Thanks to household appliances, home owners gain complete comfort. Using the same vacuum cleaners significantly reduces the physical effort spent on cleaning. Meanwhile, even super-reliable equipment, for example from Samsung, does not last forever, which says one thing: someday the time comes for repair or replacement.

However, convenient and practical units quickly make users get used to working with them. Therefore, most of their owners prefer to restore their devices to their functionality rather than buy new ones. We will tell you what repairs of Samsung vacuum cleaners can be successfully carried out with your own hands.

Device of various models

The Korean corporation Samsung occupies one of the first places in the world in the production of all kinds of cleaning equipment. It produces all types of vacuum cleaners: industrial, construction, for cleaning companies, but the most popular are household devices for home use. These devices also have many varieties, for example, for dry or wet cleaning, washing vacuum cleaners, units with an aqua filter, and even robotic vacuum cleaners .

Each type of product has its own functionality and technological features, which may determine the type of breakdown and complexity of repair. Let's look at the most common models of Samsung household vacuum cleaners and their technical characteristics.

Samsung SC4520

A budget version of vacuum cleaners from the popular Air Track series (literal translation - “air path”), where a special plastic container is used instead of a garbage collection bag. For its price, it has a fairly good suction power of 350 W and a power consumption of 1600 W. There is no suction power adjustment. Performs dry cleaning only. Equipped with a cyclone filter and a double (two-chamber) container that separates large and small debris. The volume of the dust collector is 1.3 liters, the weight of the vacuum cleaner is 4.3 kg. The length of the power cord is 6 m, automatic rewinding.

Samsung Easy1500

The full model name is SC52-EO. A household vacuum cleaner with average suction power - up to 370 W, and power consumption of 1500 W. The device is equipped with a fabric bag for collecting debris and an additional filter installed in front of the engine impeller. The volume of the dust collector is 2.5 liters. The cord length is 6 meters, automatic rewinding system. The weight of the device is 3.7 kg. Provides only dry cleaning: if moisture gets in, the engine can quickly fail. Produces an average noise level of up to 85 decibels. Has a dust bin full indicator and a power regulator.

Samsung VC-5853

Inexpensive, medium-power option, great for cleaning small spaces. Equipped with a 2.4 liter waste collection bag, it allows for dry cleaning only. The power consumption of this Samsung vacuum cleaner is 1300W, suction power is 330W. Equipped with a built-in fill indicator. The length of the electric cable is 6 meters, the type of winding is automatic, the permissible range is 8.5 meters. The device weighs 3.6 kg. Has an additional fine filter. The noise level produced does not exceed 78 decibels. The suction tube is composite and can be disassembled into three parts.

Samsung SC6570

A modern, bagless household vacuum cleaner. In it, debris accumulates in a special plastic cyclone filter with a capacity of 1.4 liters. It has a dust bin full indicator and a convenient telescopic tube on which the power regulator is located. The weight of the device is 5.3 kg. The length of the electric cable is 6 meters, the range of the vacuum cleaner is up to 9 meters. Suction power – 380 W, power consumption – 1800 W. The noise level produced is no more than 78 dB. It is equipped with an additional turbo brush and a fine filter. It involves performing dry cleaning only; getting moisture into the dust collector is extremely undesirable.

Samsung SC6573

Compact and convenient household vacuum cleaner with a plastic dust collector (cyclone filter). Equipped with a telescopic sliding tube and container filling indicator. A power control mechanism is built into the handle of the tube. The device weighs 5.2 kg, the volume of the dust collector is 1.5 liters. Power consumption is 1800 Watts, and suction power is 380 Watts. The noise level produced during operation is 80 decibels. The cable rewind type is automatic, the cable length is 6.1 meters, and the operating range of the vacuum cleaner is 9.2 meters. The kit includes a turbo brush. The vacuum cleaner is designed for dry cleaning.

Samsung SW17H9090H

A universal vacuum cleaner with an unusual and stylish design that performs both dry and wet cleaning. Dust collector type – aquafilter with a capacity of 2 liters. The kit includes an additional HEPA filter and turbo brush. Sliding suction tube with built-in power regulator. The weight of the device is 8.9 kg. The length of the network cable is 7 meters, the rewind type is automatic. The operating range of the vacuum cleaner is 10 meters. Power consumption – 1700 W, suction power – 250 W.

When choosing a model and during operation of the device, be sure to take into account the manufacturer’s recommendations regarding the type of cleaning performed. Many owners believe that if a vacuum cleaner has a plastic dust container (container), then, regardless of the model, it can be used to remove spilled liquids or during wet cleaning of carpets.

This opinion is wrong. The plastic container itself is not exposed to moisture, and it can even be washed under the tap after removing it from the device .

But if the vacuum cleaner is not intended for wet cleaning, then its filters do not retain moisture, and it, even in small quantities, certainly gets into the engine of the device. Subsequently, this can lead not only to failure of the unit itself, but also to a short circuit in the electrical wiring in the room.

The principle and design of the vacuum cleaner

The choice of vacuum cleaners is expanding. Main options:

- For dry cleaning;

- with aquafilter;

- washing vacuum cleaner.

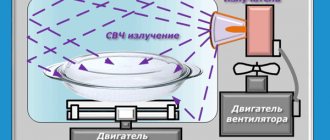

The most common and lightweight is a dry cleaning vacuum cleaner. The operating principle of modern vacuum cleaners and old ones is the same.

After starting, all debris is sucked out using a vacuum fan. Once inside, the garbage goes through several stages of filtration. Often, this is: at the debris inlet, in the engine part, and at the outlet. Each stage protects the vacuum cleaner from damage by large particles.

The first sign that the filter is clogged is that the suction power drops.

All dust and dirt are collected in a special bag. They can be reusable and replaceable from paper. There are models of vacuum cleaners that use a container system instead of a bag. All the dirt settles on the walls of the container, and then purified air also comes out.

How does a vacuum cleaner work?

Before you undertake repairs to a Samsung vacuum cleaner or another company, you should understand its structure. For example, each vacuum cleaner is equipped with an air suction unit into which air is drawn in. And in front of it there is a filter designed to purify the air (vacuum cleaners with a water filter work on a slightly different principle).

Most often, the filter for Samsung vacuum cleaner is made by Nera. The air is cleaned as it enters the Hepa filter, and then it goes to the engine, where it performs a cooling function.

The engine must be cooled to avoid overheating. If cooling is sufficient, then the vacuum cleaner, or rather the motor of a Samsung vacuum cleaner, can work continuously for 120 minutes. The way the vacuum cleaner motor works is also significantly affected by the filter for the Samsung vacuum cleaner.

It is preferable for Samsung vacuum cleaners to use a hepa filter (it is also installed on a cordless vacuum cleaner), especially for the Samsung sc 6570 model. It is recommended to keep the hepa filter clean at all times.

How to make a HEPA filter for a vacuum cleaner

Most models of modern vacuum cleaners have a Nera filter, which quickly breaks down, which affects the suction power and the quality of cleaning. If this happens, you should not rush to the store to buy a new part, but you can try to make it yourself.

