Candy washing machines are well-proven equipment that rarely cause problems.

But during long-term operation, machine parts gradually wear out, and the machine may begin to work intermittently.

If the machine, for example, stops spinning clothes, its operation can no longer be called normal. Why the Kandy washing machine does not spin clothes and what to do about it, we will tell you further.

What is the reason that the spin does not work?

There are several reasons for the lack of spin, not related to breakdown. These include:

- settings failure;

- disabling the spin cycle during the previous wash;

- uneven distribution of laundry in the drum;

- Drain filter clogged.

The first step is to check the spin mode settings. Perhaps it was turned off earlier and forgotten about it. Or for some reason the spin speed settings may have changed. The spin function must be turned on, and if it is on, increase the number of revolutions.

If the laundry in the drum is unevenly distributed, it becomes unbalanced. The machine evaluates this as a violation of the operating process and stops washing. As a result, the laundry does not go through the spinning stage and remains wet. If there is an imbalance in the drum, you need to turn off the machine, manually distribute the laundry, and start the wash.

It is recommended to clean the drain filter in your car at least twice a month . If this is not done, over time, the clog in the filter begins to interfere with the drainage of water. If the clog is severe, some of the water remains in the drum, so the laundry remains wet.

If the machine is set up correctly and its drain filter is cleaned, but there is still no spin, you need to look for the breakdown that led to this.

The most common causes are the following breakdowns:

- electronic controller malfunction;

- failure of the speed control sensor;

- drain pump failure.

Take a closer look at the pump

Next you should check the drain pump. The Kandy washing machine pump is also not very reliable, so it may well fail after several years of use. In addition to the “burnout” of the part, failure is caused by debris clogged inside the element or wound around the impeller.

Installing a washing machine at a great distance from the sewer causes faster pump failure. The length of the drain hose should not exceed three meters, only then the load on the part will be acceptable. If the “sleeve” stretches for 4-6 meters, it is not surprising that the pump will fail after a couple of years of operation. Therefore, when connecting equipment, pay special attention to this moment.

To inspect your pump:

- turn off the power to the machine;

- turn off the water supply tap;

- remove the garbage filter (according to the rules described above);

- look into the resulting hole. Ideally, there should be nothing there except the impeller. If there are foreign objects or lumps of debris, remove them;

- remove the powder receptacle from the housing;

- cover the floor with a blanket and carefully place the washing machine on its right side;

- remove the pan, if equipped;

- take a photo of the wiring diagram for the drain pump;

- disconnect the wiring;

- loosen the clamps holding the drain pipe and hose on the element body;

- pull the pipes off the pump;

- remove the pump from the machine;

- clean the impeller of debris and entangled hair;

- pry up the special latches to open the body of the part;

- inspect the integrity of the mechanism and rubber gaskets, clean out any accumulated dirt.

If the drain pump was clogged, then after cleaning the machine may start working again. Therefore, assemble the part, put it in place, connect the removed hoses and disconnected wires.

When no debris is found in the pump, you will have to check the electrical part. For this you will need a multimeter. The tester is switched to voltage measurement mode, its probes are applied to the pump contacts. If a zero or one appears on the device screen, it means the motor is “burnt out” and the part will need to be replaced.

How to identify the problem?

You will have to look for a breakdown by checking each node one by one. It’s better to start with the simplest thing – checking the pump.

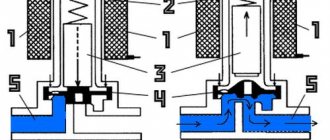

water pump

It is necessary to place the car on its side and disconnect all pipes and wires from the pump. After this, the cover is removed from the pump. Now you can check its status.

There may be two options here - the impeller is clogged or the pump electrics are burnt out . First you need to clean the impeller. It should rotate freely.

After this, use a multimeter to check the presence of resistance in the pump. If it is not there, then you need to buy and install a new pump.

After checking or repairing the pump, during reassembly, it is recommended to thoroughly rinse the pipes. This is done using a soft brush. You need to remove all accumulated mucus and dirt. This kind of prevention not only increases the wear resistance of the machine, but also eliminates unpleasant odors.

