How to change the membrane in a gas water heater: choose and install it yourself

The efficient operation of the water heater depends on the serviceability of all components and mechanisms. The membrane in the geyser is one of the important parts, but it wears out over time. How to do the replacement yourself? For this we have a detailed work plan.

Membrane functions, causes of malfunction

An elastic membrane is located at the base of the water unit and reacts to pressure changes in the system. As soon as you open the faucet, the rubber element bends under pressure and pushes out the stem. The rod in turn actuates the gas valve. This is how the fuel enters the burner.

With intensive use of the “Vector”, “Neva”, “Oasis” columns, the membrane wears out. Rubber stretches, becomes clogged and damaged. As a result, fuel does not enter the burner: the column does not ignite or ignites, but immediately goes out.

Signs of breakdown

How do you know when it's time to change the rubber diaphragm? You need to pay attention to:

- The pressure force of gas and water in the system. Open the tap and count how many liters are consumed per minute. Normally there should be at least two to three liters. The gas supply can be calculated visually by looking at the strength of the fire.

- Flame location. In devices with wick ignition, the fire should burn from the edge of the burner and be at least 3-5 centimeters high. Does not match? Then check the jets for blockages. After cleaning, look at the flame again. If the situation does not change, the problem is in the diaphragm.

- Equipment with piezo ignition should click when the button is pressed. This means that the diaphragm has worked. If you do not hear any sounds, the part may be damaged or torn.

- In some models, a rod that controls the operation of the control unit will help determine the breakdown. Remove the protective cover and open the water. If the rod does not move, the diaphragm needs to be replaced.

Once you have found the breakdown, you need to select the correct replacement part.

How to choose a new part

For each column (Termet, Ariston, Beretta), the membrane is selected individually. For foreign models, it is most difficult to find a replacement, since the product can only be purchased from an official supplier. In this case, you have a choice: spend money on a new element or buy a new speaker.

With domestic technology everything is simpler. Replacements can be found in stores or ordered online.

Experts recommend choosing a silicone diaphragm. It is more elastic and durable.

If you think that the principle of construction of all membranes is the same, this is not so. For example, in Ariston water heaters special elements are installed - “eights”. They are made of dense rubber and have a special shape. Their cost ranges from 300 to 500 rubles.

The membrane in Electrolux devices works according to the figure-eight principle. But its price is much lower - from 200 rubles.

The easiest membrane to operate and replace is “Neva” and “Astra”.

There are also universal options, but they are only suitable for temporary installation. It is impossible to fine-tune equipment without factory parts.

DIY repair

For repairs, you will need to disassemble the entire water-gas unit. You will need:

- slotted and Phillips screwdriver;

- wrenches 19 and 24;

- repair kit;

- new part.

First of all, turn off the water and gas supplies. After this, open the tap in the bathroom and drain the remaining water.

- Remove the regulators from the housing by pulling them towards you.

- If you have a display, disconnect the wiring leading to it.

- Now you need to remove the casing. In some models it is fastened with bolts at the top and bottom, in others it “sits” on latches. Pull the facing towards you and up.

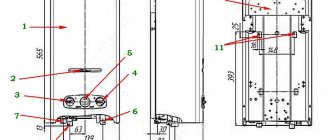

A water node will open in front of you. In earlier models it is located separately, vertically. A gas block is installed on top, a water supply is organized on the left, and a heat exchanger on the right.

To dismantle such an element:

- Unscrew the two nuts on the water pipes. Use the key for 24.

- Unscrew the two mounting screws, pull down and remove.

In the latest models, the water unit is placed horizontally. There is a special tap at the bottom through which the remaining water is drained.

- Unscrew the fastening nuts with a 19mm wrench.

- Disconnect the supply sensors.

- Remove the bolts that secure the block to the base.

- Remove the burner.

- Unscrew the fasteners of the water-gas unit with the manifold.

You can start disassembling. In the old Astra and Neva variations, you need to unscrew eight bolts to separate the assembly. In modern models “Neva” 4513, 4511, 4510, “Oasis”, “Vector” only four screws hold it.

If the fasteners are rusty and stuck, spray them with WD-40.

All that remains is to remove the worn membrane and install a new one.

Reassemble in reverse order. Upon completion of work, carry out an inspection. Gradually opening the water supply, inspect all connections for leaks. Then open the tap fully. Everything is fine? Put on the casing, supply fuel - enjoy hot water to your heart's content.

In the video they change the aperture for some models:

Choice

First of all, it is worth saying that when choosing a membrane for a geyser, it is necessary to take into account the brand of the manufacturer producing such a device, because in each case there will be an individual approach.

