over the dull edge, replacing it with a sharp one.

When there are two cutting attachments installed on the drum of an electric planer, both need to be changed at once. This will prevent the occurrence of an imbalance, which results in a decrease in the quality of lumber processing and failure of the electric planer.

Self-sharpening of electric planer blades

Reusable knives require re-sharpening after long-term use.

Sharpening a plane with your own hands at home is done in the same way as a hand tool. The difference is the number of cutting edges that require sharpening. To sharpen the blade yourself, you need to have several special devices:

- Sharpening stone.

- Emery.

- File.

To work, you will need a clamp to secure the part to be sharpened on the workbench. The knives are fixed so that the cutting edges are in the same plane.

All blades are sharpened simultaneously with a file or emery. There should be no deviations. The sharpness of the blade is checked on any wooden board.

To make the work easier, pre-moisten the abrasive stone with water. For initial processing, coarse-grained abrasives are used, and fine-grained abrasives are used for finishing. It is desirable that the sharpening angle of the knife is 30 degrees. When the cutting edge is severely damaged, it is better to sharpen it on a special sharpening machine.