Dear visitors!!!

In this topic, you will become familiar with the electric ignition device for gas stoves, their electrical circuits, and how to diagnose the electric ignition if it malfunctions.

The electric ignition unit for a gas stove consists of the following elements:

- diode;

- resistor;

- capacitor;

- thyristor;

- triac;

- transformer;

- closing contact of the push-button station \switch\;

- electric spark plug.

The principle of operation of the piezoelectric element

The electric ignition function is used only on gas stoves, allowing blue fuel to be ignited automatically, thereby eliminating the need for the user to come into contact with an open flame.

This seemingly convenient piezo ignition function is considered one of the most capricious and unreliable devices of a modern gas stove.

If a malfunction is detected, you should not try to turn on the system with the burners removed, as this may cause a breakdown on the housing

The electric ignition system is equipped with special piezoelements, which, when turning the switch on the control panel, produce a spark to ignite the gas flow.

If we consider the principle of operation of piezo ignition of a gas stove in more detail, it looks like this:

- when you turn the switch of a certain burner, voltage is applied to the capacitor area;

- then the capacitor begins charging, after which the level on the thyristor increases;

- as soon as the level reaches the set limit, the capacitor begins to discharge;

- the resulting voltage activates the spark gap, and as a result, a spark ignites the gas.

The process of igniting gas by turning on the electric ignition takes a matter of seconds, while in new models of stoves the spark always hits the area of the switched-on burner. The piezo ignition device operates from an electrical network with a voltage of 220 volts.

Often, a breakdown of the electric ignition system of a gas stove occurs as a result of a sharp jump in voltage, which may require repairing the device and replacing failed parts.

Types of electric ignition

Electric ignition of a gas stove is a function that is present in most modern models of household appliances. Its task is to light the burners without the use of additional means : matches, lighters.

Reference . Electric ignition allows you to safely ignite gas and protect the user from possible burns and other injuries.

There are two types of electric ignition:

- Mechanical (semi-automatic). It is implemented by turning the gas supply knob on the panel and pressing the special electric ignition button at the right time. When pressed, a spark is supplied to the burners and the gas on the burner is ignited.

- Automatic . This happens by lightly pressing and turning the knob on the panel that supplies gas to the burner. That is, gas is supplied and a spark occurs at the same time. Moreover, the spark is multiple, in contrast to the mechanical push-button ignition option. Operation is indicated by clicks when pressing and turning the knob.

The main difference between these two electric ignition systems is the degree of human participation at the moment of closing the mechanism chain.

The main advantages and features of stoves with electric ignition

Advantages of kitchen gas stoves with electric ignition system:

- protecting the user from possible burns when gas ignites;

- no need to purchase matches and lighters;

- simplifying the ignition process and speeding up cooking;

- ease of control of the device with electric ignition.

The system has only one drawback : if there is a power outage, the user will not be able to light the gas, since the mechanism does not work without power supply. Therefore, you should always have a box of matches hidden at home in reserve.

Reference . The presence of the electric ignition function does not change the essence of the operation of the gas device and has almost no effect on its final cost. But it makes using technology more convenient.

Electrically ignited stoves have minimal differences from other models of gas devices:

- electric ignition button with a spark drawn next to it - mechanical system;

- handles that supply not only gas, but also a spark - automatic ignition;

- white ceramic candles built into each burner;

- a power cable 1.5-2 m long, which comes out of the back wall of the device.

The mechanism itself is located inside the plate body and remains invisible to the user.

There is no spark on any of the stove burners

Have you noticed that the electric ignition does not click and a spark does not appear on any of the burners? Check first:

- Is the gas stove plugged in? Perhaps one of the household members disconnected the device from the power supply.

- Are the socket, plug and power cord working? If there are visible signs of damage to the integrity, we recommend turning off the power to the apartment, unplugging the plug from the socket and calling an electrician to fix the problem.