In some speakers the diaphragms are round, in others they have a rather complex shape. If you were unable to find a round diaphragm suitable for your water heater, then you can buy and install instead a part with the same diameter for a column from another manufacturer, for example, a membrane whose diameter is 73 mm.

If the geyser has been in operation for more than five years, then it is better to give preference to a part with plastic parts that are adjacent to it.

You can buy not a rubber, but a silicone membrane, because... it is considered more elastic and is characterized by a long service life (up to 10 years). A white or red rubber membrane is a less suitable option, because it tends to wear out quickly. User reviews indicate that sometimes it broke immediately after replacement.

How to replace a geyser membrane: reasons + instructions for repairs

Domestic water heaters - gas water heaters are used in old high-rise buildings and private houses to prepare sanitary water. Their parts and components tend to wear out just like any other equipment. Most often, the membrane of the water reducer fails, which you can change yourself.

We will tell you how to replace the membrane of a geyser. The article we have proposed describes in detail the steps to prepare for replacing the membrane and provides recommendations for its selection. Taking into account our advice, you will be able to monitor the operation of the gas heater or restore the functionality of the water heater yourself.

About the reducer and the location of the membrane

A device called a water reducer is part of almost any design of gas heat exchangers.

This part may have different configurations depending on the model of the water heating apparatus, but the principle of operation of such devices remains unchanged.

A water reducer installed on a gas water heater serves to stablely maintain water pressure directly in the water heater heat exchanger system. Due to the uniformity of pressure, a uniform flow is ensured, which means the same uniform heating of the liquid.

A part of the gearbox that facilitates smooth pressure regulation is a rubber membrane. This gear component, made in the form of a gasket, usually based on technical rubber, has the shape of a circle. It is installed inside the gearbox housing.

Due to the long-term operation of water heating equipment, being constantly in motion, the membrane gradually wears out. Wear of technical rubber in some places leads to tears in the material. Accordingly, the function of regulating water pressure stops operating according to the specified algorithm.

In such cases, it becomes inevitable to replace the rubber membrane of the reducer in the gas water heater, because the water heater does not work properly.

The quality of sanitary water heating decreases sharply, and in other cases the column simply cannot be put into operation. Comfort for the user is lost.

Reducer Diaphragm Replacement Steps

If we proceed from the rules for servicing gas equipment and strictly follow these rules, performing any installation, plumbing work, as well as work related to power supply is the prerogative of gas service providers, in particular, the local gas service company.

What do you need to know before starting work?

In other words, owners of gas water heaters are prohibited from carrying out work on gas equipment themselves. And even taking into account that the water reducer is theoretically not related to the gas system, disassembling this structural part and changing the membrane with your own hands is also prohibited.

Sometimes the desire to do everything yourself, without having practical experience in performing this kind of work, can result in disastrous consequences. As evidenced by the numerous accidents associated with household gas equipment.

However, premature wear of the membrane and other components of the water heater under pressure can be prevented by promptly cleaning the equipment with your own hands or by a gas service representative.

There are often craftsmen who are ready to independently change the gearbox membrane on a gas water heater. Moreover, it is, in fact, not at all difficult to perform such an operation if you have plumbing skills.

Do this easy job as follows:

- Using documentation or by opening the column housing and examining the internal contents, determine the brand (model) of the installed gearbox.

- Based on the technical information obtained, they purchase a new membrane on the market.

- If the equipment is imported, you may have to purchase the membrane only to order.

- If there is a membrane, shut off the gas supply to the equipment and close the cold water supply tap from the central heating system.

- Drain the contents of the gas heater heat exchanger using the service drain valve, the location of which is determined according to the documentation.

After these operations, you can begin dismantling the gearbox. However, there is no need to rush here. You need to work carefully and carefully so as not to damage other nearby parts of the gas water heater.

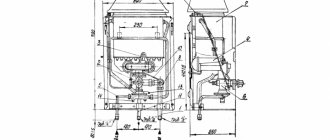

Gearbox removal and disassembly

The water pressure reducer has inlet and outlet pipes. Actually, thanks to threaded union connections, the device is mounted inside the gas system, directly on the water flow line.

Therefore, in order to dismantle the device, it is necessary to unscrew the two union brass nuts securing it to the pipeline. But before doing this work, it is recommended to unscrew one or both plugs on the gearbox drain outlets, which are located under the disc housing.

The nuts should be unscrewed smoothly, while simultaneously holding the device from possible rotation. The mechanism of the device has a regulator rod that is in contact with another part of the gas water heater. On some models, the rod head is secured with a screw. This point should be taken into account and, if necessary, loosen this screw.

Dismantling may be accompanied by residual water leakage. It is recommended to stock up on convenient, capacious containers for collection.

