How to clean the drain hose in a washing machine. Blockages are the most common problems of the SMA. In case of such a problem, calling a technician or transporting it to a service center is not necessary. It’s quite possible to solve it yourself.

Some people mistakenly believe that you can clear a blockage in a hose by simply rinsing it with running water. In principle, this is true, but first it should be dismantled without damaging it, and then installed back.

- Causes of clogs in washing machines

- Signs

- Cleaning without disassembly

- Dismantling in different models of washing machines

- Flushing

- Preventing blockages

- SMA catalog with reviews

Causes of clogs in washing machines

Clogging of the drain hose occurs due to mechanical and natural reasons. The first signal that the drainage is clogged is difficulty draining liquid from the device during squeezing or draining.

If the machine malfunctions during these steps, it means a blockage has formed. If it is strong, the drainage system is completely blocked.

Drain hose sma

Natural blockage

As a result of operation, the drain hose becomes clogged with fabric fibers, particles of dirt, hair, and pet hairs. All this sticks to the walls of the tube, reducing its lumen. As a result, a hard and viscous substance is formed, which consists of detergent residues, dirt, fibers and wool.

Mechanical blockage

Clothing accessories, coins, small toys, as well as decorative elements of things can get stuck in the drain hose.

Clean the hose when it is completely clogged

If water removal from the washing machine completely stops, a second cleaning method will be required, in which you will need to completely disconnect the hose from it. For this you will need the simplest tool - a flat or figured screwdriver and pliers. The sequence of actions in this case is quite simple:

Disconnect the washing machine from the power supply. Shut off the water supply. Carefully disconnect the hose from the machine, first placing a container to drain the remaining water. Disconnect the drain hose from the sewer and clean it.

To de-energize the washing machine, simply remove the plug from the socket. There is usually a tap on the hose that supplies water from the plumbing system; it should be closed. Basically, the drainage hose is attached to a pipe, which is located on the back of the washing “unit”. Using a screwdriver or pliers, you need to unclench the retaining clamp and remove it. For ease of access and operation, first place the washing machine on its side, placing a floor or other cloth under it. Sometimes users do not connect the drain to the sewer, but simply place the other end of the drain hose in the bathtub or sink.

Cleaning should be done with a Kevlar cable, at the end of which there is a small brush; you cannot clean it with metal objects. After cleaning the hose in one direction, the operation should be carried out in the other, then rinse well under running hot water.

To be more sure that the hose will not have to be removed again, it is recommended to inspect the filter as well. Perhaps it also requires revision and cleaning.

Different manufacturers have their own housing designs and filter mounts that require access. Trademarks LG, Veko, new Indesit models, the bottom is closed with a lid that can be easily removed with a flat screwdriver. Zanussi, Electrolux to access the filter you will need to remove the back panel. German manufacturers of washing machines - Bosch, Siemens - made the front panel removable. Then, depending on the design, the filter is removed. It is attached to the body using latches or a screw connection (bolt, self-tapping screws), sometimes it is screwed into the drain pipe. To dismantle it, you may need to remove the neck to which the drain hose is connected. The work must be carried out carefully, without damaging the gaskets and seals.

The filter should also be thoroughly cleaned and rinsed under running hot water. Then reassemble in reverse order. All connections must be tightened well, especially the hose clamp itself. The pressure when water comes out is small, but it is still there.

After the machine is assembled and connected to the power supply, it is advisable to wash it with a cleaning agent to completely remove small particles. In addition, you should inspect the connections for leaks and, if necessary, tighten the clamp.

For prevention, once every 1-2 months it is advisable to wash the machine to remove clogs and scale; in areas with high water hardness, use water softening agents. It is also recommended to use a special bag for washing.

During automatic washing of clothes, not only waste water, but also garbage and items forgotten in pockets sometimes end up in the drain

Therefore, it is important to regularly clean the system from blockages. How to clean the drain hose of a washing machine without the help of a professional? The main thing is to know the sequence of actions that we will tell you about

Online diagnostics of a washing machine

If your machine stops washing or rinsing clothes normally, then some kind of malfunction or breakdown has occurred.

You can try to find the problem yourself. Run diagnostics

Select which operation your washing machine does not perform:

1. Doesn’t drain 2. Doesn’t rotate the drum 3. Doesn’t spin clothes 4. Noises, knocks, buzzes when spinning 5. Doesn’t turn on

Checking the operation of the drain pump Is the drain pump of the washing machine working? Yes No I don’t know << Back

Clogged hoses in the washing machine If the sound corresponds to the normal sound that has always been observed when the device is working, the cause is probably a clog.

