- The motor drive belt is torn or stretched:

It is important to find out the cause of the break - natural wear of the belt material or wear of the bearings!

The belt is put on the washing machine motor and on the pulley. The pulley, in turn, is screwed to the drum.

Accelerated wear of the drive belt is a “disease” of narrow washing machines.

As a result of the dense layout, the components and parts of such models are located close to the body and to each other.

Over time, as they wear out, moving parts gain greater freedom of movement and can rub against adjacent parts.

Worn motor brushes: The machine tries to spin, but does not reach maximum speed.

Extraneous noise is heard, there is a burning smell, and increased sparking.

Unscrew the screws and remove the engine. There are two brushes on the engine, each secured with two screws. Unscrew the screws and pull out the brushes.

Inspect the motor power supply terminal from the board and the ground wire.

Very often the contacts oxidize due to humidity and the machine gives an error because of this.

Each brush is installed in a brush holder. It can be disassembled into two halves. Pay attention to how much the brush protrudes.

If the working reach of the brush is less than 7 mm, it must be replaced (both should be replaced). To do this, disconnect the wire and pull out the contact to remove it. Remember in which direction the graphite contacts are ground.

Malfunction of the electric motor tachometer: The set speed does not correspond to the selected program, the engine operates only at minimum or maximum speed.

The tachometer monitors the speed of rotation of the engine rotor.

When it rotates, an alternating voltage is generated at the terminals of the tachogenerator coil.

The frequency is compared by an electronic board and the rotation of the drum is controlled. It may be enough to tighten the sensor mounting screws or glue it to restore proper engine operation.

Short circuits and breaks in the stator and rotor windings. Reduction in power, increase in temperature and, as a result, activation of the thermostat protection.

Washing machines mainly use AC commutator motors. An interturn short circuit in the armature accounts for a significant percentage of failures, because the rotor experiences strong centrifugal loads during rotation. Wear and peeling of the collector lamellas. Heating of the housing and sparks are observed.

We check the resistance of adjacent lamellas with a tester.

It should be the same about 0.2 ohms.

As a rule, this failure is mechanical and there is no need to go into electronics knowledge.

The rotation begins with draining the water, distributing the laundry, and then the drum speed increases.

Therefore, it is important to determine at what stage this occurs.

Until the water drains, the machine will not reach maximum speed. The trapped debris interferes with the draining process and the laundry remains wet.

Cleaning the drain filter

Clean the drain pipe between the tank and the pump

Clean and check the pump itself

There is no control signal to the engine block:

Check the power supply through the triac circuit controlling the board with the motor tachometer.

Only an experienced specialist can professionally test the board for breakdowns. Do-it-yourself testing may lead to incorrect conclusions.

To replace the brushes, the motor does not need to be removed—just unscrew the back cover or tilt it for access from below. For Bosch and Siemens brushes are available in sizes 5x12, 5x32 mm.

Bosch and Siemens engines use a Hall sensor instead of a tachogenerator.

Direct drive motor

Reliable, relatively simple, and isolated cases of stator winding failure are known in practice. The magnets on the stator are of course not of the highest quality, but they almost never came off or split.

The only vulnerable part is perhaps the Hall sensor. If a malfunction occurs, there is no rotor position signal, which leads to incorrect operation of the motor phase power system. In this case, you can observe how the engine rotor locks and makes a rattling metallic sound.

If the belt slips, the drum bearing assembly (tank cross) may wear out.

How to verify this malfunction

1.Simply spin the drum by hand and you may hear a noticeable grinding noise. Extraneous noise is the first indicator of a problem.

2.Press the top of the drum and check the play (shift) due to force. There should not be much play between the cuff and the drum.

3.Remove the back panel of the machine. Rusty water leaks are another sign.

Models A800, A804, A810, A814, WD800X, S1000X, T80, T800, TL800X, TL804, etc.

Malfunctions in the DMPU engine control module:

relay K1, K2; rsimistor TR2. Diodes D1-D6, D9-10, D15, D23.

Legacy DMPA module models A1000PL, A1000XCZ, A1000XPL, WD1000PL, TL1000X:

They are used in machines that include an asynchronous drive motor and a mechanical command device.