Brief instructions on replacing the membrane

The removed pressure regulator will need to be disassembled to get to the rubber (silicone) membrane. The disassembled part looks roughly like a plate.

- Unscrew the fastening screws on the top of the plate;

- carefully use a flat-head screwdriver to bifurcate the plate;

- remove the defective membrane;

- install a new one;

- articulate the halves of the plate;

- secure the joint with screws in a circle.

The correct location of the membrane on the gear plate is determined by a special “key” recess or pin, which, in turn, is located on the radial edge in the same row as the holes for the mounting bolts.

You need to align the membrane “key” with this notch before connecting the plate halves and screwing in the screws.

The moment of screwing in the mounting screws is a traditional action. However, you should keep in mind the uniformity of tightening of the gearbox parts. Technically competent tightening is performed using the “crosswise” method. That is, first, four screws located one opposite the other are tightened sequentially, and only then all the others are tightened.

The assembled gearbox, equipped with a new membrane, is installed in place in the reverse order. Carefully insert the rod inside the tube of the control device, align the device to the level of the water pipes. The nuts are then manually screwed onto adjacent sections of the pipe.

As a rule, pipe connections require the presence of sealing gaskets and their correct installation. This point must be taken into account when installing the gearbox at the installation site. Next, all that remains is to tighten the fastening nuts, applying a little force and do not forget to tighten the drain plugs under the plate.

Membrane shapes and materials

The design of geysers is varied. Accordingly, a change in the design of the pressure reducer cannot be ruled out. Therefore, the existence of reducing membranes of various shapes also seems to be an obvious phenomenon.

If a round-shaped product, which can often be found when disassembling the valves of domestic geysers, is considered standard, imported devices are often equipped with “exotic” ones.

One such example is the geysers of a well-known foreign company that produces household appliances under the Electrolux brand. Many models of equipment from this brand are equipped with figured membranes in the form of a “figure eight”.

The devices of the foreign company Vaillant are somewhat less popular compared to Electrolux, but they also stand out from the entire range of household geysers due to the non-standard production of gear membranes. When disassembling their valve, there is a chance of colliding with the flag membrane.

For the sake of objectivity, it should be noted: products of non-standard shape show finer regulation of flow pressure, however, in terms of long-term performance, they are often inferior to standard ones. Often the degree of durability is determined by the quality of the material.

In practice, it has been noted that silicone membranes last longer than rubber ones. However, for silicone, an important criterion is careful filtration of network water. Even a small amount of sand or rust that gets into the area where a silicone product is located will dramatically reduce the service life of the material.

Technical rubber is less sensitive to the effects of suspended particles, but for the most part “suffers” from insufficient chemical resistance. That is, if the composition of the water has an aggressive component to some extent, under these conditions, products made from technical rubber usually do not last long.

Repair of geyser membranes

The desire to save on everything forces some users to resort to such a virtual replacement technique as repairing a defective membrane with their own hands.

It should be noted right away: this activity may be interesting for a home handyman, but, from a service point of view, it is absolutely irrational and pointless.

They try to repair geyser membranes in different ways:

- by puttingty with silicone sealant;

- using various types of adhesives;

- application of pentelast;

- installation of miniature patches;

- and even masking tape.

The activity of such a “repaired” part lasts, as a rule, no more than 1-2 days. After which the problems begin again, and often worsen.

Repairing membrane plates of geysers, especially with your own hands, ends in failure in any case. Tested in practice more than once. So, it is not recommended to change the “awl for soap”, unless there is a purely research interest in this matter.

If it is not possible to restore the functionality of the wall-mounted water heater, you will have to buy a new gas water heater. The following article, which examines this current topic in detail, will introduce you to guidelines for choosing equipment.

Conclusions and useful video on the topic

The video demonstrates the personal experience of one of the heater owners - that is, do-it-yourself repair of the water pressure regulator. In particular, all repairs come down to replacing the membrane. We remind viewers once again: independent repair of gas systems is unacceptable!

It’s easier to find and buy a new membrane for a geyser, replace this accessory according to the instructions described above and sleep peacefully. Moreover, replacement, in most cases, does not require significant financial costs. On average, 200-300 rubles are enough to purchase a complete accessory.

Please leave comments, post photos related to the topic of the article and ask questions in the block below. Tell us about how you selected and changed the membrane in a gas water heater. Share useful information and technological nuances that will be useful to site visitors.

The column does not ignite initially

Before you climb inside the water heater, you should perform a number of basic steps:

Advice. If there is external access to the ignition electrodes through a window, immediately clean their working part with a long brush.