Tachometer

Let's say that checking the pump showed that everything is fine with it, but there is still no spin. The next action should be to check the tachometer . It is installed on the engine rotor. Its function is to control engine speed. You can get to it by completely removing the rear wall of the car or opening the service hatch in it. The engine is located under the tank, the tachometer is on the shaft.

To check, you need to remove the engine. First, the drive belt is released, then the mount of the motor itself is removed. All wires are disconnected from the sensor. Next, it is checked for resistance, which should be 60 Ohms.

If the resistance indicator is normal, before reassembling the machine you need to make sure that the bolt holding the tachometer is well tightened - the correct operation of the device depends on this.

Control module

Malfunction of the control unit is the most unpleasant option . If the verification procedures described above can be performed independently, then it is better not to touch the control module, but to immediately call a technician.

But if you have basic skills in working with boards, you can carefully test all available controllers one by one with a multimeter. This must be done without removing the module or disconnecting anything. The cost of incorrect reverse connection may be replacing the module with a new one.

It's easier to test controllers by simply testing them all. But you can do this using a pre-downloaded scheme. If the problem is not in the controller, but, for example, with some semiconductor part, you won’t be able to find it without a diagram.

What to do?

If consumer errors are excluded, you can move on to analyzing the operation of the nodes. It is better to do this in the following order: start with the most accessible ones, leaving the most difficult ones for later.

Preliminary preparation of the machine:

- if there is water in the washing machine, it must be drained (naturally or through an emergency drain);

- disconnect the washing machine from the power supply;

- shut off the water supply to the device;

- pull out the washing machine in such a way as to provide convenient access to its rear wall;

- pull out the powder receptacle.

Drain violation

If the washing machine does not drain the water, it cannot proceed to the spin cycle. In this case, it is necessary to gradually sort through all possible problems associated with the drain.

It’s better to start by cleaning the drain filter, since even if the problem is not there, regular cleaning of this unit will benefit the car.

Next, it is necessary to diagnose the operation of the drain pump and check the permeability of all systems associated with draining water.

The drive belt has expired

If the drive belt is stretched, it does not provide the necessary contact with surfaces. If it “slips,” the part must be replaced, since it cannot be repaired.

Tachometer failure

The tachometer is an element of the washing machine that is involved in the rotation of the drum. This unit is responsible for controlling the number of engine revolutions.

If it breaks, the washing machine does not rotate the drum intensively. As a result, spinning is either not performed or is performed very weakly.

The tachometer is a fairly reliable element that rarely breaks.

Control unit failure

The control unit is a board that connects to buttons and sensors on the front panel, and also transmits signals to the components of the washing machine. It is located in the upper part of the front side of the washing machine.

Diagnosing a fault is a complex process that requires special knowledge and tools (soldering iron, multimeter, etc.).

Violations may be associated with burnout of individual elements and tracks, broken contacts, as well as damage to the loop. It is better to entrust diagnostic and repair work with electronics to a specialist.

Motor brush wear

As the drum rotates during spinning, the motor is activated. In cases where it sparks and does not create the required torque, it is necessary to inspect the condition of the motor brushes. If they do not make good contact with the manifold due to wear, the technician replaces them.

Shock absorbers are worn out

Shock absorbers in a washing machine are needed to dampen drum vibrations during the washing and spinning process. When the shock absorbers wear out, vibrations are not dampened, and electronic sensors prevent the drum from spinning.

As a result, spinning is not performed. If such a breakdown occurs, the shock absorbers need to be replaced.

When shock absorbers wear out, it is necessary to replace both at once, even if the degree of damage to one of them is insignificant.

The video will tell you about replacing the shock absorbers of a washing machine:

Bearing failure

Bearing wear can occur during prolonged use of the washing machine. During this time, the oil seal begins to lose its tightness, which causes water to enter the bearings. This causes lubricant to be washed away and leads to rusting, and vibration and rotation make the situation even worse.