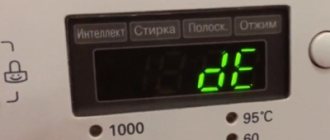

The equipment is equipped with “intelligence” and the machine usually produces an error. Spin failures occur: - due to dampness or due to low mains voltage - short circuit of the control triac - the signal from the tachogenerator does not reach the board - “sticking” of one of the contact groups of the reverse relay (there are two in total) of the drive motor - the spring washer is loose holding the tachogenerator coil - wear of the drum bearing assembly.

Control board on the Motorola EWM1000 controller:

EVO-II models wisl 103, wisl 83, wisl 82, wisl 102:

Relays K1, K3, K7 - reverse and engine speed.

Arcadia board - models (WIN - WIB):

A powerful triac BTB16-600 (TC1) coordinates the operation of the motor.

Triac TP1 controls the drive motor.

Do not overload the drum with laundry - if overloaded, the brushes will fail faster. Do not abuse the maximum spin speed; it is better to spend a little more time waiting for your clothes to dry than to change the electric motor brushes every three years. And things will quickly become unusable after constant strong spinning.

The Ardo washing machine washes, but does not spin. Is this a breakdown?

So before you get upset, take a look to see if you have one of these programs enabled. If you started the wash in these modes, the device stops working after rinsing. If you want to spin the laundry, then set the “Spin” program.

In the Ardo washing machine you can change the spin speed or cancel it. Before you run to a service center or call a technician to your home, look carefully to see if you accidentally pressed the “Cancel spin” button or reduced its speed.

Ardo also has a function to stop the water machine. Check if you accidentally stopped the device.

The imbalance control function in the Ardo washing machine distributes the laundry evenly throughout the drum and prevents overload. If you put extra laundry in, the spin cycle will not turn on. If the imbalance is high, the spin speed decreases or the spin does not occur at all, so the laundry is wet. Pull out the excess laundry and the spin cycle will start.

But it’s not just excess laundry that can cause the drum to not work properly. If you haven't loaded enough laundry into the machine, or it's very light, then the items won't be distributed evenly. Strong vibration occurs at high drum speeds.

Therefore, the control panel reduces the number of revolutions and the device does not spin efficiently enough. When washing, it is better to put one large item and two small ones in the machine.

Poor spinning can also occur with an overabundance of household chemicals. Washing powders, bleaches, and conditioners should be used only those recommended by the manufacturers of the Ardo machine. Never use washing powders intended for hand washing.

Why doesn't the Ardo washing machine spin?

If, nevertheless, you were careful and started the wash correctly, but the spin still does not work, then you need to look for faults in the machine. One of the reasons for spin malfunctions is that the device does not drain the water.

Why doesn't the water come out of the machine?

What to do if the reason for the spin failure is a pump malfunction

- Turn off the power to the machine by unplugging the cord from the outlet.

- Remove the top cover.

- Pull out the cuvette, then unscrew the screws that are located under the tray.

- Place the device on its side.

- Unscrew the fasteners holding the tray. Take it off.

- Pry up the wire that holds the cuff in place.

- Detach the cuff. Now there is nothing holding the front of the machine. Remove it carefully so as not to tear off the wires.

- The pump is accessible, pull it out. There are 2 pipes suitable for the pump - one from the drain hose, and the other, which is thicker, from the tank. Using pliers, press out the clamp and remove it.

- Use a screwdriver to pry up the edges of the pipe and remove it. You will see a lot of garbage. Collect it.

- Remove the terminals and then the pump itself. Now check if it works by connecting it to the network. He starts spinning. Press it with your thumb. If he's okay, then you shouldn't be strong enough to stop him.

- Clean the drain pump and pipe.

- Reassemble the washing machine in reverse order. Carry out a washing test: whether the water is drained, whether the machine spins.

The Ardo washing machine does not spin. Other reasons

- The cause of problems with spinning may be a breakdown of the tachometer. A tachometer is a device responsible for the number of revolutions in the drum.

DIY repair

Washing machines from different manufacturers have specific features, which in turn determine the spin recovery process. Let's look at the devices of the most popular brands and what to do in case of malfunction.

LG

An LG washing machine does not spin after washing, most often due to a malfunction of the tachometer, which is also often called a Hall sensor. To test this hypothesis, it is necessary to gain access to the sensor immediately after disassembling the machine.

You need to ring all available contacts using a multimeter and check the resistance in the circuit. If at least one of the contacts does not work, this may indicate a malfunction of the resistors installed on the board. Next, specific resistor pairs are checked. On a burnt element, the multimeter will not show any resistance.