Was there a blockage in the drain hose? Yes

<< Back

The drain pump does not work! If the sound matches the normal sound of the drain pump, it is recommended that you check the drain filter first.

After cleaning, does the drain pump work and does the washing machine drain water? Not really

<< Back

Operation of the drain pump The sound of the pump is usually immediately audible and noticeable. If there is no sound, the pump is not working. We are looking for how to separately enable the water drainage program. As a rule, this is a separate option. After the program has been turned on, the pump should start working in 1-3 seconds. If everything is done correctly and the pump is operational, a buzzing sound will appear. If you hear no buzzing or other sounds when you turn on the program, the pump is probably faulty.

Is the washing machine drain pump working? Not really

<< Back

Clogged car hoses If you have identified a clog in the hoses, you need to disassemble them, clean them, and then reassemble everything.

Does the washing machine drain well? Not really

<< Back

Hurray, you did a great job, you fixed it.

<< Return to the beginning of diagnostics

The drain pump is faulty, call a professional.

<< Return to the beginning of the diagnosis.

The washing machine does not rotate the drum. During the operation of the washing machine, such a problem may occur. Each model has a different drum operation. It rotates according to a given algorithm, which is set by the program. This principle applies to spinning and washing. If you are not sure whether the drum is not spinning or whether it is working, put the laundry in the washing machine. Start the spin program. If the machine is running, it will first drain the water and then start spinning. In this case, a rotational process will be observed. If rotation is not visible, then check the belt. First, turn off the program, then unplug the wire from the outlet so that power does not flow into the device. Now you need to remove the back cover. You will need to carefully inspect the drum belt. It is quite easy to determine whether it is in the wrong position or damaged.

Is the washing machine belt torn or stretched? Not really

<< Back

Broken drum drive belt If the belt breaks, it will be immediately visible. There are also often cases when the belt simply stretches, which is why the drum, accordingly, does not rotate. Do not allow the machine to operate if the belt breaks. It is important to check whether it has wound around the engine pulley or broken the wiring to the engine. The heating element and temperature sensor may also be damaged if the belt does catch the wires. It is imperative to ensure that the belt model is original. If you choose an unsuitable or low-quality product, this will affect the performance of other devices. How do you know what kind of belt you have? There will be a marking written on the old one, compare it with the one indicated on the belt offered to you. You can also find out belt information by car model.

<< Return to the beginning of the diagnosis.

Washing machine motor malfunction If a malfunction is not found, the block with wires must be disconnected from the electric motor. Carefully remove it. We visually evaluate the engine. It may have melting, cracks, or other effects that clearly indicate damage. We call the windings of the tachogenerator and the engine. It is important to understand that you can fully study how correctly the engine operates and whether there is a malfunction only at the stand. If rotation does not occur, there may be a problem with more than just the motor. Sometimes the cause is a malfunctioning electronic module. If a short circuit occurs in the engine, the module could be damaged, while the engine remains operational. Also, the wires could be damaged.

<< Return to the beginning of the diagnosis.

Repairing a washing machine that does not spin clothes After completing the washing process, the washing machine may not spin properly or may not start spinning. Firstly, look, perhaps another mode is set, which does not involve turning on the spin cycle at all. This happens, for example, with programs related to washing woolen items and delicate fabrics. To check, run the spin cycle separately. If the washing machine does not drain water, we proceed to check the pump.

Does the washing machine now spin clothes? Not really

<< Back

Congratulations, you have solved your problem!

<< Return to the beginning of the diagnosis.

Repair of washing machines, imbalance Modern washing machines place the laundry on the drum before spinning. This is necessary for quality work. Check if this feature works. Sometimes a situation occurs when things get wrapped up in a ball that cannot be unwound automatically within a certain time. At this point the work stops. You need to unwind this laundry yourself, lay it out and continue operating the washing machine. In this case, it is important to turn off the machine, and then, when the laundry is laid out, turn on a separate spin program.

Does the washing machine now spin clothes? Not really

<< Back

Washing machine repair, drum drive repair Now you need to check the drum drive belt. We remove the cover and visually assess the condition of the belt. There should be no damage. If the tension is weak, the spin may not turn on. If you need to replace the belt, you should only replace it with the original one. After replacing, we try the program again.

Fault found, does the washing machine spin? Not really

<< Back

The engine or electronic module is faulty, call a repairman to your home.

<< Return to the beginning of the diagnosis.