If the stove is plugged in, visually everything is fine with the socket, plug and cord - most likely there is a breakdown in the auto-ignition system. Here are the most common malfunctions in which the electric ignition does not work on any burner of the stove or hob.

| Signs | Breaking | Repair or replacement |

| No spark on all burners. | Broken ignition unit. Most often, a capacitor fails, which discharges when the button is pressed and produces a spark. | The ignition unit needs to be replaced. |

| On a gas stove with a separate ignition button for all burners, there is no spark on any of the burners, and the automatic ignition button may be pressed in a strange way (more tightly or weakly, not as usual). | Malfunction of the auto-ignition button (in models with one button for all burners, such an ignition device is typical for budget stoves Gefest, Darin, Hansa, etc.). The contacts do not close due to oxidation or mechanical damage to the button, so the electric ignition does not work. Mechanical damage to the button usually occurs due to prolonged careless use. | The contacts need to be cleaned or the button replaced (in case of mechanical damage). |

Symptoms of a problem

Gas stove specialists, based on the collected statistics, have compiled an approximate register of common failures.

- When you press the burner control knob or a special separate button, electric ignition does not occur.

- The automation of the product in a gas stove works constantly, clicks are heard, but there is no spark - the gas does not ignite.

- After releasing the button or knob, the system does not turn off.

- The device constantly continues to fire, even when the button is not pressed.

- The circuit breaker in the apartment panel knocks out when starting up.

- The piezo ignition or electric ignition circuit of the stove is closed.

DIY repair

You can only repair the burners and oven door yourself. In case of more serious breakdowns, you will need to involve a third-party technician who has appropriate access to work with such equipment.

For self-repair you will need:

- Phillips and straight screwdrivers;

- pliers;

- adjustable wrench 15-20 millimeters;

- gas lubrication;

- FUM tape for gas equipment.

Depending on the cause of the problem, a cleaning agent and a soft brush may be required.

What to do if the electric ignition fails

Problems with electric ignition mainly arise due to a short circuit caused by leaking water. To eliminate this malfunction, you will need to clean and dry the wires laid from the generator unit (located at the end of the stove, under the hob) to the burners. Next, these parts need to be placed on plastic stands. Also, electric ignition fails due to grease deposits accumulated on the candles. To fix this problem you will need:

- disconnect the wire from the candle installed on the burner;

- remove the fixing plate and remove the spark plug;

- Wash the candle in a strong detergent solution, dry it and return it to its place.

These two reasons for the failure of electric ignition can be eliminated independently.

How to repair an oven door

It is necessary to repair the oven door when this element does not fit tightly to the body of the appliance. Such problems occur for two reasons:

- fastening elements have become loose;

- The sealing gasket has become unusable.

If the reason for the door not fitting tightly is due to loose fasteners, then the latter need to be tightened. A leaky gasket should be replaced with a new one.

How to adjust the gas supply

This procedure must be carried out if the flame disappears or burns intermittently. In this case, you will need to turn off the valve through which the gas is supplied and remove the partition. Next you need to find out which damper has failed. After this, you should unscrew the set screw that locks the plate.

How to replace injectors

Over time, the nozzles on gas stoves become clogged, causing the flame to burn unevenly. To fix this problem, you will need to disassemble the burner and clean it with a wooden toothpick from traces of soot and other particles. If the burner stops working, the part must be removed and replaced with a new one. To do this, you will need to unscrew the screws that secure the element to the hob.

Safety precautions when lighting the oven

Regardless of whose manufacturer your oven is, its operation requires compliance with certain safety measures. These include:

- Constant supervision of long-term operating devices;

- Restricting access to the switched-on device for children;

- Regular cleaning after completion of its operation and complete cooling, with preliminary disconnection from the network;

- Use for cleaning only products specifically intended for this purpose;

- Carrying out the cooling process of the device only with the door closed;

- A complete ban on placing and storing flammable substances near the oven;

- Use the device only in accordance with its intended purpose;

- A complete ban on self-repairs, with mandatory contact with a specialist for these purposes.

Following these simple rules can significantly reduce the likelihood of injury when using your oven and significantly extend its service life.

Next, let's look at the basic rules for safely igniting the oven:

- Before turning on a gas oven, always ventilate it to free the space from possible gas accumulation.

- Inspect the hoses, periodically check the tightness of their connections, and if necessary, replace the worn one with a new one.

- Make sure the oven burner is fully ignited. If any section does not burn, turn off the gas supply, ventilate the cabinet and relight the flame.

- Never leave a working oven unattended, and remember to check for flames through the cabinet door window.

