Neva instantaneous water heaters are simple and economical to operate and easy to maintain. Over time, the user may encounter equipment malfunctions that are not always easy to fix with their own hands. What to do if the Neva gas water heater does not light up? Do you want to know how to perform repairs without calling a technician? Then read our article.

Why does the Oasis water heater not light up?

Let's look at the main reasons why the device does not turn on, there is no spark. Let's see how to identify the malfunction and restore the operation of the equipment.

The batteries are low

The automatic electric water heater is powered by batteries. As soon as you open a water tap, the batteries produce current. It passes through the circuit to the control unit, which sends a signal to the candle to ignite. This is how automatic ignition occurs.

Knowing this, it is easier to understand why you need to monitor the condition of your batteries. If they are discharged, install new ones; it is better to choose alkaline ones with a good charge LR20. Weak, cheap batteries will not be able to ensure stable operation of the equipment.

Open the battery compartment by turning the handle.

- If you notice signs of leakage, be sure to clean the contacts.

- Install the correct items.

If after replacement the column does not produce a spark, you need to look further for the reason.

Traction problems

Without traction, the equipment will not work. Safety mechanisms will prevent the igniter from igniting. Why? Because draft problems are caused by blockages in the chimney. This means that when the device is triggered, combustion products will go outside and enter the room. To avoid an emergency, a draft sensor and a flame sensor are installed.

Why does the chimney duct become clogged?

- Leaves and debris from the street get into the hole.

- During operation, soot accumulates in the passage.

Hole needs cleaning. If you cannot do this yourself, contact your utility company.

How to understand that there is no traction:

- Place a burning match near the control window or ventilation.

- When the chimney is working, the flame will deviate to the side. If the flame burns evenly, there is a blockage.

Pressure problems

Incorrect settings may cause the problem. The water pressure regulator is turned off or at the minimum level. Turn it to the working position to increase the pressure in the system.

If a thin stream of water flows from the tap, the reason is a decrease in pressure in the common line. You need to wait until the supply is restored. Alternatively, you can install a circulation pump: then the supply will always be stable.

Strainer clogged

A protective filter is located at the inlet of the column. It protects the system from small debris and rust from the water supply. Over time, it becomes clogged and the water pressure decreases. Therefore, the turbocharged column does not ignite.

- Unscrew the nut.

- Remove the filter.

- Rinse it under running water.

- Brush with citric acid.

You can purchase a new part and install it in place.

Water unit membrane malfunction

Stretching, wear or damage to the membrane leads to malfunction of the entire device. The working part creates pressure on the gas valve, which opens and releases fuel into the burner. You can read more about diagnostics, choosing a new element and replacement in the article “”.

The heat exchanger is clogged

Water is constantly circulated and heated in the radiator coil. When heated above 55 degrees, scale begins to settle: magnesium and potassium salts, which are contained in hard water.

Oil seal leaked

Leaks can be detected by removing the device casing. To fix the problem, you need to replace the part.

- To do this, unscrew the water unit, divide it into two parts after unscrewing the fasteners, and remove the membrane.

- Then remove the rod with the seal.

- Replace the seal and seal.

- Then reassemble the structure in reverse order.

Other problems with Oasis Turbo:

- The microswitch is broken. The part cannot be repaired; installation of a new switch is required.

- The wiring is broken. Inspect the cables and the tightness of the contacts to the main components. If the insulation is damaged, the wire must be replaced.

- Solenoid valve malfunction. It is necessary to install a working valve.

- If the electronic unit breaks down, it needs to be examined by a specialist.

- Piece doesn't work. The piezo ignition button does not work; the contacts may have oxidized. Inspection and cleaning are being carried out.

These are typical problems with Oasis water heaters. If your equipment does not ignite, use our recommendations to troubleshoot the problem.

The situation when the gas water heater does not light is, of course, unpleasant, but it is too early to panic

By following simple precautions, it is quite possible to identify and fix the problem yourself, sometimes without even resorting to the help of a specialist.

What to do if the column does not turn on

Opened the faucet but didn't get any hot water? All because the equipment does not work, the burner does not light. If the device is under warranty, you can contact the service center. If the warranty is no longer valid, then you can handle it yourself. We will describe all problems and solutions in the article.

The examples below are typical for the Neva 4610, 3208, 4510, 4510 m, 4511, 4513, 5514 models, as well as Neva Transit.

The column does not ignite well, the igniter goes out

In this case, the security system is activated. Most often, a similar problem can be found in automatic equipment with electronic ignition.

The igniter's job is to light the burner. It must work continuously. Warming up the thermocouple, the igniter brings it to the burner, where the fuel mixture is ignited. If a fire does not occur, protection sensors turn off the equipment to avoid the accumulation of carbon monoxide.

To carry out repairs, you need to understand how the security system functions.

The thermocouple consists of an alloy of several metals. When heated, it generates EMF (electromotive force), thus powering the solenoid valve. Why doesn't the column light up for a long time? Often the insulation of the thermocouple conductor is damaged and it fails. Exposed wires can short out the housing.

You cannot simply solder the detached conductor, then the thermocouple will not be able to conduct current. The unit needs to be completely replaced.

When the thermocouple reaches a certain temperature, it produces an electric current. It moves the valve stem. The latter opens, releasing gas into the burner. If there is no spark, the flame does not ignite - the thermocouple cools, returning the rod to its original position. The valve closes and the fuel supply stops. Therefore, when opening the mixer, there will be no fire.

The same thing happens when the wick goes out. This can happen when the fuel supply is cut off or there is a draft. To check the wick, do this:

- Take a 1.5 V AA battery.

- Connect to the coil winding.

- Light the wick. If it lights up, the part is working. When the battery is disconnected, the flame should go out.

The thermocouple needs to be replaced.