The washing machine hums, makes noise during the spin cycle, rumbles, and makes a jet plane noise. If the washing machine makes noise during operation, making unusual sounds, it’s time to pay special attention to it. In this case, a visible breakdown or lack of functionality may not be observed, but the appearance of strange sounds indicates that it is time to look for a malfunction. It is important to understand that a new car that has just been delivered should be inspected for shipping bolts. If you forget to remove them, noise and vibration are inevitable. So, let's begin! We turn the washing machine drum and listen to extraneous sounds.

When rotating, do you hear extraneous noise, hum, balls rolling, does the drum move unevenly with slight jamming? Not really

<< Back

If the drum rotates and uncharacteristic sounds appear, including vibration, it’s time to check the bearings. If they malfunction, they will have to be replaced.

<< Return to the beginning of the diagnosis.

The counterweight of the washing machine has come loose. The fastening of the counterweights must also be of high quality. If they are “loose”, it’s time to eliminate this defect. In some cases, you can notice that the bolts that secure the stones are completely missing. In this case, the connectors for mounting will be visible. The bolts need to be found and put in place - they probably simply came loose. A rumble heard while the washing machine is operating may indicate that the bolts have partially loosened. To check the bolts, you can simply push the drum. If it is secure, the bolts are fine. If it moves, there is a defect.

Do you hear any noise, clanging or rattling noises when moving the washing machine tub? Not really

<< Back

The counterweight has come off

<< Return to the beginning of diagnostics

Checking the shock absorbers of the washing machine Checking the shock absorbers. If you hear vibration or excessive noise during the spin cycle, there may be a problem with the shock absorbers. Sometimes the washer moves. Now let's check the functionality. Remove the top cover. Click on the tank, move it five to seven centimeters down. A normal reaction will be observed if the tank rises sharply, jumping a little and stopping in its normal place. If this does not happen, the shock absorbers need to be replaced.

Are the shock absorbers of the washing machine working? Not really

<< Back

If a visible defect has not been identified, check whether a foreign object may have entered the machine. Replacing shock absorbers. The problem with shock absorbers wearing out occurs quite often over time.

<< Return to the beginning of the diagnosis.

Replacing washing machine shock absorbers. Malfunction and wear of shock absorbers is a fairly common phenomenon.

<< Return to the beginning of the diagnosis.

The washing machine does not turn on. It is worth trying to find the cause of the problem yourself and fix it. We start by connecting the device to the network. Next, click on the “network” button. In different car models, different indications are triggered: here either the display will start working, or, on the contrary, some other button.

Does the washing machine have an indicator? Not really

<< Back

Hatch lock lock (UBL) You can check it by turning on any of the programs. We choose what we will use. Click on the corresponding button. Don't forget to pay attention to the inclusion. As a rule, the process of activating a function is characterized by the presence of a certain sound, for example a click, with which the device makes it clear that pressing again is not necessary and the machine is already working. If there is no sound, the button may be broken. In this case, the main thing that must be done is to block the hatch and start working. If this happens, everything is fine.

The washing machine is blocking the hatch and the UBL is triggered? Not really

<< Back

Water fill valve malfunction

<< Return to the beginning of the diagnosis.

The washing machine hatch does not lock

<< Return to the beginning of the diagnosis.

No indication Checking the electrical circuit. If you notice that the washing machine does not respond to being turned on, it is first recommended to check the power supply. The outlet may be faulty. Try connecting another device. If the outlet works, you need to check whether the circuit that conducts energy through the washing machine from one element to another is intact. To do this, you will need a multimeter, which will help you fully analyze the ability to respond to an electrical signal at several stages of operation. If there is no network connection anywhere, this is probably the problem. We carry out this manipulation until we reach the electronic module. If we are talking about an old washing machine, here it will look like the device’s program. When you turn on the button, there should be no breaks in the circuit. If the circuit works, everything is fine electrically.

Is the washing machine's power supply OK? Not really

<< Back

Repair of electronic module (unit)

<< Return to the beginning of diagnostics

Contact circuit fault

<< Return to the beginning of diagnostics

Some models enter push-up mode along with water. Perhaps this is the worst option, because... can lead to damage to a number of parts, and as a result, failure of the washing machine.

There is another option. During the wash cycle, the SMA drains and refills water several times. If the machine's software is not very advanced, then water may pour in without draining.

This is fraught with failure of the engine, shock absorbers, and also the module due to network overload. It is also possible for water to spill onto the floor.

Before proceeding to fix the problem, you need to read the instructions for the washing machine. Practice shows that people rarely read it! At the same time, pay attention to what other failures the model may behave in a similar way. First, you need to make sure that the problem is a blockage.