To make a HEPA filter, you will need an old filter and a cabin filter for your UAZ. The further process will consist of the following steps:

- using a screwdriver, squeeze out the paper component of the filter, doing this in the direction from the plastic grid;

- Clean the remaining plastic part from any remaining glue;

- take a car filter and use a cutter to make it according to the size of the vacuum cleaner filter;

- Use a glue gun to coat the perimeter of the filter so that there are no air holes left;

- wait until the glue dries and you can use the HEPA filter.

Is it possible to fix a vacuum cleaner yourself?

Most of the models of household cleaning appliances from the Korean company are represented by designs that are relatively simple in technical terms. Accordingly, in most cases, repairing such products is also quite simple.

Obviously, the complexity of repair work is completely related to a specific unit or part. Thus, fixing a small break in a corrugated hose is much easier than replacing a broken electric motor bearing.

It is cost-effective to repair Samsung household appliances - vacuum cleaners. However, some individual repair cases require skills and the ability to hold a screwdriver, soldering iron and other tools in order to completely disassemble the device

Let's look at common malfunctions of Korean-made household vacuum cleaners and possible ways to eliminate such defects at home. It is logical to note: with all due respect to service workshops, the amount of payment for repairs in the service often approaches the cost of a new vacuum cleaner.

Serious damage to Samsung vacuum cleaners

Repairing serious defects usually requires the intervention of certified technicians. However, here too some of the faults can be repaired yourself. For example, the owner can easily replace a damaged power switch himself.

No. 1 - power button and power cable

A faulty power switch prevents the device from being turned on, or the operating mode is not locked when turned on. In the first case, the reaction when the button is activated is zero.

In the second case, the vacuum cleaner starts when the button is pressed, but immediately turns off when the user releases the button.

A defective vacuum cleaner power button is the reason for the device’s inoperability. This malfunction is one of the most common in practice, but it can be eliminated quite easily compared to others.

The functionality of the power switch can be easily checked with a tester - an electromechanical device. A non-working button does not create contact between the terminals in any position.

A non-latching button creates contact only in the pressed position. By connecting the tester probes to the button terminals, you can check the functionality of all positions.

Checking the network button for turning on the vacuum cleaner using an electronic tester. One probe is connected to the contact of the power plug, the second the repairman touches the terminals of the button. In this way, the button and cable are tested simultaneously

Along with the network switching, the power cable of the vacuum cleaner may also be faulty. The power cord is checked with the same tester.

Checking the power cord also involves testing the power outlets that the owner uses when turning on the vacuum cleaner.

No. 2 - air suction power regulator

Many Samsung models are equipped with a suction power control module. Essentially, this module is a regulator of the rotation speed of the electric motor shaft installed inside the vacuum cleaner. The module is an electronic circuit (relatively simple) based on thyristors.

The motor speed control module is also a suction power regulator. The faulty component of the module is often the thyristor switch, which is located on the bottom left of the board

A module malfunction—usually a thyristor failure—results in either the inability to start the vacuum cleaner or a complete inability to regulate the performance of the device. In any case, it is necessary to disassemble the vacuum cleaner, remove the control module and replace failed components.

Here it is quite problematic to work with your own hands without certain skills, for example, the ability to distinguish a resistor from a capacitor or the ability to hold a soldering iron in your hands. However, if desired, these qualities of an electronics engineer are not difficult to master.

No. 3 - electric motor of a household vacuum cleaner

A complex malfunction, of course, is considered to be the failure of the electric motor of the vacuum cleaner. As a rule, the designs of modern household appliances produced under the Samsung brand use axial-type motors with a rotation speed of up to 20,000 rpm.

The electric motor of a Samsung vacuum cleaner is a design part that requires a special approach in case of repair. It is possible to replace the motor with a new one, but this option costs almost half the cost of the harvesting machine itself

Rotation at such a high frequency is accompanied by significant loads on the support bearings. Therefore, one of the common malfunctions of Samsung vacuum cleaners is defective bearings. This is usually accompanied by increased operating noise of the device, sometimes very loud.

The job of replacing vacuum cleaner bearings with your own hands is difficult, but quite doable. However, initially you will have to disassemble the entire contents of the structure of the harvesting equipment in order to get to the motor.

Of course, during the process of disassembling the vacuum cleaner, it is recommended to record the sequence of installation of parts, writing it down on paper, or you can take pictures with a smartphone.

The electric motor of the vacuum cleaner is completely disassembled. To achieve such a result, the repairman will have to work hard and also study some of the intricacies of the work.

On a dismantled engine, you will need to remove the contact brushes and impeller casing. This process is relatively simple.

Contact brushes are usually secured with one screw and can be easily removed from their mounting niches. On the impeller casing (outer half), you need to carefully bend the four rolling points and, using some force, pull off the casing.

The most difficult process is unscrewing the nut that secures the impeller to the motor shaft.

Craftsmen with experience in repairing vacuum cleaners use different methods for these purposes:

- clamp the engine manifold with wooden blocks;

- wrap an insulated wire around the collector;

- cut a groove along the end of the shaft.

As a result, the impeller can be removed. Next - a “matter of technology” - the shaft is removed by traction force, and the defective bearings are replaced. Then reassemble in reverse order.

Electrical defects in motors - breakage, winding short circuit between turns, commutator burnout - are relatively rare phenomena, but they also occur. In such cases, the electric motor is usually replaced with a different (new) copy.

Weak "pull"

As we have already found out, if the vacuum cleaner does not suck in dust well, then you will most likely have to repair the vacuum cleaner hose (you have a Samsung or a product of a different brand - it doesn’t matter). First of all, make sure that nothing is stuck in it - foreign objects caught in the hose greatly reduce traction. Simply put, look into the hose and remove the clog.

If you are sure that the hose is not clogged, carefully inspect it and check the integrity of the corrugation. Very often, housewives are too lazy to bend down to move the unit from place to place, and they simply drag it around the room “by the tail.” This causes gaps to appear between the turns of the corrugation, resulting in reduced traction. If you find a gap, take electrical tape and wrap the gap tightly in several layers. Such repairs, of course, will not be enough for a long time, and over time the hose will still have to be replaced, but it will still serve you for some time.

If everything is fine with the hose, check all the filters and the garbage bag - they may be very dirty. Clean the filters thoroughly and replace the bag with a new one. Also, do not forget to check the position of the power regulator - it may be out of order. Return it to the desired position.

How to disassemble a vacuum cleaner pipe

It is impossible to examine the telescopic pipe in detail without damaging the unit. Even if you do it as slowly and carefully as possible, some small damage will still occur. The fact is that such analysis is simply not provided for in the instructions. If you disassemble the pipe, you will no longer be able to reassemble it 100%.

Many are sure that telescopic tubes are non-separable. The opinion is wrong, you can try, but you will break the latches. Even the heating method cannot help here.

In any case, it is necessary to clean the inside of such a hose, as dust and dirt settle there. Just rinse the tube periodically with water, you can use soft brushes.