If the windows in the room are tightly closed and there is poor ventilation, the device overheats and the thermal fuse . This means that the overheating has reached 90 degrees. To make sure that the cause of the problem is the fuse, disconnect the leads and short them together. If the equipment begins to work as usual, the temperature sensor needs to be replaced.

Reasons for the lack of flame on the wick of a gas water heater

- The air supply hole in the wick is clogged. This hole allows air to flow in to ensure combustion of natural gas at the igniter tip.

- The solenoid valve coil has burnt out. An electric magnet holds the valve stem; if it breaks, the valve will close.

- The thermocouple has failed. The thermocouple, while in the flame, generates voltage that is supplied to the electromagnet.

- The sensors for monitoring the water temperature and the state of the chimney (presence of draft) are faulty. At values up to + 82 0C, the sensor is in the closed position; above this temperature, its bimetallic plates diverge and the circuit opens. The normal contact between the two plates can be disrupted by surface oxidation, mechanical or thermal damage.

- The electrical circuit of the flame control system is broken. All elements of the flame control system are interconnected by wires. Their malfunction will inevitably lead to disruption of the entire system.

- The nozzle or gas supply tube to the wick is clogged.

The inner diameter of the tube is 2.5 mm (external 4 mm) and the nozzle outlet diameter is 0.1 mm. These elements can become clogged with soot, dust, etc. - The operation of the piezoelectric element is disrupted, the spark from which ignites the gas.

Neva Transit EMT

This model is equipped with a forced exhaust gas exhaust system. The device is ideal for use in rooms where there is no smoke exhaust system. The fan effectively removes smoke through the duct. If your house does not have a centralized chimney, the Transit EMT series will be a suitable choice.

Among the design features of this model we note:

- Temperature control indicator;

- Automatic ignition system;

- Combustion flame control system;

- Built-in fuse that trips when the power supply is turned off;

- Fan with built-in blowing function;

- Smoke exhaust pipe made of stainless steel.

Note that the Neva Transit EMT dispenser is capable of operating at low water pressure. This is especially true for some regions of Russia, where water supply problems are normal.

Identifying the reason why the gas water heater does not ignite and eliminating the breakdown

To determine the reason for the lack of flame in the column wick, you must:

- Open the front panel of the device.

- Check the condition of the nozzle and air suction hole, gas supply tube to the igniter. If there is soot or dirt: remove it from the wick.

Ignition system for semi-automatic geysers.

Examine the piezoelectric element for spark generation. If it is absent, inspect the wires and terminals for mechanical and other damage. Oxide on the contacts must be removed and damage repaired.

The location of the elements of a semi-automatic gas water heater responsible for ignition.

- Determine the thermocouple voltage. To check the heat generator, unscrew the special plug of the electric valve. Carefully remove the special cable that comes from the thermocouple. Using a multimeter in DC voltage test mode, connect one probe through the Alligator clip to the outer shell, and place the other one against the central contact. Since the height between the contacts is small, make sure that the probes do not touch each other. Use a lighter to heat the working end of the thermocouple. If the voltmeter readings correspond to 15 - 30 mV, the part is serviceable; for other values, the generator must be replaced. If the special wire is not suitable for further use, the entire thermocouple is replaced.

- Examine the valve inductor. In the valve connector, which was released when checking the thermocouple, insert one end of the probe into the middle of the connector, the other onto its body. Tester in ohmmeter mode. The coil resistance should be in the range of 10 - 15 ohms. If the circuit is open or shorted, the ohmmeter will record a value of 1 or 0, respectively. The coil changes modularly, along with the stem and valve.

Measuring the resistance of the solenoid valve coil of a gas water heater.

Check the serviceability of the monitoring sensors. At room temperature, the control contacts of the sensor are in a closed state. Using a multimeter, in diode test mode, examine the two sensor terminals for circuit continuity. The tester reading if the sensor is working will be 0; in other situations, when the values correspond to 1 or a resistance of 1 - 600 Ohms, it must be removed and a working one installed in its place.

Location of the water temperature sensor and the geyser chimney sensor.

Test the condition of the wires and connections. The wires with the sensor contacts are connected by soldering with soft solder, with an electromagnet and a thermocouple using a special plug. Carefully inspect the wires, solder joints, and plug connections. Sometimes microcracks form at soldering points, which disrupt the integrity of the entire circuit.

After each remark has been corrected, it is advisable to check whether the column lights up or not.

Therm 4000 S WTD 12/15/18 AM E23/31.

Before starting, you must make sure that, on the plate installed on the device by the manufacturer, the gas marking corresponds to the gas connected to the device. The device has the ability to connect a remote control panel, which completely duplicates the operation of the display on the column.

Open the gas valve and water valves. Connect the device to the power supply.

The water temperature set by the manufacturer is 42 degrees, this is the optimal temperature.

To turn on the device, you just need to press the turn on button and open the hot water tap. To regulate the temperature, you need to press the “+” or “-” button and select the temperature you need. Until your selected temperature is reached, the display will flash.

If it does not reach this value within thirty seconds, a water tap icon is displayed on the monitor, which indicates the need to increase or decrease water flow. If you press the P button, the programmed constant temperature of 42 degrees will appear. Setting the minimum temperature reduces energy consumption and makes it possible to reduce the formation of limescale in the heat exchanger.

But if you know how to turn on the column, but encounter malfunctions (the flame goes out, does not ignite), then where the reasons and methods for eliminating them are described.

It is not always possible to eliminate malfunctions due to which the gas water heater does not light up when you turn on the water. Some breakdowns require the involvement of a specialist. On the other hand, the cause of problems in the operation of a water heater is not always associated with the failure of internal components and modules. You can fix minor damage with your own hands.