Did the above measures not produce results? Then remove the column casing and proceed to troubleshooting, following the step-by-step instructions:

An important nuance. When you discover a faulty microswitch, be sure to inspect the water block housing at the installation location. It happens that the element is flooded with water dripping from under the stem seal. It is necessary to dismantle the “frog”, pull out the leaky seal and install a new spare part.

In some models of electronically controlled gas flow columns, a special flow sensor controls the start. It operates on the principle of a limit switch - the water flows, the circuit is closed. Diagnostics is simple: open the DHW valve and test the element contacts with an ohmmeter or a light bulb - it should light up. The algorithm for a complete check of the water heater is demonstrated by the technician in the video:

How to replace the membrane

The procedure for replacing a rubber (or silicone) diaphragm differs little on speakers from different manufacturers. To independently remove and disassemble the water-gas unit, you will need standard tools - open-end wrenches, screwdrivers and pliers. The work order is as follows:

Note. On simple Chinese devices, the “frog” can be disassembled without removing the entire water-gas unit. It is enough to disconnect the heat exchanger pipe and the screws on the flange.

Disassemble the mechanism carefully so as not to lose the sealing gaskets or rubber rings. Reassemble in the reverse order; after connecting the gas pipe, test the reliability of the joints using the soaping method.

On outdated columns with a wick and a thermocouple, the membrane is replaced using the same technology. The difference is in the orientation and location of the water unit - here the block stands vertically, as shown in the photo.

To unscrew the membrane chamber on older models, you need to disconnect 2 water tubes and loosen the locking screw

Replacing a leaking rod seal

If you notice water leaking from the frog onto the microswitch, replace the worn seal immediately. A wet “limit switch” will quickly become unusable, the column will stop igniting and as a result you will have to buy 2 parts instead of one.

How to replace the oil seal yourself:

Reference. The method of fastening the oil seal and rod depends on the brand of gas-fired water heating installation. In Neva columns, the pusher is pulled out along with the plate, and the rubber ring is hidden under the screw.

Then you can go in 2 ways: replace the entire rod (recommended) or only the rubber sealing rings. The first is located at the end of the pusher, the second is pressed inside the nut. Buy rings of identical size and replace the worn parts.

Please note: the length of the rod and the diameter of the oil seal depend on the brand of the gas water heater; it will not work with another model. The disassembly process is clearly shown in the video:

How to replace the membrane in a geyser with your own hands

- Content:

- How does a membrane in a column work? What is it responsible for? Types of membranes for columns

- Signs of a membrane failure in the column - how to check

Replacing the membrane in a gas water heater yourself will be easier if you understand how the water regulator works and what purpose it serves. There are general signs that indicate that the rubber diaphragm has failed and the assembly needs to be repaired.

How does a membrane in a column work? What is it responsible for?

The principle of operation of the membrane in a gas column is as follows:

The water regulator is a metal assembly with an empty cavity divided into two parts by a diaphragm.- The first compartment is necessary for filling with water. After opening the hot water tap, liquid flows into the connected part of the regulator. Pressure is created inside the assembly, bending the gasket.

- The membrane in the gas column presses on the rod located in the adjacent section of the regulator. A metal rod opens the gas valve and at the same time gives a signal to electrically ignite the burner (in automatic dispensers).

- After closing the hot water tap, the pressure drops. There is a spring on the metal rod that returns it to its original position. The gas supply is interrupted. The burner goes out.

The design of the membrane on the gas water heater may vary depending on the model of the water heater, but the basic principle of operation remains unchanged. Over time, the diaphragm wears out, becomes insufficiently elastic or breaks, which leads to failure of the heat generator.

Types of membranes for columns

The gas water heater diaphragm is a round gasket made of black rubber or silicone. Depending on the speaker manufacturer, the membrane may contain hard plastic or metal elements. Some diaphragms are reshaped.

Gas water heaters made by European manufacturers use diaphragms that are difficult to counterfeit. For example, the Ariston Fast GIWH has a so-called “figure eight”, while the Electrolux GWH or Vaillant MAG has a diaphragm with a special eye. You can only purchase such a gasket at an official service center. A frog membrane for a European water heater costs from 200-500 rubles. For comparison, a repair kit for the domestic NEVA Lux 5013 (5016), together with plastic parts, costs only 150-200 rubles.

If we talk about the material from which diaphragms are made, there are several types:

- The black rubber membrane is a classic look. Most manufacturers prefer to make gaskets from black rubber. Such a diaphragm will last 7-8 years, provided that there are no defects.

- Silicone membrane - guaranteed to work for 10-12 years. On the market you can find gaskets for domestic and Chinese equipment. Owners of European water heaters will have to make do with black rubber diaphragms.

