Advantages of an electric meat grinder

This device has no alternatives, so the main advantages need to be analyzed in comparison with its mechanical progenitor:

- electric meat grinder works faster;

- saves human energy;

- there is no need to clean the device during operation;

- usually the devices are quite powerful; they can process tendons and cartilage, which is often beyond the capabilities of humans;

- There is no need to secure the device to the table with a clamp.

At the same time, the system of modern meat grinders is quite safe, since the device has a narrow and long neck into which you simply cannot put your fingers. The meat is fed to the augers using a pusher.

Purpose and types of meat grinders

The meat grinder is designed for grinding food. The main function is the production of minced meat, poultry and fish . The device also successfully processes any vegetables, both raw and cooked. If necessary, you can also crush, for example, nuts. The functionality of the device is expanded using different devices (attachments).

Meat grinders are divided into two main types:

- mechanical;

- electric.

There are also so-called combine devices that operate on the principle of a blender. But the final product after this process can hardly be called minced meat. Most of all, the processed mass resembles puree. Therefore, such a device cannot be called a full replacement for a classic meat grinder.

Electrical appliances have their own class.

- The highest class “A” is awarded to industrial units for high productivity. The MIM 300, 82 and 105 brand line is widely used. It should be noted that industrial models require power from a three-phase network for their operation. They are capable of processing from 200 to 300 kilograms of meat per hour. But the weight of such a meat grinder is not small - on average about 50 kg.

- Class “B” has devices that perform many functions thanks to an additional arsenal of attachments, knives and grids. They are represented by the brands Moulinex, Bosch, Kenwood. Among domestic models, consumers highlight the KEM-36 electric meat grinders.

- “C” class meat grinders are household devices of minimal power and without additional modes. Such budget models are widely produced by Zelmer, Braun and Saturn.

Meat grinder device

First, you should understand the general principle of the design and operation of a meat grinder, and then pay attention to its working part, where the grinding of meat occurs.

General device

The meat grinder consists of several elements:

- control unit, where buttons and indicators are located;

- an electric motor that converts electrical energy into mechanical energy

- the working part where the meat is ground.

Meat grinder device

Meat grinder structure: the body consists of a metal part (3), where the working part is located, and a plastic part (6), where the meat grinder motor is located. At the back of the electric motor there are grilles (13) through which heated air exits. There are often rubberized feet (8) at the bottom that prevent the device from sliding on the table.

On the control unit there is a button to start work (12) and stop it (11). Most models have a screw reverse button (10), which must be pressed when the shaft is clogged with something and needs to be cleaned. There is also often an operation indicator (9) that turns on when the device is operating.

The motor has an input for the electrical cable (14), usually a ground clamp (15) is located nearby. The motor itself (7) converts electrical energy into mechanical energy. The gearbox (5) transmits rotational motion from the electric motor to the shaft (4), which is directly connected to the auger.

Working part

The working part includes a meat grinder and a device for receiving meat. The meat receiver consists of a tray or cup and a pusher - a long plastic and narrow tube that is used to push the meat onto the augers. The key elements are the same for all models.

The simplest meat grinder scheme

The entire structure is housed in a metal casing, which prevents the product from falling apart due to the pressure inside the working chamber. On top there is an oblong or round tray with a narrow hole. A plastic pusher is inserted into it, where you need to squeeze the meat onto the augers. Processable products are placed in the tray. It itself is usually made of stainless steel or plastic.

Stainless steel oval tray

In the meat grinder pipe there is a screw, which is attached to the rotation shaft. When assembling the model, you need to ensure that the fastening is as reliable as possible, otherwise during operation the electric motor will not be able to effectively control the auger. A rubber bushing is used for the connection, which prevents moisture from the working chamber from entering the gearbox. The meat grinder pipe itself is made slightly wider than the auger so that the meat does not come out through the blades, but at the same time the axis rotates freely, not restrained by friction.

Auger with rubber plug at the end

The auger is one of the key parts of the meat grinder. It looks like a drill with high spiral blades. The screw is made from an alloy of various metals, which give the structure strength and at the same time resistance to air, water and other compounds. During movement, it pushes the meat onto the knives and grill, and also creates a high enough pressure to grind and chop cartilage.

Various knife shapes

The knife onto which the products fall from the auger looks like a screw with four sharp blades. It cuts and shreds the meat so that it passes through the grill better. The knife is made from a metal alloy, as it needs to be durable and resistant to moisture. Often the blades have a special curved shape for better cutting of products. The entire design is made so that the knives self-sharpen when rubbing against the auger and last longer.

Knives need to be sharpened periodically, otherwise they become dull and stop cutting meat.

Various grill sizes

The grille is made in the form of a thick steel plate, in which fairly large holes are made. Their size determines the consistency of the minced meat. The grille can have holes of different sizes:

- 3-3.5 mm – small;

- 4-5 – average;

- 8-9 – big.

Clamp or knurled nut

The last part is the clamp, which looks like a large knurled nut. It fixes the grille, preventing it from coming off during operation. In addition, all other attachments (knives, auger) often also do not have reliable fastenings, so it turns out that the clamp secures not only the gratings, but the entire structure in general. Typically, the knurled nut is tightened in the same direction that the auger and blades rotate, so it does not fly off due to the rotation of the internal elements.

Many models include additional grates with different holes and knives of different shapes and thicknesses, as well as augers for working with vegetables and fruits.

Classification of electric meat grinders

Modern industry produces two types of electric meat grinders:

Screw

Figure 4 - Screw meat grinder: 1 - nut 8-seat groove 9-body, 2- fine grid 9-body 10-pusher, 3- large grid 10-pusher 11-tray, 4- grill for beef stroganoff 11-tray, 5- knife 12-electric drive, 6-spring, 7-auger

Figure 5 — Screw meat grinder

Table 1 - Characteristics of screw meat grinders

Cutter

Figure 6 — Cutter meat grinder: 1-lock 6-on button, 2-knife 7-body, 3-lid 8-electric motor, 4-cup 9-power wire, 5-locking device 10-bottom, 11-fastening screws

Figure 7 — Cutter meat grinder

Table 2 - Characteristics of meat grinders

How does a meat grinder work?

To reduce the likelihood of wear and tear, you need to chop the meat into small pieces and remove the bones and cartilage. All this should be small enough to easily fit into the meat receiver. Using a pusher, we squeeze the meat inward, causing the product to fall onto the auger.

Due to its screw structure, when it rotates, it pushes the pieces onto the blades, which cut them even smaller, and then they fall on the grid. Due to the pressure created by the screw, the meat is forced through the holes and comes out in the form of a processed homogeneous mass.

Peculiarities

- The majority of models of electric meat grinders have an automatic reverse function. It is necessary if a wire or other product is wound onto the auger, which the meat grinder is not able to process.

- In mechanical meat grinders, reverse is also provided. To do this, just make a few turns with the handle in the opposite direction.

- Some models of electric meat grinders have the ability to load parts into the dishwasher. The main thing is to let them dry after washing to avoid rust.

Advantages

- The main advantage of an electric meat grinder is the fact that it grinds food continuously, unlike a blender.

- The first batch of product is ready for use within 5-10 seconds, and not after the entire procedure is completed, as happens with food processors.

- When comparing a meat grinder and a food processor with the same functionality, the first one wins in terms of power.

- To install the meat grinder, you do not need to first prepare the place and securely fasten the device. It is enough to free up space on the table near the outlet.

- Another advantage is the long, narrow neck of the receiver. If you remember the safety rules and use a special pusher to push products, you won’t have to worry about your nails and fingers.

Flaws

A number of common inconveniences that may occur when using electric meat grinders:

- Difficulties arise when cleaning the narrow feed hole of the auger shaft.

- Metal parts are difficult to maintain. If they are not properly dried in time, rust and traces of corrosion often appear.

- The electrical cord is not long enough.

- High noise level during engine operation.

- The meat grinder performs the functions of a grater/shredder poorly. The cylinders are made of thin material, which leads to deformation of the nozzle.

- Reverse starts only after the meat grinder has stopped completely.

- Large dimensions.

- The auger cannot cope with the cores, they wind up, and you have to use auto-reverse.

- The products must be cut into small cubes, otherwise they will not fit into the lower part of the neck.

- The metal parts of the meat grinder cannot be washed in the dishwasher, otherwise they will change color, rust or become coated.

- Weak sharpening of knives. The meat grinder can only handle meat without lard or veins.

- The screw shaft does not rotate well, as a result of which meat accumulates and gets stuck in this area.

- Plastic gears are fragile and break easily.

- Loading tray is not securely fastened.

- The plastic body and screw are fragile, cracks and chips quickly appear.

Operating rules

Before starting work, you should familiarize yourself with the operating rules:

- Before stuffing, the meat should be cut into small slices so that they fit freely into the meat receiver.

- Even if it is written that a meat grinder can cope with small bones and cartilage, it is still better not to try to grind them, since in this case the device begins to wear out. Which leads to failure too quickly.