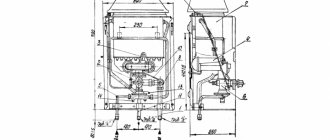

Column device

How to understand the location of water heater components? Don't worry, the diagram will help you. It is created based on columns.

External device:

- Metal casing.

- Control window.

- Gas flow regulator.

- Water regulator.

- Digital temperature display.

- Cold water connection (G 1/2 thread).

- Hot water outlet pipe.

- Pipe for connection to the gas line (cylinder).

- The pipe for removing combustion products is connected to the chimney.

- The basis. Back wall.

- Holes for installation.

Internal equipment:

- 6, 7, 8 - continuation, pipes, as indicated above.

- 12 - water unit.

- 13 — water adjustment rod.

- 14 - drain plug.

- 15 - microswitch.

- 16 - control unit.

- 17 - gas unit.

- 18 — fuel adjusting rod.

- 19 - solenoid valve.

- 20 - collector.

- 21 — manifold mounting screws.

- 22 — burner nozzles.

- 23 - spark plug.

- 24 - ionization sensor.

- 25 - copper heat exchanger.

- 26 - output to the water unit.

- 27 - output to the gas unit.

- 28 — mounting bolts.

- 29 - thermal relay.

- 30 - thermometer.

- 31 — gas outlet device.

- 32 - traction sensor.

- 33 — brackets for installation.

- 34 - battery compartment.

Having understood the design, you can begin troubleshooting.

Why does the speaker go out?

Let's think logically: if the gas burner device ignites, then the water block and the sparking system are working properly. The problem lies in the solenoid valve, or more precisely, in its shutdown and interruption of the fuel supply. Troubleshooting comes down to 3 sensors:

- traction;

- ionization;

- heat exchanger overheating.

The malfunction of the draft sensor was already mentioned above - the faulty element did not allow the column to start. The fact is that heaters of different brands can work differently; in some, the draft sensor does not allow the burner to light, in others it works later, after a gas flash. The result is that the column lights up and immediately goes out.

The test method is the same - we close the terminals of the draft sensor with a wire and turn on the water heater. If the burner does not go out, install a new part. It is strictly not recommended to constantly use a jumper wire instead of a non-working traction thermostat!

User manual

"Neva-4513" must be installed by specialists. The device must not be used if there is no draft in the chimney. It is prohibited to repair or disassemble it yourself. If the unit is in a faulty condition, it must be repaired, stopping its operation until the fault is eliminated. In order to eliminate the possibility of carbon monoxide poisoning, the device must be installed in a well-ventilated area where there are cracks at the bottom of the door or wall.

If you smell gas, you should immediately turn off the tap located on the gas pipeline in front of the column. You need to open doors and windows to ventilate the room. Do not turn on electric lights or electrical appliances until the problem is corrected. The Neva-4513 column should be installed in non-residential heated premises or kitchens. The volume of the room should be 8 m3 or more.

The operation of the device is accompanied by the combustion of oxygen, so it is important to have a window with a window to ensure a constant flow of fresh air. The Neva-4513 geyser must be connected to a chimney with intense draft

It is important to ensure a closer location to the chimney. You can check the presence of draft using a candle, the flame of which should be drawn inward and extinguished. The device must not be installed above a source of heat or open flame; this applies to electric heating devices and gas stoves.

What to do if the flame in the Neva column does not light up

If the column is under warranty, it is better to invite a specialist. Let's look at some reasons and solutions when a water heater does not ignite.

As soon as you pulled it back a little, excellent traction appeared, the smell of gas stopped, and the automation stopped turning off the column. I turn on the water, hear and see how the piezo discharge works, but the column does not turn on. BUT! What I noticed is that before it ignites there is a CLICK (like some kind of relay). Therefore, ignition occurred when gas rushed in and hit the spark. And it was even worse that out of five times, one time she wasn’t allowed in at all. Column 4511 at first glance is super for such money (5200), installed by my mother-in-law, everything is super. Soft switching on and off. Heats the water to the fullest, keeps the set temperature more or less normally.

But in summer the water temperature rises by several degrees, so the column needs to be screwed down. As a result, the water heater turns off almost immediately due to overheating.

Unfortunately, the burners in the Neva and Oasis gas water heaters (as in many others) are susceptible to blockages. It needs to be removed, for which the column is disassembled and the burner itself is removed from it. If your gas heater does not light and you decide to clean it, do it on the balcony or in the open air.

Reasons for the lack of flame on the wick of a gas water heater

- The air supply hole in the wick is clogged. This hole allows air to flow in to ensure combustion of natural gas at the igniter tip.

- The solenoid valve coil has burnt out. An electric magnet holds the valve stem; if it breaks, the valve will close.

- The thermocouple has failed. The thermocouple, while in the flame, generates voltage that is supplied to the electromagnet.

- The sensors for monitoring the water temperature and the state of the chimney (presence of draft) are faulty. At values up to + 82 0C, the sensor is in the closed position; above this temperature, its bimetallic plates diverge and the circuit opens. The normal contact between the two plates can be disrupted by surface oxidation, mechanical or thermal damage.

- The electrical circuit of the flame control system is broken. All elements of the flame control system are interconnected by wires. Their malfunction will inevitably lead to disruption of the entire system.

- The nozzle or gas supply tube to the wick is clogged. The inner diameter of the tube is 2.5 mm (external 4 mm) and the nozzle outlet diameter is 0.1 mm. These elements can become clogged with soot, dust, etc.

- The operation of the piezoelectric element is disrupted, the spark from which ignites the gas.

