Ink cartridges without a pre-installed print head

With air design

Common and simple in design, cartridges operate by using the pressure difference in two communicating reservoirs. One container is completely filled with ink, and the other has an air column.

The cartridge cover is equipped with a hole for pressure equalization. The ink used for printing is replaced by air as the chamber is released.

The bottom of the “inkwell” is equipped with a transfer valve, the hole is additionally protected by a rubber sealing collar. Installing the cartridge is accompanied by connecting the print head through the valve.

In full-color inkjet printers, the print head has a corresponding number of ink channels equipped with fittings for a strong connection with the cartridges.

With porous filler

There are designs with polymer fillers, used in Canon printers.

The most popular option has 5 cartridges, 2 of them black. One inkwell with black ink has a capacity of 19 ml for printing texts, and the other 9 ml, like the other color inkwells, is used for printing photographs together.

The cartridge body is divided into two unequal compartments. The larger reservoir contains ink-impregnated filler, and the smaller reservoir contains ink. The principle of operation is similar to that of an air cartridge, and the design resembles foam rubber, due to the compartment with filler.

There are options filled with fine-pored foam rubber, without a separate ink chamber. Fine filler cells allow you to hold a significant amount of ink, up to 7 ml. The PG fittings are connected to the cartridge through holes in the housing.

Changing cartridges in printers with a separately installed print unit requires care. It is not recommended to leave the print head without ink for more than 0.5÷1 min.

How did inkjet printing come about?

The creation of inkjet printers was preceded by the invention of William Thomson - recording devices for receiving telegraphs. The operating principle of the ancestors of inkjet printers is based on electrostatic forces, with the help of which any text was written by setting the trajectory of falling drops of ink onto the paper. The date of creation of this device is 1867.

Inkjet recording devices would have sunk into oblivion if not for the Siemens company, which intended to recreate and adapt the technology of the distant past to modern realities. What they succeeded in 1951, however, the technology of those inkjet printers was very far from the current ones. It was necessary for recording on paper any measurements and calculations of any devices, such as seismographs, electrocardiography of the heart, multimeters and others.

However, they had a huge number of disadvantages:

- Expensive;

- Carelessness (stained paper);

Even the developers themselves did not have many hopes for their invention. However, inkjet printer technology has been advanced and modernized by creating devices with separate print heads, spray mechanism and ink.

Crystals played an important role in improving inkjet printer technology. Or rather piezoelectrics. Without delving too deeply into physics, piezoelectrics are crystals that can release electrons when pressed or bent. Or vice versa - when an electric current was applied, they could bend. Thus, when current was applied, the crystal was subjected to deformation, pushing a certain amount of ink out of the head.

Competition between the richest US firms has led to rapid progress in optimizing the work and efficiency of inkjet printer devices. An engineer from the Japanese company Canon noticed that if a hot soldering iron touched a syringe filled with paints, the contents of the syringe would splatter. The Americans did virtually the same thing.

Canon used the following method: they heated the paint to a temperature of 400 degrees Celsius, resulting in a droplet of gas, which then fell onto the paper. In the West, the technology was virtually the same as that of Canon printers, with the exception of less heat required for heating and a bubble of ink falling onto the paper instead of a drop.

There were also other innovations: a simpler design, which reduced the price; piezoelectric plates instead of piezoelectric crystals.

A more significant invention was the addition of a color head by Hewlett-Packard, mixing yellow, cyan and scarlet. Thanks to this idea, it was possible to obtain almost any shade on print.

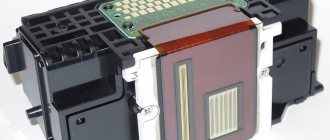

Ink cartridges with integrated printhead

With foam filling

Structurally, the cartridge is a container consisting of two blocks - an ink reservoir and a print head. The color cartridge, in turn, is divided into compartments filled with foam rubber and responsible for a specific color of the dye; there can be 3, 4 or 8 of them.

The block with the print head is located at the bottom of the cartridge and is protected from clogging by a fine-mesh filter. From the foam fillers on top, the ink seeps through the filters and enters the print head through channels.

The print head is a plate with nozzles. The design of the PG for Hewlett Packard printers using Thermal Inkjet technology consists of two elements: a chamber-forming strip and film thermistors. An electrical impulse is sent to it through a flexible cable mounted next to the head. Each color has its own set of nozzles, this ensures high color purity in photo printing.