- Never use the oven while it is on as a heating source. You cannot heat the kitchen using air heated by a burner.

- Thoroughly clean all surfaces inside the oven after each cooking. Grease deposits and other contaminants can clog the igniter holes or the burner itself, which will cause the flame to burn unevenly or be completely absent during subsequent operation.

The smell of gas or the sound warning of a leak sensor is an alarm signal in which the use of the equipment is prohibited. Ventilate the room and, if possible, find the source of the fuel leak.

You can carry out the initial diagnosis of oven malfunctions yourself if the procedure does not involve disassembling the main components. In other cases, the work should be entrusted to a specialist

It is always worth monitoring the operation of potentially dangerous equipment. Incorrect functioning of any elements should raise alarm bells and become a reason to call a technician from the gas service to carry out an inspection, diagnose the problem and fix it.

To use the Indesit, Gefest, Brest, Greta oven, it is important to remember the safety rules:

- Before turning on for the first time, check that the connection to the gas network is correct.

- Constantly monitor the flame in the Indesit oven.

- Regularly wash and wipe the device from the outside and inside.

- Do not use the oven as a room heater.

In the video, a gas company specialist talks in detail about the correct and safe use of modern ovens.

Gas stove

Thus

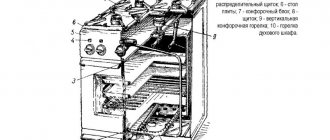

Internal structure of the stove

Before doing any repairs, you need to understand what a gas stove is, what parts are present in it, and what kind of DIY gas stove repair may be required in a given case.

The structure of the burners

The most noticeable part of any stove is the burners. Each burner is attached to the stove table using bolts. The burner also consists of several parts: they have a lid, a divider and an injector.

Each burner is connected to a steel and copper tube with a fastening similar to the American one. Due to this device, the burner receives gas.

Gas burner device

To work with the burners, you don't need any special tools: you will need a wrench, most likely a size 13, to disassemble the burner parts if it needs repairs or cleaning.

After completing the repair and assembly, you need to assemble the structure and check how tight it is to prevent gas leakage.

Each burner has two candles around its perimeter.

One helps create ignition by working with piezoelectric elements or an electronic circuit, and the second serves as a thermocouple connected to a circuit that controls combustion.

Gas burner (grill removed): 1— nozzle, 2— spark plug, 3— flame sensor (thermocouple hot junction)

The candles differ from each other even in appearance, so it will be difficult to confuse them.

A candle for electric ignition has a ceramic caftan; it is needed to prevent the spark from breaking below the required level.

That is why it is important to properly ground the stoves where electric ignition is built-in. Electric ignition also does not tolerate the use of water pipes and metal threads.

Electrical ignition circuit

It is important to separate the slab from the riser using special gaskets during installation and repair, otherwise there is a real risk of explosion

The thermocouple candle has a bronze caftan, which is a powerful heat conductor

The reliability and speed of switching on the protection that shuts off the gas after you have finished using the stove depends on how quickly the semiconductors cool after the flame goes out.

Gas flow control

Under the stove table you can see the collector. It looks like a thick tube from which leads to the burners diverge.

Gas stove manifold

The gas flow is controlled by solenoid valves, the number of which is equal to the number of burners on the stove.

This is necessary so that if the flame of one burner goes out, the others can still function.

Solenoid valves are equipped with an inductor coil. When the thermocouple is heated, an EMF is generated, which fixes the device open.

Solenoid valve with induction coil

Can't light the oven

After pressing the safety button, the fire lights up, but even after a minute of warming up, releasing the button causes the flame to go out. Cause. a faulty safety device. First you need to make sure that the flame sensor is installed correctly. It must be in the flame and reliably heated. If it is installed correctly, but the flame still goes out, then the device itself is faulty. The device needs to be replaced.

There are two types of devices in slabs. In the first version, the sensor is a copper flask with gas or liquid. When heated, the gas expands and the liquid expands or evaporates. The pressure rises. The pressure is transmitted by a thin copper tube to the valve. This keeps the valve open. A malfunction of such a system may be due to depressurization of the flask with tubes.

