Samsung household appliances enjoy deserved popularity among customers around the world. A wide range of models to suit every budget and excellent consumer characteristics contribute to the constant growth of sales. This is a reliable technique, but sometimes it breaks down. A Samsung washing machine won't turn on is a problem that anyone can face. Sometimes this is the result of a serious breakdown, but often the reason lies in the unsatisfactory state of communications in the house.

Possible causes of malfunction

A malfunction of a Samsung washing machine can be caused by numerous reasons.

The simplest thing that can explain the lack of response to pressing the “start” button is that the device is simply not plugged into the outlet.

They also consider a number of factors that can also affect the performance of a household appliance:

- lack of water,

- incorrect connection,

- failure of system components of the washing machine.

Before turning to professional experts for help, you should conduct a detailed diagnosis yourself. If you follow a certain sequence of actions, you can quickly fix the problem.

Failure of the heating element

Heaters fail due to scale. Residues of powder, clothing lint, impurities in water - all this sticks to the heating element, as a result - its efficiency decreases. Working in intensive mode, the heating element overheats: this leads to a break in the spiral or burnout of the housing (which entails a short circuit or current leakage to the housing).

| Signs | How to fix | Cost* (work only) |

| The washing machine does not heat the water or when the program is turned on, the machine switches off. In models with a screen, codes H1 H2, HE, HE1, HE2, E5, E6, NS, NS1, NS2, tE, Ec, tE1, tE2, tE3, tC, tC1, tC2, tC3, tC4 or CE, AC, may light up. ACb (AC6), 4C2. | A faulty heating element must be replaced. | from 1700 rub. |

*The price is only for the work of the master, spare parts are paid additionally.

The washing machine turned on, but the wash does not start

The washing program does not start, although the indicator lights work as normal

Make sure the hatch is tightly closed after loading laundry. Otherwise, a special protective mechanism will not allow the drum to be filled with water. Then make sure that the hatch is blocked after the program starts. If the door just latches, check to see if it has power. The current is supplied, but the hatch is not blocked? Then the locking device will have to be replaced.

Watch the drum fill with water. The presence of unusual sounds or complete silence indicate that water is difficult to get inside, and the machine simply has nothing to wash with.

Did not help? Make sure that you have selected the correct washing program (you have not pressed several buttons at the same time or accidentally poked it past). If in doubt, turn off the machine for 30-40 seconds and then turn it on again. The failure that occurred will be corrected.

The lights flash randomly or light up at the same time

In this case, look for the cause of the failure in faulty wiring. In most models LG, Indesit, Samsung, Hotpoint Ariston, Bosch. Ardo, Electrolux wires often come into contact with internal parts, which causes damage over time. Check the condition of the cables with a tester and replace the problem area.

The problem may also lie in burnt-out capacitors that should be replaced.

These simple tips will allow you to quickly and competently resolve common problems that arise in the operation of your washing machine.

Strengths and weaknesses of Samsung washing equipment

Samsung washing equipment is deservedly popular. For example, the new Diamond series, with a load of 5 and 6 kg, has unique useful innovations, including a small cell drum, Aqua Stop and Volt Control systems. Bubble washing technology - Eco Bubble - allows you to wash your laundry more efficiently.

Models such as Bio Compact S821 , Sensor Compact S803 J , WF- R1061 and WF- F861 have received high marks from Russians, as they have been serving their owners well for more than 10 years and are highly reliable.

Breakdowns of Samsung washing machines often occur due to violations of operating rules. In addition, some details are problematic , which include:

- drive belts;

- heating elements (hereinafter also referred to as heating elements);

- drain pumps (pumps);

- drain pipes and hoses;

- fill valves.

Heating elements fail due to too hard water, which forms scale. Poor quality of tap water and improper operation lead to blockages and breakdowns in drainage and water intake systems. These are the data from long-term statistics of leading service centers. But electronics are the strong point of Samsung SM and rarely require repairs.

Why does the washing machine constantly fill with water but won’t start?

This problem requires an immediate solution. You can try to deal with it yourself, but to do this you need to know why the machine constantly pours water into the drum.

If, during washing, water constantly fills inside the machine with laundry and remains at the same level, you should inspect the connection of the drain hose. It is likely that it is leaking due to an incorrect connection. To check this, you need to start the washing machine and go to the sewer. Normally, no loud noise should be heard.

