Common breakdowns

All possible malfunctions of the washing machine can be divided into several groups:

- Doesn't turn on.

- Doesn't drain water.

- There is no spin.

- Does not open.

- No heating.

- Leaking.

- Doesn't take up water.

- Makes extraneous noise.

There may be several reasons for each of the listed malfunctions. For example, the lack of water in the tank can be due to either a broken inlet valve or a simple clog in the inlet hose.

Before you start repairing the Hotpoint-Ariston washing machine yourself, you need to determine the probable causes of the problems and possible methods for eliminating them.

Doesn't turn on

Possible reasons why the washing machine does not work when turned on:

- the socket or power cord is faulty;

- The control module is damaged.

It’s easy to check the serviceability of the outlet - just plug in another, working device. Damage to the cord can often be seen visually, by testing the cable with a multimeter to be sure. If there is no resistance between the “start” and “end”, the cord should be replaced with a new one.

Only a specialist can troubleshoot the Ariston Hotpoint module. The cause of failure may be a sharp surge in voltage in the network. Reflashing or replacing a module is an expensive procedure.

In some cases, after being plugged in, the machine signals that it is ready to work (the indicators light up), but after selecting a program, the washing does not start. There may be several reasons for this:

- The inlet hose is clogged or the valve is faulty. The appliance cannot start due to lack of water.

- The electric motor burned out. Most likely, in this case, the machine will fill with water, but the washing process will not advance further. As a rule, a breakdown is accompanied by extraneous noise.

Removing a blockage at the inlet is quite simple. To do this, you need to remove the inlet hose, wash it under pressure, and clean the inlet filter mesh with a brush.

Replacing a faulty valve proceeds according to the following scheme:

- The inlet hose is unscrewed.

- The top cover is removed (the 2 bolts on the back wall that hold it are unscrewed).

- The clamps connecting the pipes and the valve are unfastened, and the terminals are removed.

- The valve is pulled out from its seat and washed. After washing, its contacts should be ringed, checking the resistance. If it is missing, the problem is not a blockage, the part has failed and needs to be replaced with a new one.

After installing the new valve, the assembly is assembled in the reverse order and a test run is carried out.

The machine does not drain water

The most common cause of this problem is a clogged drain system. The breakdown may also be due to a failure of the pump or control unit (the drain command is not given).

The process of removing clogs begins with cleaning the filter. The procedure can be represented as follows:

- The filter cover, hidden behind the front panel at the bottom of the facade, opens slightly.

- A flat dish is placed under it to collect the flowing water.

- When the washing solution has completely drained, the filter is completely removed and washed.

If the blockage is severe, not only the filter can become clogged, but also the pump and even the drain hose. If cleaning does not lead to the desired result, it is necessary to check the serviceability of the pump.

Before you begin repairing the Ariston washing machine yourself, you need to dismantle the part in the following sequence:

- Unplug the power cord from the outlet, disconnect the drain and inlet hoses.

- Lay the car on its side and remove the bottom protection.

- Disconnect the terminals, unscrew the clamps on the pipes.

- Unscrew the screws holding the pump (1 or 4 depending on the model).

What you should be wary of:

- the impeller is pushed forward;

- strong backlash;

- a large amount of scale in the filter seat.

To make sure the part is in good condition, you need to check the resistance of the motor windings. If it is absent (the norm is 140–180 Ohms), the pump is faulty and the winding may break. You can check the engine by connecting it to the network. If the pump is working properly, the impeller will begin to rotate.

No spin

There are three main reasons for this malfunction:

- The motor failed and the drum stopped rotating.

- The tachometer, which regulates the speed of rotation of the rotor, is faulty. The engine runs at minimum speed and the spin cycle does not meet the specified parameters.

- The belt is broken.

- Problems with the electronic module.

- The water does not drain and the machine cannot start spinning.

It is very easy to check the last point - just drain the water through the filter or drainage tube and start the spin program.

To check the operation of the engine and the integrity of the belt, you need to remove the back cover of the device by unscrewing the fastening screws. A broken belt can be seen visually, but the motor will have to be examined in more detail.

To check the serviceability of the engine, it is necessary to measure the resistance on adjacent lamellas. It should be the same, within 0.2 Ohm. Sometimes wear on the slats can be seen visually. The part cannot be repaired - the engine must be replaced.

If the problem is not in the motor, you need to check the serviceability of the tachometer. The sensor is located on the shaft immediately behind the engine. It can be inspected and ringed without removing it from its seat.

The device is considered operational if the resistance it produces is about 60 ohms. In this case, you can check its contacts and how well it is secured to the shaft.

The door won't open

There may be several reasons why the hatch was blocked:

- There is still water in the tank and the machine cannot open the door to avoid flooding.

- The door handle mechanism is broken.

- The hatch locking device is faulty.

- Problems with the control module.

Before you begin the repair, you need to open the door by inserting a thin ruler under the hatch and squeezing the tongue or using an emergency cable (it can be found under the filter cover).

