Causes of strong vibration:

There are quite a few reasons for this kind of malfunction, many of them can be eliminated yourself, since the difficulty in eliminating them will not be more difficult. Let's first consider the simplest problems in which the machine begins to vibrate strongly, shake, jump and make uncharacteristic noise.

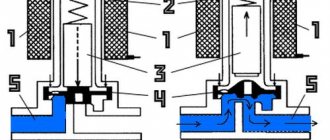

Shipping bolts not removed

One of the most common reasons why a washing machine starts to shake and jump is when they forget to remove the shipping bolts (fasteners) that are located at the back of the unit on a newly purchased machine, usually there are no more than 5 of them depending on the model. They are intended to secure the drum during transportation, so that the tank in the places where the springs are attached does not fly off the seats, and also protect the drum suspension from damage.

The removed fasteners should not be thrown away, as they may be useful to you the next time you transport your machine.

It is worth noting that when removing fasteners, you should follow the operating instructions supplied with the machine!

Dismantling sequence:

- Start unscrewing the screws until they become loose.

- Pull them out of the hole.

- Insert the plugs into the holes on the rear panel.

After removing the fasteners, the tank should hang on the springs.

Incorrect installation

Another common problem that causes the washing machine to jump and move during the spin cycle is improper installation. The main condition for the normal operation of the machine is its strictly horizontal position on a flat and non-slippery floor. The machine has legs at the bottom that are easily adjusted with a key; adjust them so that it does not wobble and stands stable; you should also level it using a building level (spirit level). It is advisable to lay a rubber mat under the unit if the floor, for example, is made of tiles.

It is not recommended to install the washing machine on soft objects!

Linen imbalance

The reason why the washing machine jumps is the uneven distribution of the laundry in the drum or, as they also say, an imbalance of the laundry. This happens when the laundry is distributed in one place, for example in the duvet cover. In this case, stop the washing, turn off the power to the unit, wait until the door is unlocked, then open it; if the door does not open, use the emergency drain of water, then distribute the items in the drum evenly so that they do not clog in one place again. This reason is more typical for cars that were released some time ago. Today they are equipped with the function of uniform distribution of laundry.

Overload of laundry

Excessive weight of laundry can also lead to abnormal vibration, so empty the excess clothes from the drum and you can start the wash again. Basically, with such problems, modern machines display error codes on the display; they may differ from one another for different models.

It is not advisable to load items into the machine that absorb large amounts of water, such as terry cloth, because this will increase the weight of the items being washed. In this case, it is better to reduce the amount of laundry loaded.

Attention! Before removing laundry from the drum, make sure that your washing machine is de-energized!

Washing machine instability

When a washer (for example, LG FH0B8LD0) is standing on a curved or slippery surface and is not adjusted, it “jumps” and vibrates strongly. This leads to an imbalance in the machinery mechanism. At the very least, the machine will fall and flood the floor. At the most, it will break or damage the surface on which it is installed, for example, break a tile.

Solution

Major repairs - leveling the floor - are not necessary. Stability of the washing device is added by a flat, rigid podium - a stand, which is covered with a rubber anti-vibration mat.

You will also need to correctly adjust the legs of the equipment: they must be screwed in/unscrewed into the body until the device is level. Place a building level on the body and guide it. When you finish the adjustment, put anti-vibration attachments (for example, Electrolux E4WHPA02) made of rubber on the legs. They will provide even greater stability to the device.

Attention! A weak wooden floor made from old boards can cause equipment breakdowns. Here, one type of quote and adjustment will not do: a vibrating machine, even if it is installed level, will break the old boards. There are two ways out: re-laying the floor or moving the washing machine to another room with a more reliable surface.

Causes of strong noise and shaking:

Bearing wear

Another common cause of vibration is worn bearings. When the seal is no longer sealed and moisture begins to enter the bearing, a process of gradual corrosion and subsequent destruction begins. First, a grinding sound appears, then the spin cycle begins to be accompanied by strong vibration. Then you just need to replace the bearing, and if this is not done in time, the machine may be seriously damaged. This is already a rather serious malfunction, in this case it is better to contact specialists; if you want to figure it out yourself, then read the article on how to change bearings yourself.