To repair an LGI machine, you simply need to resolder the faulty resistors or purchase a new tachometer for a specific model of washing machine.

Indesit

The appearance of error F08 usually accompanies a situation in which the spin cycle in the Indesit washing machine does not work. It indicates problems with the operation of the heating element switching relay or a malfunction of the pressure switch. To repair, you need to check the corresponding contacts on the board. It may be necessary to replace the control board or the pressure switch itself.

Most often, the main reason is a breakdown of the heating element on the body of the washing machine. This is checked using a multimeter set to maximum resistance measurement mode. Even small values indicate a breakdown.

It is necessary to completely replace the heating element. The old component is unscrewed and a new one is attached in its place. It is advisable to purchase a device from a reliable manufacturer so as not to encounter unpleasant consequences.

Samsung

Failure of the spin mode on Samsung washing machines may be due to a worn-out drive belt, a faulty tachometer, a malfunction in the control unit, a broken pressure switch, or even a damaged electric motor.

The most harmless malfunction can be called a situation in which a rotating element appears on the electric motor shaft. In this case, the problem will be due to the fact that the tachometer attached to this element simply cannot correctly read the revolutions and transmit information to the control unit. As a result, it is impossible to regulate the spin speed in automatic mode, and the machine’s operation timer stops at 10 minutes. To correct the problem, sometimes it is enough to simply select a washer, with which you can ensure a reliable connection of all elements on the motor shaft. The machine will stop humming during operation and will begin to wring things out correctly.

Bosch

With Bosch machines, a problem that often arises is that the spin cycle does not work correctly. The machine, in spin mode, tries to accelerate the drum, but does not pick up speed and freezes. The weak point in this case seems to be the engine, so it is recommended to start repairs from there.

The motor may burn out completely, requiring the purchase of a new motor. However, its cost and difficulty of acquisition negate all the advantages of such a solution. It is often better to purchase a new washing machine.

The most common cause is a slipped magnet on the motor shaft. The repair will include disassembling the Bosch machine, separating the engine and opening the corresponding connector. The slipped magnet will need to be pulled out, thoroughly cleaned and returned to its proper place. To prevent the problem from recurring, it is advisable to securely secure the magnet using silicone sealant.

Candy

Owners of Candy washing machines may also encounter the unpleasant problem of no spin during washing. In this case, it is advisable to immediately carefully study the indicators on the external panel. If at the moment of the first jerk they first blink and then begin to fade out slowly, then the fault lies in the capacitor installed inside.

This capacitor is located on the main board of the Kandy washing machine. It is enough to simply replace it with a similar one and the machine should start spinning in normal mode without any difficulties.

Ardo

On Ardo models, difficulties with switching to spin mode are most often associated with engine or pump malfunctions. However, any problems with the engine affect the operation of the machine as a whole. Therefore, it is advisable to assume that the pump does not squeeze well precisely because of the pump.

Sometimes the pump stops working properly due to a foreign object or excessive debris getting inside. When disassembling fireplaces, you must immediately separate the pipe and drain pump from the pump, thoroughly wash the part and inspect it for damage.

If the solution does not help, you can then pay attention to the sensors used and the main control unit. Inspection and repair of these components are carried out in accordance with the basic rules for working with electrical circuits.

Zanussi

It is advisable to start repairing a Zanussi washing machine with the simplest unit: the filter. It is necessary to gain access to it and thoroughly clean it of excess dirt. If necessary, the filter is replaced with a new one.

Then you need to disassemble the machine and disconnect the pipe. All elements are checked for debris and mechanical damage. If no external problems are observed, you should start checking the electronics. The motor and control board are checked using a multimeter. If the values at any nodes differ significantly from the nominal values, the problem will be in them.

Traditionally, the tachometer and pressure switch deserve special consideration. Models of this brand are usually equipped with inexpensive components that may well fail. If a problem is detected, these components will need to be replaced immediately.

Ariston

When using Ariston automatic washing machines, users may encounter error F05. It is accompanied by the inability to start the spin cycle, as well as the lack of automatic drainage of water. The machine itself works extremely unstable and at one point simply stops the washing process.

The repair must begin by disconnecting the device from the network and draining the water in the tank.

Further repairs involve opening and cleaning the channel with the filter. Often, it is foreign objects in this area that cause the drain to jam, as well as the impossibility of spinning.