There are holes on the lid of the container through which air escapes and the pressure inside the chambers is stabilized.

Table. Ink tank volumes of original inkjet cartridges

| Hewlett Packard | Black | 9÷42 ml |

| Color | 4÷13 ml per color | |

| Canon | Black | 3÷20 ml |

| Color | 3÷9 ml per color | |

| Epson | Black | 10÷35 ml |

| Color | 5÷10 ml for each color |

With plastic bags

Externally, the consumable item is similar to cartridges with foam filling. But, the principle of operation is the same as that of a Mariotte vessel. Only the role of the second vessel is performed by plastic bags placed inside the body.

The plastic case is equipped with a printing unit, a filter and a lock. Individual structural elements: plastic bags, coil, hole for air intake, platform for air infiltration.

Through the platform, air, in small bubbles, enters the bags. Inside, the bags are equipped with spring plates. The bags ensure a regular supply of ink to the head and prevent it from leaking. The coil keeps the ink from flowing out when there is excess air supply.

Differences between cartridges and CISS

Cartridges have their own abbreviation - PZK (refillable cartridges) or DZK (refillable cartridges). What does a cartridge consist of? It consists of a transparent body, which allows you to observe the amount of paint remaining. Equipped with two holes. The first one is necessary for refilling; the cover of this hole is made of silicone. Refilling is carried out with a regular medical syringe. The second hole is designed to equalize air pressure.

In the case of cartridges, multiple recharges are available. This becomes possible thanks to re-flashed chips on the PSC.

CISS are transparent ink containers located next to the printer and connected to refillable thin flexible tubes. The volume of such a container is about 80 ml, which is practically 40 times more than the average value of cartridges. Hence, the CISS needs to be refilled extremely rarely. One hundred percent sealing in containers ensures uniform pressure.

It is very important to evaluate the advantages and disadvantages of certain devices and draw parallels.

The price of a continuous ink supply system with a specialized installation is approximately twice the cost of purchasing conventional cartridges. However, you can try to install and configure all the necessary systems yourself, and we will give a discount of 300-500 rubles. Let's talk about what to focus on when purchasing. To begin with, let’s highlight the most significant disadvantages of both systems. Installing the safety valve into the printing device is simple, without unnecessary hassle, and does not interfere with the desktop, since it does not weigh much.

However, significant disadvantages should be highlighted, of which:

- Frequent refilling of ink due to the small volume of the ink tank, which is quite tedious, especially impossible without an ordinary pharmacy syringe. Spending a lot of time and effort on this procedure.

- Removing the cartridge to determine the ink level.

- There is a fairly high probability of not keeping track of the amount of paint, and missing the moment when it is gone, which will lead to airing of the PG. If we are talking about thermal inkjet printers, there is a high risk of holes burning out,

- To minimize the decrease in ink level, it is necessary to remove the seal from the socket.

- Frequent removal and replacement of ink tanks leads to the fact that the contact paths on the chips are damaged, and frequent failure of the PCP cartridges.

Refilling the CISS is extremely simple and convenient; just place the required amount of paint in the container. Abruptly running out of paint is almost impossible, since the bottles are constantly in front of your eyes. There are no problems with ink either.

Despite this, there are also disadvantages of CISS:

- There should be free space next to the printer to place bottles there.

- Any movements and movements of the printer are extremely problematic, and in order to avoid various types of problems, all openings should be closed.

- If bottled ink is exposed to sunlight, it may evaporate, gradually lose color, and experience other unpleasant effects.

The main disadvantages of printing machines are that one deteriorates its performance due to extremely frequent use, while the other, on the contrary, is subsequently negatively affected by too little printed material.

So, in order to choose correctly and for a long time, you should be ahead of what the printer will serve you for: if you need it for home use: printing photos, school texts or reports for work, refillable cartridges will be an excellent choice. If you need the device for professional purposes, for work or study on an ongoing basis, a continuous ink supply system would be a more suitable option.

Controlling ink consumption

Currently, it is no longer possible to find cartridges for inkjet printers without microcircuits (chips) that control the consumption of the ink composition. The chip stores data about the type of device, date of manufacture and activation, and the amount of ink used.