Motor damage

If the washing machine cannot spin, you should not miss the possibility of such a serious breakdown as the combustion of the electric motor. Malfunctions in the operation of this unit can be caused by a short circuit, stator failure and other circumstances.

The technician determines the degree of damage and makes a conclusion about the possibility of repairing the equipment. If the electric motor cannot be restored, it is replaced with a new one.

The pressure switch is broken

A pressure switch is a sensor that controls the water level. The signal from it about the water level is sent to the control module.

If the signal is normal, which corresponds to the actual liquid level, the control module, after draining, gives a signal to spin.

But if the pressure switch gives incorrect signals, the control module does not “give the go-ahead” for spinning. This situation can occur when the pressure switch freezes on a signal indicating that the tank is full of water. Even if in fact all the liquid has been drained, the control module does not receive information about this.

The technician diagnoses the pressure switch - checks for blockages and damage. After the functionality of this unit is restored, the washing machine will begin spinning.

The video will show you how to check the pressure switch in a washing machine:

How to fix a Candy automatic washing machine?

Any identified malfunction must be corrected correctly.

Electronic board

The module can be removed and taken separately to a service center. This is done in the following way:

The machine is disconnected from the power supply.- The program selector knob is fixed in the off position with tape.

- The screws on the top panel are unscrewed.

- Remove the top cover.

- Remove the dispenser body.

- Pull out and remove the side panels.

- Unscrew the screws in the front corners of the case.

- The plastic clips holding the front panel are worn out and pressed out.

- Disconnect the latches securing the board.

- Take several pictures of the position of the connectors.

Although the panel is fairly easy to remove, it is difficult to reattach. To return all connectors to their places, photos are taken, which are mentioned in the last paragraph of the instructions. But this does not give a 100% guarantee that all reverse connections will be successful.

Therefore, experts advise not to touch the module, but to call a technician to your home . In this case, he will be able to conduct a full diagnosis and inspection of all elements of the machine, repair all faulty elements, and, most importantly, start the machine and make sure it is in full working order.

Repairing the control module of a Kandy washing machine, video instructions:

Drain pump

Machines equipped with a self-diagnosis system display an error code on the display. The code can be deciphered using the fault table for a specific brand. In this case, we will assume that the pump was physically removed from the car. As a result, all blockages have been removed, contacts and connections have been checked. And testing the pump electronics showed that the part needed to be replaced.

In this process, the most important thing is to buy exactly the same pump. To do this you need to know the car model. You need to install high-quality branded spare parts. You can buy a pump for any model of washing machine in a large specialized store or through a large specialized website.

The new part is installed in place of the old one . For greater reliability, during the process of disassembling and dismantling a broken pump, you can take several photos, and then use them to verify the correct installation.

Tachogenerator

The tachometer is easily removed. But to avoid errors in installing a new part, it is also better to take several pictures when dismantling it.

The new part must match the car model. After installing the tachometer, it must be checked for resistance .

If the multimeter does not register resistance, you need to check the reliability of the wire connections. The bolt holding the sensor must be tightened firmly.

Electronic controller failure

The electronic controller is the main control element of the washing machine. It is unlikely that you will be able to repair it yourself. This can only happen if swollen capacitors are visible on the board, immediately indicating what caused its failure.

You can remove this part in the following way:

- remove the top cover of the washing machine;

- remove the tray for loading detergents;

- remove the screws holding the control panel;

- separate it from the body and remove the controller hidden behind it.

If there is no obvious damage to the board elements, you can determine which microcircuit caused the unit to not wring out the laundry by testing them with a multimeter. However, only a specialist can figure out at which points measurements should be taken with the help of service documentation.

The reason that the machine cannot spin clothes is sometimes due to a software failure.

In this case, there is no need to resolder the board elements or replace it with a new one. It will be enough to restore the factory settings. But this cannot be done without special equipment.

Call the master

If the Kandy washing machine has stopped spinning clothes, you need to call a qualified technician to perform complex repair work. Nowadays it is easy to find a specialist via the Internet. But in order not to encounter scammers or irresponsible, inexperienced repairmen, before calling a repairman, you should check reviews about his company on an independent website.