- Red membranes - low quality material is used. The rubber breaks after turning on the speaker several times. Suitable as a temporary measure. It happens that the necessary gasket has to be ordered directly from the manufacturer. Having installed the red membrane, you can continue to use hot water while awaiting delivery of the original part.

You can fully find out which diaphragm is used in the technical documentation supplied with the instantaneous water heater or after disassembling the water regulator.

Signs of a membrane failure in the column - how to check

- The water regulator is leaking - in normal condition, the gasket completely covers the part of the unit in which water circulates. It only starts to drip if the membrane is torn.

- It takes a long time from opening the hot water tap to turning it on - if the unit is working properly, the burner lights up after 1-2 seconds. There are several reasons for the long response time:

- The membrane is leaking - provided that the leaking small column will work for some time. Over time, water will begin to drip from the regulator.

The membrane has stretched - in this case, the pressure on the rod will not be enough to open the gas supply. The same problem occurs when the gasket becomes rough due to hard water.

- The microswitch rod of the electronic unit does not turn on - another characteristic sign that the diaphragm has become unusable. The column shows no signs of life.

The membrane on the column fails due to poor water quality. The surface becomes rough and loses elasticity. Over time, microcracks form that allow water to pass through.

Is it possible to make a membrane yourself and from what?

Before starting repair work, you should make sure that the poor operation of the burner device is due to a failed diaphragm. The cause of a malfunction of the water heater can be dead batteries and malfunctions in the igniter. Only after all other breakdowns have been ruled out do we proceed to repair the water regulator.

Diaphragm problems often arise unexpectedly. It takes several days for a suitable pad to arrive. To use hot water all this time, you can restore the membrane yourself or make it yourself.

For temporary laying, rubber with a thickness of 1.5-2 mm is suitable. Some people use an old car inner tube or thick household gloves as a blank. The holes for the bolts and the bypass channel are made with a punch, which is easy to make yourself from a metal tube.

A new diaphragm is cut out using the old one as a template. As a temporary measure, you can seal the membrane by applying a patch. After repair work is completed, the column will be able to work for some time, sufficient to purchase a factory diaphragm.

How to properly install a membrane on a gas water heater

The gasket is located inside the water regulator (frog). Replacing the diaphragm is not difficult. Before starting work, turn off the gas and water supplies. The liquid is drained. To do this, open the DHW tap located below the lower level of the column. Repair work is carried out in the following sequence:

- Remove the speaker casing - in most modern devices the casing simply hangs on hooks. To remove the cover, simply lift it up.

- Dismantle the water regulator - to do this, disconnect the cold water supply and unscrew the gas reducer.

To change the diaphragm on a gas water heater, the “frog” is disassembled. Typically, you will need to remove a few brass bolts. They should be unscrewed carefully so as not to damage the folds. This will give you access to the gasket. After replacing the diaphragm, the water regulator is reassembled in the reverse order. Turn on the gas and let in the water. Do a test run of the water heater.

If any of the above is difficult, it is better to call the gas service experts. Replacing the membrane will cost 900 rubles, plus the cost of the material.

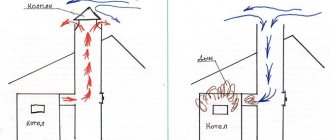

Water heater operating algorithm

If you have little understanding of the structure and operating principle of a modern geyser, we recommend that you familiarize yourself with this section, otherwise you will not be able to repair the device. The design of an atmospheric heater with an open combustion chamber is shown in the diagram below.

Note. The photo shows an old type column with manual ignition of the burner from a piezoelectric element. Updated versions of the devices (including the Russian brand “Neva”) ignite automatically; the power source is batteries or a 220-volt home power supply.

A turbocharged column is designed in a similar way, only the combustion chamber is completely closed, and a fan supplies air to the burner. The algorithm for starting the unit and heating water for DHW needs looks like this:

Reference. In older water heaters, instead of two electrodes igniting the main burner, one contact and a constantly burning pilot light are used. The presence of a flame is monitored by a thermocouple.

Now let's look at the most important point necessary for a successful repair. Under what conditions does the column automatically turn off (the main burner goes out):

Having understood the principle of operation, you can move on to diagnosing column faults and doing repairs yourself.

How to replace the membrane in a gas water heater yourself

Most water heaters, from the oldest to new generation devices with built-in smart equipment, have a special membrane for the gas water heater. It is necessary to separate the internal space of the fluid regulator. This part is classified as consumable and wears out over time. In this regard, owners of geysers often have the question of how to replace the membrane, and do they need to call a specialist for this?

What you need to know

Over time, even the most reliable membrane becomes unusable - this is one of the most common problems for geysers. It is quite possible to replace a worn-out element with your own hands. If you strictly follow the instructions in the instructions, even an ordinary person can easily cope with this.