The main malfunctions of vacuum cleaners from different manufacturers

For each manufacturer, we can identify the most common problem encountered in manufactured models. The analysis below is based on online customer reviews.

Samsung

Samsung vacuum cleaners are quite reliable, but they also require careful treatment and timely maintenance. It is necessary to monitor the condition of the filters and dust collector and clean them regularly. There are also problems with the motor and the power button.

LG

Judging by user reviews, vacuum cleaners from this manufacturer quickly clog filters and lose suction power; fragile attachments break faster than wear out. There are cases of excessive heating and shutdown during operation.

Philips

Those who at one time preferred vacuum cleaners from this company say that over time the suction ability is lost and the noise during operation increases. There are complaints about an unpleasant odor during operation and a poorly winding cord.

The Philips vacuum cleaner caused the following reaction from our author: Philips FC 9184

Bosch

Over time, the rubber seals of these vacuum cleaners suffer, and the parts fit less well to each other. Bosh often releases cordless models, and the batteries also sometimes require replacement. Often the engine also fails.

Dyson

In reviews of Dyson vacuum cleaners, there are practically no complaints about their performance. The only thing is that with wireless models, the battery discharges faster and faster over time and it has to be replaced (which, in principle, is natural).

Thomas

The Thomas company mainly produces vacuum cleaners with an aqua filter, and they require increased care - washing after each cleaning and drying thoroughly, otherwise they quickly fail and an unpleasant odor appears during cleaning. Also in the reviews there are complaints about the easily torn hose.

Vacuum cleaner device

The vast majority of vacuum cleaner models are built according to 3 design types:

- With a dry dust bag;

- With aquafilter (with air-water mist filter);

- With non-replaceable cyclone dust collector.

Design of household vacuum cleaners with a dry dust bag, with an aquafilter and with a cyclone

Any of the vacuum cleaners of these types can be equipped with attachments (brushes) for wet and dry cleaning. Nozzles have their own characteristic malfunctions, which we will also deal with further.

With a bag

In a vacuum cleaner with a dry dust collector (on the left in the figure), the air passes first through the dust bag, then through the fine filter and the fan motor compartment. T. called. The HEPA filter traps particles with a size of about 1 micron. The HEPA filter only works under pressure, and dust particles less than 3-5 microns do not affect the operation and durability of the motor, so the HEPA filter is placed after the fan motor, which in this case also works as a compressor.

Vacuum cleaners with a dry dust collector are the least prone to breakdowns, but their main drawback is disposable filters. The dust collector is made of propylene or silicone fiber and cannot be regenerated - once the bag is full, throw it away and replace it with a new one. If you try to clean it, rinse it, or sew a fabric one from an old vacuum cleaner onto the old neck, the formation of microdust increases so much that the thin and HEPA filters instantly become clogged. If you “cheat” them in a similar way, it soon turns out that engine repair is necessary, expensive and/or complicated.

The fine filter and HEPA filter also cannot be restored, but in some cases this is still possible, see below. A characteristic sign of clogged filters is that the vacuum cleaner does not pull well, makes a loud noise (without clanging or rattling), and gets hot. If there is automation, 1-15 minutes after switching on it switches to reduced power or stops. For example, over 65% of calls to warranty service for inexpensive LG vacuum cleaners regarding such a “breakdown” are caused by a clogged HEPA filter. The user is shown where it is printed in small print that this is a non-warranty case and is explained in a friendly manner how much to pay. Meanwhile, replacing the filter in an LG vacuum cleaner is a completely nonsense matter, see next. video.

Video: repairing a vacuum cleaner that turns off by replacing the filter (using the example of LG)

With aqua filter

In vacuum cleaners with an aqua filter (in the center in the figure at the beginning of the section), filtration is 2-stage; in fact, it is single-stage. The flow of incoming air whips up the water in the dust collector into a mist that immediately absorbs all the dust. A foggy vortex spins under the front visor of the dust collector and the dust settles to the bottom. Next, the fog with microdust residues passes through a fog filter, which also works as a HEPA filter; clean air without droplets of moisture cools the motor and is discharged outside. A vacuum cleaner with an aqua filter consumes 20-25% less electricity than a “dry with a bag” vacuum cleaner with the same air output and the same vacuum.

If the aqua filter of a vacuum cleaner is promptly emptied, washed and filled to the mark (or according to the norm in the instructions) with clean (preferably distilled) water, then the fog filter will last up to 2-2.5 warranty periods without replacement. If you pour tap water into the dust collector by eye, it becomes clogged long before the end of the first one. Symptoms are the same as before. case; Replacement in the service is also paid. Self-replacement - open the lid of the vacuum cleaner, release the latches of the filter cover, remove the old one, put in a new one. A clogged fog filter cannot be repaired.

Note: the fog filter of a vacuum cleaner with an aqua filter almost always fails instantly if the vacuum cleaner tips over and liquid moisture gets on the fog filter. The same thing happens when water is poured into the dust collector.

Another disease of vacuum cleaners with an aquafilter is much more serious - their motor is blown with air saturated with water vapor. On average, warranty replacement of a fan motor with burnt windings in vacuum cleaners with an aqua filter is carried out twice as often as in others, per product; Samsung vacuum cleaners of the VC/VCD series are especially guilty of this. Signs that the motor windings are “curled” (short circuit, short circuit, between turns) - the vacuum cleaner makes a loud noise, pulls poorly, and gets hot. Does not reach full capacity; It is possible that the plugs or circuit breaker may be knocked out. We check the motor for a turn short circuit. in this way (the technique is also suitable for other types of vacuum cleaners):

- We turn on the vacuum cleaner for a short time without a hose and with a dry aquafilter. You can hear a clanging or knocking sound - you need to first check the impeller and motor bearings, see below.

- It works smoothly, but pulls weakly - cover the inlet hole (socket for the hose) with your palm. If the impeller is covered with dust, but the motor is working properly, its sound should change significantly. Remained the same or the change is barely noticeable - a permanent turn short circuit.

- The motor seems to be working fine - remove your hand and wait 5-10 minutes (no more!). The thrust dropped, heating began; perhaps the plugs were knocked out - an intermittent short-circuit from heating.

- We look on the Internet or in any other way to find out how much a new compressor (fan motor) costs for this replacement vacuum cleaner model.

- We check with the service center or with the experts - such and such a model, there is a suspicion of a turn in the motor, how much will it cost to rebuild and rewind?

- We are deciding whether to send it in for repair or replace the compressor with our own hands, see below.

Note: you can also watch the video below about repairing a Samsung VC6015V 1500W vacuum cleaner:

Video: disassembling and repairing a vacuum cleaner with an aqua filter (using the example of Samsung VC6015V)

With a cyclone

Vacuum cleaner with cyclone dust collector

A vacuum cleaner with a cyclone dust collector can be recognized by the transparent “glass” on the front, see fig. on right. The masters say this to each other: well, they brought me a glass. Which generally happens no more often than with “dry bags.” This is fairness.