On the one hand, such data allows you to keep track of the consumption of the coloring composition, but on the other hand, it complicates the refilling procedure.

Chip and special elements

In recent years, most manufacturers have been producing cartridges for inkjet printers along with special security chips. Their presence makes refilling these consumables more difficult and expensive, and sometimes even impossible. All this forces users of such cartridges to buy replacements as they are used up, which is an order of magnitude more expensive than the refilling procedure.

The chip itself usually stores information such as the type of consumable material, manufacturer's name, activation date, production time, amount of paint used, etc. True, cunning craftsmen have learned to hack the recording protocol of such an element and reprogram it. In response, companies first tried to change the recording protocol, after which they developed new chips with a larger number of contacts. However, this problem was also solved over time, because A large number of chips produced by third-party manufacturers have appeared on the market, which have found wide application in CISS.

A special category element includes a piezoelectric plate, which is used for the printing method of the same name. This element is capable of bending under the influence of electric current. When arched, the plate helps to reduce the volume of the reservoir, as a result of which paints are squeezed out of the smallest nozzles onto the surface of a sheet of paper. There are also special heating elements that are designed for types of printing such as thermoelectric and bubble jet. These elements help heat the paint and convert it into a gaseous state. When heated, the ink forms small bubbles, which help push droplets of ink out of the nozzles onto the surface of the sheet of paper.

What's not to like about an ink cartridge?

- Long breaks from work.

- Excessive heat from external sources.

- Incompatible ink.

- Blowing through the cartridge to force ink into the nozzles if this is done with excessive force.

- Working in a thermal inkjet printer when one of the cartridges runs out. The nozzles working in conjunction with this cartridge may burn out.

- Cleaning contact pads from oxides with utmost effort and diligence.

- Sealing the print head nozzles with a material with an adhesive base. The adhesive layer may clog the print unit nozzles.

- Pigment ink cartridges do not tolerate low temperatures. Some of the pigment may peel off and precipitate.

About printers in general

A printer is a special digital device for outputting text or graphic information onto sheets of paper. In the office or at home, it is sometimes very difficult to manage without such technology. There are two types of such devices - laser and inkjet. There are others (matrix or LED), but they are less common.

Lasers are more often used for printing text data in offices. The operation of such equipment is fast and maintenance is simple. Inkjet printers are often used to print color images or photographs at home. Depending on the price category, the quality of their work differs. In general, they are slightly more difficult to maintain if you do it yourself.

Basic rules for an enjoyable inkjet printer experience

- Always have a spare set of cartridges for your printer. If you receive a message about running out of ink, stop printing and change the consumable within 1 minute.

- A used cartridge intended for refilling should be sealed to prevent drying out. Refill no later than 3 days from the date of removal.

- At least once a week, and preferably twice, print on the printer.

- Cartridges should be removed and installed by holding them by the side surfaces and the cover.

Despite the apparent simplicity of replacing or refilling cartridges, problems often arise. Sometimes due to a misunderstanding of the procedure, and sometimes due to incorrectly translated instructions. Considering the rather high cost of inkjet printer consumables, in such cases you should immediately contact a specialist.

4778

Tags for this article

Expert Reviews Cartridges

Comments

How does it work

Depending on their type, the operation of inkjet and laser cartridges is radically different:

- the laser works is to apply an image, and text is also considered the same, on the surface of the photodrum.

In those places, the surface charge changes to the opposite to the toner charge, due to which the powder “sticks” in the right places. Next, the toner is transferred to a sheet of paper and then “baked” in a special oven at high temperature. With color laser printing, the process is repeated four times: once for black and once for three shades of color. The principle of operation of a laser printer. A detailed description of the printing device. - When using inkjet printing, the image is applied in the form of very small dots, even imperceptible to the human eye. This process is impossible without a special print head. It can be placed directly on the cartridge or be a separate part. The paint gets onto the sheets due to its heating, which leads to an increase in its volume and the need to escape. Different tones and shades are obtained by mixing blue, pink and yellow paint in different proportions.

A few recommendations

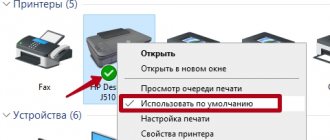

When you return the cartridges back to their place in the printer, it would be useful to perform software cleaning using the printing device software. The head, nozzles and nozzles should be cleaned even for preventative purposes. To do this, follow these instructions:

- Go to the “Printers” section through the control panel or in any other way known to you.