However, it should be remembered that repairing gas equipment involves a certain risk. Mistakes may not only result in equipment failure, but can also lead to injury, gas leaks, or fire.

Part wear usually occurs over time as a result of intense use, but it can also happen suddenly. Be that as it may, a microcrack appears in the barrier, through which water begins to leak from the adjacent cavity of the water regulator. The flow of water causes a drop in pressure levels, and the column cannot function normally. Over time, the gap increases, further reducing the pressure. As a result, the system shuts down completely.

Membrane for geyser Beretta Aqua

How to determine membrane failure

The reason that the geyser does not work correctly is most often a torn membrane. First of all, check the water and gas pressure levels. Normal operation of a household appliance is impossible if it is unstable or does not reach the standard. Count the amount of hot water consumed through the tap. Its volume should be between two and three liters per minute. The level of gas pressure can be estimated by eye, focusing on the shape of the fire in the burners of the gas stove. There are different methods for different types of speakers.

Wick ignition

When dealing with devices of this type, pay attention to the location of the pilot light and its size. Ideally, the tongue should reach three to five centimeters in height and be located directly under the edge of the main burner.

If the signs do not match, this may indicate a problem, for example, a clogged jet. Try cleaning it and inspecting it again. If the procedure does not help and the column stops lighting up, then the problem is definitely in the membrane.

Battery ignition

If the column is ignited with a button, you should periodically monitor for attempts at ignition. When turned on, the owner should hear a certain sound, similar to a click. This means that the rubber membrane is working properly, and the source of the problem must be sought in the gas part or the ignition electrode. If clicks were not heard, there is a high probability of membrane rupture. However, this phenomenon is caused by several reasons; you can find out what’s wrong only by disassembling the assembly.

Other cases

There are models of water heaters in which the performance of the membrane is determined by the movement of the rod, which regulates the operation of the electronic unit using a microswitch. The easiest way to notice this is to remove the protective casing. A static part when the hot water supply tap is open becomes clear evidence of a failed membrane. In this case, replacement of the rod is not required.

How to choose a replacement membrane

Having identified the cause of the problem, you can begin to select a replacement part. At this stage, the owner may encounter difficulties, because for some models, especially those produced abroad, there are simply no spare parts. Purchasing a membrane becomes a real problem: you can only get it from an official dealer of the manufacturer, which significantly inflates the cost. There are two ways out of this situation: purchase a new speaker or try to pick up a part from another model.

With more popular geysers such problems will not arise. Spare parts for them can be purchased in specialized stores or ordered online. Even a technician called to your home can install them for you for an additional fee. The cost of the membrane will increase depending on its type and the material used in its manufacture. The brand of a household appliance can also affect the price, because servicing advertised speakers is more expensive.

Types of membranes

There are membranes of a special shape, the principle of operation of which is different from the standard scheme. A striking example of such a part can be the consumables for the Ariston Fast GIWH water heater. It is called "eight".

It is cast in a special mold using dense black rubber. The average market price can range from three hundred to five hundred rubles, depending on the place of purchase.

The partition of a household appliance from Electrolux or Vaillant is much simpler. Created on the same principle as the “eight”, it costs only two hundred to two hundred and fifty rubles.

There is an even simpler type, for example, a membrane for a geyser from the company Neva or Astra. Despite its external unpretentiousness, the part copes with its functions perfectly. An additional advantage of this form is the ease of replacement.

There is a type of membrane suitable for all models of geysers - a kind of universal spare part. However, you need to remember that it can be used as a temporary replacement, because it is very difficult to achieve precise equipment settings without factory parts.

Replacing a failed part

The procedure for replacing a used membrane is not difficult.

First of all, you should turn off the household appliance and block access to cold water and gas. In addition, do not forget to reduce the pressure in the pipeline. To do this, open one of the hot water taps and wait a while. The pressure release procedure has its own nuances. It is best to open the tap located at the bottom of the column, usually a faucet located in the bathroom. This will allow the water accumulated in the heat exchanger and pipes to drain freely due to the siphon effect. Of course, you can open the kitchen faucet, but it may be fixed at a higher level than the liquid regulator. In this case, you need to be prepared for the fact that when disassembling the column, some of the water, namely three to five liters, will spill onto the floor. Prepare a suitable container in advance and be vigilant.

Mounting screws for removing the protective cover

Having finished with the pressure, you can begin to dismantle the protective casing of the water heater. The mounting bolts, depending on the model, may be located in different places, but usually they are not difficult to find. In some cases, they may be hidden by decorative elements or panels, as well as under device control toggle switches. New generation units can do without mounting bolts altogether - their casing is held in place by special hooks and can be removed with a little pressure. By removing the barrier, you will gain access to the interior of the device and will be able to replace the partition without interference.

