The refrigerator is an essential assistant in people's lives. Thanks to this technique, food is kept fresh for a long time. Over time or due to breakdown, its performance may sharply decrease. In many cases, after repairs, the refrigerator needs to be refilled with refrigerant. The procedure is quite complicated and can only be done by those who have experience and some skills. You can try to restore the quality of this technique with your own hands, but the result can be very unpredictable.

Refilling the refrigerator

What role does freon play in the operation of a refrigerator?

The procedure for filling a refrigerator with freon is difficult in the sense that to perform this work, you first need to have specialized equipment. Not to mention the fact that you will have to get the refrigerant itself of a certain brand, since the substance is produced differently. There is no universal solution that is suitable for all types of refrigeration equipment.

NECESSARILY!

Before you begin repairs, you need to clearly understand what this freon is and what it is used for. It is a special gas that compresses well and also expands quickly, thereby accumulating cold or heat. It is the property of good compression that made it effective and one of the best heat exchangers that has received widespread use.

When deciding to repair a refrigerator compressor yourself and then refill it at home, you need to know about the variety of types and varieties of coolants. Freon is not a specific gas with a single chemical formula. The word describes a whole collection of chemical substances with similar properties. This substance can have two atomic states: gas and liquid. Its distinctive feature is the absence of color and odor, that is, in fact, you will not notice a leak if it has occurred. Nevertheless, a certain liquid flows out of the system at the point of rupture, which has an odor. It is given this by a special oil that circulates along with the gas. It serves to lubricate all components of the system, eliminating the formation of corrosion and other types of damage.

There are at least 16 varieties of freons, which, in turn, can be divided into 2 categories: highly soluble in non-polar solutions and poorly soluble in water and non-polar solvents. Domestic refrigerators use R-134a (tetrafluoroethane) refrigerant. It is made on a hydrofluorocarbon basis, therefore, when released into the environment, it does not cause any negative reactions in the form of depletion of the ozone layer or harm to human health. Still, drinking it is highly not recommended, because it will cause unpredictable reactions in the body.

IMPORTANT!

The use of this particular substance as a refrigerant is due to its ultra-low boiling point. It begins to evaporate already at -26.3 degrees Celsius. Thanks to this property, it easily contracts and expands quickly, transferring heat from the work area to the radiator. In order not to be mistaken with the type of freon used, you should first study the label on the compressor. On it, each manufacturer indicates all the necessary information.

Causes of refrigerant leakage

Refilling the refrigerator with refrigerant is most often required when the seal is broken. Still, it’s worth listing the maximum number of possible causes of this unpleasant defect:

- Depressurization of the circuit as a result of the destruction of solder at the pipe welding site. The peculiarity of any such system is that all its parts are made of mesh and are connected to each other exclusively by welding or soldering. It will be extremely difficult to do such work with your own hands, but this opportunity should not be missed if you have the desire and the supplies. Often, frost accumulates at the site where a hole or crack appears, and droplets of that same oil appear.

- Violation of the integrity of the system due to damage or replacement of one of the system components. For example, the compressor itself, the dryer, one of the pipes or a valve, depending on the design of the refrigeration equipment. There are at least several of them at the moment.

- Replacement after long-term operation and comprehensive maintenance of all connections and main sections. Many owners of such equipment have noticed an interesting pattern. After 6-10 years of operation in the absence of visible causes of leakage, the refrigerator cools worse. Considering the service life, most often the thought arises of buying a new one and sending the old one to a landfill.

Contaminated capillary tubes

In addition to leakage, refilling the refrigerator may be necessary if the capillary tubes are dirty. It would seem that what could cause a blockage in a obviously sealed environment? In fact, over the entire history of repairing such equipment, 2 reasons for this phenomenon have been identified. One of them is the freezing of trapped moisture. More precisely, it could have been there initially and penetrated along with oil or low-quality freon at the manufacturing plant. The second is contamination by waste oil particles, or more precisely, by what floats in it.

Ice on the evaporator

A compressor is a motor that has a piston group. During operation, constant friction of parts occurs, accompanied by the formation of metal dust. This is what causes the blockage. In this case, the system is deliberately depressurized to fill with refrigerant after all capillary tubes have been cleaned.

Problems that may arise when refueling yourself

Studying the theoretical part of the process and accurately completing everything point by point does not guarantee the absence of problems during the refueling process. Therefore, it is worth learning in advance about possible difficulties and common errors:

- Moisture in the circuit after drying. It may remain if you save time or rush too much. Leads to compressor failure and capillary clogging. Therefore, it is recommended to dry the system thoroughly, spending a little more time. The error can only be corrected by refilling.

- Excessive refrigerant charge. How much freon is needed to refill household refrigerators of a certain brand is indicated in the technical documentation. Excess gas overloads the compressor, creating excess pressure in the system. This leads to breakdown and the need to replace elements.

Before you start refueling, you need to familiarize yourself with possible difficulties that may arise during the work.

It is difficult to pump freon with your own hands. It is necessary to take into account all the nuances and features of the procedure and device model. Failure to do so may result in more expensive repairs or equipment replacement.

See alsoHow and with what to clean the refrigerator inside and out?

