The main purpose of an air compressor is to compress gas and continuously supply a stream of air under pressure to pneumatic equipment and pneumatic tools. This air is an energy carrier and ensures the operation of spray guns, airbrushes, impact wrenches, and a tire inflation gun.

air compressor

The listed pneumatic tools are safer to use than power tools, for example. Pneumatic equipment cannot have a short circuit that could lead to electric shock and fire. That is why such a tool is widely used in auto repair shops or when repairing a car with your own hands.

An air compressor is used in households and when it stops working, there is a need for repair. However, repairing compressors is not particularly difficult; it can be done independently.

Purpose, main elements and principle of operation

The main purpose of air compressor units is to create a continuous, uniform stream of compressed air. The flow of dense gas is subsequently driven by various pneumatic tools.

These can be airbrushes, tire inflation guns, impact wrenches, cutting machines, pneumatic chisels, nailers, etc. In the minimum configuration, the compressor unit is equipped with a supercharger (an engine that creates an air flow) and a receiver (a container for storing compressed gas).

Useful! Compressors with an electric motor of a piston system are most widely used in auto repair shops. In the supercharger crankcase, a transfer rod moves along the axis back and forth, imparting an oscillatory moment to the reciprocating movement of the piston with sealing rings.

The bypass valve system located in the cylinder head works in such a way that when the piston moves downwards, air is taken from the inlet pipe, and upwards - it returns to the outlet.

The gas flow is directed to the receiver, where it is compressed. Due to its design, the supercharger produces an uneven stream of air. Which is not applicable for using a spray gun. A kind of capacitor (receiver) saves the situation, which smoothes out pressure pulsations, producing a uniform flow at the output.

A more complex design of a compressor unit involves attaching additional equipment designed to provide automatic operation, dehumidification and humidification. And if in the case of a simple design it is easy to localize a fault, then the complication of the equipment design makes the search difficult.

The following are the most common malfunctions and methods for eliminating them for the most common compressed gas supply systems with a piston-type supercharger.

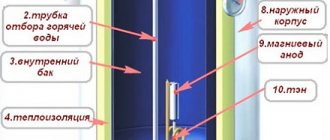

Air compressor device

To understand compressor problems, you need to clearly understand what elements it consists of and what they are intended for. A compressor, in its minimum configuration, consists of a supercharger (an engine that creates air flow) and a receiver - a container that contains compressed air. Piston compressors are most often used.

One of the main requirements for a compressor is its safety. If the pressure in the receiver is not controlled, the compressor will burn out. There is a high probability that the receiver cylinder may explode. To prevent this, the receiver is equipped with an electronic relay that automatically turns off the compressor when the air pressure reaches a certain value.

compressor device

The air compressor is equipped with a pressure gauge that shows the amount of air pressure in the cylinder. To protect the compressor from negative influences, a check valve is used. Its main function is to prevent air from returning back to the compressor when turning off or otherwise interfering with the operation of the unit.

More complex compressor designs are characterized by the presence of additional equipment, such as automation for the compressor. Typically in small compressors, the automation unit maintains pressure up to eight atmospheres using a pressure switch, turning on or off the power to the electric motor when the minimum or maximum pressure in the receiver is reached.

In this case, there are two pressure gauges: the large one shows the pressure in the receiver cylinder, the small one at the outlet. The pressure switch can be equipped with a relief valve. When the unit stops, it will be open, which makes it easier to start the engine later.

Some models have a cooling radiator on the air supply pipes from the compressor to the receiver.

Air cooling contributes to less condensation formation in the receiver. This little detail in the design extends the service life of the automation.

The presence of a drain valve allows you to quickly drain the condensate from the receiver, because it is advisable to end each session of operation of the unit with this operation.

The safety valve releases the increased pressure in the receiver if for some reason the automation does not work, which protects the compressor motor from overload.

The air filter protects the piston system from sand, dirt, and paint fumes.

The following types of compressors are distinguished:

- Volumetric action - holds gas or air in a confined space, increasing pressure. Among them are:

- rotary, the principle of operation is suction and compression of gas when the plates rotate; the working volume decreases, this leads to an increase in pressure.

- piston - pressure is created by the movement of pistons and valves; reliable in operation, but noisier than rotary ones.

- Dynamic - provide compression by increasing the speed of gas movement, increasing its kinetic energy, which is converted into compression energy. There are:

- centrifugal - used for air exchange in mines;

- axial or axial.

Let's consider how a piston-type compressor works; the air or gas in it is compressed by a piston that moves along the cylinder:

- As the piston (3) moves up the compressor cylinder (4), the working gas is compressed. The electric motor moves the piston through the crankshaft (6) and connecting rod (5).

