What does an electric or manual meat grinder consist of - device and parts

In fact, the parts and operating principle of an electric and mechanical meat grinder are almost identical. Therefore, knowing the structure of one, you can easily understand other modifications.

The only difference is that the electrical appliance has a motor. The action of a manual meat grinder starts the rotation of the handle.

Another difference I can mention is the fastening of the mechanical device to the surface - an electric meat grinder does not require such fixation.

I think that when you figure out how to use a meat grinder, you will want to make minced meat - so read on to learn how to choose the right meat for it.

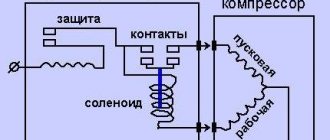

Electric motor

The electric motor allows the working part (screw) to function - on average, the performance indicator is 30 kg per hour, but it may vary depending on the model and functionality of the device.

In conjunction with the engine in any meat grinder there is a gearbox. Its task is to reduce speed and increase torque. The gearbox consists of gears of different sizes, made of plastic or metal - most often manufacturers use plastic. Devices with metal gears are less common (since they are more expensive), but are considered somewhat more reliable.

In addition to the gearbox and motor, manufacturers also install control boards and fuses.

Screw

From German, the word “auger” is translated as “snail” - obviously, the name is due to the appearance of the part. The main task of the element is to move the meat inside the meat grinder towards the exit. It is made from durable metal alloys - when the meat hits the ribs of the auger, it is trimmed, ground, turning into minced meat.

You can connect the auger to the housing using:

- Metal hexagon. This method is found on low-power devices. To use a meat grinder with such a mount without problems, be sure to make sure that there is protection against jamming.

- Plastic spline connection. It is installed on medium-power meat grinders. This method has a significant disadvantage - if the edges break off, the engine will run idle.

- Metal spline connection. This mount is installed on powerful meat grinders. The more faces such a slot has, the better it can withstand loads.

Cutting part

The main part of this part is the knife, which cuts the products passing through the working container. Modern models are equipped with forged screw-shaped knives made of stainless steel, so they are not afraid of contact with liquid.

During rotation, these knives are partially sharpened on the grid, which is also made of steel.

But for high-quality cutting and long-term operation, it is recommended to periodically sharpen the knives yourself with sandpaper. The sharper the edge, the better the meat is processed.

The shape of the knives is also important, as it directly affects the shape and quality of chopping products. For example, curved ones are considered the most optimal because they easily crush veins and fibers and prevent the auger from clogging.

Lattices

Grates are perforated discs with holes, the size and shape of which determines how the mince will be. There are options for hole diameters:

- small - from 3 to 3.5 mm;

- medium - from 4 to 5 mm;

- large - from 8 to 9 mm.

You can change the grates to get the consistency and grind you want.

For example, small grids are most often used for grinding nuts, and large ones are used for preparing juicy minced meat for pasties.

The discs have a different number of holes through which the minced meat comes out. The maximum quantity can reach 48 pieces - meat for meatballs, chopping cheese and nuts is best achieved with such a detail. A disk with 18 holes will produce coarse minced meat; it is usually convenient to make homemade sausage from it. Modern models are equipped with different disks.

You might be interested in recipes for delicious homemade sausage.

Clamp

The task of the part is to fix the grid and rotating knives. In working condition, the clamp nut tightens itself, since all parts rotate quickly.

Modern meat grinders come with a special device that will help you unscrew the nut or tighten it. In earlier generation models, the nut can be unscrewed by hand counterclockwise (for example, by wrapping it in a cloth).

Tray

Products for grinding are loaded into it - sometimes manufacturers call it a tray in the documentation. There is a hole in the tray leading into the neck of the meat grinder, through which the products are pushed down by a pusher.

The element is made of plastic and metal - in the first case, the tray is less wear-resistant and loses color over time. Trays come in different shapes and sizes, it all depends on the configuration and configuration of the meat grinder.

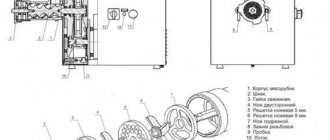

Device [edit | edit code]

A classic manual meat grinder consists of the following parts:

Meat or other product, through a meat receiver, enters a screw conveyor, with the help of which it is pressed against the grate, and then cut off with a knife sliding along the surface of the grate. The meat receiver of a manual meat grinder has ribs, with the help of which smaller pieces are cut from a piece of meat that is too large to pass through the auger. Unlike a blender, food grinding in a meat grinder occurs continuously: the product is placed in the meat receiver and comes out through the grate.