In the second version, the sensor is a thermocouple. When heated, the thermocouple releases electricity. This electricity is sent through wires to an electromagnet that holds the valve open. The malfunction of this version of the safety automation is usually associated with damage to the wires from the thermocouple to the electromagnet.

Unfortunately, errors are periodically found in articles; they are corrected, articles are supplemented, developed, and new ones are prepared. Subscribe to the news to stay informed.

Good afternoon I make do with one working capacitor of 45 microforads and have 400 watts. Good sine wave, everything works except the refrigerator. Is it worth increasing the power of the transformer to make the refrigerator work? Read the answer.

Good afternoon. This is my problem. BURNING stove, gas. I turn and press the stove handle to turn it on. The burner lights up. Everything here is no problem. After waiting a certain time, I release the power knob and the burner goes out. This problem is only with one burner. Thank you in advance. Read the answer.

Good afternoon. When I turned on the oven, the entire stove became very hot. handles, side walls, top. All! There is no smell of gas. stove , about 3-4 years old. What could be the reason and is it dangerous? Read the answer.

Please tell me where the jets are located in the ARDO 640 oven. The kit includes 6 jets for bottled gas for replacement, but the instructions describe the replacement on the table (the easiest), but there is nothing about the oven. Read the answer.

Hello, I have the following question: stove: 'Kaiser'. When you put the frying pan on the burner (the largest one), a strong smell of kerosene appears. Without a frying pan, it burns without smell. The remaining burners burn normally. The smelly burner burns with yellow ends, with characteristic jerks. Thank you in advance for your response. Read the answer.

Hello. I have a BOSH gas hob with electric ignition. In operation for 4 years. The power cable began to get very hot. What is the reason for this phenomenon? Read the answer.

There is a Datid gas hob with a service life of 3 years. Recently the following began: when you ignite and hold the handle down for 5 seconds (as expected) or even more (up to 1 minute), the flame still goes out in most cases (you have to either hold it for a long time or try many times). What is the reason? Do you need to replace the thermocouple? Read the answer.

How to determine how much gas is in a propane tank. Is it right for him? How to find out how full a cylinder is. What gas pressure is guaranteed during replacement?

Why is it cold at home, where does the heat go, heat loss. Why is it cold at home? Where does the heat go? How to make it warm? Those losses.

Homemade wooden country bench, table. Garden bench design. How to make a comfortable bench in your country house with your own hands.

How to cut laminated chipboard, laminated chipboard without chipping? How to repair chips. When making furniture, you have to cut laminated chipboard. Chipboard doesn't like this very much

Electrician's tutorial. Features of a household network. Let's learn electrical installation. Everything an electrician needs to know. self-taught. Self-instruction manual. Features of household lighting.

Refinement of a coal solid fuel boiler. avoiding overheating. Ensuring stable combustion of a coal boiler without overheating. Boiler modification.

Do-it-yourself gas stove repair

It is impossible to imagine any kitchen without a hob, be it an electric or gas stove, since it is on these units that the cooking process takes place. But unfortunately, these devices fail over time for various reasons. A qualified gas service specialist must repair gas stoves, eliminate breakdowns of various kinds and carry out maintenance. But there are minor malfunctions in which you can repair a gas stove on your own. So, you can repair a gas stove with your own hands if the following malfunctions occur:

- One or all burners do not light;

- electric ignition does not ignite gas;

- after igniting the gas, the burner goes out;

- The oven lid is not closed.

Causes of failure

Why doesn't the electric ignition of a gas stove work? There are several reasons for this device to malfunction.

- There is no spark at the electrodes.

- There is moisture or grease on the inside of the system or the surface of the spark plug.

- A crack has appeared or the ceramic candle insulation has burst.

- The transformer burned out - the spark generation unit.

- The contacts of the power button have oxidized or carbon deposits have formed on them as a result of a short circuit (short circuit).

Some malfunctions may appear after wet cleaning of the hob, when moisture gets into the inside of the stove. To eliminate them, it is enough to do preventive measures: cleaning contacts, drying spark plugs - almost the same measures are taken by car enthusiasts.

If only one burner does not light, the reason may be damage to the high-voltage wire to the ignition electrode, the ignition device itself, or a malfunction of the channel of the entire unit.

How to repair a piezoelectric element

To troubleshoot the problem yourself, you need to find out the cause, and then begin to eliminate it.