- The suction and exhaust valves are opened and closed by gas pressure.

- The left diagram shows the gas suction phase into the compressor. When the piston moves downward, a vacuum is created in the compressor and the inlet valve (12) opens. Thus, gas enters the compressor space.

- The right diagram shows the gas compression phase. The piston rises and the outlet valve (1) opens. Gas leaves the compressor under high pressure.

operation scheme

The blower itself produces an uneven stream of air, which cannot be used, for example, for using a spray gun. The receiver saves the situation by smoothing out pressure pulsations.

Having replenished the stock of information about the compressor installation, you can repair the compressor yourself. The following compressor unit malfunctions are distinguished:

- The compressor unit's supercharger does not start.

- The thermal protection circuit breaker trips from time to time.

- When the compressor starts, the thermal protection circuit breaker trips and blows the fuse.

- The unit’s engine runs, but does not pump air into the receiver or does so slowly.

- When the supercharger is turned off, the pressure in the receiver drops.

- High moisture content in the outlet air stream.

- Strong engine vibration.

- The compressor unit operates intermittently.

- The air flow is below normal.

Compressor installation defects

To make it easier to find the problem, all defects can be classified according to the nature of the malfunction:

- the compressor unit's supercharger does not start;

- the compressor motor hums, but does not pump air or fills the receiver too slowly;

- upon startup, the thermal protection circuit breaker is triggered or the mains fuse is knocked out;

- when the supercharger is turned off, the pressure in the compressed air container drops;

- The thermal protection circuit breaker is periodically triggered;

- the output air flow contains a large amount of moisture;

- the engine vibrates strongly;

- the compressor operates intermittently;

- the air flow is consumed below normal.

Let's look at all the causes of problems and how to fix them.

System supercharger does not start

If the engine does not start and does not hum, it means that there is no supply voltage supplied to it. First of all, you should use an indicator screwdriver to check the presence of “zero” and “phase”, as well as the reliability of the connection between the plug and the socket. If there is poor contact, measures are taken to ensure a tighter fit. If there is 220 V at the input of the circuit, the fuses of the compressor unit are looked at.

Failed ones are replaced with passive protection devices of the same rating as the defective ones. Under no circumstances are hot-melt inserts designed for higher electric currents allowed. If the fuse blows again, you should find out the cause of the failure - there is probably a short circuit at the input of the circuit.

Information! The second reason why the unit does not start is that the pressure control relay in the receiver is faulty or the level settings are lost.

To check, gas is released from the cylinder and the supercharger is started for a test. If the engine is running, the relay is reconfigured. Otherwise, the faulty part is replaced.

Also, the engine will not start when the thermal overload circuit breaker trips. This device turns off the power supply circuit of the electrical device winding in the event of overheating of the piston system, which can cause the engine to jam.

Useful! Allow the blower to cool for at least 15 minutes. After this time has passed, restart.

The temperature sensor does not work

It is either broken, in which case you need to call a repairman, or a layer of ice has built up on it. You can remove the ice yourself by defrosting the refrigerator. In modern refrigerators, the temperature sensor is a sensor device; in older models, it is an electromechanical thermostat. But the operating principle is similar. To restore the functionality of the mechanism, it needs to be provided with optimal external operating conditions.

The simplest reason regarding the temperature sensor is that you yourself set the wrong (low) relay response level, and the refrigerator stopped turning off. Check the electronic and mechanical settings of the device.

In modern models, the level of sensor response is displayed on the display in the form of temperature readings (they can be changed using buttons on the display). In older devices, the temperature limit is set by turning the control knob to a certain point.

Error due to ignorance:

The inverter-type compressor is always on, but it operates under different conditions with automatic power changes, so when the intensity of cold production is increased, it can make noise, and you may find it strange why the refrigerator runs for a long time and does not turn off.

We repeat - such a unit always works. Vibrations and extraneous sounds appear from friction of poorly secured elements and assemblies. Therefore, it is worth checking all mechanical connections. We wrote more about extraneous noise in the article 30+ reasons: Why does the refrigerator make strange sounds, how to fix the problem.

The engine hums, but does not work or produces low speeds

When the mains voltage is too low, the electric motor cannot cope with the rotation of the axis, and it will hum. In case of this malfunction, first of all, we check the voltage level in the network using a multimeter (it must be at least 220 V).

If the voltage is normal, then the pressure in the receiver is probably too high and the piston cannot push the air through. In this case, manufacturers recommend setting the automatic “AUTO-OFF” switch to the “OFF” position for 15 seconds, and then moving it to the “AUTO” position.