The pipe in modern Ariston models is reliable and almost never fails. The problem may lie in the control unit or the motor itself. For a more accurate determination, you need to ring the main contacts and replace faulty components.

Beko

Beko washing machines are reliable and unpretentious. However, even they can fail in some cases. The lack of spin in such devices is rare in itself. Most often, the problem occurs simultaneously with the fact that the machine does not drain the water. This could be due to faulty components or simple clogging of the internal parts.

In particular, a foreign object that gets into the pump blades immediately negatively affects the operation of the entire device and leads to the machine not squeezing. To carry out repairs, you need to disassemble the machine and gain access to the internal parts. Then all elements are checked for blockages or mechanical damage. If none are found, you should immediately check the serviceability of the electronic circuits using a multimeter.

What to do?

Don't panic prematurely. First, make sure that the cause lies directly in the malfunction. Perhaps you turned off the spin yourself, and the machine is not able to complete the entire program. Check the management panel. There is a possibility that you have set an operating mode that does not involve spinning, or you have set a delicate wash. In this case, set the normal operating mode and adjust the speed.

Top-loading SMAs are able to respond to overload with things. In addition, there may not be enough laundry, an imbalance occurs, and the washing machine stops after several attempts to spin the drum. Simply open the loading door and remove excess laundry or distribute items throughout the drum. Remember that such problems are typical for older models, because modern washing equipment is equipped with a function that protects against imbalance.

Breakdowns typical for SM Ardo

A breakdown is usually indicated by a number of signs. By carefully studying them, you can recognize the failure. Therefore, it is better to start with an overview of the signs of breakdowns that occur most often:

- Water does not drain. This can happen for a number of reasons, including, mainly, blockage of the drain system, consisting of a pipe, a drain hose and a pump (drain pump). It is extremely rare that this problem occurs due to a failure of the temperature sensor.

- The water stopped heating. This is especially noticeable in high-temperature washing modes. You can tell that the water is not heating up by looking at cold laundry and unwashed stains on it. The failure of the heating element (heating element) causes breakdown. Limescale and scale slowly but surely destroy the part, causing it to burn out. The wasted resource of the part cannot be ruled out.

- The drum stopped spinning - it was stuck rooted to the spot. The design of Ardo washing machines is such that the drum is driven by a special belt. If the belt falls off the pulley or breaks, the tank stops spinning. In this case, you need to correct or replace the belt.

- Noise and “left” sounds - knocking, humming, rumble. If you hear them in operating mode, then the reason lies in the bearings. An object that has fallen into the tank often makes noise - a button, a coin, etc.

- Water leak. The cause of a dangerous breakdown is a violation in the pump or pipes. In the most severe case, you will need to replace the bearing and seals of the Ardo washing machine.

- Program crash. The machine does not start. All this is typical for a control module failure.

Don’t panic, you can often do without a specialist. Perhaps, having correctly identified the breakdown and its cause, you will be able to repair the washing machine yourself.

Causes of malfunction

In most situations, the reasons why the Ardo washing machine does not spin clothes are quite trivial. And the question is not related to failure - the user often makes mistakes, causing spin failure. What is meant in this case?

- The washing machine drum is overloaded with laundry, or there is an imbalance in it . By putting more laundry than normal or one large and heavy item into the washing machine, you run the risk that your Ardo washing equipment will freeze without starting to spin the laundry. A similar situation occurs when there are few things in the drum of the machine, or all of them are light;

- The operating mode for the machine is not defined correctly. The latest Ardo household appliances have a large number of operating modes and functions, selected taking into account certain factors. If the work task is not set correctly, the spin mode may not work;

- untimely maintenance of the laundry washing machine . Everyone knows that your washing machine needs to be maintained regularly. If you do not clean the garbage filter for a long time, it becomes clogged with dirt and creates problems for normal spinning. To avoid such a nuisance, in addition to periodically cleaning the filter, it is recommended to perform a similar procedure with the washing powder tray, drain and water intake hoses.

What problems can you fix yourself?

First of all, we advise you to make sure whether the problem is really a breakdown of the unit. There are situations when the washing machine does not spin due to the carelessness of its owner. In such cases, it is possible to eliminate interruptions in the operation of the device even without special knowledge of the design of household appliances. The most common user mistakes:

1. The washing mode without spinning is started. All modern washing machines have several washing programs for different types of fabrics. In modes such as “silk”, “wool” or “gentle wash”, the spin cycle is not programmed, so the items in the drum do not wrinkle or stretch.