In cases where the washing machine constantly draws water, but the washing does not start, the problem is in the inlet valve. You can simply replace it so that such situations do not arise again.

If the tips for correcting problems with the operation of the equipment did not give results, and it still does not work as it should, perhaps it should be replaced with a new one.

Pump fault

The drain pump is another “weak” point of the Samsung SMA. Debris from clothing pockets and foreign objects (for example, clothing accessories) getting into the pump “wedge” it. As a result, the pump impeller breaks or the pump motor fails.

| Signs | How to fix | Cost* (work only) |

| The washing machine does not drain water. Errors 5E (SE), E2, 5C may appear. | It is necessary to carry out diagnostics and, if the pump is intact but clogged, clean it. If the pump fails, the unit is replaced with a new one. | from 1900 rub. |

*The price is only for the work of the master, spare parts are paid additionally.

Symptoms of failure

If your washing machine suddenly suddenly stops working completely or stops working correctly, do not rush to call the service center and call a technician. We are not necessarily talking about a breakdown that you cannot fix with your own hands. First of all, observe the car and its behavior.

- If the washing machine does not turn on at all, no matter how much you press the on/off button, then there is either a problem with the power supply or with the electrical system of the machine itself.

- If the washing machine turns on, but you cannot set any program or function, then the problem is in the electronics.

- If the washing machine washes, but at the same time makes very strong extraneous sounds: knocking, metallic grinding, ringing, the problem is in the moving mechanism of the drum.

- If the washing machine washes but does not drain the water, freezing at this stage, then the problem may lie in the drain pump.

You can continue the thought for a very long time, because there can be hundreds, and maybe even thousands of these “ifs”. The main thing is that you understand the meaning, start thinking logically and be attentive to your home assistant.

In addition to externally studying the symptoms of a washing machine failure, it is also necessary to study the self-diagnosis system of a specific washing machine model. The fact is that the control module of any modern automatic washing machine includes recognition of many typical faults. If the machine detects such a malfunction, it will stop working and display a specific error code on the display. Your task will be to decipher this code, after which you will understand what is broken.

Let's give an example. Error code E20 on an Electrolux washing machine means that the machine cannot drain waste water. A system error doesn't tell you exactly what's wrong, but it does greatly limit the range of problems that could potentially occur. In this case, either the pump, or the water level sensor, or the control module triac is broken.

For your information! On washing machines without a display, the error code can be recognized by the indicators lighting in a certain sequence.

Malfunction of the control module (electronic controller)

The module is a key component; it controls the operation of the washing machine and is located behind the control panel of the machine. Its memory chip (EEPROM) stores all washing programs. Signs of a faulty control board are very varied.

| Signs | How to fix | Cost* (work only) |

If the control board breaks down, a Samsung washing machine can generate almost any error codes and behave in an unpredictable way. For example:

There may be other signs of damage. | Module failures are usually associated with power surges or moisture getting on the board. In both cases, burnout of tracks or individual elements of the module (resistors, relays, diodes, capacitors, triacs, etc.) is possible. The specialist conducts diagnostics and, based on its results:

| from 2400 rub. |

*The price is only for the work of the master, spare parts are paid additionally.

Doesn't work after voltage drop

Are you sure that the device stopped working after a power surge? First of all, check the surge protector. The latter prevents the electronic module from burning out and is primarily affected by power surges.

The check is quite simple:

- Unscrew the mounting screws on the rear panel and remove the top of the unit.

- Find the surge protector (located near the side).

- Look at the contacts that go to it and the part itself. Have you seen an inflated filter or burnt out parts? Replacement is the only right solution.

- Did you find any problems? Test the contacts with a multimeter. The latter could burn out due to changes in the network.

Connecting the machine to an electric generator will protect against voltage surges and device failure.

