The washing machine lock is not the most complicated device, but without it, washing is impossible.

It is needed to block and seal the hatch during the process of washing, rinsing and spinning clothes. This device is designed to provide reliable automatic protection against inadvertent opening of the door and, in the event of a breakdown, stops the washing program. If the door locking device malfunctions and wears out, it requires repair or replacement of the lock on the washing machine.

Purpose and definition

The washer hatch locking device is a compact mechanism, where the main element is a mechanical latch and an electric lock. UBL performs the function of a monitoring protective device. This device prevents flooding of the room and injury to a person when the drum rotates.

The device ensures fixation of the hatch when the eye falls into a special cell. When the equipment is turned on, current is supplied to the device, the closure of the contacts blocks the door. Correct operation generates a signal to the machine control unit that it is ready for work. Failure of this unit does not allow starting the washing procedure.

UBL with temperature sensor

When electricity is supplied, the UBL locks the hatch in the closed position. It closes the contacts of the switching device and signals that the wash can be started. A special lever mechanically secures the lock. This lasts the entire wash cycle.

And at the moment when electricity stops supplying to the locking device, you need to wait about 2-3 minutes. The latch then retracts and allows the door to be opened.

How does the locking device work?

A resistor is involved in the operation of the UBL.

Its resistance increases as its heating increases. This effect causes the two plates that are located in the lock to change their shape. This produces a displacement of the lever. The lever closes the contacts of the switching device. At the same time, the latch connected to the contact plate moves, creating a fixation of the hatch door. The entire process occurs within a few seconds after the electricity is applied. When the power supply is interrupted, the temperature sensor cools down. Cooling takes 1 to 3 minutes. After which the plates take their normal shape. The contact is no longer closed and latching is terminated.

Resource

Replacing the lock in a washing machine is rarely done due to its high reliability and maximum simplicity of design. The part does not have a specific resource. The unit is designed for the entire operational life of the equipped equipment. The reliability and durability of the device is determined by the quality of the assembly and the raw materials used in its manufacture. When buying a new part, it is better not to save money. Cheap analogues will require frequent replacement, so the benefits will be short-lived.

To extend the life of the UBL, you need to follow the operating rules and handle household appliances with care. No lubrication or other maintenance is required for this unit. It is enough to clean the well cell when visible contaminants get inside.

Reasons for failure

Natural wear and tear

Even with maximum reliability, over time you will have to replace the hatch lock in the washing machine. Critical resource depletion during long-term operation is inevitable. In expensive models, it is quite difficult to achieve this period; most of the parts will have to be replaced first. And in cheap models of washing machines, the resource exhaustion occurs after 3–5 years of active use. The problem of accelerated wear can be a misalignment of the fastening, deformation of the latch tongue, etc.

Sudden voltage changes

Installing a new UBL in a washing machine is often required due to a short circuit. Frequent and excessive power surges can burn out the contacts, leaving only the mechanical part intact. In some cases, functionality is only partially impaired, allowing for quick repairs.

Violations of operating rules

Service center technicians often have to replace the lock on a washing machine due to inept user handling of the equipment:

- destruction of the mechanism due to clogging of the hole;

- closing the door with great force in the presence of obstacles in the opening;

- an attempt to independently influence the operation of the blocker;

- violation of the startup or shutdown sequence.

Often the cost of replacing a washing machine UBL increases due to the discovery of additional damage resulting from incorrect actions and/or carelessness.

Manufacturing defects

Even modern systems working in conjunction with humans and auxiliary subsystems cannot ensure 100% quality in mass production. Because of this, about 1–2% of repair cases are caused by manufacturing defects. Damage can be expressed in the following moments:

- Mechanical defects - thickness of some parts that does not meet the standard, defects, weak contacts, soldering.

- Incorrect assembly - use of parts that do not comply with the regulations, violation of the sequence, unfinished actions.

In such cases, as a rule, the UBL of the washing machine is replaced during the warranty period.

Procedure for repairing/replacing the lock on the door body

What we do during renovation work at a client’s home.

- Disconnect the washing machine from the network. For safety reasons, be sure to turn off the power to the washing machine.

- We remove the door from the car. To do this, unscrew the screws that secure the door to the SM body.

- Let's disassemble the door. The mechanism is located inside the door body. To disassemble the door we perform five steps:

- dismantle the hinge on which the door is attached to the car (on some models it can not be removed, it does not interfere with disassembly);

- Unscrew the screws holding the outer and inner halves of the hatch body;

- carefully press out the latches that secure the parts;

- we separate the halves of the hatch body;

- remove the outer part and take out the glass.

- Inspecting the inner half and the lock. We have gained access to half of the door body with a handle and a mechanical lock and can inspect them to understand whether the machine lock will need to be repaired or replaced. Based on experience, inspection reveals three main lock faults:

- the plastic tongue or hook is damaged - the main part that connects the door to the UBL;

- the metal rod has fallen out of the groove, so the tongue has shifted and does not fit into the hole of the locking device;

- The mechanical plastic groove (fastening) of the rod broke.

- We remove the handle and disassemble the lock. Everything is together - the handle and the mechanism parts are attached to one pin, we pry it up with a screwdriver and move it to the side, then pull it out completely. If the latch (lock tongue) is broken, install a new one. If a pin falls out on one side, put it back in place. Sometimes the pin falls out because the plastic groove is broken. In rare cases, it can be “fixed,” but more often than not, you have to replace the entire door. Or, if you’re lucky enough to find it, we change the inside of the hatch body.

- We assemble the door and mount it on the body. When the lock is in order, you need to assemble the car hatch and install it in place. First we place the glass in the groove of the inner part. Then we put the outer part on top and snap the halves together. We tighten the fastening screws into place and screw the hinge onto the door (if you removed it). Then we install and secure the door to the body of the machine.