- All elements must be thoroughly washed after each use of the meat grinder. To do this, the structure must be disassembled; without this, all internal elements cannot be cleaned. Remember that the union nut also often needs cleaning, not just the auger, knife and grid.

- Knives should be sharpened in a timely manner. Just because they sharpen themselves doesn't mean they shouldn't be done. Self-sharpening extends the time that the knife works without sharpening, but does not eliminate this need.

- You should not put your hand into the meat receiver and try to remove a bone or large piece of meat from there while the device is running. You cannot lower the meat onto the augers with your fingers; a pusher is specially made for this.

- The meat passes through the grill under high pressure, that is, it is pushed through the holes with new portions of the product. Therefore, after use, a few grams of minced meat always remain on the knife and cylinder. It must be removed after each use.

- Before use, it is recommended to wipe the auger, knife and grid on the knife side with vegetable oil. This will reduce friction, save energy, speed up meat passage and improve productivity.

Also read: How to clean a meat grinder after a dishwasher?

Additional accessories

Various additional attachments are available for both types of meat grinders, designed to perform work not related to grinding conventional minced meat. Such devices are included when the device is delivered or can be purchased separately.

Juicer

To extract the juice, you can use the grill with the largest holes. But in this case, the final product will have pulp. And a special nozzle, in which an additional screw directs the raw material onto a fine grater, allows you to obtain liquid without the admixture of solid particles. At the same time, losses of raw materials are minimal.

Shredders

Using a set of various shredders, you can quickly cut food for any salad. The device easily copes with the work of a food processor.

For sausages

The peculiarity of this attachment is that it specially distributes ground minced meat into sausage casings. With the help of the device you can make not only sausage, but also sausages and sausages.

For the test

A device for working with dough is capable of forming original cookies from the dough. There is also an attachment that will help you make homemade pasta.

Advice! Additional accessories turn an ordinary meat grinder into a device that can facilitate the preparation of dishes of any complexity. Therefore, a set of attachments purchased separately will not be superfluous in the household.

Assembling a meat grinder

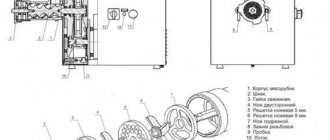

In general, the design of the working part is simple enough to master assembly and disassembly the first time. But you need to pay attention to certain important nuances that are often forgotten. The disassembled meat grinder is shown in the picture below, and various grate options are also demonstrated there.

How different parts should be inserted

Disassembling the meat grinder

You need to disassemble and clean the meat grinder after each use. To get the grate, screw blade and auger, it is usually enough to unscrew the clamp, since it is this that holds the entire structure, and the internal elements are often no longer secured in any way. The knurled nut can fit very tightly, so you have to apply force to unscrew it.

After removing all internal components and unfastening the tray, wash the parts thoroughly. Often all surfaces become greasy, especially if vegetable oil was used to make the appliances easier to operate. To remove fat, you can use alcohol, as they destroy lipids.

Assembling a meat grinder

The procedure for assembling the meat grinder is as follows:

- Before assembly, you need to make sure that all parts of the meat grinder are clean.

- First, the auger is installed. Before doing this, you need to place a rubber plug on its back side, which will prevent liquid from getting into the device from the working chamber. Then you need to connect the auger to the gearbox.

Connecting the auger to the gearbox bushing

- Then the knife is mounted. It is placed in such a way that the flat part of the blades is on the grate side. An exception is the circular knife; it should be placed with the grooved surface closer to the grate.

Correct installation of the knife

- Then the grate is installed.

- Then the clamp is tightened. Place it tightly enough so that the entire structure is securely fixed.

- At the end, the meat receiver tray is attached to the body.

The most reliable meat grinders according to customers

Meat grinder Polaris PMG 3043L ProGear Inside on Yandex Market

Meat grinder Moulinex ME 542810 on Yandex Market

Meat grinder BBK MG2003 on Yandex Market

Meat grinder Kitfort KT-2103 on Yandex Market

Meat grinder UNIT UGR 466 on Yandex Market

A meat grinder is a mechanical household appliance made of metal or its alloys for processing various food products. The manual version has long been outdated and has been replaced by modern and powerful electric models. The design of a new type of meat grinder and the principle of its operation is the topic that we will cover in this article.

Before thoroughly understanding the structure of an electric meat grinder, we will list its advantages over other household appliances, in particular, its mechanical progenitor.

- An electric meat grinder is more powerful than any food processor in a similar mode, not to mention the muscular strength of an ordinary person.

- An electric meat grinder will grind any product faster than a person can do with a manual version of the product - this saves time and effort.