For a manual meat grinder to work, it requires quite a lot of effort to be applied to the handle, which means a strong attachment to the table. Therefore, manual meat grinders are equipped with a clamp. Electric meat grinders do not require a clamp and are manufactured in tabletop or floor-mounted versions. Household electric meat grinders also usually have a narrower and longer meat inlet neck, and they come with a pusher to prevent your fingers from getting caught in the auger. For an electric household meat grinder, it is advisable to cut the meat into smaller pieces before feeding it into the meat receiver.

Additional accessories and functions

In modern realities, a meat grinder is quite capable of replacing a food processor or blender in the kitchen. With various attachments included, you can:

- Make juice with pulp from fruits and berries.

- Thinly slice cheese and potatoes and other hard vegetables. Cutting vegetables is possible in various ways, depending on the shape of the vegetable cutter

- Use special attachments for molding cookies.

- Use the tubes for cooking sausages and sausages.

- Grind coffee and poppy seeds.

- Make noodles.

Read expert advice on how to choose a meat grinder and what to look for when purchasing.

Industrial electric meat grinders

Industrial electric meat grinders, unlike domestic ones, differ primarily in size, performance, and of course price.

For a rough idea, here are some device parameters:

— Dimensions: 68×40x44 cm

— Productivity: 75 – 600 kg/hour, i.e. by the standards of household meat grinders - from 1.25 to 10 kg per minute.

— Prices: 3500 – 13 000 UAH, or 430 – 1600 USD

The purpose of industrial electric meat grinders is catering and meat production.

How to assemble a meat grinder correctly

The assembly principle is quite simple - you can figure it out without any problems if you have assembled a conventional manual meat grinder of an old modification at least once.

First of all, you need to study the instructions - in fact, all electric meat grinders are technically similar.

For clarity, I will give you a photo with a diagram of how to assemble a meat grinder:

How to properly assemble a meat grinder - instructions:

- First, connect the gearbox housing to the auger housing, its end should be immersed in the gearbox groove. Once the parts are in the desired position, turn the auger clockwise until you hear a click. If you installed the parts incorrectly, you will not be able to turn the auger.

- When you put the auger in place, make sure that the protrusion coincides with the hole in the housing. Otherwise the shaft will not work.

- You need to put a blade and a grid on the other end of the auger so that all the holes and protrusions match, and it is important to install the knife with the correct side of the blade. The photo shows how to correctly place a knife in an electric meat grinder.

- Now the structure can be fixed with a clamping nut.

- Place the loading tray and check the build quality. If you hear uncharacteristic knocking or clinking noises during operation, disassemble the meat grinder and try again.

At the time of buying

When you purchase an electric meat grinder, you need to perform a couple of steps:

— Check for functionality. Many sellers like to say the phrase: “Already verified.” Don't listen, it will save your nerves if the device doesn't work.

— Check the stability of the device. The meat grinder must stand firmly on a flat surface and not wobble.

— Complete set according to the passport for the device. And then suddenly someone “borrowed” a knife to their home or a net from the kit.

— See if the outlet height is conveniently located; you may have to immediately purchase a special bowl for minced meat. From this point of view, the higher the “exit” is located, the better and more convenient. But this is not a reason to refuse an electric meat grinder that is suitable in terms of characteristics, design and price.

Principle of operation

Once you know what an electric meat grinder consists of, you can consider the working system as a whole. To reduce the likelihood of the mechanism stopping, it is recommended to cut the product into small pieces before starting work. They should fit well into the meat receiver. Using a pusher, we push the piece into the sleeve, after which it falls onto the augers. Having passed through this structure, the meat is pressed tightly against the lattice nozzle and cut with a knife that glides smoothly along the surface.

There are ribs on the shaft of the meat receiver. They are designed to reduce large pieces of meat that get caught in the mechanism. Small pieces are cut off from the largest ones, after which they all fall onto the auger. The product to be ground is placed in the tube. After a few moments, the minced meat is ready. This is what the user sees.

Basic rules of use

To maintain good condition for many years, you should adhere to a small list of simple rules. They will help preserve every detail and the entire mechanism as a whole.

- Bones should not be sent with meat. It is necessary to cut it into small pieces before processing to avoid wear on the engine and knives. Only small tubular bones and cartilage are allowed to be inserted.

- Rinse and thoroughly dry the components of the device after each operation.

- Constantly monitor the sharpening of knives. If they are always sharp, then engine wear will not occur soon.