Possible column malfunctions and how they can be eliminated

If you have a minor breakdown, you can fix it yourself. Here are some of them:

- After a short operation, the water heating device turns off. The reason is low traction. To do this, just clean the chimney. It also wouldn’t hurt to check the connection of the gas exhaust pipe. In the event of a malfunction, the connection must be sealed;

- If the outlet is water with a temperature above 90°. To eliminate this problem, you need to reduce the gas consumption and, on the contrary, increase the water consumption. In this way, the desired inlet temperature can be achieved;

- If when opening the tap the column does not start. To do this, you need to replace the batteries or check their installation;

- Formation of carbon deposits on the flame sensor. It needs to be cleaned;

- If the water pressure in the system is weak, then you should contact the utility service;

- If the amount of water is insufficient, the fluid flow must be adjusted;

- If scale has appeared in the heat exchanger or the filters are clogged, it is necessary to clean it;

- It is necessary to fully open the water inlet and outlet taps if they are partially open;

- If after opening the tap the column does not start, but there is a spark. In this case, it is necessary to open the gas supply valve;

- When you turn it on for the first time or after a long period of inactivity, air often appears in the communications. To solve this problem, you can open the tap for a few seconds, then close and open again. This procedure can be carried out several times;

- If a spark does not enter the gas stream. If this problem occurs, you need to adjust the distance between the burner and the spark plug electrode.

Before you start using the Neva-4511 gas water heater, you must carefully study the attached instructions. It describes in detail all possible problems and how to eliminate them. In more difficult situations, it is necessary to contact specialists.

The Neva-4511 column is an excellent inexpensive option that is produced in Russia. In addition, it has many positive aspects. This speaker is perfect for a small family.

Device and principle of operation

In many cases, fixing a problem with automatic ignition or with other components of the device is quite easy, and you don’t even have to seek the help of professionals. However, in order to understand why the Neva geyser does not work well, it is worth studying its structure.

The system includes:

- housings (for wall-mounted models - supplemented with mounting loops);

- heat exchangers made of copper;

- water circulation units;

- burner complexes;

- concentrators of gaseous combustion products (diffusers);

- pipes for connection with the chimney;

- water supply tubes;

- igniter electrode;

- faucet regulating the passage of water;

- segment for batteries;

- a system that regulates heating power and fuel consumption;

- ionization fire indicator.

The typical method of operation of a gas burner is very simple. As soon as the water tap supplying hot water is opened, the pressure of the jet begins to act on the membrane of the control unit. Under its pressure, the rod moves, which opens the gas valve, and the contacts of the switching device close. Through the electrical circuit, current from the batteries begins to flow to the controller. The electronics sends two signals at once: one by one, the valve opens, allowing gas to pass through; the second, an electric spark appears on special electrodes.

As soon as the fire detector detects characteristic ionization, it sends a signal to the central automation. It stops initiating the spark. Heating is carried out in standard operating mode. The mixer valve is closed. The membrane immediately moves back, and the gas passage valve closes.

At this moment, the limit switch is activated, stopping the flow of current to the controller. Without power supply, the electromagnet remains. Since no gas enters the burner, it should go out immediately. The valve is connected to the same circuit as the draft meter. When this draft disappears or is weakened excessively, the heated sensor opens the circuit, thereby stopping the power supply to the electromagnet and the passage of gas to the burner.

Ignition of the column

- manual ignition;

- piezo ignition;

- electronic;

- microturbine.

Manual ignition is a rarity for modern speakers. Older models required matches to ignite the gas. Today such models are rare.

Piezo ignition. By analogy with piezo electric stoves, to ignite the gas you need to press a button on the column panel. This method is still used in modern models.

Electronic. The most convenient and popular way. Reliability and economical gas consumption make such models a little more expensive. By analogy with a car, a spark is created by a small battery; batteries are often used. The NEVA 4511 column belongs to this model range.

As for microturbines, the current in them is generated by a hydrodynamic generator controlled by a water flow. The cost of such copies is much higher.

Columns with electric ignition are easy to use. The gas is ignited automatically when you open the water tap, thereby saving gas consumption.

Prevention

To avoid having to tinker with the unit too often or constantly call the repair service, you should adhere to the following rules.

- Set the temperature at the optimal level so that there is no need to dilute the water, then scale will not appear so quickly. To avoid having to adjust the column every season, it is preferable to choose a model that remembers the settings for winter and summer modes.

- To remove salts from water with high hardness, you can install an electromagnetic system that will purify the liquid.

- Regular cleaning of the chimney and parts of the water heating system is necessary.

- Modern speakers that have a built-in electronic controller are better connected to the network through a stabilizer and not turned off at night.

- If the hose is longer than 3 meters, the pressure during gas supply will greatly decrease.

- When the column is operating, it is better to open the window; this simple method will allow you to get a lot of air for the normal functioning of the unit.

- The chimney and parts of the column that quickly become dusty should be periodically checked for dirt, cobwebs and the like and removed with brushes and a vacuum cleaner.

Signs that unscheduled maintenance and technical inspection from a specialist are required:

- the pressure in the water supply is normal, but the heat exchanger still works for a small amount of time;

- the unit constantly turns off or does not function at all, although the supply of gas and water is carried out in optimal mode;

- often the thermal protection is triggered for no reason, causing the working system to shut down;

- The heating of the water decreases, although there are no noticeable operational disturbances.

To check the column from the inside, you need to remove the upper housing. This is done using a Phillips screwdriver, which is used to unscrew the screw located on the handle of the gas lock valve. The handle itself is removed by pulling it towards you. Then, using a flat-head screwdriver, remove the screws that secure the case, after which it can be removed.