- The electric device copes well with stringy meat

- there is no need to constantly unwind the product, clean the knife and reassemble it. - A meat grinder with an electric motor can work on any flat surface without additional mounting.

- The safety of working

with them is ensured by a narrower neck with a sufficient length so that fingers cannot reach the auger. The kit includes a special plastic pusher.

How to choose a meat grinder?

Despite the simplicity of the device, choosing a meat grinder that is ideal in all respects is quite difficult, so you need to carefully understand this issue. When purchasing, you should pay attention to the following characteristics.

Performance

Productivity is how much minced meat a meat grinder can produce per unit of time. This indicator is influenced by the power of the device, as well as the width of the working chamber. It is clear that the wider the meat grinder pipe, the more product can pass through it. But at the same time, the need for power increases, since due to the increased diameter of the screw, more energy is needed to rotate it.

Standard productivity is 1-1.5 kg/min. But there are meat grinders with capacities of 0.5 or 2.5 kg. With the same power (for example, 1900 W), the performance may vary (for example, it can be 1.5 or 2 kg/min). Higher performance is ensured precisely by the size of the working chamber or the speed of rotation of the screw.

Power

The speed of rotation of the screw depends on this indicator, and this directly affects productivity. Power also affects the force load that the auger blades can create. The higher these indicators, the faster the meat passes through the working chamber and the easier the device copes with cartilage and tendons.

Each model has a maximum and rated power. The maximum indicators indicate how much work the engine can do when working for wear, when cartilage or bones get into the auger. This criterion does not affect performance, but indicates the capabilities of the meat grinder. The nominal value characterizes how the device will operate under standard conditions.

The maximum power of most devices ranges from 1000-2000 W, but there are meat grinders in which this figure is 400 or 3000. If you are not going to grind cartilage and bones, then 1000 will be enough for the job. It must be remembered that the more powerful the meat grinder , the more noise it creates during operation.

Material

The device can use plastic, aluminum, stainless steel and other alloys. Metal meat grinders are heavier, but they are stronger and last longer. All internal working parts of the meat grinder must be steel, but the body can also be plastic. Sometimes there are meat grinders with plastic augers. Such devices are suitable for chopping berries or fruits, but when processing meat, such parts often break.

Knives are always made of metal. The most preferred are ferritic stainless steels, which are highly resistant to corrosion and aggressive compounds. Martensitic alloys that have corrosion resistance and mechanical strength are also suitable. Remember that knives need to be sharpened periodically, so they should be made of stainless steel.

Gearbox

Often the gears of the gearbox are made of plastic, since it is cheaper, and the device fulfills the warranty period. In addition, this makes the meat grinder easier. But at the same time, cases arise when the gears in the gearbox break due to increased load. If possible, you should choose devices with metal gears or high-strength plastics.

You also need to pay attention to the sleeve-coupling to which the meat grinder auger is connected. Through this element, the liquid component of the processed product often penetrates into the Chinese device. You need to properly disassemble the device and evaluate the tightness from the inside, but this can only be done at home.

Reverse

The reverse button causes the auger to spin in the opposite direction. This feature allows you to remove veins and bones that caused the device to stop during operation. When reversing, the auger pushes the processed mass in the opposite direction. If this is not possible, you will have to disassemble the device every time there is a blockage, stopping grinding meat during assembly and disassembly.

Number of speeds

For most housewives, two speeds are enough. The first is needed for grinding meat and other viscous or strong products. The second is used for squeezing juice from vegetables and fruits. Sometimes manufacturers make 3 speeds, but remember that maximum speed is not always required. In addition, the faster the auger rotates, the more noise the meat grinder makes.

Continuous operation time

The time during which the meat grinder can operate without interruption depends on the speed of the auger. The engine must be turned off so that it cools down and does not overheat. Make sure that the device, even at the highest speed, can operate for 10-15 minutes without having to turn off. Typically, the continuous operation time depends on the presence of fans in the design or the volume of the case.

Motor protection

Various options are used to protect the motor from overheating. Some have an electric thermal fuse that breaks the electrical circuit when overheated. On other devices, a safety sleeve is mounted, which mechanically blocks the auger. Any of these elements protects against overheating equally. When choosing a meat grinder, you need to pay attention to the resistance of the fuse to shock and vibration.

Main quality indicators of electric meat grinders

What you should immediately pay attention to when choosing an electric meat grinder is its power; it is the main indicator of the capabilities of an electric meat grinder, because if the power is not enough, the machine will become completely useless in the kitchen. An excellent power indicator is a value of 800 W, the optimal is 500-600 W, however, there are mini models with a power of 200-400 W. The second important parameter when choosing is the material from which the device is made. In general, there is nothing wrong when special food-grade plastic is used for this, which can withstand the loads transmitted to the body.