- Select your printer by clicking the mouse.

- Open the context menu and click on “Printer Properties”.

- Go to the “Maintenance” tab and run the cleaning procedures.

- If after these procedures the printer continues to print poorly, you can try washing the print head on the cartridge according to these instructions.

- Do not let the ink in Canon cartridges stagnate and therefore dry out. This will cause the print head to fail.

- Be careful to ensure you have enough of each color. Even a short absence of it can easily lead to overheating and burning of the nozzles. Since paint also acts as a coolant.

Why doesn't the printer print even though there is ink? Causes and solutions to possible problems.

Ink types

There are two types that are used in the cassette. What is the difference between the ink in an inkjet cartridge?

- Water soluble. This is an aqueous solution of organic substances. An excellent choice for home and office. However, experts recommend using water-soluble ink only with photo paper or special paper for inkjet technology. The main advantage is low cost.

- Pigmented. A solid colored pigment is used as a dye. The ink is ideal for interior printing and photo printing. The main advantage is considered to be high quality, rich colors, water resistance and durability of the pattern.

Which cartridge is better to choose?

Before purchasing a toner, consider the following points:

- frequency of cartridge use and print level;

- speed of operation, acceptable frequency of refills or cartridge changes;

- manufacturer;

- price.

An inkjet cartridge is suitable if you want to get high-quality color photos and plan to use the equipment as usual, without a large amount of printing.

Laser toner will provide high printing speed and long-term operating mode without replacement, and will produce quick results even with a large number of sources. If the high price of the product does not bother you, then this is your option.

If you have no experience in choosing a specific model, you can pay attention to products from such popular manufacturers as HP, Epson, Canon, known for their quality and affordable price.

How to soak dried ink in a cartridge?

1. Digging. Take out the cartridge and turn it over, install it with the lid down, respectively, with the nozzle pad facing up. In the area of the PG (print head), clumps of ink are visible, left by the sides of the cap. Drip flushing liquid onto the pad and around it using a medical syringe (Fig. 9); the syringe needle must not touch the surface of the pad of the PG nozzles.

Rice. 9. Applying flushing liquid to the nozzle pad of the PG cartridge

Let it soak for a while, let the clumps soak, and blot with a napkin. I would like to draw your attention to blotting only with a dry cloth; no scented or “wet” ones are suitable; the manufacturer adds various essential oils and fragrances to them. Just blot it, not three times, so as not to caulk the nozzles with clumps of ink. So, we cleaned the surface of the nozzle area from “dirt”. Now we apply the washing liquid in drops so that a hemisphere of liquid is formed on the site, and wait. Depending on the contamination, after a certain period of time, the liquid will begin to be absorbed by the SG nozzles, in other words, the liquid will noticeably decrease. Add liquid to the area again, three times will be enough. Now take a clean napkin again and begin to blot the area (Fig. 10). The napkin will be left with a streak of diluted ink tint left by the rows of nozzles. After drying with a napkin, we repeat the application of the washing liquid to the site, trying to ensure that the PG absorbs 1-2 cubes of the washing liquid. Soak and dry the PG again.

Rice. 10. Blot the nozzle area

Rice. 11. Imprint of the washed print head

These operations are repeated until the mark on the napkin is completely light, without any admixture of color (Fig. 11). If you don’t have flushing liquid on hand, you can make it yourself; in extreme cases, you can simply buy a solution of ammonia at the pharmacy and use it. In fairness, I should note that flushing the SG with an ammonia solution is a more powerful cleaning attack, a more gentle option, of course, is the use of washing liquids for SG.

2. Airing of GHG. The PG streaks, refilling the cartridge does not correct the printing. What to do? Let's try to get rid of the air plug in the nozzles - (airing of the GHG). To begin with, using the “dig and soak” method, we will try to eliminate the “clog” of the PG. Does not help? Wrap the cartridge in several layers of paper towels. We wrap it carefully, a large mass of paper should be located opposite the platform of the PG nozzles. Now, taking the cartridge with your hand so that the PG is located downwards, with a wide sharp swing, from top to bottom, shake the cartridge, sharply braking at the end of the swing. Shake it a few times.