The main advantage of vacuum cleaners with a cyclone is that there are fewer disposable filters that you need to buy and buy, and water containers that need to be carefully refilled and cannot be knocked over. It would seem that the motor could be weaker; There appears to be minimal resistance to air flow. But no. Since the dimensions and configuration of the vacuum cleaner cyclone are far from optimal based on the physical properties of the air, the motor, on the contrary, is needed the same 20-25% more powerful than for a “dry with a bag”.

In household cyclone vacuum cleaners, double cyclones are used almost exclusively (on the right in the figure with the diagrams above); These trade names contain the designation twin. When the dust container is full, shake it out; no flushing required. The purified air then goes into the engine compartment and out through the HEPA filter. Since the formation of microdust in the cyclone is minimal, the HEPA filter of the cyclone vacuum cleaner lasts much longer.

Disease of cyclone vacuum cleaners - mesh filter at the outlet of the cyclone; it protects the fan motor from large particles. In general, cyclone vacuum cleaners perform well in rooms where the housewife (or maid) walks with a vacuum cleaner every day. If the room is cleaned once a week or less, the mesh filter quickly becomes clogged. The symptoms are the same as those from a clogged HEPA filter. And it happens that a very powerful vacuum cleaner with a cyclone, for example, a Samsung 1800W (Samsung SC8431 twin) does not reach full power in a normal room until the mesh filter is completely removed, see next. video.

Video: repairing a cyclonic vacuum cleaner with a clogged mesh filter (using the example of Samsung SC8431)

Removing the mesh filter is certainly not beneficial either for the longevity of the motor or for the cleanliness of the air and room. Suddenly the vacuum cleaner catches a brooch, a badge, a paper clip, or any small hard object - you can count out money for a new fan motor with peace of mind, because... a dented impeller instantly disrupts the balancing of the motor armature, see below. Samsung's lower power cyclones do not require mesh removal (they have it less often), but another characteristic defect appears - a broken lower bearing. However, replacing it is much simpler, cheaper and possible on your own, for example, see the story on how to repair a Samsung 1600W with the following fault:

Video: replacing a bearing in a cyclone vacuum cleaner

Required Tools

The set of tools needed will depend on the type and model of Samsung vacuum cleaner. When disassembling and repairing, preventing or cleaning the device, as well as its individual elements, you cannot do without the following devices:

- Phillips and slotted screwdrivers - their sizes are selected in accordance with the type and depth of the screws;

- pliers;

- a stationery knife, or better yet a professional construction knife;

- lubricant;

- electrical insulating tape;

- electrical tester.

The type of work performed will largely influence the choice of tools. For example, to clean the surface of a suction hose before gluing cracks, you will need sandpaper and a degreaser (acetone, solvent). It is convenient to remove dirt on the shaft of the vacuum cleaner brushes with scissors, but to remove blockages you will have to use a long, stiff wire. For gluing cracks or chips on the body, universal super glue is suitable, but for moving parts, such as a hose, a more elastic adhesive material is needed.

Difficulty of repair depending on the type of damage

The complexity of the repair depends on the type of fault.

| Electrical breakdowns | Mechanical failures |

| The cord at the base of the plug broke | For example, a bearing failure. Most often, such breakdowns occur as a result of not very careful handling of the vacuum cleaner, for example, if it was dropped, stepped on the hose, and so on. Such breakdowns are visible to the naked eye, they can be easily eliminated - you just need to replace the parts with new ones. |

| switch fault | |

| cord break along length | |

| filter or capacitor burnt out | |

| the rotor or stator winding has broken | |

| winding burnt out |

Electrical repairs are easy. Often it is only necessary to replace the listed parts. It is important to understand that you should purchase only high-quality licensed parts. You cannot save on this, otherwise the situation will repeat itself or become more complicated. If the stator or rotor of an electric motor has been rewinded, several points must be taken into account:

- cross-section of copper wire;

- number of turns of copper wire.

In this case, it is better to replace the electric motor. Seeing electrical faults is not easy and may take time. When repairing a vacuum cleaner, it is important to remember that there is a difference between the motor for a Samsung 1600w and 1800w vacuum cleaner, which may affect what type of repair.

If the cause of the breakdown is difficult to determine after an initial examination or is too complex, then it is better to contact a specialist. This especially applies when the problem concerns engines.

How is the problem solved, and is it possible to prevent it?

Why doesn't the vacuum cleaner work? Let's look at some trivial reasons that any user can deal with. Automation failure can occur for the following reasons:

- Filling the dust container. This will be indicated by the presence of a dusty smell.

- Ingress of large debris. Large sizes of dirt stuck in the air duct interfere with the flow of air sucked by the vacuum cleaner.

- Debris stuck in the hose. Evidence of this is a change in sound when the device is turned on.

- Pre-engine filter is dirty. During this process, an unpleasant burnt smell appears.

Let's consider the possibilities of repairing a faulty Samsung vacuum cleaner, and what to do when the vacuum cleaner does not turn on. You can fix the above problems yourself, but it’s still better to avoid them in the first place. To do this, you will need to disconnect the equipment from the power source, then disassemble the device and clean the debris accumulated inside.

To access the dust container, remove the top cover. Some dust containers can be cleaned, or you can replace them with new ones. It is also advisable to wash the dust collector and dry it. In order not to spill dirt and dust, you should close the existing valve for a tight seal. When installing the dust collector back into place, make sure that the neck fits snugly against the bag holder. If this does not happen, then dirt and dust will seep into the structure, which will lead to overheating of the motor and accumulation of dirt on the components.

Filters require additional care. Be sure to read the instructions and find out how many filters are installed in your particular vacuum cleaner model. All filters installed in the structure should be checked. Some types of filters can be washed with running water to clean them. But before installing it in the structure, you should definitely dry it. Starting a vacuum cleaner with a wet filter will cause damage. Periodic replacement is carried out according to the manufacturer's recommendation. When the filter has served its useful life, it is replaced with a new one. The filter life is indicated in the operating book.

All replacement consumables, filters, brushes and other accessories can be purchased at a specialized store.

To remove blockages in the nozzle, unscrew the corrugated accessory from the body, inspect its integrity, remove the accumulated dirt and screw it back. Dirt stuck in the bellows prevents air flow.

But still, if the vacuum cleaner does not turn on, what should you do? If the repair of the breakdown is serious, it is better to contact specialized technicians who can solve this problem.

But it is worth remembering that the main possible breakdowns occur due to engine overheating. You should adhere to the following rules:

- To prevent overheating, use the vacuum cleaner for no more than 30 minutes when cleaning. At maximum mode, use the device for no more than 10-15 minutes. Longer operation may lead to overheating; to do this, allow the device to rest and cool down.

- Make sure the dust bin is full to remove accumulated dirt and dust. An excess of dirt and dust will not allow air flow to pass through, which will lead to overheating of the electric motor. Also, an excess of dust in the dust collector will lead to clogging of the structure inside the device.

- Clean the pre-motor protection filter in a timely manner. Excessive contamination can lead to the formation of an unpleasant burnt odor.