Periodic preventive maintenance and checks can increase the life of the device due to the timely detection of problems in the functioning of the column. The work itself should usually be carried out once a year, but if the column is already old and often malfunctions, then if it is impossible to replace it, checks should be carried out more often. It is better to entrust the annual inspection to professionals from specialized gas services, as they will be able to accurately determine the condition of the unit. High-quality maintenance usually includes a complete disassembly of all equipment, searching for defects and areas of damage that can cause interruptions in the operation of the column. Each main part is also cleaned (wet and dry cleaning), all components of the gas water heater are adjusted or returned to their original position, reconnected and tested for readiness for operation.

The main malfunctions of geysers are in the following video.

Repair and maintenance of gas-water unit

The design of the gas water heater water reducer has a simple internal structure. Everything is easy to understand. If desired, you can repair the geyser frog or carry out preventive maintenance without calling a technician.

How to remove a frog from a gas water heater

First you need to turn off the water and gas supplies. After this, work is carried out in the following order:

- drain the water from the heat exchanger - for this purpose it is better to use a tap or mixer located significantly below the water heater;

- disconnect the gas and water supply pipelines (an adjustable wrench will be required);

- Now you can remove the water unit of the gas water heater; if everything is done correctly, the frog should be easily dismantled.

The design of the gearbox may differ depending on the model of the flow column. In order for the removal of the water block to be successful, it is necessary to unfasten all parts and pipes suitable for the main structure. The housing can be easily removed; no physical effort is required.

Cleaning the water unit of a gas water heater

Held at least every year. There are several fixation bolts on the frog cover

When unscrewing, care must be taken not to damage the folds. After removing the cover or disassembling the gearbox into two parts (depending on the model of the column), the internal space is cleaned and the structural parts are serviced:

- when cleaning the gearbox, scale and solid residues settled at the bottom of the unit are removed, and at the same time the coarse mesh on the inlet pipe is cleaned;

- the rod can be lubricated with castor oil or grease;

- The gasket can also be coated if it feels rough to the touch and has lost its elasticity.

Regular maintenance of the frog will extend the life of the instantaneous gas boiler and ensure its smooth operation.

Which components should be replaced?

The gearbox contains several elements that are constantly exposed to mechanical pressure and poor quality water. At each service, the functionality of the following components is checked and replaced:

- rod seal - replacement of the seal is necessary on average every 3 years to protect the gas valve from moisture;

- membrane - replacement of the gasket is necessary when it ruptures, as well as when microcracks appear;

rod and components - the spring that brings the rod to its original position fails after intensive use after 4-5 years.

For maintenance, it is better to use ready-made branded gaskets for the gearbox. The membrane is usually sold separately, but if you wish, you can purchase a factory repair kit with all the components that need to be replaced.

How to adjust the reducer on a gas water heater

Setting up the water unit will help optimize gas flow and water pressure at the outlet of the column. Adjustment of the water reducer of an instantaneous gas water heater is carried out using bolts located on the back side of the unit. Usually they are set in factory conditions, which is sufficient for normal operation of the column.

If you need to adjust the water pressure, the bolts are loosened a little. The DHW pressure at the outlet should increase. Adjustment of the gas water heater reducer is not carried out unless absolutely necessary. It is better to have the work performed by a gas service representative.

After the maintenance is completed, the water unit is installed back. Check for water and gas leaks. The column is launched and used as usual.

Problems with ignition

Why doesn't the gas heater light up? It happens that there is very little gas pressure in the pipes. Look how the gas stove burners burn. Such fuel supply should be reported to the gas service.

Neva and Vector water heaters have electric ignition. If draft, pressure, gas supply are normal, but the column does not ignite, the reason may be the generation of a spark. When you open the tap, a characteristic cracking sound should be heard. We are trying to replace the batteries.

When using hydrodynamic ignition, you should check the operation of the generator. Such repairs will require certain knowledge and skills.

Gas water heater Astra automatic with electric ignition. The reasons that prevent the device from igniting are still the same. It may also not light up if the gas and water shut-off valves are closed. You just need to open them.

Other reasons

The gas water heater lights up and goes out due to a failure of the mechanism that allows access to the gas. This is a solenoid valve and a servomotor. You'll have to call a specialist.

Over time, the tubes in the column may become clogged. You need to make sure they are passable. In case of blockages, special cleaning agents are used.

Burners in gas water heaters often become clogged. Why is this happening? The reason is the accumulation of soot. It is necessary to disassemble the column, remove the burner and clean it with any tools. At the same time, clean the heat exchanger.

The membrane may rupture. It's difficult to buy.

It is necessary to check all the details. Many speakers have electronic components and sensors. For example, in a Neva gas water heater, the draft sensor often breaks down, as a result the device will not light up.

Electronic components will most likely have to be repaired by a technician.

So, you know what measures to take if the gas water heater does not light. We fix many breakdowns ourselves, and in more serious cases we turn to specialists. When repairing a gas water heater, all safety measures must be observed. Always turn off the gas. It is better to clean the gas water heater outdoors.

Gas water heaters have become widespread due to their availability, high performance and cost-effectiveness. Not only the comfort of the residents, but also their safety depends on how well the gas water heater works. After all, like any equipment consisting of many mechanical parts, a geyser is subject to wear and tear.

The reasons for the incorrect operation of a gas water heater can be associated with both external factors and malfunctions of the internal components of the device. Only by correctly identifying the problem can it be quickly and effectively eliminated.

External factors affecting the operation of the gas water heater include:

- Mechanical damage to the equipment power cable;

- Insufficient ventilation draft;

- Low pressure in the system;

- Gas pressure is too strong or too weak;

- Low water temperature;

- Incorrectly installed pipes;

- Discharged batteries.

In order to diagnose ventilation, you will have to remove the pipe to remove combustion products leading from the gas water heater to the ventilation hole. After this, the draft can be measured with a special device - an anemometer.

To understand what the problem is (pipes, or insufficient pressure in the system that does not squeeze out water), you need to contact the housing office. It is the housing maintenance office that must monitor the serviceability of the water supply in your home.