I warn you , the cartridge must be carefully packed with paper napkins in several layers. Otherwise, you will be “pleasantly” pleased with the new art design of walls, furniture and floors. You can smear ink on everything around you. Having unfolded the napkins, we are convinced that ink has come out of the nozzles, sometimes even in significant quantities.

Of course, you don’t need to get carried away and wave the cartridges left and right, you are not a Jedi, and the cartridge is not a lightsaber.

The secret of this seemingly primitive technique is that the inertial forces caused by sharp braking at the end of the arm swing push the ink through the capillaries of the nozzles and, with additional shaking, the body of the absober-sponge is partially freed from the adhesively deposited clots of ink on its fibers.

3. Dynamic shaking of the cartridge helps with airing and minor blockages of the PG, as well as with drying out of the absorber.

Another one in a series of “Isuit” techniques. The refilled cartridge is wrapped in napkins. Tap the bottom of the cartridge body on the table. In this case, the blow should be “masterful”, only with the lower rear part of the body. It is forbidden to strike with the platform of the SG nozzles, as well as in the area of the contact pads. Do not knock the front of the cartridge. The PG can be damaged. Therefore, if you are not sure, then it is better not to perform such a technique. Ink will splash out of the nozzles onto the napkin, which is what we need - to push a portion of ink through the PG nozzles.

4. Cleaning the absorber. With each cartridge refill, its useful volume decreases. And after a certain number of refills, we discover that we can refill the cartridge with half its original volume, and often less. As soon as we start refilling, ink immediately begins to flow from the cartridge nozzles. What is the reason? The absorber is to blame - a porous spongy part 4 located inside the cartridge body 1 (Fig. 12).

Rice. 12. Cartridge design

There is a banal clogging of the absorber pores. Clumps of ink fill the porous voids, and the dye also adheres to the surface of the absorber fibers. All this leads to the fact that the absorber is able to hold less and less ink in its body (the ink is retained in the pores of the absorber due to the forces of surface tension of the liquid).

It is not difficult to restore the properties of the cartridge absorber. For this:

- The cartridge cover is separated (with an office cutter or scalpel, carefully so that the cartridge body does not burst);

- The absorber sponge is removed (ordinary medical tweezers are good for these purposes);

- The absorber is washed with running hot water and dishwashing detergent;

- Rinse the absorber thoroughly until any remaining detergent is completely removed;

- The washed absorber should be light; a slight tint of the corresponding color is allowed;

- Dry the absorbent sponge completely;

- Assemble everything, the lid does not need to be sealed, it is only important to securely install it in its place, to ensure normal pressing of the contact pads of the cartridge, with the CISS installed, the lid must be glued absolutely hermetically, but then there is no need to wash the absorber.

To glue the cartridge cover, you can use silicone sealant, super glue will also work, but do not overdo it.

5. Flushing of NG using a filling (flushing) station (addition).

A cartridge is installed in the clip station (Fig. 13), in this case it is a Canon CL-38 color monoblock cartridge. Nearby, on the left, you can see a replacement gasket for a black single-color cartridge.

Rice. 13. Washing station (clip)

The structure is turned over (Fig. 14) and a syringe with flushing liquid is inserted into the hole of the gasket. It is enough to fill 1.5-2 ml of washing liquid.

Rice. 14. Washing station (clip)

Rice. 15. Rinsing the head using a station (clip)

Black single color cartridge:

- Fill the syringe with 1.5-2 ml of washing liquid,

- The syringe piston is pulled out slightly, by 2-3 mm, thereby creating a slight vacuum, the ink is mixed into the washing liquid,

- Slowly inject the flushing liquid, pressing the syringe plunger,

- The syringe plunger is pulled out to 2-3 ml, thereby creating a slight vacuum,

- The mixture of ink and washing is drained and the syringe is filled with a new washing liquid of 1-2 ml,

- The flushing liquid is injected again,

- 3-4 ml of ink is withdrawn by pulling out the piston,

- The PG print on the napkin is checked.

Color tri-color cartridge:

- The syringe plunger is pulled out, 1-1.5 ml, taking out the ink,

- The ink mixture is drained and the syringe is filled with 1-2 ml of washing liquid,

- Slowly inject the flushing liquid, pressing the syringe plunger,

- The syringe plunger is pulled out to 2-3 ml, thereby creating a slight vacuum,

- The mixture of ink and washing is drained and the syringe is filled with a new washing liquid of 1-2 ml,

- The flushing liquid is injected again,

- 3-4 ml of ink is withdrawn by pulling out the piston,

- The PG print on the napkin is checked (see photos 4, 5).