- Avoid sucking large objects that may block the blower. Before using a vacuum cleaner to clean the floor covering, you should collect large debris and accidentally fallen items by hand.

- You need to monitor the level of noise produced. If the sound changes, this may indicate a clogged brush or bellows accessory.

Monitor the performance of your home assistant, and provide timely care for the vacuum cleaner and its replacement consumables. Then it will be easier to avoid breakdowns of equipment to maintain cleanliness in the house.

Minor defects of vacuum cleaners

Minor defects usually do not cause global malfunction of the device. The Samsung vacuum cleaner continues to work, but the technical parameters no longer correspond to exemplary values.

As a result, the traction force decreases and at the same time the power consumption of the equipment increases. Accordingly, the quality of cleaning decreases, but most importantly, the risks of more serious defects increase.

Minor defects in the vacuum cleaner usually lead to a significant decrease in performance. The suction force weakens, and the electric motor and other parts heat up, which leads to more serious breakdowns.

Therefore, minor faults should not be ignored. On the contrary, they should be eliminated as soon as possible.

Classic defects of this kind for Samsung vacuum cleaners:

- reduction in HEPA filter efficiency;

- clogging of the cyclone filter mesh;

- blocking of the brush turbine by foreign objects;

- blocking wheel rotation by foreign elements;

- clogging of the rod tube;

- rupture of the corrugated hose.

Let's look at each individual group of defects in more detail.

Problem #1 - reduced filter efficiency

As a rule, all existing models of cleaning equipment from Samsung are equipped with reusable filter components. That is, after each cleaning, the owner of the device removes the filters, washes them, blows them out and returns them to their place. The cycle is repeated.

Periodic cleaning of the filter elements of harvesting equipment cannot go on forever. There comes a time when filters need to be changed, and if this action is not completed on time, the consequences lead to complex repairs.

However, the filter material cannot be thoroughly cleaned. With each cleaning, the pores of the material become more and more clogged with microscopic particles. Finally, the moment comes when the filter loses its air transmission efficiency to 50% or less. This is already a limit that violates the technological principle of operation of the vacuum cleaner.

The motor continues to operate at full power, but resistance on the suction and discharge sides increases the load. Currents increase, the winding and, accordingly, the parts of the electric motor become very hot. If you continue to operate the equipment in this condition, the day is not far off when the motor will simply jam or burn out.

This is what a fully used HEPA fine filter looks like, which is used in almost every model of Samsung vacuum cleaner. The clogged pores of the filter do not allow air to pass through, which creates a load on the motor

Which exit? Of course, complete replacement of filter elements at all stages, including the HEPA filter. Typically, any type of filter material (foam rubber, porous sponge, siprone) is available commercially.

Problem #2 - a worn-out HEPA filter

It’s a little more complicated with the HEPA material, but you can find a way out here too. That is, the user just needs to buy a suitable material, cut out the elements of the required size and use them to replace the material that has lost its performance.

Installing a homemade version of the HEPA filter is somewhat more difficult. You will need to carefully open the double mesh frame (usually the frame is made of plastic) to remove the replacement filter material.

Filter frame holding the working material. Essentially, this configuration cannot be repaired. However, if desired, the frame can be opened and the material replaced with new one at home.

It is necessary to cut around the perimeter with a sharp stationery knife the area where the two plates meet, and then, with a little force, divide the frame into two parts. Next, replace the HEPA sheet with a new one and re-glue the frame-holder.

The same applies to the mesh filter and the motor protection filter, which are used in cyclone models.

Both the first and second filters become densely clogged with dirt, by the way, due to the fault of users who violate the regime of filling the container above the specified mark. There are cases of clogging of the rod tube. Blockages are removed by cleaning.

Problem #3 - rupture of the corrugated hose

The accessory connecting the vacuum cleaner inlet and the rod tube with the working nozzle, a corrugated soft hose, is damaged at the points of soft folds due to wear of the material or as a result of loads applied to this point.

Traditional points of damage are the joints of the hose with the lock pipe or with the rod tube pipe.

An example of a damaged corrugated hose from a Samsung household vacuum cleaner. Often they try to fix such malfunctions using ordinary tape. But this option is short-lived

The repair process in such cases is not particularly difficult. It is enough to cut off the hose a little further from the point of the break and carefully remove the remains from the inside of the pipe (the factory fastening is glued).

The inside of the pipe usually has a thread exactly for the hose coil. Using this thread, the cut hose is simply screwed into the pipe and the repair can be considered complete. Practice has shown that there is no need for any additional fastenings using glue.

If a rip has formed in the central part of the corrugated hose (or, for example, you need to extend the accessory), in such cases it is convenient to use a piece of a rubber tube from a bicycle tire.

When a break in a corrugated hose occurs directly in the central area or there is a desire to lengthen the hose, then a bicycle tire tube is ideal for repairing or upgrading

In terms of size and tight fit, this material is ideal. First, the parts of the hose are cut and glued, and then a rubber coupling from a bicycle tire is pulled over the created joint. A coupling 30-40 mm wide also “sits” on the glue.

The process of replacing a vacuum cleaner hose is described in detail in the article, in which each step is thoroughly analyzed and recommendations are given.

Problem #4 - blocking the movement of mechanisms

These malfunctions are inherent in mechanisms such as the brush turbine, as well as (occasionally) the wheel chassis. Both units have rotating parts - shafts, gears, rings. During cleaning, hair, threads and even thin small metal wires inevitably get into the area of these nodes.

These pieces of debris wrap around the shafts of gears, rings, and wheels and, over time, accumulate in such large quantities that they completely block rotational motion.

The turbo brush that comes with Korean vacuum cleaners has a collapsible design. It is enough to find the plug on the side end and turn it 45 degrees to remove the entire mechanism

Such moments also affect the operation of the vacuum cleaner, increase the load on the engine, and force the user to increase the traction force on the corrugated hose, which is damaged in places of folds.

In this condition, the first step is to unblock the movement of the nodes. The turbo brush must be disassembled (the manufacturer provides for disassembly) and the internal area must be thoroughly cleaned.

The dismantled top cover of the vacuum cleaner body allows access to the inside of the large wheel rims. This is where debris in the form of threads and hair often accumulates, which blocks the rotation of the rims.

To access the inside of the large wheels of the vacuum cleaner, you will have to remove the housing by unscrewing several screws from the bottom. Both actions are quite accessible to do with your own hands.

Samsung vacuum cleaner does not work

Samsung vacuum cleaners are very popular among housewives. Good quality, nice design and relatively affordable price make these devices very beneficial for the user.

Despite the high quality, you can often come across questions on forums: “the Samsung vacuum cleaner does not turn on, what is the reason.” The reasons here are the same as in the cases described above. The vacuum cleaner turns off during operation due to poor contact, clogged filter, hose or worn motor brushes.

If the vacuum cleaner overheats and turns off, repeat the procedures described just above. The Samsung vacuum cleaner gets quite hot, so if it stops working and turns off, don’t forget to let the device cool down properly first.