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Ask a Question

Attention! Some models from manufacturers Samsung, LG, Indesit, Ariston have a specific fastening for the drainage hose. It connects to the panel on the bottom. To disconnect it, the machine must be turned over.

Bathroom drain

Types of blockages and reasons for their occurrence

The appearance of blockages in the drain hose is one of the most common phenomena that can damage the washing machine.

Specialists in service centers for repairing washing machine drains distinguish two types of blockages : regular and mechanical.

Mechanical

The main reason for the formation of mechanical blockages is the entry of foreign objects into the filtration system of the structure.

Most often, the role of such “clogs” is:

Money coins and small buttons.- Locks from clothes.

- Bra clasps and underwires.

- Toothpicks, napkins, small toys.

- Money and other contents of pockets.

When foreign objects enter the filtration system, the drainage system is blocked and the washing machine simply stops working.

Ordinary

Apart from the entry of foreign debris, the drainage system of the washing machine can become clogged in other ways, naturally.

This often happens due to the accumulation on the filter of all kinds of fluff, fluff and pieces of cotton wool that were on the machine.

The fur of your pets also remains on all objects, and especially on the machine. And during a new wash cycle of your bedding set, clothes or anything else, wool also gets into the drain hose, where it remains, and after a certain amount of time it becomes tightly clogged in the filter.

A blockage in the drainage system of a washing machine can be identified by a number of obvious signs:

Reducing the rate of drainage of used liquid (contaminated water).- A software malfunction occurs when the washing machine does not switch to rinse or spin mode on its own.

- Complete blocking of the unit.

If your washing machine still has an unexpired warranty period, you can easily repair it without any financial investment. But if the problem appears after several years of use, you should try cleaning the system yourself. You can do this simple operation to remove clogs in your washing machine yourself in half an hour.

Cleaning without disassembly

Natural blockages can be removed without disassembling the washing machine. This option takes less time and effort.

In addition, it is recommended to use it if the equipment’s warranty period has not yet expired. The main method of combating drain hose contamination is the use of chemicals.

Scale dissolving agents are used as substances that will help deal with blockages. They can be purchased at household chemical stores and supermarkets.

Algorithm of actions:

- Cleaning agent should be added to the powder receptacle in the required amount recommended by the manufacturer.

- Then select the washing mode with the highest water heating temperature.

- If possible, cancel the spin function and start the program.

- When finished, turn on the wash cycle again to remove any remaining detergent.

- Take out the tray, wash it, dry it and put it back in place.

Signs that your washing machine drain is clogged

It is quite simple to understand that there is a blockage in the SMA: it does not drain water. Or it drains, but for a very long time. Unfortunately for the “sofa craftsmen”, we inform you that the same symptom occurs with a broken drain pump. At the same time, the sound of the drain pump operating or the absence of “rumbling” is not a reliable sign of a blockage. For example, if the pump blades break, you will hear the noise of its operation, but the water will drain slowly or not drain at all.

Thus, it is possible to accurately determine whether a blockage has occurred or the cause is a pump failure only after diagnostics.

Dismantling in different models of washing machines

There is nothing difficult about cleaning a pipe. The main task is to remove the drain hose from the washing machine without damaging it. To do this, you need to open the case and disconnect the fastener.

Depending on the model, the drain hose may come out from the back, side, or front. Therefore, before starting work, you should study the instructions.

Procedure:

- Disconnect communications from the washing machine.

- Drain the remaining water by placing a container or a cloth.

- Unscrew the part of the siphon to which the hose is attached or remove it from the drain.

- If necessary, lay the washing machine on its side, placing a towel or blanket under it. This will help avoid scratches. The SMA should be placed slowly and carefully. It is very important that the electronic module is located on top.

- Using a flat-head screwdriver, unscrew the panel bolts on the device where the pump is mounted.

- Loosen the drain pump from the bolts and pull it out.

- Using pliers, unscrew the clamp that connects the pump and hose. Release the pump from the hose.

- There may be bolts or other fixing elements on the body on the inside and outside. They should also be removed before removing the hose.

- Then you need to pull it out of the body.

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Ask a Question

Some washing machine models are equipped with a removable tray. But on most of them, it is missing.

In washing machines “Siemens”, “Bosch”, “Samsung”, “LGi” and AEG the front panel is removable. When dismantling it, access to the pump and drain hose opens.

It is dismantled as follows:

- Remove the top cover.

- Open the bolts securing the control panel and remove it.