Debris getting between the tank and the drum

It happens that a foreign object gets into the space between the drum and the tank, causing noise and grinding. This mainly happens when they forget to remove everything unnecessary from their pockets, and it is also not a rare case when a bra wire gets caught. To remove debris, you need to remove the heating element (heating element) and remove all excess through the hole. You can also remove debris from the drain pipe.

It is important to know! Before you start washing, always make sure that there is nothing in your pockets; you should fasten the zippers and buttons on your clothes!

Electric motor is faulty

If the washing machine, after starting the wash, takes in water and after a while the drum begins to spin sharply, and at high speeds, this will cause severe shaking. The whole problem is the malfunction of the tachometer. This sensor is located in the electric motor, which is located on the rear. The tachometer is used to adjust the shaft rotation speed. This is no longer a simple repair that requires qualifications. It is best to contact a specialist and consult with him.

Shock absorbers are faulty

Shock absorbers are often the source of the problem. Faulty shock absorbers cause severe knocking and vibration. Shock absorbers are designed to dampen vibrations of the tank and beating against the body. They are always used in conjunction with spring mechanisms. Mostly they dry out. It is quite simple to make sure that they are in good working order: open the hatch, pull the tank towards you and immediately release it. The drum in place indicates that there is no cause for concern. If the drum begins to oscillate in all directions, this indicates the need to replace them with others.

Counterweight faulty

Vibrations during spinning also occur due to loose fastenings of the counterweights, so the process of their destruction begins in the places of fastenings. Counterweights can be plastic or concrete, which tend to crumble after some time of operation. But most often there are problems with fastening. If a similar situation arises, then it is worth replacing the mounting bolts or adjusting the counterweight.

What to do if the counterweight bursts and splits into two parts? The best solution to this problem is, of course, to replace it with a new one, but it is not so easy to find, so you can try to fix the counterweight yourself if it is not plastic. You need to dilute PVA glue with cement and glue the parts together. After the operations, you need to make sure that all parts are well glued, after which you can try to start the wash.

How to eliminate shaking in washing machines of different brands

LG washing machines

It is better to entrust the repair of washing machines to professionals!!!

We present to you our unique catalog of private craftsmen and service centers —

Select your city and artist in the filter: by rating, reviews, price!

Often, the cause of high pulsation during spin cycles in LG washing machines is manufacturing defects and bearing failure. To change a bearing:

- Remove all elements of the case - remove the meter from the front part, remove the rubber cuff from the groove and unfasten the front cover.

- Disconnect the device tank itself - the fill valve, drain pipe, all the terminals of the heater, the fill pump and the cables feeding it, motor cables, counterweights, weights, shock absorbers, water level sensor with pipe.

- Disassemble the tank and unscrew the bolts (there may be latches), disconnect the pulley, and carefully knock out the axle.

- Unfasten the bearing, disconnect it with gentle movements, and clear the drum opening of debris and old grease.

- Install a new bearing. Secure the oil seal in place, lubricating it in advance.

Samsung washing machines

One of the most common breakdowns is damage to the drive belt. In order to replace this part you need:

- Open the back panel;

- Remove the belt by pulling it between the pulley and the engine;

- Release it from the chute using a Phillips screwdriver;

- Replace the damaged belt with a new one by placing it on the pulley and turning it a little.

Bosch washing machines

High pulsation often appears due to a clogged filter on the front panel. Which you can clean yourself:

- Remove the rubber seal from the front of the machine;

- Remove the drawer for detergents and the bottom panel;

- Disconnect the door lock;

- Unfasten the tire;

- Pinch the sleeve clamp and pull it out;

- Wash the sleeve and treat the internal walls of the system with a brush.

The presence of malfunctions is determined using the test diagnostic mode. Also, the unit must be installed at the building level and there will be no difficulties.

Washing machines Indesit

This budget brand has increased vibration during operation and especially during spinning. Often, repairs come down to setting the machine on a solid surface and loading the drum correctly. One of the most labor-intensive repairs is the replacement of bearings and the breakdown of any part of the drum (often this is the oil seal) - this means replacing the entire unit or purchasing new equipment.

We recommend reading the following article: Types of breakdowns of the Indesit washing machine, error codes, troubleshooting common breakdowns.