A faulty handle does not respond to pressure; if it breaks, it must be replaced with a similar one. The locking device located on the front panel must be removed by first unscrewing the bolts holding it and pulling off the cuff. The part rings and changes in the absence of resistance.

No heating

If the machine washes in cold water, most likely the heating element has become unusable. Replacing it is quite easy.

Troubleshooting proceeds according to the following scheme:

- Remove the front panel.

- Find the heating element at the bottom of the tank and test its contacts with a multimeter.

- If there is no resistance, replace the part with a similar one.

The cause of the breakdown may be accumulated lime or mechanical wear of the heating element.

Leaking

You can determine the location of the leak by observing the washing machine during the washing process. If water appears while filling, the inlet hose is probably damaged. If during reset - drain hose or pipes.

Water that accumulates under the bottom during washing may indicate a leaky tank. If it flows down the front wall from the side of the hatch, it’s all a matter of a leaking cuff.

To restore the tightness of the joints, it is necessary to replace the leaky part with a new one, tightening the joints.

Doesn't take up water

The main reasons why the machine does not take in water:

- clogged inlet hose;

- Fill valve malfunction;

- problems with the control module;

- The pressure switch is faulty - without water it gives a signal that the tank is full.

All of the listed parts except the faulty module can be diagnosed and replaced at home.

The machine makes strange noise

The probable cause of the grinding noise is wear of bearings, shock absorbers, suspension springs, as well as foreign objects getting inside the drum.

Replacing bearings in Ariston vertical washing machines follows the following algorithm:

- The device is disconnected from the electrical network and water supply.

- Unscrew the screws from the back and front that hold the side panel and remove the panel.

- Remove the pulley after first unscrewing the bolt holding it.

- Having reached the hub, unscrew the screws and remove it from the seat.

- Carefully knock out the bearing and seal.

- An oil seal is installed in the hub, the bearing is pressed in, the place where the oil seal comes into contact with the shaft is cleaned and lubricated.

- The hub is installed back, the car is assembled in the reverse order.

The bearing on the other side of the washing machine is changed according to the same principle, only without removing the pulley.

The bearing in front-loading Ariston washing machines changes according to a standard algorithm, like any other machine of this type.

What types of malfunctions are there?

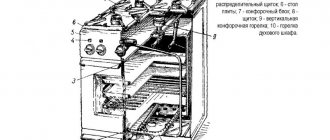

Ariston produces automatic drum-type washing devices. The models are of the same type and include:

- housing with loading hatch and shock absorption system,

- Control block,

- drum tank,

- Electrical engine,

- tubular electric heater,

- bearing unit,

- inlet valve,

- pump for draining water.

If a machine breaks down, you can quickly find and eliminate the defect based on characteristic signs. Let's look at typical malfunctions of the Ariston Hotpoint washing machine and other models of the Italian manufacturer.

Water does not drain

When washing is completed, water is not pumped out of the tank. Possible reasons:

- The pump connection or drain hose is clogged.

- Drain filter clogged.

- The pump has failed. Signs:

- the pump hums, but there is no drain;

- stops during washing;

- slow drain.

Doesn't start

The washing machine does not turn on, the display does not work. Possible defects:

- damage to the power cable;

- network filter defect;

- control unit malfunction;

- Damage to internal wiring.

Doesn't take up water

The indicator works, but no water flows. Causes:

- clogging of the intake valve filter;

- valve malfunction;

- water level sensor malfunction;

- malfunction of the hatch locking device.

Water does not heat up

Possible malfunctions:

- water level sensor malfunction;

- damage to the wires supplying the heater;

- heating element malfunction;

- temperature sensor failure.

Spin mode does not work

The wash has been completed, but the laundry has not been spun. This is possible for reasons:

- the permissible weight of the laundry has been exceeded;

- clogged drain filter;

- pump malfunction;

- failure of the rotation speed sensor;

- electric motor defect.

Water leak

Main defects leading to leakage:

- wear of the bearing seal;

- damage to the drain hose or internal pipe;

- destruction of the door seal;

- damage to the hoses supplying water to the detergent tray;

- drum damage;

- incorrect installation of the drain filter.

Extraneous noise

Extraneous sounds (grinding, rumble, creaking, whistling, etc.) or an increased level of normal sounds may indicate:

- foreign objects in the drum (coins, keys, etc.);

- destruction of drum bearings;

- shock absorber wear;

- foreign objects in the pump;

- pump shaft failure;

- engine malfunction;

- counterweight damage.

The loading hatch does not open

This leads to:

- water sensor failure;

- program crash;

- malfunction of the hatch lock or opening handle.