Finding out the cause

Often you have to deal with the fact that the electric ignition of one burner does not work.

This means that troubleshooting must be carried out along the path of the electric current to the faulty piezoelectric element. First of all, an external inspection is carried out. The presence of foreign objects on the contact surface must be excluded.

If the piezoelectric element is working and the gas does not ignite, turn on the burner using another fire source and carefully observe the combustion process. If the fire is dim or has a yellowish tint, then the cause of the malfunction is poor-quality mixture formation, due to the need to service the gas supply channels and burners.

A defect identified during inspection is eliminated by replacing the broken element. A tester is used to detect hidden faults in the electrical wiring of a gas stove. By measuring the voltage at the moment the button is turned on, the operability of the tested section of the circuit or control unit and the current coming out of it are determined.

Carrying out repairs

After inspecting the accessible elements from the outside and the need arises to examine the inside of the slab and carry out repairs, it is necessary:

- Remove the top cover of the stove or gain access to the lower part of the hob, embedded in the kitchen furniture.

- After diagnostics have been carried out and a faulty piezoelectric element has been identified, it is unscrewed from the inside of the hob. To do this, sometimes light tapping with a wooden object is required so as not to damage the ceramic body.

After installation, check the functionality of the slab and secure everything in its original places.

If a malfunction is detected in the control unit or contact wires, the faulty parts are replaced, and then the operation of the stove is checked.

Requirements for a stove with electric ignition

The main requirement for a device with electric ignition is to connect the device to an electrical network with a voltage of 220 volts.

For this purpose, the stove comes with a cord - a three-core cable with a cross-section of at least 1.5 mm, ending with a grounding plug. An outlet with a grounding circuit is installed near the installation site of the device.

To ensure additional safety, a special residual current device is installed on the common incoming panel, which blocks the network in the event of a current leak.

Important . It is better to invite an electrician to carry out the work.

Ignition produces a spark, but the burner does not ignite

In cases where the electric ignition produces a spark, but the burner does not ignite, you should try replacing the thermocouple. Sometimes the problem is related to the solenoid valve, and after updating it, the equipment operates normally. You should check the ignition unit, because if everything is fine with it, but ignition does not occur, you need to look for a problem in the power wire or burner spark plug.

If a spark is supplied, the flame lights up, but immediately goes out, try holding the gas button longer. It is likely that the sensors responsible for the formation of the flame simply do not have time to warm up.

Electric ignition does not work on two burners

In some cases, a gas stove on two burners does not light. Sometimes lighting it with a match helps - everything works normally, without interruption. The cause of this malfunction is damage to the spark plug responsible for ignition. We repair electric ignition as follows: clean the spark plug and look at its condition; perhaps it’s enough just to clean the spark plug’s power wire.

If there is a crack on the element, we buy a new part and put it in place of the old one. The electric ignition may also break down due to a faulty ignition button. Moisture or small debris could have gotten into it, or it could have been damaged mechanically. To fix this, you need to clean the oxidized buttons or replace them if they are mechanically damaged.

What problems do you often encounter with gas stoves?

Some popular problems in the performance of the device that are significant are highlighted. Their repairs should only be carried out by specialists. These problems include:

Gas flows poorly to the burner or is absent altogether. Usually this problem is not affected even by fully opening the tap, since in any case there is an extremely weak flame, and often there is no flame at all. For repairs, you have to remove the burner, in which the nipple is cleaned. If this does not lead to the desired results, you have to turn to gas workers. The plug turns tightly. Also, when it returns to place, there is no special click, so the pin does not fit into the corresponding recess. Usually the reason here is that the lubricant used for this element thickens, so turning the plug becomes difficult and tight. Also, the recess often becomes clogged with various products or oils. Here you will have to disassemble the tap, and the general flow of gas will certainly be blocked. To remove the tap, the handles and decorative panel are dismantled. Next, the pins will open, which act as a holder for the plugs in a special protective housing. All parts are removed and thoroughly cleaned in a special solution. Then they are dried and inserted into place. Since you have to work with complex elements in a gas stove, it is best to entrust the process to specialists. An unpleasant smell of gas appears during operation of the equipment.

In this case, it is important to completely stop any activities with the gas stove and contact a gas specialist.