Among the internal factors affecting the operation of the water heater are:

- Wear of elements of the water intake unit (clogged inlet filter, deformation of the water block membrane);

- Clogged heat exchanger tubes;

- Malfunction of gas supply valves;

- Wear of the solenoid valve or servomotor;

- Failure of the ionization sensor (electrode clogged).

In addition, after long-term operation, owners of gas water heating equipment often encounter clogging of the ignition wick. What should you do if your gas water heater stops working correctly?

Who can install the BaltGaz geyser

Only specially trained specialists can install speakers. The specialist must have permission to work with indoor gas equipment. Such specialists undergo annual examinations and confirm their qualifications.

Also, the technician who performs the installation for you must be on the staff of an organization that has an SRO permit for certain types of work. Type of work allowing installation of gas equipment: 19.8 Installation and dismantling of gas equipment for consumers using natural and liquefied gas.

The installation organization must also coordinate its documents with the manufacturer. If the documents are not agreed upon, warranty service may be denied.

If the installation is carried out by a private owner himself, then the manufacturer does not provide warranty service. We recommend that you contact our specialists for the installation of geysers, then you will receive warranty service for 5 years, and you will also have peace of mind for yourself and your family that the gas water heater is installed correctly.

Construction of the NEVA gas water heater and principles of operation

Water enters the inlet of the water block, then pressure is created in the block, there is an automatic flow sensor in the block, which informs the control unit about the presence of pressure. also, if there is pressure in the water block, as a rule, mechanically, depending on the column, the gas valve opens. The device has a battery compartment, usually located in the lower part, which directly supplies the control unit, which, when pressure is present, causes the electric ignition to turn on and not go out.

Next, the solenoid valve is opened, through which gas passes to the burner, after which the ionization electrode detects the fact of gas combustion and reports this to the power supply, after which the power supply turns off the electric ignition. Water is heated by heat exchange; the heat exchanger itself is usually located at the top of the column. This information is needed for a general understanding of the operating principles of most gas water heaters, and it in turn gives a little understanding of the principle of their repair.

How to disassemble and reassemble the NEVA LUX geyser

Before starting repairs, be sure to turn off the gas and water supply taps.

To remove the casing of the gas water heater, you first need to unscrew the two screws located in the right and left corners of the lower part of the rear wall using a Phillips screwdriver from below, from the side of the pipe inlet.

The left knob for piezoelectric ignition of the igniter and rough adjustment of the gas supply cannot be removed. The right handle for fine adjustment of gas supply is held only by the casing with two clamps. You don't have to take it off either. But I usually remove it before removing the casing. In addition, so that the handle rotates easily when adjusting the temperature, I filed it along with the clamps in a circle where the handle touches the casing. Now it no longer clings to the casing and rotates easily.

Next, you should pull the casing towards you until the handles are recessed and, when the casing does not touch them, move it up. The upper slots of the casing will come out of the hooks located on the base of the gas column, and it will easily separate.

The geyser casing is installed in place in the reverse order. First, put it on the upper hooks with the slots, for which you will have to stand on a raised platform, then get the hole onto the adjustment handle and at the same time make sure that the holes located above the holes for fastening with self-tapping screws hit the guides. Screw the two screws into place.

The photo shows the appearance of the NEVA LUX-5013 geyser without a casing with a new heat exchanger.

Automatic gas water heater - do-it-yourself repair.

Automatic geysers have recently become even more common than semi-automatic ones. These are mainly Chinese gas water heaters of such brands as Oasis, Vektor, Ladogaz, Ariston and domestic gas water heaters Neva.

Let's identify the main typical malfunctions of geysers and algorithms for identifying the specific problem of your geyser with your own hands. Let's consider all the possible problems:

The column lights up with a pop.

Most likely, your gas water heater's batteries are simply dead. Therefore, I recommend starting with them to troubleshoot an automatic gas water heater. You only need to buy date-fresh, alkaline batteries. Salt batteries are cheaper, but also last significantly less

If the problem cannot be resolved in this way, then you need to pay attention to the gaps between the ignition electrode and the gas water heater burner. Problems will occur if the gap is either too large or too small

With a large gap, there will be generally gaps in spark formation; with a small gap, the spark will be weak, poorly igniting the gas mixture. In any case, gas will first accumulate in the gas water heater, then be ignited in an untimely manner with a bang or even a noticeable explosion.

First of all, we look between the water and gas blocks of the column in the area of the microswitch. It is more convenient to do this together. One opens the water, the other watches what happens. When the water supply is opened, you can see how the water block rod moves and releases the column microswitch button. There are two options:

- the rod moves quite briskly, releases the claw of the microswitch of the gas water heater, but that’s all it ends, then there is silence... The piezo sound is not heard. Most likely the microswitch is to blame. Easy to check. The microswitch connector is removed and the contacts are closed directly in the connector. If there is a crackling sound, then the reason is in the microphone. If there is no crackling sound, then you need to look at the traction sensor, overheating sensor, and the column ignition unit itself.

There is piezo ignition, but the column does not turn on.

Usually the culprit is dead batteries. There is enough energy for a spark, but there is no longer any way to retract the coil on the gas valve. The gas valve makes a characteristic click when opened. If you hear the piezo crackling, but do not hear the click of the valve, then the gas is not flowing to the burner precisely because of the valve. Either it is faulty (which is rare), or the column batteries do not have enough energy to open the valve.

The column does not turn off, the gas continues to burn when the water supply is turned off.

A very unpleasant and terrible breakdown that can lead to both failure of the water block and injury to the person using this column. If this happens repeatedly, then you need to stop using the gas water heater. Most likely the reason lies in the water block (the rod is jammed, the plate has fallen apart, or something else).