The final cost, including a specialist’s visit to the customer’s home, diagnostics, repairs, dismantling and installation of components, must be agreed upon immediately.

The cost of the specialist’s services depends on:

- region,

- scale of the settlement,

- pricing policy of a specific service center,

- and, of course, on the type of repair.

So, some companies charge a certain cost for calling a technician. In other services, the call and diagnosis are free, and payment is only for certain repair operations performed. Built-in equipment is dismantled and installed back, usually at an additional cost.

Replacing the drain pump can cost the owner 1,500 - 2,500 rubles. The tachometer can be replaced for 1-2 thousand rubles. Repair of the control module will depend on the type of failure, and will cost at least 2 thousand.

List of possible causes

If your washing machine does not spin clothes, look into the following reasons, of which there may be several. They can be either frivolous (you can handle the repair of the breakdown yourself) or serious (you will have to contact a repair service specialist).

Frivolous reasons:

1. You have loaded the machine drum too much. The washing machine does not handle overload well. This problem often occurs when washing large items (for example, a blanket or blanket). Items may not be distributed evenly throughout the drum. As a result, strong vibration begins during washing. And the machine, as a well-programmed device, automatically reduces the spin speed.

Your actions: if the washing machine does not spin out the laundry due to improper placement, remove the excess or evenly distribute the items throughout the entire volume of the drum.

2. The program on the washing machine was set incorrectly. No matter how trivial it may be, quite often people simply do not turn on the spin function when washing, and then get scared that the laundry is wet and their washing machine is not working well.

Your actions: program the machine according to your wishes and operating rules. Press the buttons correctly, then your washing machine will not spin poorly.

3. The filter of the machine is clogged. You can learn how to clean the machine filter from this educational video:

In addition, you will be able to clearly see where the filter is located on the machine, how to open it and find out what items most often clog the machine and why, in the end, Samsung does not spin.

Serious reasons:

- The sensor responsible for the water level is broken.

- The sensor responsible for engine speed is broken.

- The drum motor is broken.

- The electrical module is broken.

- The pump is broken.

These are more difficult breakdowns, the repair of which often requires large financial investments.

Kandy washing machine does not spin - reasons and what to do

- Malfunction or normal error?

- Typical faults

- What to do if a malfunction is detected?

- Conclusion

Household laundry washing machines are considered excellent home helpers. You need to put dirty laundry in the drum, wait for a while while doing other work, and then remove it from the machine almost dry. The disadvantage of such devices is that even the most reliable and advanced models sometimes fail, and therefore you have to return to the manual method of washing. But if your Kandy washing machine does not spin clean clothes, this is not a reason to abandon it and go in search of a new device. The fact is that not all machines are distinguished by their reliability in operation and build quality, and sometimes breakdowns that occur can be easily fixed with your own hands.

Failure of the speed control sensor

Another reason that the Candy washing machine has stopped spinning clothes after washing may be a breakdown of the tachometer, which transmits information to the control module about the operation of the engine and the rotation of the drum. It is located directly on the motor. To check its status, you need to:

- remove the back cover of the device;

- release the tank from the belt;

- disconnect the wires from the engine;

- Unscrew the bolts holding it.

After this, you need to measure the resistance of the sensor with a multimeter. The device should show a value close to 60 ohms. Other values indicate a malfunction and the need for replacement. If the sensitive element is operational, you need to make sure that its contacts with the electrical circuit of the washing machine are not broken.

Why doesn’t the Candy washing machine spin clothes and what should I do?

- Possible user errors

- Technical reasons for problems with spinning

- How to repair?

A breakdown of the Candy washing machine can happen at any time; one of the most common problems with SMA is the lack of spin. Of course, this problem is unpleasant, but don’t panic ahead of time; most problems can be fixed on your own without turning to the services of a specialist. We'll talk about why SMA Candy stops pushing up and how to deal with it in our review.