Thus, problems with gas stoves are considered quite frequent and popular. Some of them are complex and specific, so they must be trusted to specialists

Simple and standard problems can be solved on their own, for which it is important to know the cause of the breakdown, which can be easily eliminated, after which the ease of using gas equipment for its intended purpose is ensured

When to contact a specialist

Most of the breakdowns that cause defects during the operation of electric ignition are not dangerous to humans. But the continuous crackling and clicking can get pretty boring. What to do if the electric ignition does not work, and you couldn’t fix the problem yourself? A gas stove is a dangerous technique because it can cause gas leakage. It is better not to try to disassemble and repair the electric ignition yourself. Find out how to check the ignition unit of a gas stove, and if a problem is detected, contact a specialist. Repair of electric ignition in Moscow is carried out by calling a specialist to your home.

How does a gas stove work?

The design of gas stoves varies depending on the type of equipment. But all such devices include:

- burners;

- hob;

- oven.

Some types of gas stoves are complemented by an electronic control unit for the burner and other components. In particular, equipment is often equipped with a sensor, which, if the fire goes out, shuts off the supply of “blue” fuel.

Burners

The burners consist of the following components:

- gas supply nozzle;

- swirler;

- throttle;

- guides;

- lid;

- divider

The latter divides the general flow of flame into several uniform tongues extending outward. Older stoves use diffusion and kinetic burners. The first ones are installed in ovens. Diffusion burners are distinguished by the fact that gas is mixed with air (due to this process the fuel ignites) in a natural way. Modern stoves use combined burners.

Gas flow control

In the center of the stove burner there is a thermocouple that regulates the gas supply. When heated, this element generates a current that is supplied to an electromagnet. The latter holds the damper open, so that gas flows to the burner continuously. If the fire on the burner goes out, the thermocouple begins to cool. Because of this, the magnet is discharged, as a result of which the damper automatically closes, interrupting the gas supply.

How to replace a light switch in an apartment, installation and connection

This configuration significantly increases the safety level of the slabs. However, due to the thermocouple, you have to hold the regulator knob down for several seconds.

Scheme of modern electric ignition

Many gas devices are equipped with a modern ignition circuit, mainly comfort stoves. The method is implemented using various electrical circuits, but the principle of operation is the same for all - a voltage source is required to ignite the gas.

Basic elements of a modern mechanism:

- ignition button or rotary knobs;

- transformer;

- capacitor;

- thyristor – semiconductor element;

- candles.

Scheme of work:

- Pressing a button or drowning and turning the knob on the panel.

- Applying voltage to the capacitor, which begins to charge.

- When the capacitor is fully charged, it supplies a pulse of current to the thyristor.

- The thyristor opens and the capacitor quickly discharges through the thyristor and the primary windings of the transformer.

- High voltage pulses are induced in the transformer.

- Sparking occurs on the burners in the candles. The spark is used on the burner to which the gas supply is open.

- The gas on the burner ignites.

The mechanical and automatic options for electric ignition are based on this scheme .

Oven – door and thermal insulation

The thickness of the oven's thermal insulation layer is usually 5-10 mm. The foil that covers it on the outside has low thermal conductivity. Thermal insulation is made from environmentally friendly materials and allows you to reduce the cost of energy needed to heat the device. As for the door glazing, the design is more complex. The oven can be equipped with two or three glasses - external and internal, as well as middle

If handled carelessly, the glass may break, which will require replacement. Typically, the glass on the front wall of the door is a single structure with a picture or company logo

Below is a short list of the most common malfunctions in gas stoves and tips for eliminating them.

Malfunction – the burner axes are displaced. The reason is that the traverses or the fastening of the regulator body are loose. Remedy: Place the crossbar in the correct position and tighten the screws. Strengthen the regulator body.

Fault: weak grip on faucet handles. The reason is that the rod slots have failed. Remedy: Remove the handle and use a screwdriver to open the slot on the rod.

Malfunction – it is impossible to close the oven door tightly. The reason is that the axis is not fixed in brackets. Remedy: You need to remove the door cover, tighten the spring and insert the axle into the ears.

Fault – poor baking results. The reason is the setting of the wrong mode or the door being skewed. Remedy: Use the stove's instruction manual or adjust the door.