In the instructions for the device you need to find a description of the selected program. If it does not involve spinning, then most likely there is no damage. Just select a different washing mode next time or run the spin function for already washed laundry separately.

Some units have a separate button, by pressing which you can turn off the spin cycle in any washing program (indicated by the image of a crossed out spiral)

If the laundry remains wet after washing, this option may have been selected carelessly

2. Overloading the washing machine. If you have loaded too many things into the device (or their weight exceeds the permissible norm), it is quite possible that the machine simply cannot fully spin the drum. A similar situation can occur when too few clothes are loaded and they form a ball, thereby causing an imbalance in the device and limiting the drum speed.

To avoid such a problem, always follow the recommendations for the weight of the loaded laundry specified in the instructions (they may vary for different programs and modes). If this condition is met, but things still bunch up in one direction, put special laundry balls in the drum and repeat the procedure.

3. The machine does not drain the water. Before the unit can start the spin program, all water from the tank must be drained. When a clog occurs in the drain system, water cannot flow correctly into the sewer system. If your washing machine does not spin, try unscrewing and cleaning the drain filter. It is located behind a small door at the bottom of the front panel of the unit. You should also check the drain hose and sometimes the sewer for blockages. The pipe is washed with running water or cleaned using a special cable.

If the drain filter is clogged, the machine cannot drain water and start spinning.

Pump or electric motor?

It is no secret that problems associated with the performance of the drain pump of the Ardo washing device can not only affect the spin cycle, but also disrupt other operating mode programs. And here the strange behavior of the equipment cannot absolutely indicate the pump, and there are reasons for this.

According to the design of the control system, the management module is required to notice this fact and stop the washing process by sending a signal corresponding to the code error. But this does not happen, since during the washing process we most often use programs that do not consume a large amount of water. This means that the draining process is still completed quickly. A different matter is represented by another working stage - rinsing. It consumes quite a lot of water, and a pump that is broken is not able to quickly pump it out to drain. Most of the liquid is drained, but the washing machine manages to freeze without starting the process of spinning the laundry.

If you are familiar with these faults, check the pump first. The algorithm of actions is as follows:

- The tray for detergents is removed from the Ardo washing machine;

- the device tilts to the left side;

- the screws securing the pallet are unscrewed;

- The pipe and sleeve of the drainage system are disconnected from the pump;

- the pump is disassembled, cleaned of dirt, and the condition of its impeller is checked;

- The resistance value is measured using a multimeter.

The problem is caused by faulty sensors

Other reasons why the electric motor stops working normally are associated with the tachometer. This small device, resembling a ring, is located on the motor. With its help, the number of engine revolutions is determined and controlled. If there is a breakdown in it, then the control module will not be able to influence the performance of the motor, which will entail certain failures of the specified program.

Checking the tachometer is determined with a multimeter. The resistance value is measured, and the electrical wiring suitable for the sensor and terminals is checked. The wiring has a thin cross-section, breaks or is easily damaged, and when this happens, the tachometer stops performing its functions.

In addition to this element, the sensor responsible for the water level in the Ardo washing machine may fail. They call it a pressure switch. In such a situation, the washing machine freezes immediately after rinsing, and the spinning process does not begin. To make sure that the problem lies precisely in the pressure switch, try to activate the spin process separately, no matter what washing program is set, and see how correctly the washing machine performs it. If everything happens normally, then we can confidently assume that the breakdown lies in the water control sensor.

It is possible to access the pressure switch in the Ardo washing machine through the top panel of the housing. After removing the cover, you will see a round device made of plastic material, to the terminals of which electrical wires are connected. This is a sensor that monitors the liquid level. It is necessary to check it with a multimeter, blow out the tubes, and, if necessary, replace it with a new analogue.

Some useful tips

Try to prevent the occurrence of malfunctions rather than bring the matter to repair work. To do this, it is proposed to follow some simple rules:

- before loading laundry into the drum, check the contents of its pockets for foreign objects;

- install the washing machine and connect it in accordance with the operating instructions;

- Wash linen with decor in special bags;

- load things in accordance with the established norm. Otherwise, the washing machine will be subject to rapid wear and tear and perform poor washing;

- use a voltage stabilizer to protect household appliances from sudden breakdowns;

- Clean the drain filter and washing powder tray regularly;

- Leave the hatch door open after washing to prevent the appearance of mold and mildew.