Samsung SMA error codes

By displaying fault codes on the display, the system informs the user about a problem that has arisen. You need to understand the meaning of Samsung washing machine error codes and start repairing it yourself.

| Fault codes | What do they mean |

| 1E | Failure of the pressure switch. |

| 3E, 3E1, 3E2, 3E3, 3E4 | Malfunction of the SM motor tachometer. |

| 4E, 4E1, 4E2 | There is no water in the tank. |

| 5E | Error draining water. |

| 8E | Failure of the SMA electric motor. |

| 9E1, 9E2, Uc | Electrical error. Voltage too high or low. |

| AE | There is no connection between the electronic board and the display panel. |

| bE1, bE2, bE3 | The washing machine does not turn on. |

| SE | The water in the tank has exceeded the heating rate. |

| bE1, bE2, bE3 | Problems with closing the hatch door. |

| F.E. | Ventilation is not working. |

| NOT, NOT1, NOT2, NOT3 | The heating element (heating element) is faulty. |

| LE (LE1) | There is a leak. |

| OE (OF) | There is too much water in the tank. |

| tE1, tE2, tE3 | Thermal sensor is faulty. |

| HER | Failure of the heating element or drying temperature sensor. |

| UE | An imbalance has arisen. |

| Sud | Foam concentration exceeded. |

Prevention of washing machine breakdowns

In most cases, the service life of a washing machine without repair can be increased by following simple rules:

- Proceed according to the device manufacturer's instructions;

- To protect against voltage surges and short circuits, the washing machine can only be connected through special protective devices (RCD);

- Use the machine with the intention of relaxing. If several washes are planned per day, you need to take a break of 2-3 hours between them;

- Prevent the appearance of mold and the proliferation of other fungi at the installation site of the device and in the device itself. To do this, after finishing washing, the compartment intended for loading the powder, as well as the rubber gaskets of the hatch, must be wiped dry and the loading tank door must be left open for several hours;

- Use only high-quality detergents for washing. Modern powders and gels are made with the addition of special elements that prevent the formation of salts on the structural elements of the washing machine;

- At least once every six months, run a preventative washing cycle on a program that provides for a high temperature regime, with the addition of anti-scale agents.

Such preventive measures will not only prevent breakdowns that lead to the washing machine not turning on, but will also save the consumer’s money spent on electricity.

Basic problems and solutions

The external inspection of the washer has been completed, but no problem has been identified. It's time to start disassembling the household appliance.

In order for the work to proceed quickly and efficiently, you must ensure in advance that you have all the necessary tools:

- a set of keys and screwdrivers of different sizes,

- pliers,

- as well as a multimeter (a special device for measuring current and resistance).

Before disassembling the Samsung washing machine, the device must be disconnected from the power supply, water supply and sewerage. To make it easier to approach the washing machine, it is moved away from the wall.

Having prepared for work, you can begin a step-by-step disassembly, diagnostics, and, if necessary, replacement of damaged elements of the Samsung washing machine.

Cord and plug

First of all, check the integrity of the cable at the bend points and the junction with the plug.

To do this, set the multimeter to the “buzzer” mode, apply the probes to the wire cores on both sides . The characteristic squeak of the device indicates the serviceability of the element.

When examining the plug, special attention must be paid to ensure that the plastic body is intact, without cracks or signs of melting. The metal pins in the plug should not move.

If any irregularities are detected, the plug or cable must be replaced.

Hatch door

A prerequisite for starting a Samsung washing machine is that the hatch door is tightly closed (a characteristic click should be heard when closing). If the door does not close tightly, but there is no external mechanical damage, a multimeter will help check the lock’s functionality .

To do this, with the hatch door open, use the tester probes to touch the opposite sides of the lock. If there is no resistance, the number 0 will appear on the device display.

Similar actions are carried out with the hatch door closed. If the resistance indicator has changed, the lock is working; if the indicator is still 0, then the locking element will have to be dismantled and a new one installed.

The work is carried out according to the following algorithm:

- Using a screwdriver and pliers, remove the cuff clamp.

- After unscrewing the fixing bolts from the body, remove the old lock.

- Disconnect the connectors of the old element.

- Connect the connectors to the new lock.

- Fix the new part with bolts to the body.

- Install the cuff and secure it with a clamp.

If the lock is jammed when the door is closed, you need to remove the top panel and, by pressing the latch, open the hatch door.

Power button

Most often, the failure of the power button is caused by wear or oxidation of the contacts . In order to check the functionality of the button, it is tested with a multimeter in the on and off position (the washing machine is disconnected from the power supply).