- It is necessary to loosen or pull off the clamp in front and remove the rubber seal.

- Remove the tray.

- Remove the front panel by first unscrewing the bolts.

- The hatch lock does not need to be removed.

Important! Do everything carefully and slowly so as not to damage components and fasteners.

Pump assembly with pipes and emergency drain

Top loading machines

As a rule, everything is more convenient here. The drain hose is accessible from the side for machines with a vertical drum. You can get it out by removing only the side panel. This is usually the left panel. You can determine more precisely by looking at the location where the drain hose exits the housing.

- Using a screwdriver, remove the fastening on the side wall of the tank. It is located at the back. Carefully remove it. As a rule, the panel still fits into the grooves of the housing from above. Washing machines "Indesit" and "Ariston" still have mounting screws on the front. They are closed with a removable bar.

- There will be access to the drain pump and the hose attached to it.

- Remove the clamp using pliers or another tool.

- Pull the hose out of the housing.

As a rule, there are fastenings, sometimes disposable ties. We bite them off, but it is very important to restore everything later so that the hose does not dangle during operation.

Disassembled "vertical"

How to clean a drain hose with your own hands

If you do find a malfunction that arose due to a clog in the drain hose of the washing machine, then first of all you need to ensure full access to the drain system.

Cleaning the filter

The filter system is located at the bottom of the washing machine, on the right, behind a small door with a hatch. In order to open it, you need to pry the edge of this hatch with your fingers or some kind of flat, blunt object. In some models, the panel can be opened by pressing the latch or by bending the rotary hooks.

Clean the filter in the following sequence:

- Unscrew the screw and carefully remove the filter.

- We tilt our structure, drain all the available liquid, having previously placed a container with low sides for this purpose.

- After there is no water left in the machine, we remove all foreign objects that are stuck. If structural elements are completely covered with scale, they must be completely replaced.

- Next, when you have already removed the dirt by washing with water and wiping with a damp sponge, inspect the place where the filtration system is located and remove the remaining dirt from the walls.

- Clean the pump and the adjacent system, and then connect your device to power and enable the drain mode. If you did everything correctly, the blades and impeller of the pumping system will rotate without interruption.

All the details can be found in the video review, which describes the process in detail.

Attention: there are exceptional situations when the system is so dirty that it simply cannot be removed. In this case, it is recommended to remove one wall of the washing machine and carefully clean the filter from the side of the pumping system.

Disassembling the drain pipe

It is also possible that the flow of liquid will simply be blocked, even just at the junction with the sewer pipes. To clean the drain in this case, you need to disconnect the hose.

Everything is carried out in several stages:

- Unplug the washing machine.

- Close the water supply valve.

- Using a flathead screwdriver, remove the side or front bottom panel.

- Pour the remaining used water through the drain filter.

- Using pliers, disconnect the end of the hose from the sewer pipe or trap.

In devices from brands such as VEKO, Ariston, Candy, Samsung and Indesit, you can only get to the drainage hose through the bottom. In such cases, to make it easier to clean the washing machine from blockages, place your unit on its side, placing some cloth under it in advance. After you open the clamp with pliers, you can safely disconnect the hose from the pump.

In Electrolux or Zanussi washing machines, the hose runs along the back wall. To get to it, remove the back cover of the case. Next, we open the latches, unfasten the drainage hose, and then unscrew it from the water supply hose. To completely remove the drain hose, you should completely remove the top cover by unscrewing all the bolts and loosening the clamp to secure it.

In machines such as Bosch and Siemens, you can get the hose by removing the front panel of the case. Everything is done in the following order:

- Remove the sealing rubber from the front panel and unclench the clamp.

- We take out the bottom panel and the retractable tray for detergents.

- Unscrew the bolts to secure it and remove the hatch door lock.

- Remove the front panel of the case.

- Unclench the clamp and pull out our hose.

Cleaning the washing machine drain hose

Clean the drain hose by washing and treating the walls from the inside using special brushes. Masters in this business are accustomed to using not metal brushes, but those made of synthetics.

To clean the walls from the inside, the cable is inserted into the contaminated hose and moved back and forth. After this procedure, you need to rinse the hose with water. If the contamination cannot be removed the first time, the procedure should be repeated.

Helpful advice: in order for you to achieve the best effect when washing, use warm water with citric acid added to it.

The hose, washed from all sides, just needs to be fixed in its old place, performing all the described steps in reverse order.

Flushing

It is not difficult to clean the lumen of the removed drainage. First you need to prepare a basin that can accommodate the drain hose. You will need to heat the water to a temperature of 60-70 degrees and prepare the detergent.