Internal parts such as grates, knives, and auger must be made of metal, since they bear all the loads during operation of the device. The auger is the main part of the spiral shape; nozzles and knives are attached to it. When rotating, the auger also moves the meat from the inlet neck to the outlet of the device. It happens that electric meat grinders have two screws: plastic for fruits and berries and metal for meat, for example the Tefal ME7011 model. A meat grinder, the body of which is entirely made of metal, will be more stable, but will also increase its weight.

No less important parts than the auger are the knives. Knives must be made of good steel; they can also be sharpened periodically, and the frequency of this process will depend on the quality of the steel. However, there are models of meat grinders that do not need to sharpen knives; they are either made of high-quality steel or are self-sharpening.

Reverse or reverse scrolling, that is, rotating the auger in the opposite direction. It is used in cases where you have a stuck core, then using reverse the auger will return it to the inlet hole. If the electric meat grinder does not have such a function, then you will have to do it all manually, disassembling the device.

Motor protection can be in the form of a circuit breaker or electrical fuse, or a mechanical interlock. However, both types of protection are designed to protect the motor from overloads and overheating.

Another indicator of the quality of electric meat grinders is the gearbox. To reduce the cost of construction, plastic gears have recently been used in gearboxes; they are less reliable than metal ones and are suitable where there are no heavy loads, or the service life of the device becomes 2 times less. Fortunately, imported manufacturers offer assembled gearboxes that can be replaced at home or in a special workshop for repairing household appliances.

electric meat grinder malfunction diagnostics

Figure 8 — Metal gear of the electric meat grinder gearbox

Figure 9 - Plastic gears from Bosh

It is officially considered that the manual meat grinder is already outdated, and it has been replaced by a more advanced electric model. But in fact, the preferences of housewives are divided equally: a mechanical unit is no less popular than its electrical counterpart. For some, it is a force of habit, and they continue to remain faithful to a simple and trouble-free device. Others want to keep up with the times and are happy to use new technologies.

Popular models

You can find a good meat grinder at the best price. An overview of several popular models is given below. The table compares the cost and main characteristics.

| Name | Nominal power | Maximum power | overheat protection | Performance | Price |

| Zelmer 687.5 | 500 | 1300 | + | 1.5 kg | 3800 |

| Bosch MFW 66020 | 600 W | 1500 | – | 3 kg | 6200 |

| Panasonic MK G1800PWTQ | 300 W | 1800 | + | 1.6 kg | 15000 |

| Aksion M 31.02 | 230 | 1500 | – | 1.7 kg | 3400 |

The table shows that performance and power, although they affect the price, are not directly proportional.

Components

To understand how a meat grinder works, you need to consider all the components. They are presented below:

- frame. Made from plastic or metal;

- lattice;

- knife;

- fixing disk;

- engine. It is installed inside the device;

- pusher;

- food receiver with a tray in the upper part;

- screw shaft

Various meat grinders come with add-ons. They often increase the price of the device, but they are also often indispensable in the kitchen. Depending on the components and brand, the following parts are supplied:

- gratings with different hole sizes;

- second set of knives;

- attachments for processing fruits and vegetables;

- knives to help shape shortcrust pastry;

- knives needed for stuffing sausages.

Advantages and disadvantages

The undeniable advantages of such machines include:

- compact dimensions,

- increased starting torque, “versatility”, operation on alternating and direct voltage,

- speed and independence from network frequency,

- soft adjustment of speed over a wide range by varying the supply voltage.

The disadvantage of these engines is considered to be the use of a brush-commutator junction, which causes:

- decreased durability of the mechanism,

- sparking between the commutator and brushes,

- increased noise level,

- a large number of collector elements.

Device and connection diagram of a commutator AC motor

AC commutator motors are widely used as power units of household appliances, hand-held power tools, electrical equipment of automobiles, and automation systems. The motor connection diagram, as well as its structure, resemble the diagram and structure of a DC electric motor with series excitation.

The scope of application of such motors is due to their compactness, light weight, ease of control, and relatively low cost. The most in demand in this production segment are low-power electric motors with high rotation speeds.

Electrical circuit diagram

Category: Household appliances diagrams

Subcategory Kitchen appliance diagrams

circuit diagram of the ZELMER 986 meat grinder

To enlarge, click on the image (opens in a new window)

Do you repair household appliances, have any questions or want to share your experience?

Come visit us at the FORUM!