If the power button is working properly, then in the on position the multimeter will begin to emit a characteristic squeak. If no signals are heard, the button is faulty. If you have a soldering iron, replacing the button will not be difficult.

Algorithm of actions:

- unscrew the fixing bolts and remove the front panel;

- if the cause of the malfunction is oxidation of the contacts, they are simply cleaned; in another situation, the old button is replaced with a new one;

- check the functionality of the new element with a tester.

Before purchasing a new button, it is very important to check that the item number and series match the type and model of the washing machine.

Interference filter

A network noise filter (abbreviated FPS) is an element of the electrical circuit of a washing machine that protects equipment from electromagnetic radiation that occurs during the operation of other household appliances located nearby.

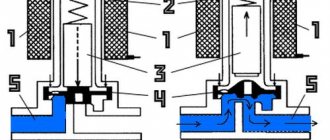

A faulty FPS blocks the operation of the washing machine. In a Samsung washing machine, the FPS is located under the top cover. It looks like a small barrel with five terminals. Three outputs for input (phase, zero, ground) and two for output (phase and zero).

The filter is tested after the element is removed from the washer lid. The FPS is checked with a multimeter (the tester is set to “voltage” mode). Lack of voltage at the outputs indicates a breakdown of the element.

Replacing a surge protector is easy, following a certain algorithm of actions:

- Remove the top cover of the housing.

- The old device is disconnected from the power supply (the bolts are unscrewed, the connectors are disconnected).

- Connect a new element and test it with a multimeter.

The new filter must exactly match the brand of the previously installed part.

Control module

If during the diagnostic process all elements of the electronic circuit turned out to be serviceable, then the reason why the Samsung washing machine does not turn on most likely lies in a faulty control module.

It is possible to determine whether this is so only by ringing each element of the module with a multitester. Before diagnostics, the module (the element is located behind the control panel) must be dismantled.

Repairing or replacing a module requires a highly qualified technician , so without certain skills and knowledge you should not start solving this problem.

The washing machine does not turn on: common causes of breakdowns

Before unscrewing the device or pressing the operating panel buttons, you should:

- Double-check, what if you simply forgot to plug it in?

- Double-check whether there is voltage in the network (by plugging in any other electrical appliance).

- Check if the cord and plug are damaged. There should be no creases, tears, or traces of burning.

Have you identified problems with the cord or plug? Do not use the machine - it is unsafe: it can cause electric shock and even fire.

Is everything okay with the cable, socket, plug? This means that the SMA does not work due to malfunctions in the “internals” of the unit itself.

Depending on the cause of the failure, the device may require:

- Simple repair. Problems can be easily eliminated without special knowledge and skills or special tools.

- Complex, expensive repairs, including comprehensive diagnostics of faults, replacement of individual parts and assemblies.

The most common reasons why the washing machine refuses to turn on:

- The hatch door for loading laundry is not closed. If the lock does not work (the latch does not click), the device will not give the command to start. The cause of the breakdown is obvious - a malfunction of the hatch locking device (UBL). There is only one way out - replace the faulty element with a new UBL.

- The “ON” button is broken. The malfunction can be determined by ringing the wires going to it and the entry and exit points (in working position). No ringing? The only correct solution is to buy and install a new button.

- The electronic module is broken. You can repair it if you have experience working with electrical engineering. Isn't there one? Contact the service center immediately. The specialist will determine the need for repairs and replace faulty elements.

- The interference filter has failed. This part eliminates interference that appears during the start of the cycle, disrupting the operation of other equipment installed nearby. You can determine whether the filter is broken using a tester by ringing the contacts. The part does not work - you will have to replace the filter and the machine will work again.

- Internal wiring faults. The indicators blink, but the device itself does not function. Perhaps the lights were turned off for a short time when you were not at home. Visually inspect the wires and mounting sockets. Did any fall out? Paste in their original places. Replace burnt ones with new ones.

Bearing failure

According to our repair experience, bearings in a Samsung washing machine begin to “crumble” after 5 years of operation. But if the machine is often overloaded, then younger SMAs also experience bearing problems. Due to vibrations during operation, the bearings gradually become loose, the seal weakens, and water gets inside. The corrosion process begins, the bearings are destroyed, and the washing machine does not spin the drum.

| Signs | How to fix | Cost* (work only) |

| The machine rumbles, creaks or knocks during operation, the sounds intensify during the spin cycle. The drum is dangling or, on the contrary, is blocked by a collapsed bearing. If you remove the back wall in front-loading machines or the side wall in vertical ones, then rusty stains will be visible on the tank. The Samsung machine can issue codes UE, E4, UB. | The technician changes the bearings and seal. | from 4000 rub. |

*The price indicated is for labor only, spare parts are paid separately.