Procedure:

- Inspect the tube for integrity.

- Using a long and thin stick, remove any mechanical blockage if present. If this cannot be done, the hose must first be washed and then cleaned.

- Immerse the tube in water, after adding an aggressive detergent, for example, for cleaning stoves, and leave for 30-40 minutes.

- Put gloves on your hands and arm yourself with a sponge.

- Take out the hose, wipe its surface with a sponge and wash with running water.

- Clean the inside.

Are you unplugging your washing machine?Oh yes! No

- Treat the outer and inner parts with detergent, place in a bathtub or empty basin and leave for 20 minutes.

- Clean off any remaining dirt and rinse well under running water.

- Wipe and dry.

- Attach it back to the washing machine, securing it with a clamp.

- Reassemble the device in the reverse order, paying special attention to tightness.

- When the drain hose is installed, run the quick wash mode for preventive purposes.

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Ask a Question

Important! Prepare in advance a thick and stiff wire or a thin stick, which can be used to clear the resulting blockage. Its diameter should be no more than ½ the thickness of the hose.

There is another quick option. You need to attach the end to the tap. Turn on hot water under acceptable pressure. Use your hands to stretch and compress the hose corrugation. If the washing machine has been in use for a long time, a lot of deposits will come out, possibly causing a bad odor.

Important point! If there was an extension using a coupling, then it must be disconnected, because congestion often occurs in this area.

How to clean a washing machine drain hose that is completely clogged

During operation, the drainage device of any washing machine accumulates small particles of dust, hair, soap solution, and threads. After a few years, the hose accumulates so much dirt that the water can hardly find its way out. What to do in such a situation and prevent a flood at home? For this purpose, the hose is sanitized.

How to rinse the drainage device of a washing machine according to all the rules?

First, turn off the cold water supply tap and disconnect the machine from the power source. Next, free the drain filter from possible residual water and disconnect the hose from the sewer. The main difficulty is disconnecting the drainage device from the body of the machine. It all depends on the model of the machine.

Next, using a thin cable with a brush at the end, clean the inside of the hose, turning the cable on one side and the other. After freeing the hose from large particles of dirt, it is washed under the tap with hot water several times. Later, all that remains is to put the device in place, secure it tightly and connect it to the sewer.

Preventing blockages

A clogged drainage tube is most often caused by natural causes. Mechanical is a rarer occurrence. Small items do not often end up in the drain, preferentially remaining in the drum or tank. Following preventive measures will help you avoid blockages:

- Before washing, you need to carefully inspect the item for small items in the pockets. If necessary, remove them.

- Clothes with zippers should only be washed in a machine when zipped.

- Shoes and bras, as well as clothes with decorative elements and accessories, should only be placed in the machine in special cases.

- Use high-quality laundry detergents that contain a water softener.

- Clean the device every 3-4 months by running a wash cycle with citric acid or a special product.

- Wash the filter regularly and inspect the drum for the presence of small objects.

With proper care and preventive measures, blockages can be avoided. If such a problem occurs, then cleaning the drain hose of the washing machine at home is easy. The main thing is to follow all the recommendations described in the article, and also carefully study the manufacturer’s instructions.

Video

How to clean a drain hose that is partially clogged

This often occurs due to a clogged drainage system. There are two ways to solve this issue, and you can do it yourself. Method one is to clean the drain hose without disconnecting it from the washing machine. In case of partial blockage, when the water begins to drain more slowly, it is possible to eliminate this problem without disassembling the drainage system. This is usually caused by the settling of detergent particles and small lint and fibers that have passed through the drain filter.

There are various products available on the market to dissolve deposits that form on the inside walls of the drain hose. Before use, you must study the instructions for use, usually it is a powder or solution, sometimes found in tablet form. There is no need to worry that the use of these drugs may damage gaskets or seals. Washing machines produced by well-known global manufacturers have high quality components.

If you have doubts about the quality of the connections and gaskets, you can wash the drain hose with baking soda. To do this, you need to add 100-150 grams. soda directly into the drum and turn on the washing machine without laundry in the “cotton” mode.

If water removal from the washing machine completely stops, a second cleaning method will be required, in which you will need to completely disconnect the hose from it. For this you will need the simplest tool - a flat or figured screwdriver and pliers. The sequence of actions in this case is quite simple:

- Disconnect the washing machine from the power supply.

- Shut off the water supply.

- Carefully disconnect the hose from the machine, first placing a container to drain the remaining water.