How to repair a vacuum cleaner hose

If the hose from a vacuum cleaner breaks, do not rush to get rid of the equipment, as the breakdown is easy to fix.

If the rupture occurs at the point where the hose is attached to the vacuum cleaner, the rupture site can be wrapped with tape or tape, although such repairs are short-lived. You can try cutting off the damaged part by making the hose a little shorter.

If the gap occurs in the middle, then this problem can also be fixed independently. The vacuum cleaner hose is a spiral of steel wire with a PVC or fabric cover on top. Armed with pliers, wire cutters, a screwdriver and a piece of copper wire, you can get to work.

Cut the wire into pieces of 7-8 centimeters. Their number depends on the size of the gap. Make small hooks out of them, which you insert into the holes made on the hose at the break point. After this, the wire is aligned, as shown in the photo, and tightened together in turns so as not to damage the insulation.

Excess parts are removed with nippers, and the twists are bent, after which the sharp edges are processed with a file. The top of the seam is wrapped with electrical tape and such a patch will allow you to continue to fully use the vacuum cleaner.

Dead batteries

Some vacuum cleaners can be turned on with a button on the handle to which the hose is attached. If you have such a vacuum cleaner, try turning it on with the button on the body.

If the vacuum cleaner starts from the button on the body, replace the batteries in the handle and continue using it. If the vacuum cleaner does not turn on from the button on the body, proceed to the next recommendation.

Repair it yourself or call a professional?

You can repair a Samsung vacuum cleaner yourself, or entrust this work to a professional. Both options have their advantages and disadvantages that you need to consider before making your final decision.

Equipment under warranty

For most models of Samsung vacuum cleaners, the warranty is 1 year, although for devices in the SC20F70, SC07F80 and SC12H70 series it is 5 years .

In addition, some models with an inverter motor come with a 10-year warranty from the date of purchase.

If the vacuum cleaner breaks down, but is under warranty, you do not need to repair it yourself. You should contact a service center, where all parts will be replaced free of charge. If the equipment cannot be repaired, it must be replaced or the money returned. The main thing is not to attempt to open the case yourself.

Pros and cons of home renovation

Advantages of home renovation:

- financial savings;

- arrival of the master anywhere in the city, at a time convenient for the client;

- repairs are carried out in front of the owner of the equipment.

The main disadvantage of home repairs is the difficulty in finding a qualified specialist and the risk of meeting scammers.

Therefore, it is better to contact craftsmen who have already proven themselves by performing similar work for relatives or friends. It’s good if he has a narrow specialization, that is, he only repairs vacuum cleaners.

Advantages and disadvantages of repairing at a service center

Repairing equipment at a service center has the following advantages:

- Original parts are always available.

- The likelihood of encountering scammers is minimal.

- Large organizations employ qualified specialists.

- All work is carried out under a contract. Replaced parts are guaranteed.

The disadvantages include the need to deliver equipment to a service center and the high cost of work (compared to private craftsmen).

You can find a specialist by looking at an advertisement in a newspaper or on the Internet . The average cost of repair work is 1,500 rubles, depending on the complexity.

There is a smell during operation

The cause of such a breakdown may be the hose (this is a common case for Samsung): dirt and debris often gets stuck between the turns of the corrugation, which over time begins to emit an unpleasant odor. Rinse the hose thoroughly with a stream of water, preferably under pressure and using detergent. After this, be sure to dry the corrugation thoroughly before using it again.

Another source of unpleasant odor can be the belt. Check its tension, tighten it if necessary or replace it with a new one. The smell of burnt rubber will disappear.

How to understand what is causing the vacuum cleaner to heat up?

A clogged filter as a cause of malfunction Often, dirty filters with broken components, faulty motor systems and full dust containers are the reason why the vacuum cleaner starts to heat up. To understand what exactly is the reason for the heating, you can follow these steps:

- Turn off the vacuum cleaner after use, remove the hose and restart. If it stops heating, then the problem is in the pipe or nozzle. In the same way, you need to check the exit for obstacles.

- Turn off the heated dust collector and remove the filter, removing all debris from it. Then run it again and check its operation.

You can also clean the filters. Sometimes the reason why the vacuum cleaner turns off during operation is because of them. The engine itself often breaks down. In this case, if the vacuum cleaner overheats, it will turn off itself. In most cases, repairs are made independently, without the help of professionals. This does not require special knowledge. But there are times when you should seek help from a qualified specialist.

What exactly can you do yourself?

- Clean the dustbin, filter, and vacuum cleaner hose.

- Change the power button. Replace burnt parts and, if necessary, plug.

- Check the wire and control board.

- Disassemble the engine and (if you have experience) try to restore it. More details in the following articles about vacuum cleaners.

You can also buy a robot vacuum cleaner: they operate on batteries with a voltage of no higher than 15 V, so their motor is unlikely to overheat. Repairing a robot is much easier. Examples of brands are Iclebo Arte and iLife.

What you can do on your own

What should I do if the vacuum cleaner turns off during cleaning and does not turn on again, or when it does not turn on after storage? First you need to understand what happened. The algorithm of actions (and it must be performed sequentially) will be the same for all devices, regardless of the type of dust collector, be it a container, bag or aquafilter.

- Check the power source. If there is electricity in the apartment, try plugging the vacuum cleaner into a different outlet. Perhaps the breakdown did not happen to him, but to the socket.

- Inspect the power cord and plug for breaks, kinks, or other defects. The plug should not be melted, there should be no visible damage in connection with the cord or on it itself.

- The next likely problem is the dust collector. If it is clogged, a safety shutdown may be triggered. Empty the dust container or change the bag. Check the hose to see if it is clogged with large debris.

Dust container is full

If the vacuum cleaner does not come to life at any stage of the diagnosis, the problem is a broken or burnt out motor. In this case, only service technicians will help, who will test the device on professional equipment and repair it.

The main causes of breakdowns and recommendations for safe operation of the vacuum cleaner

The main causes of breakdowns are incorrect or careless operation of the device and insufficient care. In order for the vacuum cleaner to last longer, it is important to perform simple preventive actions:

- Monitor the cleanliness of the filter elements - collect dirt, wash if necessary and change on time. Using a vacuum cleaner with damaged filters will sooner or later lead to engine failure;

- lubricate and promptly replace bearings with new ones;

- do not drop or hit to avoid mechanical damage - chips, cracks;

- store correctly. A suspended or unsuccessfully twisted corrugated hose will sooner or later break, high humidity in the room or too low temperatures contribute to the failure of electrical contacts, etc.;

- read and follow the operating instructions.

It is important to protect not only the vacuum cleaner, but also yourself: under no circumstances use a device with a damaged housing or power cord insulation - this could result in electric shock.