Old speakers

The gas water heater of the previous generation has a special structure. Its membrane is located in the fluid regulator, which is installed as a separate element. It is quite easy to distinguish it from other parts - this is the first element that is connected to the pipe through which cold water is supplied to the column.

Column fluid regulator

To remove the water regulator you need to:

- unscrew several nuts securing the water pipes;

- then unscrew the three screws that perform the function of fixing the regulator in the gas section;

- Carefully remove the regulator from the groove by pulling it down.

New generation household devices

Progress does not stand still, and new types of devices are becoming more and more complex every year. Manufacturers integrate automatic ignition and water heating control systems, batteries and touch screens into them. However, to remove the water filter, you will have to follow the procedure described above.

To work with the device, you will need to remove the cover from it. This can be done by unscrewing several nuts and screws with an internal sprocket. By choosing the right screwdriver, you'll get the job done in no time. Having eliminated the obstruction, disassemble the fluid regulator and replace the worn partition with a new one. Carefully monitor the installation of the part, do not place it in the wrong position. After this, reassemble the column in reverse order. This is how the membrane in a conventional gas water heater is replaced.

Sources: https://sovet-ingenera.com/otoplenie/vodonagrevatel/kak-zamenit-membranu-gazovoj-kolonki.html https://avtonomnoeteplo.ru/vodonagrevateli/727-zamena-membrany-gazovoy-kolonki.html https: //tehnika.expert/klimaticheskaya/gazovaya-kolonka/zamena-membrany-v-gazovoj.html

Malfunctions and their elimination

No spark discharge when opening hot water

- Insufficient water pressure in the water supply network (with the tap fully open, less than 2 liters per minute). It is necessary to call the service to eliminate the causes of low pressure in the pipeline.

- Check the functionality or correct installation of the batteries in the battery compartment (if the polarity is correct). If the elements are discharged, they must be replaced.

Battery pack

- Check whether the hot water tap at the inlet in front of the column is open enough. If necessary, open it completely.

- Or the problem may be insufficient water flow when the water pressure adjustment knob is selected - switch it to the required mode.

Control knob

- It is necessary to check the degree of contamination of the filter in front of the device. If necessary, replace the filter element or clean it.

- It is necessary to check the heat exchanger for the presence of scale on its walls. If necessary, remove it and wash it with Solita.

- Check the membrane of the water unit.

Radiator leak

Hot water appears thanks to the existing heat exchanger.

The heat exchanger radiator consists of metal pipes and plates located close to each other. The plates come into direct contact with the fire, due to which soot appears on them during operation. Signs of soot accumulation include:

- The flame is yellow;

- When burning, the fire deviates to the side and heats the body (the flame should tend upward);

- Soot falls off the gas water heater;

- Even when operating at full power, the water heats up weakly.

To remove soot, you will need to remove the casing by unscrewing the bolts (latches) that secure it.

After the assembly is removed, it must be washed by placing it in a container with water for several hours to loosen the soot. This will make it easier to clean the space between the heat exchanger plates. For quality cleaning, it is recommended to use running water, a long-bristled brush and detergents. After drying, the radiator is put in place.

Green spots on the heat exchanger indicate existing cracks and holes.

If the geyser is leaking due to a failure of the heat exchanger radiator, then the actions should be as follows:

- The water supply pipes must be shut off to prevent water from entering the gas water heater. After which the hoses are disconnected and the remaining water is drained. The remaining liquid in the coil is removed with a pump or vacuum cleaner; you can try blowing the water out with your mouth using a hose. This must be done, since the remaining moisture absorbs heat during the soldering process, and it will not be possible to heat the metal to the desired temperature.

- Damaged areas (they are green) will need to be cleaned with sandpaper and degreased with a solvent, and then wiped dry.

- Crushed rosin or an aspirin tablet should be sprinkled on the work surface. Rosin and aspirin will serve as solder here.

- Using a soldering iron with a power of at least 100 W (since they will have to work at temperatures above 180 degrees), it is necessary to increase the solder to a height of approximately two millimeters. If the soldering is loose, this means that the working surface is not heated enough. You can additionally heat the soldering area with an iron or another soldering iron.

- Each through-hole fault will need to be soldered in a similar manner.

- After the soldering work is completed, you need to wait until the working surface has completely cooled and assemble the gas water heater.

- Before full operation, the equipment is started in test mode.

If the geyser is leaking, but no leaks are visible on the radiator, then perhaps they are located where it is turned towards the body. In this case, you will need to remove the heat exchanger from the housing, which will require disassembling the entire column. Before starting the procedure, it is advisable to familiarize yourself with the diagram in the passport, since this is a rather labor-intensive process and knowledge of the structure of a specific model will simplify the work.