Failure of the hatch locking device (UBL)

If the UBL fails, the machine does not block the door, so the wash does not start. This is built into the SMA operating algorithm for security purposes. The opposite situation is also possible, when the machine door does not open after washing.

| Signs | How to fix | Cost* (work only) |

| The Samsung machine does not lock the hatch and the wash does not start. Sometimes the opposite situation occurs: the door does not open after the end of the program. In both cases, the machine can display codes DE, ED, DOOR, DE1, DE2, DC, DC1, DC2. | It is necessary to replace the faulty UBL with a new one. | from 1600 rub. |

*The price is only for the work of the master, spare parts are paid additionally.

There is an indication

If, when you turn on the network and select a program, lights or symbols flash on the display, then in this case you need to figure out what the machine is not doing. First of all, pay attention to the door lock.

UBL

If the hatch opens freely during startup, the reason may be the following:

- UBL is faulty;

- wiring burned out;

- The control module is damaged.

A mechanical hatch locking device is checked using a specific method. This will be covered in another article. Pulse UBL can be diagnosed using an oscilloscope. We replace the faulty lock with a new one.

Hatch locking device

We check all wiring with a multimeter and repair damaged areas.

The module must be replaced and repaired by a good electronics engineer.

If the hatch is locked

If the hatch is locked and the wash does not start, then the following reasons are possible:

- the pressure switch is faulty or clogged;

- the pump is damaged;

- Fill valves do not work or are clogged.

If the level sensor is broken, the machine “thinks” that the tank is full and does not start washing. To solve the problem, it is necessary to replace the pressure switch. A similar situation may occur due to a clogged sensor tube. After cleaning, the machine will start working.

Before adding water, the module checks the serviceability of the pump. If it burns out, the wash cycle will not start. This is the logic behind the work. We replace the pump with a similar one.

The fill valves are burnt out, so the machine cannot start washing due to lack of water. We replace them with new ones, and also check the mesh for possible blockages.

Calling a Samsung repairman: where to find it, how to avoid falling for scammers?

In a situation where self-diagnosis and repair of a Samsung washing machine did not lead to the desired result, there is only one thing left to do - call a professional technician.

It’s worth finding out in advance how to do this correctly so as not to encounter scammers.

washing machine repairman

The first leading place in the ranking is occupied by an online service for selecting repair specialists.

There are a sufficient number of services, registration on which will help you quickly choose a specialist and apply for repairs. The advantages of this method: accessibility anywhere in the country, round-the-clock access to the necessary information, a large selection of specialists at various levels.The disadvantages include not always truthful reviews, which can affect the final choice.

- The second item in the ranking is newspaper advertisements. This is a fairly popular and familiar search for a master. A phone call allows you to immediately discuss the details of interest, the cost of the work, and also draw up a preliminary portrait of the person who may come to the call. One of the disadvantages of this method is the amount of time spent on calling.

- The third place of honor in the ranking is occupied by the so-called “word of mouth”. It would seem that what could be more reliable is the recommendations of a friend. But you should never forget that the previous client’s opinion is based not only on the results of the master’s work. A person can formulate a review based on personal feelings. So, for example, being in a not very good mood, few people pay attention to the positive qualities of the master, paying attention only to his shortcomings and shortcomings.

- The fourth place is occupied by service centers. The advantage of such organizations is that both the master and the client are always legally protected (a service agreement is drawn up). It is this official document that will become the basis for legal proceedings in the event of unsuccessful repair of the washing machine.

- The last place in the ranking of the most popular ways to find a craftsman is advertisements on a pole. Of course, this method is not relevant for large cities, but for small towns and villages, advertisements on a bus stop pole will help you find a good local washing machine repair professional.

To avoid dealing with scammers, when choosing a specialist, you should pay attention to the following:

- the master, without studying the problem, immediately names the final diagnosis and the amount of future repairs;

- the so-called “specialist” demands advance payment (even partial) for work not yet completed.