When turned on, the column lights up and goes out almost immediately.

The reason lies in the ignition electrode. It has either oxidized and become covered with a layer of soot (clean it), or it is poorly heated by the burner flame, and the column “does not see” that the gas is on and cuts off the gas supply to the burner.

The geyser goes out during operation.

There are several options. The most easily repairable faults are traction or overheating sensors. A less successful scenario is if the radiator of the gas water heater burns out (and this is almost the cost of the entire water heater), or there is no draft in the chimney. Some have not encountered this, but those who have encountered it will agree that the problem is unpleasant. Usually, if there is no draft in the chimney, then this cannot always be eliminated by utility workers. The problem is sometimes not permanent, but appears when there is strong wind outside, frost or, conversely, heat.

I have described typical faults and methods for finding them.

Types of columns

The energy source of the geyser is gas

When choosing equipment, first of all you should pay attention to the technical characteristics, price and quality of the device. According to technical characteristics, geysers are divided into:

- By power. The volume of heated water depends on it.

- By the type of chimney.

- By type of ignition.

- By size.

- According to security conditions.

- For additional options.

The Neva company is a domestic manufacturer. They produce quality products at reasonable prices. On the Internet you can find a lot of positive reviews about this company. The assembly and components of the device are performed at a high level. The Neva company provides a 12-year warranty on equipment. You will be able to service your geyser under warranty for 2 years.

Geyser Neva 4510 does not ignite does not light up does not turn on

The Neva 4510 geyser does not light up, does not light up, does not turn on. That is, it does not start when the hot water tap is opened.

We go from simple to complex. We name the reasons known to us. (information as of June 20, 2014 refers to Neva columns 4510, 4511, 4513)

Reason 1. Insufficient rarefaction due to the speed of water flow. There is such a concept as “Minimum inclusion flow”. It involves opening a tap with such a stream of water (in smart terms, “performance”) that a 3-liter jar can be completely filled in a minute. If the jar does not have time to fill, in essence, the column simply does not sense the flow. Technically this means this. The membrane bends due to the speed of water flow, namely due to the rarefaction that is created behind the membrane at the so-called “minimum switch-on flow”. Typically this threshold is 2.5 - 3 liters per minute. And it is not the pressure of 5, but the membrane that is provided by the design of the water unit itself.

Now this is most likely almost impossible. There is usually always enough water in each tap. For geysers Neva 4510 and 4511, as well as 4510 M, it is possible to adjust the incoming water flow so that the column starts. Reason No. 2 speaks about this.

Reason 2. Incorrect position of the water flow speed adjustment knob. The column is equipped with a so-called “water flow adjustment knob.”

The adjustment knob we need is on the RIGHT.

But the presence of a water adjustment knob does not actually mean that you have to constantly adjust the flow of water more or less. This knob is set only once at the very beginning, when starting the column, in accordance with the existing water flow, to create the necessary pressure to activate the membrane of the water unit. Unclear? Example. If the water flow is weak, weak, less than 2.5 liters per minute, then no water pump in the world will start under such conditions. But, if the flow rate is more or less normal, but for some reason insufficient to start the dispenser normally, then we recommend setting the adjustment knob to the extreme left position and, when starting the dispenser, gradually close the tap until the dispenser starts. Once the column has started, leave the handle in this position. If the handle has reached the extreme right position and there is no effect, we look further. You don’t have to fiddle with your brain, but immediately put the knob in the extreme right position and, if the column doesn’t start, we look further.

Reason 3. When opening the tap, the rod of the water unit does not move. If the column has worked for more than 3 years, then most likely the membrane has ruptured or stretched. It is also possible for the plate with the rod, which is driven by the membrane, to split. Disassembling the water unit Neva 4510, 4511, 4513 and replacing the membrane here.

Reason 4. It is extremely rare, but it also happens that the gas rod gets bitten. And since the water rod moves the gas rod, when the latter is bitten, it is impossible to move the water rod. But, we repeat, this is very rare.

Moreover, when the gas unit rod is bitten, the column generally turns on poorly and turns off also poorly. Maneuvers for checking the gas assembly rod are here.

Possible malfunctions of the “frog”

The body of the water regulator is durable and designed to operate at high water pressure (flow rate up to 3 m3/hour).

There are few parts in the water unit that can become unusable and cause breakdowns of the gas water heater. Possible malfunctions:

- membrane rupture;

- violation of the integrity of the plastic plate - the membrane cannot move the rod;

- scale formation on the rod, slowing down the movement of the rod or leading to its jamming, which occurs due to leakage of the oil seal;

- destruction of the retarder ball (very rare, but it happens), clogging of the channel, jamming of the ball;

- the filter mesh is filled with debris, which reduces the water pressure due to blocking the passage;

- debris getting into the Venturi fitting due to which the pressure in the hot water tap decreases, the column does not work;

- wear of gaskets and seals is the cause of leaks leading to scale formation.

Most of these malfunctions have characteristic symptoms that can be identified during an external examination.

Leakage of the oil seal gasket leads to the formation of scale and souring of the rod. All scale should be removed. Unscrew and clean the bushing, replace the gasket and seals, clean and lubricate the rod

Any leaks require intervention, which should not be delayed for long. Prolonged exposure to water oxidizes contacts. As a result, the microswitch becomes irreparable and completely unusable.

Why does the column of the above models not light up, as well as for the Neva Transit?

One of the most common reasons for a device malfunction is that it does not ignite. That is, the column does not start heating the water when you open the tap. Let's consider possible failure options:

The water pressure is less than the minimum permissible (for all Neva models).

This means that the device does not perceive the flow, since it is weak. From the technical side, it looks like the membrane changes shape due to the force of water pressure. Deflection may occur as a result of inappropriate assembly structure. Geysers make it possible to solve the problem with water pressure using a regulator located on the device.