Fault: low oven temperature. The reason is a clogged tap or nozzle, insufficient gas pressure. Remedy: repair of the nozzle or tap.

Malfunction – there is an unpleasant burning smell. The reason is a malfunction in the tightness of the gas paths. Elimination - it is necessary to check all connections with a soapy solution, eliminate leaks, grind or re-lubricate the taps.

Why did the electric stove break down?

These stoves are much safer than gas stoves - there is no open flame, but if used carelessly you can get an electric shock. The products are very reliable, but sometimes users call the service center to report that the electric stove has broken down. Of course, major repairs of such household appliances with increased danger should be carried out by a qualified technician. But in some cases, you can cope on your own, you just need to know what the cause of the malfunction is, and also have a general understanding of how an electric stove works.

Poor heating

Weak heating of the surface of the induction burner of an electric stove can occur due to the fact that the bottom of the cookware is much smaller than the diameter of the latter, or there is not enough contact - cookware with a deformed bottom. Smart burners do not heat up in this case. To eliminate the malfunction, you must use only special cookware that is suitable for an induction hob.

Another reason for poor heating is a loose fit of the burner block on the inside of the glass-ceramic stove. In this case, it is necessary to adjust the springs of the clamping device. This can also happen if the induction winding is severely overheated, which happens extremely rarely.

How to repair an electric oven yourself?

When we talk about an electric stove, we mean a combined device of an oven and a hob, which are enclosed in one metal box. Therefore, before starting repairs, you need to understand exactly how to get to the oven itself. After all, a visual inspection from the inside will provide practically no information about the problem.

To understand what you might encounter inside, you need to know the design of the slab. This knowledge will help you avoid getting confused when disassembling and repairing the oven.

Tip Before starting work, do not forget to disconnect the device from the power supply. The stove operates from a three-phase network with a voltage of 25 A and 32 A. This current strength is deadly to humans.

How can you tell if the electric ignition is broken?

- When you normally hold down the button or turn the knob in the right direction, the electric ignition stops working.

- When using the stove for its intended purpose, the electric ignition makes a sound similar to a click.

- After turning off in the usual way, the electric ignition continues to work for some time.

- Electric ignition produces sparks even if the stove is not in use.

- It is impossible to set the burner on fire the first time; you constantly need to make every effort.

- The machine in the dashboard is constantly knocking out.

The product does not turn on

Why do the indicators on the stove not work, the burner does not heat up, and there is no reaction to switching modes? The reason lies in the lack of electrical current supply to the product. To localize slab faults, you need to do everything step by step:

- We check the voltage in the socket with a multimeter, if not, turn off the home network, disassemble and eliminate the detected wire break;

- if everything works in the socket, we disassemble the plug and do a similar check;

- then we check the power cable connecting the stove - perhaps there has been an internal wire break, it needs to be replaced;

The second reason may be the burnout of the heating element of the burner or the heating element of the oven - they cannot be repaired, they are simply replaced with new devices. There is also this option: the indicators light up, but the burners and heating element of the oven do not heat up, why does this happen? In this case, you need to figure it out without haste. First, everything needs to be inspected visually: are all the connections tightened properly, has the wire come loose somewhere, or is there melting of the PVC protection, which indicates a burnt wire. In this case, make the connection again, eliminating the burnt area.

The third, quite common reason is that the switch may break, so the burner or oven simply does not turn on.

Oven failures

Often, only the oven in the electric stove does not work. The most common malfunction is that there is no backlight inside the device; as a rule, there are two reasons.

- There is no contact between the supply wire and the lighting system - check the button responsible for turning on the backlight, and if it breaks, replace it.

- A light bulb has burned out - the lampshade protects it from high temperatures, but the way they are designed is that they very often burn out from the slightest voltage drop.

When a short circuit occurs in the electrical system of the stove, the lamps in the oven burn out first.

Nozzle clogged

The nozzle (nozzle) of the unit may become clogged if food products, washing powders or gas combustion products get on it. In this case, self-repair of a gas stove is very simple: you need to remove the burners and clean the nozzle with a wooden toothpick (do not use metal objects, such as a paper clip or a needle, for cleaning).

