The principle of operation and design of a jigsaw

An electric jigsaw consists of a small number of components and parts, but most of them require high precision manufacturing and assembly. The main working part of the device is the file. It is attached to a rod that moves up and down with an adjustable frequency and is located at the front of the device. The rod is driven by an electric motor through a gearbox and a crank mechanism. To increase cutting speed, many devices have a pendulum function added: the blade moves not only down and up, but also back and forth. A work area illumination and a laser sight are placed near the attachment point. The pendulum stroke regulator is located on the side of the body. The device rests on the workpiece with a flat platform; in many devices, this platform can be rotated around the longitudinal axis at a fixed or arbitrary angle. On the back side of the platform there is a pipe for connecting a construction vacuum cleaner and removing sawdust from the work area.

At the top there is a handle in the shape of a bracket or a mushroom; on it there is a regulator of the engine speed and a switch.

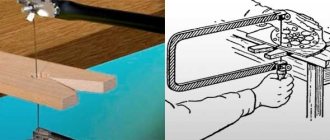

Hand jigsaw design

This is the simplest tool that even schoolchildren love to make beautiful crafts with.

It consists of:

- a frame made of a metal plate in the shape of an arc, endowed with the properties of a spring;

- pens;

- files;

- screw or locking clamps.

To process workpieces, saws with different material hardness and tooth shape are used. Thin blades with particularly fine teeth allow you to make the most delicate cuts quite accurately.

Since the file is made in the form of a thin toothed strip of metal, it is fastened at two points located at the ends of the frame with clamps.

Sawing is carried out at a workplace equipped with a special stop, secured to the table with a clamp. The file must be oriented perpendicular to the surface of the workpiece, and its teeth must be directed downwards when installing. Then, when the machine moves upward, the blade will slide along the cut, and in the opposite direction it will cut the material, simultaneously pressing it against the table.

Jigsaw and methods of its use

There are several methods for using an electric jigsaw. In everyday life, straight and curved cuts are most often used. In the case of a direct cut, the device is brought to the beginning of the line and the beginning of the platform is supported on a securely fastened board or sheet. The pointer on the edge of the platform or laser marker is aligned with the marking line. The jigsaw is turned on at the lowest speed to mark the beginning of the cut, then the cut is slowly carried out until the platform is completely resting on the part. Now you can turn up the speed.

Curvilinear cut: a hole is drilled inside the marked contour. A special file for curved cutting is attached to the chuck of an electric jigsaw, the pendulum mechanism is turned off, it is inserted into the hole until the platform is in full contact with the part, and they begin to saw at low speed. Bring the cutting line to the intended contour tangentially at a slight angle and make a working cut.

The structure of the electrical part of a jigsaw

The electrical part of the jigsaw looks like this:

- Motor stator winding

- Copper winding terminals

- Rotary collector plates

- Rotor

- Brush holder with graphite brush

- Stator (electrical steel core).

As you can see, the tool uses a commutator electric motor, the main elements of which are: stator, rotor, carbon brushes. The stator is made of electrical steel and has a rectangular shape with grooves in which the stator windings are located. There are two stator windings - they are located opposite each other.

The motor rotor is a shaft (located inside the stator) with special grooves in which the so-called armature windings are located. From these windings come leads connected to the collector plates. The collector itself is pressed onto the end of the rotor shaft.

During operation of the electric motor, graphite spring-loaded brushes move along the commutator plates. Thanks to the latter, electrical voltage is supplied to the armature windings

By the way, when repairing any power tool, priority attention is paid to the condition of the brushes.

The last thing to consider about the jigsaw and its electrical part is the button and capacitor. The jigsaw button is a rather complex element in terms of functionality. With its help, voltage is supplied to the engine and the rotation speed of the armature shaft is regulated. The shaft rotation speed is adjusted using a rheostat built into the button. In other words, using the rheostatic button, the user can manually speed up or slow down the movement of the cutting file.

As for the capacitor. The main purpose of this element is to remove residual voltage from the windings after turning off the jigsaw. In addition, the capacitor smoothes out ripples that occur in the electrical network due to the operation of the tool.