If this does not help, then the pressure control relay in the receiver is faulty or the bypass (control) valve is clogged.

Expert opinion

Ilya Vyacheslavovich

Consultant for body repair at krasymavto.ru

Ask a Question

You can try to eliminate the last drawback by removing the cylinder head and cleaning the channels. Replace the faulty relay or send it to a specialized center for repair.

How to change the pressure gauge in a compressor

Replacing the pressure gauge on a car compressor will be necessary if it fails. This measuring device can be installed separately from the unit, on a hose, or on the cylinder head.

If the pressure gauge shows incorrect values or does not work at all, you should unscrew it and buy a similar one, with the appropriate thread and scale.

Advice! In order not to make a mistake when buying a new pressure gauge, it is recommended to take it with you and ask the seller to select an analogue.

In some cases, choosing the right device can be difficult. The way out of this situation is simple: purchase a pressure gauge for a car compressor and a tee with a thread suitable for it. Attach a pressure gauge with a tee to the end of the hose, as shown in the following photos.

Advice! It is recommended to purchase a pressure gauge with a valve installed on it. It will be useful if the tire pressure is exceeded. To bleed a little air from the wheel, you just need to press the pressure gauge button.

When the supply voltage is turned off, the air pressure in the receiver drops

A drop in compressed air pressure indicates that there is a leak somewhere in the system. Risk areas include: high pressure air line, piston head check valve or receiver outlet valve. We check the entire pipeline with a soap solution for air leaks. We wrap any detected defects with sealing tape.

The drain valve may leak if it is not tightly closed or faulty. If it is closed all the way, and the soap solution on the spout is bubbling, then we change this part. When screwing in a new one, do not forget to wrap the fum tape around the thread.

If the air line and outlet valve are tight, we conclude that the compressor control valve is not operating correctly. To carry out further work, be sure to bleed all compressed air from the receiver! Next, we continue repairing the compressor with our own hands, disassembling the cylinder head.

Expert opinion

Ilya Vyacheslavovich

Consultant for body repair at krasymavto.ru

Ask a Question

If there is contamination or mechanical damage to the bypass valve, we clean it and try to correct the defects. If the malfunction is not eliminated, then replace the control valve.

Regular activation of automatic thermal protection

This defect is observed when the power supply voltage is too low, poor air flow or elevated room temperature. We measure the voltage in the network using a multimeter; it must be no less than the lower limit of the range recommended . The filter should be replaced or washed according to the unit's maintenance manual.

Interesting! The piston engine is air-cooled and often overheats when placed in a poorly ventilated area. The problem is solved by moving the compressor unit to a room with good ventilation.

The gas outlet stream contains a lot of moisture

This situation occurs under the following conditions:

- large accumulation of moisture in the receiver;

- the air intake filter is dirty;

- the humidity in the compressor unit room is increased.

Moisture in the output stream of compressed air is combated using the following methods:

- Regularly drain excess liquid from the cylinder;

- clean or replace the filter element;

- move the compressor unit to a room with drier air or install additional filter-moisture separators.

In general, piston engines are characterized by high vibration. But, if a previously relatively quiet compressor unit begins to rumble, there is a high probability that the engine mounting screws have become loose or the material of the vibration pads has become severely worn out.

Important! This malfunction can be eliminated by pulling all the fasteners in a circle and replacing the polymer vibration isolators.

Operating principle of the air conditioner

Air conditioners are divided into budget and expensive, even based on the principle of operation. Cheap devices require more careful handling and compliance with all operating rules. Their electronic control unit has no protection against misuse, so they are easy to break. It doesn’t matter whether an expensive or cheap model is installed in an apartment - repairing the compressor will cost half the cost of the unit itself.

Expensive air conditioners are not so easy to destroy because they refuse to start unless the conditions for normal operation are met. At this moment, distrust of expensive equipment arises, but in this way it protects users from unnecessary costs for spare parts.

The design of expensive and cheap cooling devices is not much different:

- The compressor forces freon to move around in a circle in the system.

- The heat exchanger located in the external block cools the liquid.

- The heat exchanger in the indoor unit evaporates the refrigerant and converts it from liquid to gaseous form.

- The fan blows air over the heat exchangers of the external and internal blocks.

The general principle of air conditioning is the intake of warm air, cooling it inside the unit and delivering it back to the room. Coolant circulates under pressure through a copper pipeline.

Compressor runs intermittently

Interruptions in engine operation can be caused by incorrect operation of the pressure control relay or too intense compressed air intake.