© obzorok.ru

Prevention of breakdowns

In order for equipment to last as long as possible, it must be properly cared for. If we talk about vacuum cleaners, then you need to adhere to some simple rules:

- promptly replace garbage collection bags and wash the dust collector;

- clean the turbo brushes. For example, improper care of the turbo brush can lead to its breakdown and then you will have to pay about 1000 rubles for a new spare part;

- do not forget to regularly check the air channel to ensure that there are no foreign objects in it that interfere with the operation of the equipment. Checking the channel is simple, just put your hand on the suction hole with the vacuum cleaner turned on, and then put your hand on the hole of the vacuum cleaner itself with the hose turned off. A difference in suction power will indicate that the hose needs cleaning;

- do not use a vacuum cleaner to collect sharp objects, water and construction debris if this vacuum cleaner model is not designed for this;

- do not use damaged equipment. A damaged wire or housing indicates that the equipment requires repair;

- if the vacuum cleaner model has a fabric filter, then it should never be washed, otherwise it will lose its functionality;

- Lubricate the bearings every few years and check the carbon brushes once a year.

__________________________________________________

Vacuum cleaner repair

You can only repair the vacuum cleaner yourself if the damage is minor. In other cases, you may need specific parts and tools, as well as experience working with household appliances. If the problem cannot be found during disassembly or appears serious, we recommend contacting a professional.

- Let's see if the engine is clean from the inside: remove several insulating layers from its surface until you are left with a metal engine box in your hands.

- Conduct a visual inspection of the motor and check for integrity, whether there is dust or foreign objects in it, then try connecting each of the two wires in turn.

- If you notice a break in the wire, strip both ends and select a suitable insulating terminal to crimp.

After checking and repairing, you need to assemble the vacuum cleaner and connect it to the network to check the correct assembly.

The vacuum cleaner does not pick up small debris

In this case, repairing a Samsung vacuum cleaner with your own hands will involve a thorough inspection of the brush. Make sure it is low enough to contact the floor - if it is not, pull it out all the way. Inspect the brush itself - the bristles are probably too worn out and will need to be replaced.

Turn on the vacuum cleaner and inspect the brush in working condition - if it does not spin or rotates weakly, you will have to work hard. In the first case, the bearings are probably jammed. Disassemble it and check whether threads or hair are wound around the ends, remove them. In the second case, the brush belt may become loose - disassemble it and replace the part with one suitable for your model. Please note: although spare parts for Samsung vacuum cleaners are often interchangeable for different modifications, it is best to choose the ones that are suitable specifically for your model.

Disassembling the vacuum cleaner

Now we come to the most important and complex breakdown - repairing the engine of a Samsung vacuum cleaner. To verify this, you need to disassemble the vacuum cleaner. Carefully remove all protective parts of the housing and find the engine itself. Now, very carefully, observing all safety precautions, turn on the vacuum cleaner. If the cause of the breakdown lies in the motor, then most likely you will see a bunch of sparks coming from the engine. There may be several reasons for this:

- brush wear;

- interturn short circuit in the winding;

- increased load on the “engine”.

So, in order. To replace graphite brushes, you first need to unscrew and remove the plastic caps and remove the springs. We take out the brushes themselves and insert new ones. Next, we perform all the steps in reverse order - insert the springs, tighten the caps. In order for the brushes to work properly, they need to be ground in. This can be done by stretching fine sandpaper between the brush and the commutator. In this case, the abrasive of the sandpaper should be turned towards the brush and, as it were, scratch it a little.

If all the manipulations performed did not lead to success, and the engine continues to spark when turned on, it means that the engine has shorted out. You won’t be able to independently repair the motor of a Samsung vacuum cleaner (or any other one) at home; you’ll have to take it to a service center.

Another cause of engine failure that you can try to fix at home is replacing the bearing. It is very easy to check whether this is necessary. Take the engine in your hand and gently shake it by the armature: if you notice that the shaft is wobbling from side to side, then replacing the bearing cannot be avoided. To do this, you need to remove the brushes and unscrew the screws holding the housing together. After this, remove the motor covers one by one, using a small hammer and a screwdriver to help you. Perform this procedure very carefully, otherwise you risk damaging the winding. Carefully, helping yourself with tools, remove the bearings (preferably both at once) from the armature shaft. Very carefully, using a hammer and a tube of suitable diameter, push the new bearings into place and assemble the engine.

One little piece of advice: before you decide to disassemble the engine, draw a wiring diagram. Believe me, this will be very useful.

Vacuum cleaner diagram

Any vacuum cleaner has the following basic devices:

- dust collector full indicator;

- automatic engine shutdown when the dust bin is full;

- electric motor power regulator;

- automatic cord winding;

- waste compaction;

- regulation of air flow.

In addition, newer models have special filters that collect all the debris.

To ensure that the engine runs smoothly, the equipment is equipped with an interference suppression system, the chokes of which smooth out high-frequency network ripples. The existing capacitor also contributes to smooth operation of the engine.

Any vacuum cleaner has a special compartment in which, if not needed, about three meters of network cable is hidden.

More expensive models are equipped with an electronic control system, touch-sensitive power regulator and engine operating mode switch.

The figures show typical diagrams for turning off the vacuum cleaner.

Most vacuum cleaner models have standard electrical circuits

Simple connection diagrams

Poor air intake

It happens that the vacuum cleaner works well, but does not suck in much air. There may be several reasons for this:

- incorrectly selected power. If your Samsung vacuum cleaner has a power regulator, then it is worth checking whether it is set to minimum power;

- maximum filled bag for collecting garbage and dust. If the bag is full, it must be replaced. First, disconnect the vacuum cleaner from the electrical network. Then carefully remove the lid to gain access to the bag. If its neck is not equipped with a self-closing valve, then cover it and only then remove the bag from the Samsung vacuum cleaner and get rid of it or empty it of debris. It is not recommended to turn on the vacuum cleaner without a dust bag.

When installing a new bag, it is important to ensure that its neck fits snugly against the neck of the bag holder. If you do not adhere to this rule, the electric motor may overheat during operation.

- clogged filters. The instructions indicate how many filters the Samsung vacuum cleaner model is equipped with and they must be regularly checked for clogging. Before checking the filters, the vacuum cleaner must be disconnected from the mains. The dust motor filter is carefully removed, making sure that dust does not end up in the fan chamber. Some models of Samsung vacuum cleaners are equipped with filters that can be washed in warm water, which must be indicated in the instructions. The washed filter must be dried before returning to the device. You should install a new filter yourself every 3-4 bag changes;

Vacuum cleaner filter clogged

- hose clogged with debris. To check the hose for clogging, you need to disconnect it and inspect it. If there is a noticeable blockage in it, you can clear it by removing the nozzle and straightening the hose, after turning on the vacuum cleaner. Full draft can help clear jams;

- clogged air duct. It is necessary to check the hose connection socket in front of the canister model of the vacuum cleaner or under the cover of the vertical model. After unplugging your Samsung vacuum cleaner, disconnect the pipe and remove debris, if any. It is also worth checking the air duct from the alkaline roller to the back of the roller compartment;

- air leakage from the system. Check the tightness of the connection between the hose and the device body. If everything is normal, then disconnect the hose and examine for small cracks in the corrugation. It is also worth inspecting all the seals and if there are any that have lost their shape, they must be replaced.