We've sorted out the electrical part, let's move on to considering the mechanical component.

Main types of jigsaws

When choosing a model, you first need to decide on the class of the device. Based on the type of power supply, electric jigsaws are divided into mains and battery-powered. Cordless ones do not depend on wires and are convenient where you need to make a lot of cuts in places at a construction site that are spaced apart from each other. Their power decreases as the battery discharges. Mains ones require sockets and extension cords, but are much lighter, do not require breaks to change and charge batteries, and have constant power that does not depend on the duration of operation. According to their purpose, electric jigsaws are divided into household and professional.

Household

The motor power in household appliances rarely exceeds 500 watts; their performance, continuous operation time and overall resource are limited. They are suitable for small volumes of work and can cut wooden parts up to 80 mm thick, as well as metal up to 4 mm. Continuous operation time rarely exceeds half an hour.

Household jigsaw

Advantages:

- Low price.

- Low weight.

- Rich choice.

Flaws:

- Small resource.

- Short time of continuous operation.

- Small thicknesses of sawn parts.

- Few optional accessories and functions.

Professional

Professional models have more powerful motors - from 750 to 1500 watts, this makes it possible to handle wooden workpieces up to 130 mm, steel up to 10 mm and aluminum up to 20 mm. Daily operating time is from 8 to 16 hours, continuous operating time is up to 3 hours. Advantages:

- High performance.

- Wide functionality.

- Increased resource.

- A large number of additional functions and devices. Disadvantages Increased weight and dimensions.

- High price.

Professional jigsaw

Chinese semi-professional devices try to combine the advantages of household and professional devices, but this often comes at the expense of quality.

What is it and what is it for?

An electric jigsaw is a cutting tool that is electrically driven. Its difference from saws, cutters, and milling machines is considered to be significant accuracy when making cuts. A jigsaw is a universal device that cuts various types of material. Using the device, you can make not only longitudinal cuts, but also figured ones, not excluding cutting materials at an angle.

If you need to make a straight cut or with a complex trajectory, a high-precision cut with clean edges, rough cutting of a workpiece, cutting holes of different shapes and sizes, then in such a situation you cannot do without a jigsaw.

This type of tool should be considered a small saw, which is equipped with an electric drive. The jigsaw has found use in household work. During renovation of premises, it can be used for cutting laminate, ceramic tiles, plywood, and drywall.

Characteristics and design features

Characteristics of an electric jigsaw that must be taken into account in order to choose the right model:

- The engine power affects both the maximum thickness of the workpiece processed and the frequency of the rod stroke.

- The frequency of the working stroke determines the productivity and maximum cutting speed

- Cutting depth is the maximum thickness that the device can handle, depending on the material.

- Power type: battery or mains.

- Continuous operation time - how many minutes or hours the device can work without interruption.

- Availability of additional functions.

Jigsaw power

The functionality and performance of the entire device directly depend on its heart - the electric motor. Power determines the force with which the blade will move. For example, an electric jigsaw with a power of 400 W. will be able to handle 60 mm of wood and 4 mm of metal, and a 600-watt one will be able to handle 80-85 mm of wood and 6-8 mm of metal. Power varies from 300 to 1000 watts. For a home craftsman, it would be wise to choose among devices with an average value of 500-600 W. Weak devices are useful only for a narrow range of tasks, while more powerful, professional ones are too heavy and expensive, and also consume a lot of electricity.

Blade movement frequency

The stroke frequency directly determines the speed of movement of the saw - the more often it moves up and down, the faster it will cut the material. For different models, the maximum frequency lies in the range of 2300-3200 strokes per minute, and the most powerful models, the frequency of the rod movement reaches 4000 per minute. Most modern models allow you to adjust the stroke frequency: stepwise using a separate regulator or smoothly as you press the power button harder.

The second option is better suited if the master is going to do sawing or shaped cutting of material. Frequency control makes it possible to work with various workpiece materials, so for wood the frequency should be maximum, for a more even cut surface, and for metals, on the contrary, low, in order to avoid overheating of the saw and its breakage.

Another important parameter is the cutting depth

Cutting depth is a key characteristic of an electric jigsaw. It determines what maximum thickness of the workpiece the device can handle, provided that a blade of the appropriate length is installed in it. By the way, if you use a 100 mm saw to saw a beam 100 mm thick, the end of the cut may turn out sloppy, with burrs. It is better to have a length reserve of 5-10 mm. The depth depends on the material and is indicated separately for wood and steel. Aluminum blanks, as a rule, can be cut one and a half times thicker than steel ones. For household models, the depth is 50-110 mm for wood and 4-6 mm for iron. For professional ones - 150 and 10 mm, respectively

Replacing the rod

The procedure for removing a damaged rod and installing a new one is quite trivial and boils down to a banal disassembly of the tool. Depending on the design of the jigsaw, you can access the element by unscrewing the front panel or the side panel, if the first is missing. The faulty rod is removed and a new one is installed in its place. When installing, pay attention to the moving metal parts located on the base of the rod. They must be positioned in such a way that they fit into the grooves of the upper fastening and the metal frame that serves as the base of the rod. The assembled structure must be generously lubricated with a thick lubricant such as litol-24.

A more visual demonstration of replacing the rod can be seen in the video below about repairing a fiolent jigsaw with your own hands.

Additional functions

To choose an electric jigsaw that has all the functions you need, but is not overloaded at your expense with unnecessary bells and whistles, you need to understand these functions.

Pendulum stroke

Currently, the pendulum stroke has become an attribute of even the most budget models. When this option is enabled, the blade begins to move not only up and down, but also back and forth. This speeds up cutting, but at the same time reduces the quality of the surface. The length of the pendulum stroke is adjusted by a switch located on the side wall of the device. It makes sense to enable the option for large volumes of sawing and disable it when performing a curved cut or one that requires special precision and quality of the cut surface.

Sole angle

If your budget allows, then it is better to choose a model that has this function. By turning the sole at a certain angle around the longitudinal axis, you can make a cut at an angle of 30, 45, 60 degrees. In professional models, these positions are not fixed, and the angle can be changed smoothly, focusing on the protractor.

Jigsaw with pendulum stroke and variable angle of inclination of the sole

On inexpensive models, the sole is fastened with a hex key, on more expensive ones - in a quick way, using a special clamping lever.

Smooth start

For a novice master who does not yet have much experience, it is better to choose a model that has the ability to start softly. It allows you to start cutting at minimum speed, gradually increasing it. This will allow you to accurately start the cut along the intended line, eliminating the blade falling off or moving to the side.

Maintaining speed under load

It is worth choosing an electric jigsaw with this function if you plan to do a large amount of work with hard wood or metal. The function protects the engine from overload by stabilizing the speed using an electronic circuit.

Chip blowing

This option should definitely be chosen by those who intend to do sawing. The chip blower system, using the air flow from the engine cooler fan, blows sawdust away from the work area, providing good visibility.

Backlight

Illumination of the work area will be very useful in low light conditions and in cramped conditions.

Laser pointer

It is reasonable to choose a device with a laser pointer when a large number of straight cuts are required.

This option allows you to save time on marking by marking only the start and end points of the cut on the workpiece, and guide the electric jigsaw along a laser-illuminated straight line.

Frequent malfunctions

For a conventional four-stroke, four-cylinder automobile engine, an inductive sensor is used. Before troubleshooting a jigsaw, you will need to arm yourself with instruments such as a multimeter and a probe.

This will make it even more straightforward. If we consider devices with control units, then the model will require a controller.

One of the main ones is the not so high accuracy of cutting samples if you work manually. Models with legs If necessary, you can make this jigsaw machine with your own hands.

The convenient thing is that, upon request, the machine, made in a short time, can quickly be disassembled, and you can use a manual jigsaw again. Such a device can easily cope with the processing of small workpieces, the thickness of which does not exceed 30 mm. This type of damage can be eliminated by disassembling the button and cleaning the contact.

If the cut needs to be made at an angle, the support sole is shifted by the required number of degrees.

The design of electric jigsaws and their malfunctions The design of jigsaws from different companies differs little. There are models that operate from portable chargers. How to use a jigsaw correctly

How to choose the right electric jigsaw

To choose the right jigsaw, you need to analyze all its characteristics together.

Speed adjustment as an aspect when choosing

The number of revolutions, which determines the stroke frequency of the rod, is set depending on the material of the workpiece. So, for wood you should choose the maximum number of revolutions in order to get an even and neat cut. For plastic and metal, on the contrary, it is minimal to avoid overheating of the blade and material, respectively.

Carving with an electric jigsaw

Adjusting the pendulum stroke

You should choose a model with a pendulum stroke if you have a large number of straight cuts to make. The pendulum stroke, or additionally the oscillation of the blade back and forth with a small amplitude, can significantly increase the cutting speed, while reducing the quality of the surface. True, it is now difficult to find a model without a pendulum stroke.

Replacing the file

The method of replacing the blade greatly influences the ease of working with an electric jigsaw, and if a large volume of various cuts is planned with frequent changes of material and cutting method, it directly affects productivity. For common European-style cartridges and saws with a cross-shaped file head, there are two ways to change the file:

- Screw clamp - the file is fixed in the chuck with a hexagon screw.

- Quick-release clamp - the file is fixed using a special lever that is pressed with your finger. Changing the blade occurs in a couple of seconds.

Cutting the workpiece at an angle; sole rotation function

Adjusting the angle of the sole also allows for two methods of fixation - with a hexagon screw or in a keyless way by pressing the lever.

The keyless method is much faster and more convenient, but requires careful checking of the quality of fixation in the selected position to avoid play and rattling during operation.

How does a jigsaw work?

Structurally, the device is made of a housing, inside of which electrical parts and moving mechanisms are located, and outside:

- file;

- controls;

- power cable;

- support sole;

- dust collector pipe;

- protective case.

Case and its contents

The jigsaw has a body made of durable plastic. It houses an electric motor with a brush-commutator mechanism, connected to the power supply via a cord with a switch. It has the same design as a regular electric drill.

The rotation of the rotor shaft is transmitted to the crank mechanism, in which, due to the movements of the balancer and the rod, a reciprocating motion is created for the cutting blade. It moves along guide rollers or support jaws.

The jigsaw is equipped with a cutting acceleration function in the horizontal plane using a pendulum mechanism. It additionally creates a slight displacement of the file along the axis of movement. This function speeds up sawing straight sections and improves their quality.

The jigsaw is made with a body handle, which can be made:

- mushroom-shaped form for curly cutting of surfaces with two hands;

- a bracket that allows you to work with one hand;

- combined design, which is rare.

Sole

There is a support platform at the bottom of the body. It is made by casting from a steel alloy or stamping. The second design option has less thickness and weight. Household tools are equipped with such parts.

Molded soles provide increased stability to the jigsaw. They are installed on a professional tool.

Due to the special locking mechanism, you can set the angle of the file relative to the base of the sole at a right or oblique angle, which is convenient for making perpendicular or oblique cuts.

Jigsaw file

Canvas shape

Depending on the material being processed: its thickness and strength, files from various alloys with a specialized tooth profile (pitch, setting, sharpening method) are selected.

Mounting lug configuration

It should be taken into account that each manufacturer uses a certain type of shank for its products. Sometimes, during factory research, he can change its shape to a more optimal one, as Bosch did by switching to a T-shaped profile.

Marking of files

For the convenience of jigsaw users, a notation system is used, consisting of a sequence of Latin letters with Arabic numerals.

General principle

An explanatory table will help you decipher the marking of any canvas, for example, T101AO.

| T (U, X) | XXX | A (B, C, D) | F (R, X, O, P) |

| Shank design type: T, X or U-shaped | Three numbers. For the home craftsman, the first one is important, indicating the working length of the file in mm: 1 - 75; 2 - 90; 3 - 150; 4 —>150. | One of the letters indicating the size of the teeth: A - smallest; D—maximum; V. C - intermediate between the two extremes. | A letter denoting the unique purpose of the material: F - durable bimetallic blade R - reverse tooth for processing layered products prone to delamination X - universal blades for cutting plastic, wood, metal O - making curved cuts with high precision of the vertical cut surface without distortions; R - blades of increased thickness, eliminating bending for precise cutting of inclined surfaces. |

Example entry: T101AO

File material

The jigsaw blade material marking is indicated in Latin letters near the shank.

| Web marking | Metal and processed materials |

| "HM/TC" | Made from hard alloys for cutting steel, ceramics, tiles, fiberglass |

| "HSS" | Hardened steel for cutting non-ferrous metals and soft alloys |

| "BIM" | Bimetals with strength and flexibility for versatile use |

| "HCS" | Carbon steels for general soft materials |

Features of wood files

Any jigsaw is designed for processing wood and materials made from it: plywood, fiberboard and chipboard sheets, MDF boards... Other functions are considered additional, secondary, and the home master may not use them.

Saw blades for wood processing can have different tooth sizes:

- fine allows you to make precise precise cuts of complex shapes without creating chips on laminated and painted surfaces;

- large - high-speed rough sawing of boards.

When choosing a blade for cutting wood and products made from it, start with simple, inexpensive samples that have universal properties. They need to be tested for cut quality. There is a high probability that it will be no worse than that of specialized files.

For example, the T101BR brand file, which has a reverse tooth direction, is designed to perform several types of cuts. One of them is laminate processing. However, such work requires skills, because reverse vibrations occur on the laminated surface. But the same cut can be obtained with blades with small teeth.

Features of metal files

All blades for this purpose have fine teeth and are made of high-strength alloys, designated by the letter “A”. As the hardness of the workpiece increases, the tooth size decreases.

The configuration of the cutting surface is created for sawing different materials:

- a flat edge is inherent in a universal-purpose blade used for cutting any metal;

- wavy - thin sheets of steel or non-ferrous metals.

Cutting aluminum is a specific task due to its softness and toughness. An ordinary blade does not cut it well: small teeth quickly become clogged. Files of the T224D series are produced for it, marked with the Alu index.

Particularly hard steels and materials are treated with diamond-coated blades. But they will have to cut slowly.

When cutting curly lines on thin sheets of metal, it is convenient to place plywood or fiberboard under them, which will provide the necessary rigidity of the surface being processed and will not allow it to deform.

How to choose an electric jigsaw with additional functions

There are several additional features that make the purchase more expensive, but certainly make it easier to interact with an electric jigsaw. Before choosing, the buyer should decide whether increased convenience is worth that kind of money in each specific case or not. These include:

- Vacuum cleaner connection (you should at least have a construction vacuum cleaner).

- Laser pointer (very helpful when making large volumes of straight cuts).

- Parallel guide (allows you to save on markings when cutting sheet materials).

- Circular guide (allows you to cut out perfect circles without marking).

In addition to convenience, the reason for choosing an electric jigsaw with one or another addition can be the large volume of work for which this addition is intended.

Safety precautions

Being even the most experienced craftsmen who have studied the tool inside and out, we, by chance, can be exposed to harmful influences during its operation. We are also talking about banal cuts, severed limbs, loss of vision, and less predictable effects associated with hearing loss and nervous system disorders with all that entails. It may seem that safety rules when working with a jigsaw are mostly needed by professionals who work with this device for several hours a day. We recommend that everyone try to follow the rules below at all times.

- Protective means. Safety glasses, gloves, respirator, earmuffs and a hat if the operator has long hair.

- Safety precautions with an electric jigsaw strictly prohibit using the tool while under the influence of alcohol or drugs, as well as under the influence of medications that affect attention and concentration. Stress or sleepiness can also cause injury.

- Before use, check the condition of the electric jigsaw. Make sure that there is no obvious damage to the cable or device body. Holding the jigsaw suspended, turn it on and press the start button to check the serviceability of the mechanism.

- When using an electric jigsaw, place your free hand to the side of the direction of the tool, but not in front of it. Do not point the jigsaw sideways or towards you. The movement of the tool during work should be directed only away from you. Make sure that the electrical cable does not get caught under the running saw blade.

- Upon completion of work, unplug the jigsaw, clean the body of sawdust and check for damage. Do not leave the tool on the floor, but put it in a dry and preferably ventilated place.

article from the Rating section

- 80

Power tools Carpentry tools (for wood) For working with metal Tools for ceramics

Save this page on your social media. network and return to it at any time.

ADD A COMMENT

By type of handle design

The consumer can choose between the two most common forms of handles:

- Staple-shaped. The convenient bracket-shaped handle is more widespread; it allows you to hold the electric jigsaw with one hand and control its position and direction of the cut.

- Mushroom-shaped, preferable for curved cutting and cutting inclined sheets and boards. You will have to hold the device with both hands.

Electric jigsaw with staple handle

Which jigsaw is better to choose, professional or household?

To answer the question: which jigsaw to choose, household or professional, the consumer should first of all evaluate:

- Scope of upcoming work.

- Their nomenclature.

- Materials.

- Affordable budget.

Household unit

It makes sense to choose a household appliance if there is a small amount of simple work to be done in a home workshop with a material of small thickness, for example, making a cabinet or shelf. A jigsaw for the home will not have a long service life and many additional functions, but it will be light, affordable and will not end up as a dead weight on the shelf.

Industrial

Industrial-grade devices are heavier, power-hungry, and bulkier. High performance, long service life and a large number of additional functions make them several times more expensive than household ones.

Stationary industrial jigsaw

Choosing such a device will make sense in case of commercial use or when building a large house with your own hands.

Power of household and industrial hand tools

The power of a household-grade device is from 300 to 700 watts, while industrial designs have a power of 500 to 1000 watts. It should be remembered that when cutting 1 linear meter, an industrial device will consume more electrical energy, in proportion to its superiority in power.

What actually affects the power of an electric jigsaw?

Engine power affects several parameters:

- The frequency of the rod movement and therefore the performance.

- Maximum cutting depth.

- For battery models - for the duration of operation without recharging: the greater the power, the faster the charge will be used up.

For all types of power supply, wattage affects power consumption - the higher the wattage, the higher the bill for the same amount of work.

How to use a sewing machine?

It's hard to believe, but it can also be converted into a jigsaw. How can this idea be brought to life?

- We remove the part that ensures weaving of threads (the lower part of the machine).

- We remove the cotter pin and drive shaft.

- We remove the upper part, which protects the mechanism from mechanical damage.

- We expand the part for the needle for the file.

- Let's modernize the file. The file should not be longer than the needle.

It allows you to create even the most complex patterns and turns. However, this design has its drawbacks:

- The leg may get tired from working with the pedal;

- Vibrations may occur that complicate work.

If it is not possible to purchase an expensive design, you can get by with small losses. A jigsaw - a machine made independently can be an excellent solution. The main thing is to follow the instructions exactly when working and conscientiously fasten all the elements together.

Consider a table base so that it becomes a reliable support for the mechanism

It is important that the table does not rock or vibrate when the mechanism is running.

The more static all elements are in the end, the easier it will be to work, avoiding unnecessary movements and mistakes. And mistakes in such a matter are most often not acceptable.

A homemade jigsaw machine with your own hands is not such a complicated story as it might seem at first. After studying the article, understanding the basic elements and how to create your own tool, you can get to work.

It is worth noting that very often such a homemade machine is much more convenient than a purchased one. This saves money, but most importantly, this table is personalized. It will perfectly suit your workplace, your height and weight.

Such a design will fully meet the objectives, because the most convenient mechanism can be created only by the person who will use it in the future. In addition, in case of minor breakdowns, it will be clear how to repair and what can be fixed.

For a purchased sample, you will have to look at the instructions and study forums in search of a specific model and its characteristics. Have fun creating, and let the new jigsaw give you confidence and the desire to start a new renovation!

Consumables and contents

The models offered on the market differ greatly in their configuration. Cheap ones, as a rule, only have the electric jigsaw itself and a warranty card. The more expensive ones include a starter set of saws, hex wrenches, a parallel guide and a well-printed user manual. For cordless models, a spare battery will be a big plus - if you buy it separately, it can cost up to half the price of the electric jigsaw itself.

Electric jigsaw complete set

The starter kit also sometimes includes oil for periodic lubrication. Any components and consumables sold as a set increase the price, but are noticeably cheaper than those purchased separately.