The PG print must be clear, without breaks in the lines; if necessary, washing is repeated.

Characteristics of GHG

It is worth paying attention to certain characteristics of the print heads that affect the quality of the resulting images:

- The number of colors is a global characteristic not only of the head, but also of the printer, determining the number of shades available for printing. In modern printers it varies from 4 to 12 (although there are also black and white printers with one color).

- Ink droplet size is the volume of ink in one droplet released from the nozzle. Varies widely from about 1 picolitre and affects print resolution. In many modern printers, the nozzles in the print heads have variable sizes.

- Print Resolution - one of the main characteristics of a printer, measured in the number of dots (ink drops, essentially) per inch (Dots per inch, DPI). The higher the value of the characteristic, the less pixelated (grainy) the picture is. The resolution is affected by the number of PG nozzles and the droplet size. Note: it is also worth distinguishing DPI from the PPI indicator (pixels per inch), which reflects the quality of the original computer image, and has nothing to do with the characteristics of PGs and prints.

More about ink

The coloring agent is also an integral part of any model of inkjet cartridge. They can be pigmented, solid, water-soluble, solvent-based, etc. The choice of one or another type of ink depends on such a parameter as the printing technology used. However, each manufacturer of such products has its own unique composition, which it adapts to the models of office equipment for which it is intended. In order to create effective shades using key ink colors when printing, it is necessary that the paint does not change its original color as it dries. In addition, good ink has a number of qualities, which include environmental friendliness, non-toxicity and fade resistance.

The ink may contain 6-14 components, each of which has its own functional purpose. The quality of these products depends on a number of physical characteristics, which include viscosity, surface tension, conductivity, color absorption, visible color, and purity. The last characteristic is especially important, because all sorts of impurities that are in ink can clog the nozzles and cause damage to the entire printer.

Links[edit | edit code]

- We disassemble the inkjet printer cartridge (thermal inkjet printing) (unspecified)

(inaccessible link). Retrieved November 12, 2012. Archived December 3, 2012. - Description of the principle of inkjet printing (undefined)

. Access date: November 12, 2012. - Boomburum.

Learn more about inkjet printers

(undefined)

. geektimes (December 1, 2009). Date accessed: October 8, 2021. Archived December 3, 2012. - https://club.cnews.ru/blogs/entry/import_sravnivaem_tehnologii_pechati_strujnaya_lazernaya_svetodiodnaya_led__sublimatsionnaya_tverdochernilnaya_74dd Printing speed of inkjet printers.

Refilling Epson cartridges

Epson replacement cartridges are simply a reservoir filled with ink. The head and mechanism that provides printing are located in the printer and cannot be replaced. More precisely, they are subject to it if they fail, but this will have to cost an amount reaching 75% of the cost of a new printer. And what’s most interesting is that the Epson printing unit most often fails precisely because of the use of counterfeit cartridges or home refilling with bad ink, and the warranty in case of such breakdowns is invalid. So if you are the owner of an Epson printer, you better think ten times before you decide to refill! However, the process itself is very simple.

The most important thing is not to remove the cartridge from the printer for more than a minute: otherwise the print head will dry out and you will have to struggle with cleaning it. And this, believe me, will not lead to anything good. The way out of this situation is quite simple and... not very pleasant: you will have to purchase another cartridge - take out the empty one, immediately insert the full one.

The refueling procedure itself, as I already said, is extremely simple, and it is the same for color and black models. The only difference is that in color cartridges you need to refill from 3 to 5 different compartments (according to the number of colors). This is done as follows.

Also interesting: Tracing paper (paper) - sizes, types and applications

As soon as you remove the cartridge from the printer, immediately seal the exit hole with a previously prepared piece of tape. Further actions depend on the cartridge model. If the tank has holes (they should be sealed with film) on the lid, then you are in luck, otherwise you will have to drill them yourself. Having sorted out the holes, insert the syringe needle to the bottom of the cartridge and slowly pump in ink. That's all. All that remains is to seal the filling holes (be careful not to accidentally seal the ventilation holes).