- Disconnect the drain hose from the sewer and clean it.

To de-energize the washing machine, simply remove the plug from the socket. There is usually a tap on the hose that supplies water from the plumbing system; it should be closed. Basically, the drainage hose is attached to a pipe, which is located on the back of the washing “unit”. Using a screwdriver or pliers, you need to unclench the retaining clamp and remove it. For ease of access and operation, first place the washing machine on its side, placing a floor or other cloth under it. Sometimes users do not connect the drain to the sewer, but simply place the other end of the drain hose in the bathtub or sink.

Cleaning should be done with a Kevlar cable, at the end of which there is a small brush; you cannot clean it with metal objects. After cleaning the hose in one direction, the operation should be carried out in the other, then rinse well under running hot water.

To be more sure that the hose will not have to be removed again, it is recommended to inspect the filter as well. Perhaps it also requires revision and cleaning.

Different manufacturers have their own housing designs and filter mounts that require access. Trademarks LG, Veko, new Indesit models, the bottom is closed with a lid that can be easily removed with a flat screwdriver. Zanussi, Electrolux to access the filter you will need to remove the back panel. German manufacturers of washing machines - Bosch, Siemens - made the front panel removable. Then, depending on the design, the filter is removed. It is attached to the body using latches or a screw connection (bolt, self-tapping screws), sometimes it is screwed into the drain pipe. To dismantle it, you may need to remove the neck to which the drain hose is connected. The work must be carried out carefully, without damaging the gaskets and seals.

The filter should also be thoroughly cleaned and rinsed under running hot water. Then reassemble in reverse order. All connections must be tightened well, especially the hose clamp itself. The pressure when water comes out is small, but it is still there.

After the machine is assembled and connected to the power supply, it is advisable to wash it with a cleaning agent to completely remove small particles. In addition, you should inspect the connections for leaks and, if necessary, tighten the clamp.

For prevention, once every 1-2 months it is advisable to wash the machine to remove clogs and scale; in areas with high water hardness, use water softening agents. It is also recommended to use a special bag for washing.

https://youtube.com/watch?v=xZn7-uTPoYQ

You might be interested in

You can leave the first comment

Updates on the site

2015-2018 – All rights reserved

When copying materials, an active and indexed link to the source site is required.

Causes of urinary stones and limescale

If dirt and deposits appear in the toilet, take immediate action to avoid unpleasant odors and sediment buildup.

The following types of pollution are formed inside the toilet:

- Urine stone is the result of laziness and carelessness of the owners. Most often, yellow, inconspicuous stains form on the plumbing fixtures of people who forget to flush after themselves. Initially, drops of urine dry out and form a thin hymen. With repeated failure to rinse, a more durable film is formed - urinary stone. You can only get rid of it using special methods, but it is better to prevent its occurrence by carrying out prevention.

- Limescale – minerals contained in water (well or river, tap water). The more often you wash off, the more actively a film forms. You need to get rid of it regularly, because over time it clogs the holes supplying water to the toilet, which leads to a complete breakdown of the plumbing.

Enameled plumbing is less prone to the formation of plaque that cannot be removed, but on rough surfaces it appears more often and more intensely.

Filler pipe repair

To ensure that a part is in working order, you need to find it. It will be most convenient to inspect the tube by unscrewing the top cover of the CM. In the left corner, you should immediately notice a tube connecting the water intake valve to the powder receiver - you have found what you were looking for. The element is intercepted on both sides by fastenings - clamps.

To ensure the integrity of the pipe, remove it using the following procedure:

- Armed with pliers, loosen the clamps and slide them to the center of the part. Handle them with care - they will be useful for installing the part in place.

- With a little force, but carefully pull off the pipe - first from the valve, then from the outlet of the cuvette.

- Inspect to see if there are any blockages. If there is, take a bottle brush, it will easily remove them. If everything is in order, rinse with running water and put back in place.

- Found any defects? Buy a new filler pipe for your model and brand of washing machine. Use the clamps to put the tube in place.

Attention! If everything is intact, but the tube feels “oaky” to the touch and does not bend, then it is better to change the part.

Dirt in the filter. Getting rid of it ourselves

The filtration system is a prime location for contaminants to accumulate. Their accumulation and prevention of further penetration into the design of the machine is its primary task.