The above signs indicate that most likely the master is a fraudster whose services you should refuse.

The final cost of washer repair depends on many factors:

- price of components,

- urgency of order fulfillment,

- complexity of work.

On average, replacing a lock will cost from 1,500 to 2,500 rubles, replacing a drain filter up to 2,500 rubles, replacing a drain pump up to 4,500 rubles, repairing a module up to half the cost of a new unit.

Find out more about repairing Samsung washing machines in this section.

What to do if the washing machine does not turn on

Start by inspecting the equipment:

- Check whether the washing machine's power cord is connected to the network.

- Check the panel - perhaps the electricity in the room has turned off.

- If the machine does not respond to the power button, connect another device to the outlet and check if it works.

- Inspect the power cord for damage; it may be pinched by some object. The damaged area can be secured with electrical tape, but it is better to replace the wire completely.

If the inspection does not yield results, further diagnostics and repair of the washing machine will be required. Let us describe the typical causes of SMA failure.

After the purchase

What to do if your new washing machine doesn't work? If you have just installed the washing machine and it is not working, there is no need to disassemble it yourself. Contact the store for warranty. There may be a manufacturing defect.

After a power surge

After a power surge, the first to suffer is the network filter (SFP), which protects the electronic module of the machine from combustion. The filter also serves to neutralize interference to which devices adjacent to the washing machine may be exposed. As a result of a breakdown, the filter may not allow electricity to pass through.

How to check:

- Remove the top cover from the washer body by unscrewing the screws on the back.

- At the side wall you will find a surge protector.

- Inspect it and the contacts included with it. Burnt parts or swelling of the filter are usually noticeable. Then he immediately needs a replacement.

- If nothing is visible visually, the filter contacts are tested with a multimeter.

- The part cannot be repaired. To remove it from the housing, disconnect the wiring and unscrew the mounting bolt.

From the filter, the wiring leads either to the start button or to the control module. Depends on the year of manufacture of the car. After a voltage drop, the wiring could burn out.

The start button must allow current to pass when turned on. You can find out by applying a multimeter probe to its wires. If it shows resistance on the screen, it means the button is working; if not, it needs to be replaced.

You can order a button specifically for your model in the online store.

Sometimes the button gets stuck if detergent gets on it. Then you need to clean the socket and put the key back in place.

To avoid voltage problems, it is recommended to connect the washing machine from an electric generator.

After moving

Your car used to work fine, but after moving it won't turn on? The electronic module needs to be checked. The fact is that water that was not removed from the dispenser tray (it always remains there) could get onto the module during shaking or turning of the machine. This immediately disables it or leads to a short circuit when turned on.

Module check:

- Unplug the washing machine.

- Remove the top cover.

- Remove the dispenser tray by pressing the lock in the center.

- Remove all screws that secure the control panel and remove it from the case.

- Take a photo of the wiring location and disconnect it.

- Unlock the plastic latches and remove the board from the panel.

If no damage is found during inspection, take the board to a service center for diagnostics.

The hatch cuff has become unusable

The rubber door seal is moldy or mechanically damaged. It is torn or pierced during washing by sharp objects forgotten in pockets, various accessories - rivets, zippers, underwires from bras, etc. In rare cases, in SMAs with a long service life, the cuff wears out due to vibrations.

| Signs | How to fix | Cost* (work only) |

| The machine leaks when washing. Codes LE, LE1, E9, LC, LC1 can be displayed on the screen. | The technician determines the location of the damage to the cuff and either seals the puncture (possibly with minor damage) or changes the sealing rubber completely. | from 1900 rub. |

*The price is only for the work of the master, spare parts are paid additionally.

Fill valve failure

The fill valve consists of a body, an electromagnetic coil and a membrane (it opens when voltage is applied). Most often, the coil fails, so no water flows into the washer.

| Signs | How to fix | Cost* (work only) |

| The washing machine does not draw water at all (models equipped with a single-section fill valve) or only during rinsing (models with a two-section valve). The malfunction is most often accompanied by errors 4E (CHE), E1 and 4C. | The faulty valve must be replaced. | from 1800 rub. |

*The price is only for the work of the master, spare parts are paid additionally.