- Let's check the lock. Turn on the washing machine, select any wash mode, for example, quick. Press the “start” button and see if the washing machine turns on. If it starts, it means the lock is working correctly and locking the door.

Note! Sometimes the lock is fine and the door does not close due to skewed hinges or for another reason. Then the door itself needs to be repaired. Read more about this in the article Repairing the door (hatch) of a washing machine.

Signs of failure

Due to the simplicity of the device, you can determine the breakdown without the help of specialists. The following signs indicate a problem.

The hatch door does not open

The door can be blocked at the moment of closing, either with or without power. It is important to remember that after finishing the wash, the hatch remains locked under standard conditions for 10–180 seconds, depending on the specific model. If the locking does not turn off even after 30 minutes, it means that the bimetallic plate cannot return to its original position or the grips have received critical damage. In such situations, in order to replace the hatch lock in the washing machine, you will have to disassemble part of the structure.

The hatch door does not lock after turning on the machine

The locking mechanism should be activated when the power is turned on, the start button is pressed, if the hatch is previously closed. There are two reasons when the device does not work:

- failure of the electronic module;

- damage to the mechanical lock.

The activation of the module will be indicated by a characteristic click, after which the program will start.

Visible mechanical damage

There is visual damage to the insulation and/or casing on the surface of the device. In this case, the blocker works, but the operation of such equipment is unsafe. The latch may open during the washing process or a voltage breakdown on the housing may occur.

Reasons why door locking problems occur

The washing machine door may not open for various reasons.

Sometimes the source of the problem is a system failure, and sometimes it is a pump failure.

Reasons not related to equipment breakdown

This category includes situations that can be resolved independently. There is no need to contact customer service. Among them are:

- Blocking while working. Most users begin to pull the door too early, when the signal about the end of the cycle may not yet have arrived. Modern machines are often equipped with a sound or color indication indicating the completion of the wash. The doors of these models will not open until an alert appears.

- The child lock was accidentally activated.

- Power outage. If the power is lost during washing, the door will be locked. It will be possible to open the hatch only after resuming the interrupted program.

Reasons associated with washing machine malfunction

List of breakdowns that cause the door to lock:

- Software failure. Occurs due to fluctuations in the power supply, the system freezes and the cycle stops. Often the problem can be solved by turning off the power to the device for a while and then restarting it.

- Problems with the lock. A part needs to be replaced and the door must be opened in an emergency. To do this, it is advisable to follow the user instructions.

- Broken door handle. The part will need to be replaced; opening can be done with pliers. If there is still a mechanism that opens the door, you can pick up the remaining piece with a tool and turn it in the desired direction.

- Presence of water in the tank. In this case, the equipment will not open the door because the drum is full. Therefore, you need to look for the reason why pumping is not performed. Among the possible problems are a malfunction of the pump, blockages in the hose or filter.

- The water level sensor has failed. In this case, the system will wait for a signal about the water leaving. However, due to a broken sensor, the system cannot track the fullness of the tank. Even in the absence of water, the module will block the door, since it will not receive a signal to pump out liquid. Operation can be restored by replacing the sensor.

- The intelligent module is faulty. A case that requires specialist intervention. This may require anything from a firmware update to a complete replacement of the part.

How to unlock the door?

If the lock on the washing machine is broken and the hatch cannot be opened in the usual way, you can get to the part through the bottom. To do this, you will have to dismantle part of the case on the lid - the handle or by removing the front panel. You must first turn off the power and water supply. If the design includes a non-removable handle and/or front panel, carefully place the equipment on its side. Then remove the underbody skid plate, if equipped, and remove the latch by hand. The exact algorithm of actions depends on the specific modification of the washing machine.

Procedure for repairing/replacing UBL

During renovation work at a client’s home, we perform the following work:

Replacing the hatch locking device (UBL) of a washing machine: stages

Each model and series has its own characteristics, while the sequence and number of stages are always identical. It is important to strictly adhere to the maintenance schedule specified by the manufacturer. Stages of work:

- Inspection. You need to make sure that the problem is in the lock. Perform a test run and visually inspect the structure.

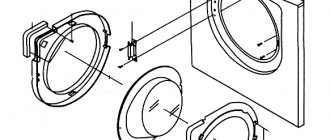

- Removing the insulating clamp. The easiest way is to get to the part through the hatch hole. Carefully move the protective clamp in the area of the UBL socket.

- Removing the lock. The lock is fixed with special latches or screws, depending on the model.

- Lock diagnostics. You need to visually inspect the part and check the contacts.

- Installation of a new spare part followed by testing. First connect the contacts, then fix the part in the socket, return the insulating clamp to its place. After replacing the hatch lock in the washing machine, check the serviceability of the unit.

It is important to remember that an automatic washing machine is a complex mechanism that requires certain knowledge, skills and experience to operate. To avoid increased prices for repair work, as well as wasted time and effort, entrust the work to professionals. Specialists of specialized service will quickly eliminate faults with a guarantee! We service all models and modifications of household appliances.

Troubleshooting

After disassembling the washing machine lock, you can usually visually easily determine the cause of the breakdown. If the cause of the breakdown is not clear, you need to check the following:

- Thermistor resistance. When cooled, it is equal to 900 Ohms.

- Voltage on the contacts after closing the door;

- It is necessary to simulate the procedure of closing the door, applying voltage to the thermistor, and monitor the operation of the bimetallic plate;

- Check whether the pin fits into the hole.

To diagnose the operation of the loading hatch lock, you must have a multimeter.

If you doubt your own abilities, contact our service center, our technicians will quickly fix the problem and your machine will be back in service.

This video will help you understand the process of repairing and replacing the lock: