Recommendations for choosing a reciprocating saw blade

A reciprocating saw is a kind of combination of an electric jigsaw and a chain saw, occupying an intermediate position between them.

The reciprocating motion of the blade was taken from the jigsaw, and from the chain tools there was no need for a support platform. This allows you to perform tasks with an electric hacksaw in the most inconvenient areas. The tool is designed for cutting a wide range of materials:

- Wood of different densities (including fiberboard, chipboard and others).

- Various products made of steel and non-ferrous metals (pipes, angles, profiles).

- Concrete, ceramic and stone building elements (bricks, blocks, tiles, tiles).

Specifications

There is a large assortment of reciprocating saws on the market, and a small set of numerical values, called technical characteristics, helps you decide.

Power

. The main indicator not only of a reciprocating saw, but also of any equipment with an electric motor. The higher it is, the faster the material will be cut. However, as the power increases, the weight of the tool will also increase, which is not always convenient for the user who constantly holds it in his hands. Also, the power value affects the cost of the device. A side factor in power growth is vibration.

Before purchasing the most powerful reciprocating saw, you should weigh all its advantages and disadvantages. For household needs, a tool up to 1200 W is quite suitable. It is capable of penetrating metal and wood to an average depth of 13 cm and 30 cm, respectively.

Depth of cut.

Essentially, this is the same power indicator, but more understandable for the average user. This technical characteristic determines the maximum thickness of the workpiece that the tool can handle without getting stuck and causing overheating. Some owners put a fairly long blade on electric hacksaws with low power, however, this can cause damage to the device. The average cutting depth of a tree is 18 cm.

Blade stroke frequency

. If you plan to cut a very hard material, such as stone, a high speed is required. While for cutting trees, productivity depends only on power. Before deciding on this parameter, it is recommended to think about the area in which the tool will be used. This is due to the fact that the great capabilities of a reciprocating saw allow you to cut any material. It is optimal to purchase equipment with a frequency control.

Weight

.

If the equipment is intended to be used in conditions where it is impossible to grasp it with both hands, for example, when trimming vegetation in the garden, the large mass of the tool will significantly complicate the work. The priority of this value depends on the intended conditions of use of the tool. Pendulum stroke.

The principle of operation is similar to the operation of an electric jigsaw, when in addition to reciprocating movements, the blade also performs oscillatory movements. This allows you to increase the productivity of the equipment and increase the service life of the file. On models with this function implemented, there is a regulator with which you can determine the amplitude of movement. The harder the material you are working with, the smaller the step should be. If we talk about hard materials such as stone, it is recommended to turn off this function. It is also necessary to turn it off when cutting shapes. Quick-release fastening of the file. This is a tool feature designed to make the user's job much easier, as it shows whether it is possible to quickly change the cutting blade without using additional tools, such as a screwdriver.

Reciprocating saw models have a soft start feature. This does not affect operation in any way, however, with its help you can significantly increase the safety of the equipment and its service life. In the first case, when starting to work, there will be no sharp jerks that could tear the tool out of your hands. This option also increases the cost of the tool, so it is worth considering whether such a feature is needed or not.

The last thing worth mentioning regarding the characteristics of the tool is the presence or absence of a support shoe. This is a device on which you can rest the reciprocating saw if necessary. This function is often used when cutting shapes. In some cases the support shoe is fixed at a right angle, and in others it deviates significantly. Essentially, this feature expands the capabilities of the tool.

Characteristics of cordless reciprocating saws

The capabilities of saber autonomous devices are determined by the following characteristics:

Classism . There are household, semi-professional and professional saws. The best option for working in the garden and dacha are semi-professional models.

Engine power. The power of cordless saws depends on the engine voltage. The higher the voltage consumed, the more productive they are. In most cases, this figure is 20 V.

Battery type. There are 3 types of batteries: nickel-cadmium, nickel-metal hydride and lithium-ion. Lithium-ion (Li-Ion) batteries are the most popular. They are distinguished by their low weight, high capacity and minimal memory effect. They charge quickly and do not require a full discharge.

Depth of cut. Measured in millimeters, ranges from 30 to 300 mm. The higher this indicator, the thicker the workpiece the tool can saw through. The saw can cut through metal, wood and plastic. But manufacturers indicate the cutting depth for wood and metal. For example: Max. cutting depth (wood) - 255 mm, (steel) - 10 mm.

Stroke frequency. Measured in moves per minute. Displays the performance of the tool. The higher this indicator, the more productive the tool.

Blade replacement mechanism. It can be instrumental or keyless.

Instrumental replacement of the blade is carried out using a key, keyless - using a locking ring or a locking lever.

Review of electric saws. Jigsaws and reciprocating saws, electric hacksaws

Review of electric saws. Jigsaws and reciprocating saws, electric hacksawsEach type of power tool has its own scope of application. Their functions may partially complement and overlap each other, but to properly use an electric jigsaw, reciprocating saw and electric hacksaw, you need to know the features of each type of device.

Electric jigsaw

The main advantage of a jigsaw is the ability to make curved cuts. A jigsaw is needed when you need to cut out some shape more complex than a rectangle - a circle, a wave, an oval.

A jigsaw allows you to cut out the most intricate patterns. With its help, it is easy to make internal holes of various shapes in sheet material. To do this, just drill a starting hole in the desired place on the sheet, and then cut out any geometric shape according to the markings. To cut perfectly round shapes, most jigsaws include a special compass attachment.

The jigsaw works quite well with natural wood and artificial wood materials, it can cut non-ferrous metals, plastic and ceramic tiles. The jigsaw works great with modern sheet materials - drywall, laminated boards, clapboard, vinyl panels, MDF.

Sometimes you can hear that it can replace a circular saw in the household, but this is not true - a household jigsaw cannot cope with a large amount of work. However, there are a number of tasks that only a jigsaw can handle. For example, make window frames or curly shutters.

If you are serious about high-quality repairs and plan to install lining or laminate yourself, then you need to purchase a jigsaw - an easy-to-use and high-speed tool. Modern models of jigsaws can be operated with one hand.

Jigsaw Makita 4326

Device and principle of operation. The main working element of a jigsaw is a small file 50-120 mm long. During operation, it makes reciprocating movements vertically with an amplitude of 20-30 mm and a frequency of 500 to 3000 working cycles per minute. In this case, the thickness of the cut is approximately 1 mm.

The jigsaw blade is driven through a special gearbox by an electric motor. To make the cutting process efficient, most modern models are equipped with a pendulum mechanism. With its help, the file not only moves up and down, but also makes oscillatory movements back and forth according to the principle of a clock pendulum. This speeds up the sawing process and reduces the load on the engine.

When moving downward, the cutting blade is retracted from the material, and cutting is performed only when it moves upward, which makes the tool more productive and stable in operation. To obtain a clean and even cut, as well as when cutting fragile and hard materials, it is better to turn off the pendulum mechanism.

Since the cutting tool of a jigsaw is a file, it is also the main cost item when working with it. The range of saws for jigsaws is very diverse, and each of them has its own purpose. Files vary in shape, size, and sharpening. They are made from various materials and are designed for a specific class of tasks.

Jigsaw files

You should pay attention to the pitch of the saw teeth: for wood, a blade with a pitch of 2.5 to 4 mm is suitable, for metals and plastic - from 1 to 2 mm. To cut non-ferrous metals, you need saw blades with a wave-shaped cutting edge.

For working with glass and ceramic tiles, files with abrasive coating are used. Diamond-coated files have high performance, but they are quite expensive.

In order to guarantee high precision work, a base plate is attached to the jigsaw. It is also called the sole. Using a base plate frees the operator from having to hold the jigsaw suspended. Thanks to the sole, the distance to the surface being processed remains constant, which guarantees stable operation of the tool.

Jigsaw Bosch GST 75 BE

What should you pay attention to when choosing a jigsaw?

Power. The most important factor that determines the cutting speed of various materials and the maximum cutting depth. Most jigsaws have motor power in the range of 400-800 W. A jigsaw with a power of 400 W can cut a wooden sheet up to 50 mm thick, steel - up to 3 mm, non-ferrous metals - up to 8 mm. A jigsaw with a power of 800 W easily cuts wood up to 100 mm thick, steel sheet up to 7 mm, non-ferrous metal up to 20 mm.

Blade fastening mechanism. Saw blades are most often fixed using a quick-clamping device. The most common type of shank is a cross shape, developed by Bosch. It is recommended to buy a jigsaw for such files as the most common ones.

Sole. The convenience and accuracy of work largely depend on the quality of this part. The most preferred option is a cast sole. Although the use of modern stamped base plates made of durable material does not affect the quality of work.

Speed adjustment. A very popular feature if you plan to cut materials that differ in structure. Wood requires a maximum stroke rate, and metal requires a minimum.

Dust extraction system. It improves the quality of work because the cut line becomes visible. The amount of sawdust and dust in the workplace is reduced.

Reciprocating saw

The world's first reciprocating saw entered the market back in 1952. It was a simple electromechanical device. Over the course of sixty years, it has transformed into a modern, high-tech instrument. Reciprocating saws can cut almost all types of wood, plastic, drywall, aerated concrete, pipes, sheet metal and profiles with great success. This versatile tool is indispensable for precision cuts, for example when working with window frames.

A reciprocating saw is a power tool that is similar in many ways to a jigsaw. The cutting surface of the reciprocating saw also makes translational and pendulum movements. But, unlike a jigsaw, a saw is shaped like a large drill, which has a cutting blade installed instead of a drill.

Reciprocating saw Bosch GSA 1200

A reciprocating saw is much better at cutting any material than a hand saw. Modern models of electric saws allow you to make cuts not only in a straight line, but also along a curved line. This advantage makes it possible to cut out parts of complex shapes, but requires some preparation and a steady hand.

A reciprocating saw can be used as an alternative to a jigsaw or circular saw. It will not provide high cutting accuracy, but it is quite suitable for rough processing. A reciprocating saw can be used for work in the garden - it can easily cut down small branches, and you can use it to shape the crown of trees.

Characteristics of reciprocating saws. Like most jigsaws, reciprocating saws are equipped with a pendulum mechanism. The saw blade is automatically moved away from the cutting site, which reduces its heating, extends its service life and simplifies the removal of sawdust. The work requires less force, because you don’t have to press hard on the hacksaw, as in manual analogues.

The speed of the cutting blade is adjusted depending on the material being cut. Most manufacturers of power tools equip their equipment with special tables, with the help of which you can select the optimal speed.

Like all power tools, reciprocating saws are divided into household and professional models. Household saws are designed for light loads and small amounts of work - no more than 20 hours per month. Professional reciprocating saws have more power. They are made from durable materials. This tool can be used every day for 6-8 hours. It is necessary for people who are professionally engaged in construction. It is not worth buying such a tool for household use, since you will overpay, but will not get a noticeable difference in the quality of work.

Reciprocating saw AEG 413235

Reciprocating saws, like jigsaws, are equipped with a soleplate. It can be moved along the axis of the hacksaw in order to provide the required cutting length. It allows you to press the hacksaw against the material while working, which increases accuracy and quality, and also facilitates the cutting process.

Reciprocating saw blades range in size from 100 to 300 mm with a wide variety of teeth to cut a variety of materials. There are blades on the market for all materials: short and long, with fine and large teeth, as well as sprayed.

Household reciprocating saws can be equipped with several saw blades. As a rule, these are two sets consisting of three to four universal saws, suitable for rough and fine cutting of most building materials.

Carpentry electric hacksaw

An electric carpenter's saw (alligator saw, universal saw) is similar to an electric chain saw, which has a wide blade of a hand-held carpenter's saw instead of a bar with a chain. In fact, this is not a blade, it is a guide along which two narrow files move in opposite directions. It serves to fix the electric hacksaw at the cutting site. During operation, the blades move back and forth at a speed of up to 3000 movements per minute and with an amplitude of 30-50 mm. Two small files imitate the movements of a regular hacksaw.

Thanks to its design, the hacksaw cuts thick timber and chipboard very accurately and quickly, resulting in clean carpentry cuts. In terms of cutting accuracy, the “alligator” is superior to chain saws, but inferior to circular saws. But in terms of softness of cutting and safety, it has no equal.

Electric hacksaw Bosch GFZ 16-35 AC

An electric hacksaw can make cuts in already finished wooden and plasterboard walls. For example, cutting through a door or window opening. To perform this operation using a reciprocating saw, you first need to drill holes and then cut along them. In the case of the “alligator”, simply turn on the electric hacksaw and cut a passage in the wall.

Characteristics of a universal saw. The universal saws that exist today differ from each other in power and working length of the saw part. The longer the working part, the more convenient it is to cut logs of large diameters. Most “alligators” have adjustable blade speeds, which allows them to be adapted to work with wood of different hardnesses.

Cutting blades for electric hacksaws

Unlike a chain saw, the motor power of an electric hacksaw is much less - up to 1500 W. Low power allows you to power the universal saw from a low-power 2000 W generator. This will make it possible to work where previously only a chainsaw could do it.

The alligator's engine operates normally and is not overloaded, so the electric hacksaw can operate for a relatively long time and continuously.

The cutting speed can be adjusted very smoothly by pressing a key. This makes the tool much more accurate, which is important when building with calibrated parts.

The reciprocating saw provides a precise and straight cut that is very predictable. It will be slightly wider (due to the combined thickness of the guide and two files) than when using a hand saw, but it will be an order of magnitude more accurate and smoother than that of a chain saw.

If you have the skills to work with a chain saw, then learning how to work with an “alligator” will be easy. The saw is brought to the cutting site, “start” is smoothly pressed, and the blades begin to plunge into the material. The operator's task is to guide the saw by slightly rocking it up and down and moving it back and forth (to remove sawdust).

To increase the cutting speed and service life of the saw blades, we recommend that you lubricate the “alligator” more often and drip any machine oil into special holes on the guide bar every 15-20 minutes of operation. Electric hacksaw blades must be completely lubricated if you have not used the tool for more than two weeks.

Application area

The reciprocating saw is used in various fields, due to the possibility of using the tool for sawing the following materials:

- wood;

- ferrous and non-ferrous metals;

- stone;

- plastic.

Due to the fact that an electric saw is capable of cutting all types of materials, it has found its use not only in everyday life, but also in construction, especially in the construction of houses made of wood. It is also popular in gardening, electrical engineering (it can cut any cable diameter) and other industries. This hacksaw is actively revered by mechanics, joiners and carpenters. With its help, you can not only make straight cuts, but also curly ones with a complex curved shape.

An electric hacksaw can handle tasks that a jigsaw, circular saw or chainsaw cannot handle. A hand hacksaw requires a lot of time and effort to achieve results, a jigsaw can only cut blades of small thickness, a circular saw cannot be reached everywhere, and a chainsaw does not accept metal materials. All these factors are eliminated in the reciprocating saw, which will become an indispensable assistant not only for the builder, but also for the home craftsman.

It is important to know! The main advantage of a reciprocating saw is that it produces a precise and clean cut.

Reciprocating saw device

It is primarily necessary to note that electric saws are divided into two types: mains and battery-powered. Both the first and second types have their advantages and disadvantages. The main advantage of corded saws is their high power, while cordless hacksaws are mobile and can be used in the field. Battery powered hacksaw makes working with the tool easier.

Rating of the best cordless reciprocating saw models of 2021

Battery-powered units are in high demand due to their mobility. The rating of cordless reciprocating saws for the garden includes several models with an optimal balance of characteristics and price.

Black&Decker GKC108

The pendulum reciprocating saw is equipped with a 1.5 Ah battery. Equipped with an anti-vibration system and a lock against accidental activation, the blade can be replaced without the use of keys. Allows you to make cuts on wood and metal, the self-discharge period is 90 days.

The average cost of Black&Decker is 7,000 rubles

Bosch GSA 18 V-LI C Professional

One of the best battery devices weighs only 2.5 kg. The battery capacity is up to 5 Ah, a full charge is enough for approximately 100 cuts. The tool comes with 3 replaceable saber blades, has vibration protection and the option of locking the start button.

The average cost of Black&Decker is 7,000 rubles

AEG BUS 18-0

This powerful battery-powered tool is almost as good as corded models. Equipped with a pendulum stroke and backlight, the handle is rubberized, the start button can be fixed in one position. Allows you to quickly saw wood, plastic and thin metal; the blades in the tool are changed without the use of keys.

AEG BUS 18-0 - a saw with an average cost of 11,000 rubles

What can a reciprocating saw do?

Everything is the same as a hacksaw and even more:

- cut boards, beams, sheet materials (plywood, fiberboard, chipboard, OSB)

- cut branches of trees and bushes

- cut old boards even with nails

- cutting out shaped parts from plywood and thin boards

- cut steel pipes and angles without creating sparks

- saw off protruding excess boards, bricks, steel reinforcement

- make openings in wooden walls

- cut up frozen meat with bones

Moreover, for all this it is not at all necessary to fasten the material on a workbench. The reciprocating saw is perfectly suited for working “in weight” and the material can be cut directly on the spot in almost any position. It is a rare professional tool that will allow this.

At the same time, it is quite difficult to name a professional area in which a reciprocating saw will be a truly necessary tool. Perhaps, only during dismantling work it will be difficult to replace it with something else. But in everyday life it can turn out to be such a valuable assistant that soon after acquiring it you will be surprised how you ever managed without it. Even professionals who have their own workshop filled with all kinds of tools should not pass by a reciprocating saw: after all, everyday problems arise for professionals too. And by using a safe and convenient reciprocating saw in such cases, you can save a lot of time and effort.

What is a reciprocating saw used for?

A reciprocating hacksaw can replace several tools, and in some types of work it performs better than others. Here are some jobs in which it is very useful and convenient:

- Pruning branches . An electric hacksaw is much lighter and more compact than a chainsaw, so it is better suited for cutting small branches and trimming some bushes. You can also use a hacksaw to cut the trunk of a bush or tree almost to the root a couple of millimeters from the ground, which cannot be done with a chainsaw without catching the ground. It is often used by landscape designers. If you have to do seasonal pruning of fruit trees, then a reciprocating unit is the best option.

- Curly cut. An electric hacksaw, like a jigsaw, can be used to make shaped cutting in wood. However, a reciprocating hacksaw allows you to do this in hard-to-reach places, for example, cut grooves and niches, and create complex curved shapes.

- Angle cutting. Only a reciprocating saw (or an ordinary hacksaw) can do this work. Here the canvas can bend, so you can easily trim the old pipe flush with the wall or cut off an old rusty screw. You simply can’t get around with a grinder.

- Vertical and horizontal cutting. An electric hacksaw can make both horizontal and vertical cuts with high precision. Of course, in some cases you can also cut horizontally with a jigsaw, but the quality of the cut will be quite poor.

- Cutting multiple types of materials simultaneously. There are special blades that can cut several types of materials at the same time. For example, you can saw a wooden beam with nails or cut off an extra section of the roof, which consists of slate, roofing felt and a wooden gable. On a grinder, the circles would have to be constantly changed.

Tool selection criteria

When choosing a tool, the buyer must take into account the characteristics of the saw and his own requirements, i.e. why does he need it?

A reciprocating hacksaw must be made at a high level, carefully. The material from which the canvas is made must be of high quality, because... this affects how long the saw can run. The mechanism inserted into the hacksaw must also be of high quality.

When purchasing, it is important to pay attention to the characteristics of the tool, the manufacturer and the material used to create the saw.

Types of power saws

The heart of our device is the electric motor. It is installed in two positions: along and across. The former, due to their design features, lengthen the electric saw. An engine located transversely, firstly, makes the device wider, and secondly, heavier. This is due to the inclusion of a gearbox in the design.

Electric saws are divided into:

- chain;

- disk;

- saber

Chain ones are those whose working part is a chain with cutting elements. The edges of the chain are connected to form a ring. The cutting process occurs due to the rotation of the cutting element along the body along a guide (the so-called “tire”).

Before choosing a chain for an electric saw, you need to pay attention to its profile. Low profile chains have lower productivity than higher profile cutting tools. But the vibration in this case is lower, which means high operational safety. A video about choosing a chain saw will help you pay attention to the most important points:

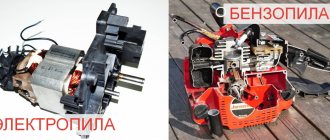

chain saw vs reciprocating saw. who is better?

Replaceable discs are used as the cutting element of the circular saw. They can be of different diameters and are designed for different materials.

If cutting with discs involves working with metal and stone, it is better to choose a tool with a cutting depth of 100 to 130 mm. The inconvenience is that such a tool weighs from 10 kg. Therefore, when choosing an electric saw, you need to look for a model with the possibility of permanent installation.

Reciprocating saws are also called electric hacksaws. They are very similar to chain tools. The difference is the installation of flat panels in such products. They move back and forth, resulting in cutting. The speed of the cutting part can reach 3 thousand movements per minute. This parameter will be one of the important ones when choosing a reciprocating electric saw. The tool is quite effective because its cost is high:

Types of electric hacksaws

Many people ask the question, what is the difference between an electric hacksaw and a reciprocating saw? There are no differences, because these are the names of the same instrument. According to the principle of operation, it is a familiar hand hacksaw or jigsaw, but with an improved design and a built-in motor that ensures fast and less labor-intensive work.

The reciprocating electric hacksaw is classified according to several criteria. The first of these is the power source, depending on the type of which the instrument is divided into two categories:

Network

– electric hacksaws are equipped with a cable powered from the mains. This device is powerful and versatile. It is usually used for domestic work indoors. Allows you to saw wood, metal and other materials. The only drawback is the dependence on the electrical outlet, but manufacturers solve the problem with an extended cable, sometimes reaching a length of up to 5 meters.

Rechargeable

– the most mobile devices for garden manipulations and in the forest. Used in conditions where there is no access to a mains power source. The disadvantages of such equipment are the short battery charging time, high cost and insufficient power for serious work. Approximate service life is about five years.

Operating principle of an electric hacksaw

A reciprocating saw (or electric hacksaw) refers to electric sawing and cutting tools. The operating principle of an electric hacksaw is quite simple and is based on the reciprocating movements of the saw blade. In essence, it is similar to the work of a regular hand hacksaw. An electric motor, used instead of muscular traction, makes cutting material much faster and easier.

The rotating rotor of the electric motor drives the gears. The gearbox helps reduce rotation speed and turns it into reciprocating motion. Thus, the frequency of movement of the saw blade is up to 3000 rpm. This is quite enough to cut even a metal structure.

Many models of electric hacksaws have a pendulum mechanism that slightly raises the blade during the reverse movement. This design solution helps to avoid overheating of the sawn material and blade, extend the service life of the blade, get rid of scale, reduce the amount of sawdust, shavings and dust, and, most importantly, significantly increase the speed of work.

The pendulum mechanism is used when working with wood, since in this mode the electric reciprocating saw literally bites into the material itself and sawing occurs much faster. True, a significant difference in time is noticeable only with a large volume of work. When used for domestic purposes, when you just need to quickly cut something, the difference will not be felt so clearly. When using a pendulum stroke, the cut is quite rough. Therefore, if you need to get a more accurate cut, this mode must be disabled. It also turns off during curved cuts. But even with the pendulum mechanism disabled, it is difficult to achieve particular accuracy. Moreover, doing figure cutting using an electric hacksaw is not the best idea: the result will most likely disappoint.

Different cutting tasks require an appropriate approach, but in general, to start cutting material, you must first turn on the electric hacksaw and then bring it to the workpiece. To avoid excessive vibration and shock from the equipment, the guide movable shoe must rest against the workpiece being cut. To understand how an electric reciprocating saw works correctly, a video with detailed instructions is quite enough.

No special skills are required to operate an electric hacksaw. After a couple of hours of training, even a beginner will learn to use the instrument quite well. Of course, basic safety precautions must be observed. In addition, all particularly important points must be indicated in the instructions for the instrument.

The main advantages and disadvantages of the Makita reciprocating saw

Advantages of the saw:

- Most models have a keyless saw blade;

- Availability of LED illumination of the working area;

- Use of new technologies in the production of the reciprocating saw engine and gearbox;

- Ergonomic body and light weight;

- Environmental friendliness and autonomy (battery models).

Flaws:

- Expensive original spare parts;

- Counterfeits of original Makita products have appeared on the market.

Using Guides

During the work process, it is not always possible to maintain perfect accuracy when making a cut. There are cases when the edges of the cut turn out to be split due to the sharp approach of the cutting blade to the workpiece. Going beyond the marking line and not observing the angle also happen quite often.

To avoid this kind of defects, you can use guides. These devices, as a rule, are not included in the equipment supply, as they are professional.