Preparatory work

When deciding to refill a refrigerator at home with refrigerant, you need to do some preparatory work. They consist of purchasing all the necessary equipment and fixtures. In particular, to perform diagnostics and the freon refilling procedure itself, the following materials and tools are required:

- Refrigerant R134a. It is sold in 5 liter cylinders. They are equipped with an atmospheric valve for easy refueling.

- Tools. These should include a 10-14 wrench for unscrewing the crimp nuts, a hacksaw for cutting the service pipe, etc.

- Since repairs may take an indefinite period, it is better to put all food from the refrigerator in a cool place and isolate it from heat as much as possible.

- It is necessary to establish the fact of the leak and find the very place where the circuit is damaged, because you can refill it 10 times, but all attempts will be in vain.

- After identifying the specific cause of the leak and eliminating it, you can proceed to refueling. If you have any doubts about performing this procedure yourself, you should contact a professional.

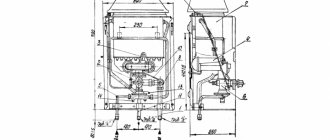

Refrigerator vacuum cleaner

The procedure for performing work to replace freon

Is all equipment and tools available? Then you can begin the refrigerant charging procedure, but it is important to follow these instructions so as not to mess things up. In fact, it is not as complicated as it seems at first glance.

Step 1. Diagnose the problem yourself

REMEMBER!

The refrigerant is also a lubricant, which ensures the normal stable operation of the equipment. Not only lubrication is important, because the coolant itself is freon - a gas dissolved in oil. Its deficiency or complete absence harms the equipment, which is why after some time the compressor is guaranteed to fail.

Diagnosing the problem

Before refilling the refrigerator with freon, it is necessary to diagnose the reason for the decrease in its pressure. There are several ways to perform this procedure. First you should check for clearly visible defects:

- increase in temperature in the chambers;

- the frequency of compressor switching on has increased;

- the engine runs constantly;

- there is always condensation in the chambers;

- an odor uncharacteristic of normal operation appeared;

- A large number of snow formations constantly accumulate on the evaporator.

Removing ice when washing the refrigerator should be done extremely carefully, because the tubes in the evaporator are very thin and made of aluminum. They can be pierced with any steel knife or other device. In this case, leakage is observed immediately after damage.

If the leak is not visible, but is present, then you can check the integrity of the system using compressed air. To do this, you need to cut off the service pipe that comes from the compressor and connect an external pump with a pressure gauge to it. Considering that part of the system is made of copper and the other of aluminum tubes, no more than 15 atm should be pumped into the system.

Check the pressure gauge readings after 2-3 hours. If the pressure drops, then there is a hole in the system that needs to be found. The next step is to spread the soap solution on all the joints. It must be so concentrated that it can cover the metal with a continuous shell. At the site of a crack or other defect, abundant bubble formation will begin.

Step 2. Preparatory work before replacement

If you decide to fill the refrigerator with freon yourself, then first of all fix the hole. To do this, you will need to either re-crimp the threaded connection and replace the gasket, or solder the puncture site by installing a coupling. Soldering may require a powerful soldering iron of at least 150 W to heat thin tubes, semi-automatic welding or a torch with an attachment to create a thin flame.

Soldering

Simultaneously with the repair, flush the refrigerator's freon circulation system, because during operation the oil loses its lubricating properties. It also forms solid accumulations in the form of plaque on the tubes and in various elements. Larger particles remain in the dryer, so it is enough to unsolder this part for washing. Smaller and lighter ones go into the compressor and clog it.

Freon

Step 3. Remove any remaining refrigerant

There is always some part of the coolant remaining in the freon circulation system, so before refilling a new one, it is necessary to remove the remaining refrigerant. For this purpose, the system has an element called a filter drier. It is necessary to make a small hole in it for the atmospheric valve. It is necessary for purging the system, which should be done for 10-15 minutes. After performing this procedure, it is necessary to remove the filter and blow out the system again, only after that a new one is installed in its place.

Removing remaining refrigerant

The next step is to prepare a place for installing the valve. It is installed on the compressor on a special outlet. Freon should come out through the hole formed in the dryer. After the last drop falls, blow all the elements with nitrogen, since the air contains moisture that will cause harm.

Refilling is carried out through a Schrader valve, to which an external pump is connected, glued to a cylinder with freon. The valve is necessary to prevent the outflow of refrigerant. When filling the cylinder, it is recommended to turn it over and place it on the scale, since the entire volume from the container will not be needed.

Preparation of equipment and materials

Before starting work on refueling the refrigeration unit with freon, you should prepare the necessary tools and materials. These include:

- Refrigerant . A sign will help you identify the correct brand. Filling a refrigerator with freon that is not prescribed by the manufacturer is prohibited. The quantity of required consumables is indicated in the operating instructions. The cost of the minimum volume of R600 refrigerant is 500 rubles. This option is most often used in modern refrigeration systems.

- Vacuum pumping station . With its help, a vacuum is created in the system. It also helps with direct refueling.

- Welding.

- Solder . Its type depends on the type of tubes used.

- Filter drier . It must be replaced if there is any depressurization of the refrigeration system.

- Schrader valve . Responsible for creating a vacuum and increasing pressure in the system.

- Leak detector . It is used to determine the location of freon leaks and check for leaks after refilling.

- Nitrogen . Used for purging the system.

You can buy all the necessary tools or rent them, since they are quite expensive, and a one-time use will not repay the cost of the equipment.