Excessive gas consumption occurs due to a mismatch between the compressor performance and power consumption. Therefore, before buying a new pneumatic tool, carefully study its characteristics and air consumption per unit of time.

Expert opinion

Ilya Vyacheslavovich

Consultant for body repair at krasymavto.ru

Ask a Question

Consumers should not take more than 70% of the compressor power. If the power of the supercharger exceeds the demands of pneumatic tools by a margin, then the pressure switch is faulty. We either repair it or replace it with a new one.

Air flow is not normal

This malfunction occurs as a result of a gas leak in the high pressure system or a clogged air intake filter. Air leakage can be eliminated by pulling all butt joints and wrapping them with sealing tape.

Sometimes it happens that when draining condensate from the receiver, they forget to completely close the outlet valve, which also leads to a gas leak. This problem can be easily solved by tightly closing the valve. If the dust filter is clogged, clean it, or better yet, replace it with a new one.

Most of the above malfunctions can be avoided by correctly performing the first start-up and running-in of the mechanisms, as well as by performing regular maintenance.

Timely maintenance guarantees the performance of the unit

In order for the device to function properly over a long period of time, the recommended maintenance should begin during the initial stages of operation. Experts recommend the following actions from the moment of purchase:

- When opening the transport package, the presence of the installation passport, technical documentation and compliance with the factory inventory of components is checked.

- Before the first start of the engine, the oil level is checked using the dipstick and, if necessary, topped up to the recommended level. The oil should be filled as recommended by the manufacturer and specified in the technical documentation. To ensure better spreading of the lubricant and check proper operation, let the compressor run for 10 minutes at idle speed.

- If there are no comments, a pneumatic tool is connected to the compressor unit and work begins. Note: It is not advisable to supply power to the supercharger if there is excess pressure in the receiver.

- Try to keep track of the operating time of the compressor and change the oil with new oil after 500 hours of operation. To do this, the crankcase flange cover is removed, the waste is drained and the accumulated contaminants are cleaned. Only after this fresh lubricant is poured in.

- Clean the air inlet filter weekly.

- After 16 hours of operation, the moisture is drained from the receiver using the outlet valve. Manufacturers also recommend cleaning the inner surface of the cylinder every six months using special products.

- At the end of the work, the compressor unit is disconnected from the supply network, and the air is bleed from the high pressure system.

- If the blower has not been used for a long time, the air valve contact pads must be cleaned and lubricated before starting.

- Non-current-carrying metal parts must be grounded. As a rule, manufacturers lead the grounding conductor into the Euro plug. And you only need to ground the corresponding contact in the socket into which the compressor unit is connected.

Timely compliance with these simple requirements will allow you to keep the mechanism in good condition. Such a labor-intensive procedure as repairing a compressor with your own hands will be required extremely rarely.

Information! Proper grounding will avoid problems with the electrical part of the device. Regular replacement of oil and cleaning filters will prevent premature wear of rubbing parts.

Air conditioning compressor failure

Problems with the air conditioning compressor begin when the filter, the purpose of which is to protect the internal parts, becomes clogged. If this is not done, dust clogs the small cells so much that air stops circulating. The compressor may overheat and the pipeline may freeze. When turned off, the ice melts and water drips. The filter needs to be cleaned urgently before the evaporator becomes dirty. This is done with warm water and detergent, the part is dried and inserted back.

Filters in home air conditioners are cleaned once every two weeks and more often if the equipment is located in the kitchen, where there is evaporation in the form of grease.

Coolant leaks cause the compressor to overheat. The problem can be detected by inspection:

- ice is visible on the fitting connections;

- The operation of the compressor is disrupted - it cools the room much weaker than usual.

If the air conditioning compressor does not turn on, the cause may be damage to the windings and cables. The resistance should be checked. This requires a special tool, but it is better to invite a specialist who will immediately replace the wire.

The air conditioner may not turn on if the outdoor unit is clogged with dirt. The same thing happens when the fan is blocked by debris or branches.

Compressor sounds

If the compressor does not turn on, then first of all listen to it; Depending on whether it makes any sounds or not, equipment breakdowns are determined. Can't hear the buzz? So this is due to the following reasons:

- The compressor starts operating after a short delay, after 3–5 minutes.

- If the temperature set on the remote control does not match the surrounding atmosphere in the room. In this case, you need to set the indicator lower than the room temperature. It happens that the compressor does not start if the ambient temperature is lower than the operation of the equipment in cooling mode. As a rule, this parameter is within 16 degrees.

- For faulty thermistors. To eliminate the breakdown, you need to inspect all the parts and the control board.

- Compressor protection is triggered. It turns on due to incorrect phase connection or voltage surges.