Poor suction does not always indicate a serious breakdown.

Samsung washing machine won't turn on

Sometimes, when turned on, the washing machine may simply not start. This malfunction is quite common and occurs for various reasons. For example, after the previous wash, the owner again pours in the powder, puts the laundry in the drum, turns on the machine, but it shows no signs of life. Many people cannot immediately figure out what to do in this situation, although the reason may be the simplest.

As a rule, the washing machine does not respond at all when turned on; the indicators and lights remain extinguished. The following are considered the main reasons:

- There is no electricity. Sometimes it may not be there due to a normal shutdown. However, most often it is the circuit breaker or residual current device that trips. The socket may malfunction due to poor contact. In all cases, a check is carried out and all identified faults are eliminated independently. The serviceability of the outlet is first checked by connecting the washing machine to another outlet.

- The network cable is faulty. When using an extension cord or surge protector, the problem may lie with them. To check this fact, you need to plug the machine directly into an outlet. The power cord of the machine itself may be faulty due to wear and tear. The wire is checked using a multimeter and, if faulty, must be replaced.

- The power button does not work. This happens in models where power is supplied directly to the button through the power cord. It is checked with a multimeter in buzzer mode. The washing machine should be de-energized and checked alternately in the on and off state. In the first case, the multimeter will beep, but in the second - not. This means the button is working.

- FPS - noise filter is faulty. The flow of current through the circuit is blocked and the Samsung washing machine will not turn on. The filter is also checked with a multimeter for the presence of voltage at the input and output. If it is present at the input, but not at the output, the FPS needs to be replaced.

- Control module malfunction. Its complete replacement is very expensive, and repairs are carried out only in a specialized service center.

The main signs of a broken drainage device in different models

Most models of Samsung, LG, Indesit washing machines are equipped with a self-diagnosis system, which allows the owner to independently determine the cause of the breakdown by looking at the display (read more about how to identify faults and repair washing machines yourself, read here). The information screen contains error data in the form of numbers and symbols, the meaning of which can be found in the operating instructions.

If the machine does not have this function, the malfunction is determined by the following signs:

- after starting the pumping program, the system does not drain water;

- the draining process is accompanied by extraneous noise and hum;

- some of the water remains in the tank after draining or pumping is slow;

- the washing machine turns off without draining the water completely;

- the pump motor is running, but water does not flow out;

- The control panel freezes while draining water.

Depending on the type of breakdown and model of the machine, the malfunction is expressed by one or more symptoms or is supplemented by others. To figure out that the pump is the reason for the incorrect operation of the washing machine, first the unit is inspected for other damage and the functionality of other components and parts is checked.

LG

The following signs are typical for pump failure in LG washing machines:

- strange, uncharacteristic noise in the lower right part of the body;

- poorly drained water during draining;

- problems when turning on or off the pump;

- error code on the display.

Samsung

The first signs of a pump malfunction in a Samsung washing machine:

- An error code appears on the digital screen. It usually appears after the washing process freezes while water is being pumped out of the tank.

- The machine stopped working mid-cycle with a full tank.

- The pump runs without stopping.

- Water leaves the tank irregularly.

To make sure that the pump has failed, perform the following steps:

Check whether the program has set the spin function

If not, the mode is restarted. Check that the drain hose is positioned correctly and that there are no blockages in the filter. Pay attention to the pump impeller. If the part stands still or turns with difficulty, you will have to work on the pump.

Ardo

A breakdown of the drain pump in the Ardo machine is indicated by error code E03, F4, which appear after increasing the drain period. Typical symptoms of a malfunction:

- complete stop of the pump in the middle of the wash cycle;

- the motor runs loudly when pumping and draining water;

- pumping out water during spinning is not complete;

- the machine does not respond to the specified programs;

- the washing machine turns off when the tank is filled with water;

- water enters the tank in insufficient quantities;

- the pump does not turn on or does not turn off.

A common reason for stopping is that foreign objects get inside, for example, buttons, coins and other small things that block the operation of the part and prevent the impeller from rotating. Or failure of the pressure switch, which does not send a signal to the control module about the need to supply water (how to repair the pressure switch yourself?).

Indesit

A malfunction of the pump in the Indesit machine is indicated by error code F 05, which appears on the information panel screen. If there is no display, a problem is indicated by a combination of indicators that light up on the panel:

- spin;

- soak;

- additional rinse;

- super wash.

If self-diagnosis does not work, the following signs indicate a broken pump:

- remaining water in the tank after washing;

- the process of pumping water is accompanied by a strong hum;

- water does not drain under the specified program;

- turning off the machine while draining the water after washing.

Troubleshooting other problems

In addition to problems with filters, the owner of a vacuum cleaner may encounter clogged impellers. It is cleaned dry. If you managed to remove the engine and you find wear on its brushes, you can replace them yourself and clean the commutator with fine sandpaper. If the fuse is blown, it is better to immediately take care of purchasing another vacuum cleaner, since its cost is slightly less than buying a new unit.

If you suspect a wire break, you need to test the voltage in the remaining nodes with a multimeter. After checking and finding the break point, the fault can be quickly eliminated with a regular soldering iron. Before checking, make sure that the vacuum cleaner motor is not de-energized: this often happens when the temperature sensor is triggered. If it turns out that the engine is de-energized, do not rush into checking and other actions. Most likely it's a matter of normal overheating. After the vacuum cleaner has cooled down, it will automatically restore its functionality.

A problem with bearings can be easily distinguished from another malfunction by the characteristic squealing or grinding noise emitted by the unit after it is plugged into the network. You can lubricate the bearings with machine oil, but it is better to replace them immediately, because the lubricant will not last long, and after a while the home assistant will begin to “creak” again.

Another malfunction that you may discover while disassembling the case is a loose power cable. Most often the problem is with the spring. It can either be loose or too tight. Adjust the tension of the drum by unwinding or, conversely, winding the wire.

How a vacuum cleaner works: mechanics and electrical

The basis of any vacuum cleaner is the air pump (or fan). The engine is equipped with an impeller, which, while rotating, absorbs the air flow with blades and, after compression, sharply releases it out. The lines are located in the housing, as well as at the beginning and end of the air pump. Suction lines operate under low pressure, and pressure lines operate under high pressure. Air circulates in the housing, which is discharged during engine operation. Along with the air flow, dust particles are drawn into the hose with a nozzle and fall into the dust collection container. The dust settles there, and the air blows its small particles back out. In order to prevent the return of the smallest dust particles, modern models of vacuum cleaners are equipped with filters.

Important!

Conventional vacuum cleaners (Samsung 1600 W and others) are intended for household use. They cannot be used to remove construction debris and dust from concrete.

The fan impeller is driven by a commutator-type electric motor. The alternating current indicator for such a mechanism is 220 V. Thyristor regulators are installed in high-power household units. With their help, you can limit the dust suction force and carry out gentle cleaning of the room. The electronic functions of the vacuum cleaner are controlled by a board located inside the housing.