Ariston washing machine error codes

Error codes in the form of symbols on the screen help determine the cause of the failure.

| Error code | Malfunction |

| F01 | Motor circuit short circuit |

| F02 | Problems with the tachometer |

| F03 | Temperature sensor malfunction |

| F04 | The pressure switch responsible for the water level in the tank is faulty |

| F05 | Problems with draining (the pump does not pump or the level sensor does not signal the end of draining) |

| F06 | Problems with the control buttons (in the Dalogic series) or the sunroof locking device is faulty |

| F07 | Malfunction of the pressure switch (heating element without water) |

| F08 | The machine receives a signal that heating has begun when the tank is empty (“pressostat is stuck”) |

| F09 | Device memory problems |

| F10 | The pressure switch does not signal the water level |

| F11 | The drain pump does not respond to module commands |

| F12 | The display module does not receive a signal from the control module |

| F13 | Drying temperature sensor reports an error |

| F14 | The heating element responsible for drying clothes is faulty |

| F15 | Drying does not turn on |

| F16 | An error occurred while parking the drum (for machines with vertical loading) |

| F17 | The hatch door is open |

| F18 | Microprocessor malfunction |

| F20 | An error occurred while drawing water |

In models without a display, a certain periodicity of indicator blinking corresponds to a particular error. Thus, the owner of the washing machine will be able to find out which unit has problems.

Features of AVSL 100 repair

Sometimes owners of AVSL 100 machines encounter problems whose solutions are not so obvious:

- The washing machine interrupts the program before spinning or rinsing. If the device is disconnected from the network and then turned on again, the unit will complete the process. The likely problem is a faulty drain pump that jams from hot water.

- The device freezes during operation and the fault is not detected. After cooling, the washing machine resumes washing. The probable cause is wear of the motor brushes; they need to be replaced with new ones.

In general, malfunctions of washing machines of this series can be considered typical.

Broken heating element

Due to the fact that hard water is poured into the washing machine, scale forms on the heating element, as a result of which the part breaks. In case of such a breakdown, the wash is performed in cold water or the program does not start at all. To diagnose and perform repairs yourself, you must:

- Disconnect the Ariston washing machine from the network and communications, remove the back cover.

- The heating element is located below. You need to take a multimeter, switch to resistance measurement mode and install the probes on the contacts of the part. If the device is working properly, the display will show 25-30 ohms. A value of 1 ohm is reported for an open circuit, and a value of zero for a short circuit.

- To disconnect a faulty heating element, you need to unscrew the fastening bolt, disconnect the wires and, by shaking, pull the part out of the seat.

- Install the new heating element in reverse order and assemble the washing machine.

Features of AVTF 104 repair

Top loading washing machines such as the AVTF 104 have a number of features:

- If water accumulates under the bottom of the machine, not only the tank and various connections may leak, but also the seal at the top.

- An imbalance of the unit can lead to spontaneous opening of the hatch flaps. As a result, the heating element may be knocked down, the doors themselves may be broken, and the tank may be damaged.

- Vertical machines are distinguished from frontal models by the principle of fastening the drum, which is supported on two axle shafts equipped with two bearings. Accordingly, to replace them it is necessary to remove not the rear part of the unit, but the side panels.

It is worth considering that top-loading models are made in Europe, therefore, replacement parts for them are more expensive and less common.

Features of the Margarita 2000 repair

This model was sold back in the 2000s, but you won’t see it on store shelves for a long time. However, in some families it still serves faithfully. Despite the outdated design, the model has a standard design.

There are some nuances during dismantling - the powder receiver of this washing machine does not extend forward, but rotates 450 degrees clockwise, so in addition to the standard two horizontally inserted screws, it is held in the desired position by another vertical one.

Margarita 2000 has a mechanical control; when a malfunction is detected, the command device begins to rotate clockwise. The frequency at which the “On/Off” indicator lights up will help you navigate current malfunctions.

The number of blinks forms an error code, for example, 3 blinks in a row corresponds to F03, two blinks – F02, etc. The pause between series is 4 seconds.

The model is far from new, so its main malfunctions are associated with long-term operation: wear of the electric motor brushes, failure of bearings, inlet valve, drain pump, heating element.

Bearing wear or destruction

It is clear that such a malfunction is more difficult to correct on your own, but nothing more. Simply replacing bearings still requires certain skills. First of all, it is impossible not to notice that if signs of problems with bearings appear, you should not waste time and “finish off” the machine while it is running.

A problem that is not resolved in a timely manner can lead to a situation where repairs are impossible or simply unprofitable. A symptom of bearing wear is a hum or even a knocking sound during spinning and washing; there may be play in the drum. The difficulty of repair is that the car will have to be almost completely disassembled.

An additional problem is created by the design of the tank of most Ariston washing machines. It is soldered from two halves and cannot be disassembled. You may also need special tools to remove old worn bearings.

Although the process of replacing bearings yourself is quite educational. A non-separable tank can be quite easily transformed into one that can be sawed with a hacksaw and then glued with silicone sealant and bolted together.

It’s even somehow pointless to talk about what devices for removing bearings a big-headed and handy person can come up with. As a last resort, to remove the bearing on the removed tank, you can contact the nearest car service center.

In any case, it will be cheaper than what a service center servicing washing machines will “ask” for. Moreover, it is not a fact that the service even knows how to carry out such repairs.