In order to remove contaminants in the filtration system, you must first study the main types of access to them:

Cleaning the washing machine filter

- the system is located in the lower right part of the equipment behind a special door with a hatch. It is hermetically sealed, so to open it you will need to make an effort and use a flat object. After opening it, you should remove and clean the filter installed there. To do this you need to unscrew it. Actions are performed counterclockwise;

- The design involves the location of the system at the bottom of the machine in the form of a special rectangular panel. To open it, you need to press the special latches or bend the rotary hooks. To remove and clean the filtration system, it must be unscrewed;

- lack of special access. In this case, it is necessary to remove one wall of the structure housing and clean the pump wings, drain hose and pipes yourself.

How to prevent the problem from occurring?

To avoid such problems, listen to the following recommendations:

- Before washing, be sure to check your clothing pockets for small items.

- Use special covers and bags for washing linen and other delicate clothes.

- During washing, all zippers, buttons and fasteners must be fully fastened.

- For preventive purposes, install an additional filter on the supply pipe when installing the device.

- Use detergents recommended by the equipment manufacturer. In our separate publication you can learn about liquid laundry detergents.

- Use additional water softeners if there is no filter in the pipeline.

- Carry out preventive measures to clean the drain system regularly once every two months.

- Regularly descale your washing machine, otherwise it will be difficult to remove it later.

Main stages of work

To clear the clog in your washing machine yourself, you must follow these steps:

- cleaning the filtration system and draining the liquid. After unscrewing it, place a deep container under it to drain. If a special hose is connected to the system, water can be removed through it. To make the action as effective as possible, it is recommended to install the machine at an angle, placing an object under it;

- After the structure is completely freed from water, it is necessary to remove all existing contaminants. After this, the structure is put in place;

- checking the pump system and cleaning it;

- After completing the work, you should connect the machine to the power supply and turn it on to the “drain” mode. In this way, the pumping system is checked. During normal operation, the blades and impeller should rotate;

- if after this check the liquid still does not drain, the blockage in the pipe should be removed;

- checking the siphon and sewage system to which the machine is connected. If they are contaminated, the liquid flow may also be blocked. To do this, it is necessary to disconnect the connected hose and pipe from the sewer system, and then remove the snail from the pumping system;

- the detached snail is washed and cleaned of dirt. Then you should reassemble the sewer system and connect the hose to it.

After all manipulations are completed, it is necessary to check the operation of the washing machine. To do this, you need to turn it on and check that it is working correctly.

Repair of dispenser pipe

The dispenser connection may require extensive cleaning and repair. Who can clean this pipe better than you, especially considering that you refused the services of a master a priori. Let's figure out where to find the dispenser pipe.

In a number of washing machine models (for example, LG washing machines), the dispenser pipe can be removed in the same way as the water inlet pipe through the top cover. But in some cases, you can get to it only by disassembling and removing the front wall of the washing machine. You can read about how to do this in the article Disassembling a washing machine; we will not dwell on this point separately. So, what do you need to remove the dispenser pipe?

- Unscrew the screw clamps holding the pipe on both sides.

- Carefully disconnect the pipe on one side from the dispenser, and on the other from the tank.

- We inspect the pipe for blockages and damage and, if necessary, replace it with a similar one.

In theory, everything looks simple. But in practice, getting to the screws that hold the clamps in place may not be so easy. Also, do not forget that many cars have a flow filter mesh installed on the neck of the tank. Often, when removing the pipe, the mesh falls out, and when installing a new pipe, they simply forget to put it back - be careful. This mesh is needed and it is better to put it in place after cleaning is done.

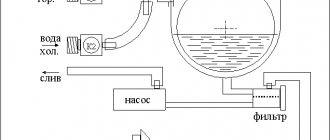

Design features of the drain system

If a problem is detected in the washing machine, you can fix it yourself. This requires access to the liquid drainage system in the equipment design. To avoid any difficulties during self-repair, it is recommended to first study its design.

In the design of modern models of washing machines, the liquid used after washing flows from the tank into a special pipe. It is made of rubber material and has a corrugated shape. It is connected to the main cleaning filter. This is where dirt and small foreign objects come from the washing machine drum. Passing through it, the liquid flows into the pump onto its impeller. The impeller is necessary to create working pressure in the structure. To achieve this, the impeller is in constant motion.

Under the influence of the created pressure, the liquid flows towards the sewerage system. To enter the sewer system, water passes through a special drain hose. Typically, manufacturers place it inside the machine body. Its outlet part is connected either directly to the sewerage system or to a siphon located in the nearest sink in the room. In some cases, consumers do not connect the hose to the sewer system; during washing, it is simply discharged into the sink or bathtub to drain water.

A blockage can form in any of these parts of the structure. However, its most common location is the filtration system.