If you cannot clean the nozzle without disassembling the stove, you should remove the top panel of your device by unscrewing several bolts. To properly clean the nozzle, you can unscrew it.

Burners won't light

This malfunction can be caused by a number of reasons:

- clogging of the gas supply nozzle;

- failure of the spark plug;

- damage to the insulation of the wire going to the spark plug;

- faulty unit that controls electric ignition;

- malfunction of the power button.

Electric ignition does not ignite gas

Before disassembling the gas stove, you should turn off the power supply (voltage for the candle - 220V), which is required for electric ignition. This malfunction of a device with electric ignition can affect either one burner or all of them at once. If a spark does not occur on one burner, this means that the ignition plug (electrode) has failed. A crack may form on it, in the ceramic insulator, as a result of which the electrode stops working .

To repair a gas stove with your own hands to replace the spark plug, just remove the burners, open the stove lid (unscrewing several bolts), and replace the electrode with a new one.

Also, a common malfunction of electric ignition on one burner can be damage to the wire going to the spark plug. To check this, you need to press the ignition button with the unit lid open. If the wire is “broken” in any place, then you will see a spark jumping in this place either onto the body of the device or onto the foil that covers the oven. Repairing the electric ignition of a gas stove with a damaged wire consists of replacing it with a new one, or it needs to be moved to another place so that there is no breakdown to ground.

If the electric ignition does not work on all burners, including the oven, this means that the ignition unit has failed. To repair auto-ignition, you need to replace the unit with a new one after removing the top panel of the device.

READ How to properly glue drywall to a wall

Electric ignition not working on gas stove? This is where you come COMPETITION

The process of repairing Darin's electric ignition gas stove is shown in detail here

Hephaestus

The following breakdowns occur in the popular Hephaestus

- The burner flame is uneven. It is necessary to clean the nozzle, channels, and adjust the gas supply.

- The burner goes out spontaneously. This indicates a failure of the flame control thermocouple.

- The flame does not appear due to a breakdown of the electric ignition or a failure in the control system. There is also a banal reason, which is the lack of gas supply due to a broken tap.

- Unexpected display signals that light up or vice versa, light bulbs that do not work, temperature control failures - all this indicates an electronic failure and requires qualified repairs.

Button malfunction

Sometimes the cause of a spark plug not working may be a faulty button. This malfunction during the repair of Gorenje or other brands of gas stoves can be determined by transferring the wires (after first removing the top panel of the device) to another gas stove button. If the ignition works when the burner tap is opened, then the faulty button must be replaced.

Ariston

The following breakdowns and malfunctions occur in Ariston stoves.

- The burners do not light up. It is necessary to check the gas supply and the operation of the electric ignition system.

- Failures in the electronic control system manifest themselves in a variety of ways and require qualified repairs.

- No burner ignition. The most common cause is a solenoid valve failure.

- The burner flame is uneven, which indicates that the nozzle is dirty.

- As a result of the accumulation of dirt, disturbances in the ignition system, spark ignition unit, and uneven gas supply may occur due to blocking of the burner channels.

Indesit

Indesit slabs have the following list of typical faults.

- When dirt accumulates in the nozzle or burner channels, an unpleasant odor appears after the burners are turned off.

- The gas control knobs are difficult to turn, indicating the need for cleaning. There is another reason - a broken fastener. In this case, the entire handle is changed.

- If the burner nozzles malfunction, they may produce an excessively bright flame. When supplying gas from a cylinder, in this case the reducer must be adjusted.

- The flame is very weak. It is necessary to check the cleanliness of the jet and, if necessary, adjust the gas supply and pressure on the reducer.

- If all burners do not light, you should check the electric ignition unit. If only one doesn't work, it needs a thorough cleaning.

- Soot from gas combustion may indicate severe contamination of the nozzle and burner channels. It would not be superfluous to check whether the flame arrester is installed correctly. Another reason is excessively high gas pressure or low quality.

- If there is no light in the oven, the first thing to do is check the functionality of the light bulb installed there. Then they examine and, if necessary, clean the contact groups of the cartridge and switch.

- The stove is turned off and there is a distinct smell of gas. The set of checks is standard; all connections are examined, supply hoses and pipes, and shut-off valves are checked.

The gas stove smokes and leaves marks on the dishes