Soldering damage to pipes can only be used as a temporary measure to eliminate the reason why the geyser is leaking, since the repaired surface remains vulnerable. The best option for troubleshooting problems that result in water dripping from the column is to replace worn elements with new ones.

The gas makes a loud noise when burning in the wick.

After installing the Neva-3208 gas water heater, an unpleasant phenomenon appeared that did not affect the quality of the water heater. When the gas burned in the wick in standby mode, it produced a rather loud sound, which was unpleasant to the ear and created discomfort. After some thought and experimentation, I managed to get rid of the noise in a simple way. He assumed that a stream of gas in the burner under pressure, escaping from the nozzle and hitting the wall at the bend of the burner, creates conditions for noisy combustion.

To test this assumption, I inserted a strip of tin approximately 3 cm long and 5 mm wide into the burner, the main thing being that it fit inside the burner. The noise disappeared. If your gas water heater is also noisy, then you can take any metal strip, for example, cut it from a tin can, make a hole in it at the edge, put the strip on a straightened paperclip bent at the end and put it into the burner. The result will be something like a fishing lure. The paperclip is needed so that you can remove the strip of metal back from the burner if the noise does not disappear, although if it burns normally, you don’t have to remove it. This experiment can be carried out without even removing the casing from the gas water heater.

Is it possible to get by with repairing the diaphragm?

DIYers couldn't pass up the opportunity to try and repair a leaky rubber part.

Practitioners have tried the following methods:

- applying patches using various adhesives;

- puttying the surface of the diaphragm with silicone sealant;

- use of silicone compound Pentelast.

Experience has shown that such measures will not help for long, perhaps only for a day or two, since the membrane works under strain. A new failure of it could worsen the situation. Therefore, there is no need to resort to gluing and patching the gasket.

Water comes out with weak pressure

Water comes out with weak pressure

Most often this happens due to the column heat exchanger being clogged with scale. Typically, the cause of clogging is prolonged “idle” firing of the igniter. The device heats the heat exchanger to a temperature sufficient to evaporate any remaining moisture.

There is no water flow, scale is not washed out of the heat exchanger, and before the next time the equipment is turned on, it sets, as a result of which the column ceases to function normally. Cleaning the heat exchanger usually helps. In advanced cases it has to be changed.

To replace it, it is better to immediately contact professionals, but you can handle the cleaning yourself. Prepare screwdrivers, rubber hose, open-end wrenches and paranitic gaskets. Buy a descaling mixture from a hardware store. This is usually called anti-scale. A more budget-friendly option is washing with vinegar essence. Work in this order.

First step. Sequentially remove the fittings and casing from the heater.

Second step. Shut off the water at the inlet and open the hot water tap, preferably as close to the water heater as possible.

Third step. Unscrew the water supply tube from the heat exchanger and then move it to the side. After unscrewing the nut, the column heat exchanger will begin to release water. In total, about 1 liter will be drained.

Fourth step. Place a hose of a suitable diameter onto the inlet of the heat exchanger and lift it slightly above the heater. Insert an ordinary funnel into the attached hose and begin to slowly pour in the prepared solution in a thin stream (preparation instructions are given on the package). There's no need to rush. If you pour too quickly, the antikipin will simply push it back out, and you are unlikely to like it.

Flushing the geyser heat exchanger

Leave the cleaning agent in the heat exchanger of the heater for 2-3 hours (usually the required time is indicated on the packaging).

Place a suitable container under the water tap and carefully resume the flow of liquid to the heater. Watch what comes out of the hose

Did a lot of sludge come out, and then the pressure returned to normal? Everything is fine. Otherwise, the washing will have to be done again. Typically, the need to re-rinse occurs only when using vinegar essence. Antiscale can cope with most situations the first time.

Setting details

These devices have only one geyser temperature regulator. Thanks to it, the heating temperature and power are adjusted. The self-diagnosis system evaluates the operation of the components when turned on. If there are problems, the red light comes on and the device is blocked from starting. Then it is necessary to adjust the water pressure.

Then you need:

- Remove batteries from the compartment;

- Turn off the microswitch;

- Provide a source of electricity;

- Turn on the hot tap and turn on the microswitch;

- The pressure on the burner should be maximum;

- After saving the settings, the orange lamp will turn on.

In other columns, the water temperature is adjusted by turning the toggle switch and controlling the strength of the water flow.

Unfortunately, it is impossible to easily set the settings according to the instructions. Each system has different meanings. If you have difficulty setting up the gas water heater temperature regulator yourself, you should turn to professionals.