Difficulties with models

In many ways, leaks in geysers are caused by the same reasons. But in devices of different brands, specific breakdowns more often occur, leading to similar problems.

For example, the Neva gas water heater leaks most often for the following reasons:

- Membrane failures.

- Rod seal leaks.

- Violations of the integrity of the rod plate

Automatic budget models of this brand, such as Neva 4510, often leak due to heat exchanger failures. It has an aluminum body and is not very durable.

In such units, gas often leaks due to the thin-walled igniter tube and drying out of the seal.

It is also extremely difficult to eliminate a leak in the rod seal, since the connecting bolts of the gas and water compartments are very difficult to unscrew, as well as the microswitch. These fasteners often break during disassembly.

Water drips from the Junkers geyser for the following reasons:

- Radiator failures.

- Drying the O-rings (more common in older models).

- Cracks in the place where the frog is attached (flow regulator).

- Membrane wear.

You can solve these difficulties with your own efforts. Point 1 can be corrected by carrying out soldering work. P.2 – replacing these rings. This is also one of the ways to correct step 3.

In general, we need high-quality and timely repair of the water unit of the Junkers geyser.

At home, you will need to disassemble the column and remove this unit. In most cases, the problem lies in a worn membrane and cover. These elements need to be replaced.

Such problems most often occur with models of the Junkers W 275 1 line. And if replacing the problematic parts does not bear fruit, you need to contact the specialists.

Quite often, customers contact the service - owners of Bosch speakers, the membranes of which wear out quite quickly. Experts recommend always having several of these products in stock.

Owners of Ariston speakers often complain about leaks from below. This is due to a worn flange gasket. It has to be replaced. To do this, the device is de-energized and all the water is drained from it. The cover is removed, the flange is taken out, the gasket is changed.

The second common reason for models of this brand is a violation of the sealing of the connecting sections. The solution is to coat these areas with a powerful sealant.

The same problem is relevant for Oasis speakers. They also often leak from under the flange and due to scale accumulation. The owners of this equipment need to change the anode 2-3 times a year. Otherwise, the heating element will leak or completely collapse. Therefore, you should regularly clean the device from dirt and scale.

Owners of Astra gas water heaters often complain about leaks in the connecting areas and wear and tear of the maintenance equipment. A temporary solution to the problem is soldering. Effective - purchasing new maintenance.

In Electrolux speakers, the most common causes of leaks lie in the radiator. The solution is quick and high-quality soldering.

Vaillant models often have problems with gaskets and maintenance. It is logical to replace these elements.

Whatever type of gas water heater you have, regularly remove dirt and scale from it. If problems are discovered, fix them immediately if you have the necessary experience. Most often, the most effective method of solving a problem is to replace a particular part or assembly.

Finding and eliminating causes

So, why doesn’t the gas water heater turn on? A number of situations could be to blame:

- Error in connecting pipes;

- Lack of draft in the chimney

; - High sensitivity protective relay

; - Low ignition system batteries

; - Weak water pressure or its complete absence

; - Filter contamination

; - Membrane deformation

.

Let's consider all the listed reasons in more detail and look at effective methods for eliminating them:

Reason #1: error in connecting pipes

The water heater protection system itself shuts off the gas supply if errors are made in connecting the pipes. To prevent this from happening, simply stick to a simple and clear scheme:

Reason No. 2: lack of draft in the chimney

Due to contamination of the chimney as a result of the accumulation of soot or construction debris entering it, the vector of movement of combustion products changes to the opposite direction. This poses two dangers:

The returning mixture of carbon monoxide and air extinguishes the burner. As a result, the protection system is triggered and the operation of the gas water heater is blocked;

The returning mixture of carbon monoxide and air penetrates into living spaces. This option is even worse, as it poses a danger to the health and even the life of household members. It is possible in the case when the force of the “overturned” draft is not enough to extinguish the fire.

Let's figure out what to do in the described situation:

| Photo | Description |

| First of all , check if someone has installed a satellite dish above the exit of the ventilation shaft. This may be quite enough to create a backdraft effect. In this case, the problem can be solved by negotiations with neighbors without calling chimney cleaning specialists. | |

| Call a professional to clean the ventilation duct. If no external factors interfere with the exit of combustion products, then the reason for the lack of draft is clearly a clogged chimney. You can try to clean it yourself, but there is a danger that without the appropriate experience you will damage neighboring branches with your actions. |

Reason #3: high sensitivity of the protective relay

Does the gas heater light up and then quickly go out? In this case, the problem most likely lies in the oversensitive relay, which triggers protection against overheating. There are two options to solve the problem:

Temporary. You should open the window to reduce the temperature in the room;

Radical. The problem can be finally solved only by replacing the relay.

Reason No. 4: discharged ignition system batteries

Another reason why the main burner does not light up may be dead batteries. This can be determined by the idle clicks of the piezo ignition element when hot water is turned on.

It is also worth noting that the described problem applies exclusively to water heaters equipped with an automatic switching system.

Reason No. 5: insufficient water flow or its complete absence

In order for the geyser to turn on, there must be a certain amount of water pressure present. If it is too weak, the unit will not turn on. In this case, you should first clarify the source of the problem by opening the cold water tap in the bathroom:

If the water supply level there is weak, it means that the problem is in the city water supply system. There is nothing you can do here, you will have to wait;

If the liquid flows normally, most likely the column itself is clogged.

In the second case, you can call a technician, or you can try to clean the device yourself. The instructions look like this:

- Shut off the gas supply

; - Unscrew the pipes

;

- Remove the gas water heater from its hinges

;

- Place it upside down on the table

; - Use a syringe to pour a special cleaning liquid inside.

The price of such a mixture is not very high, and it can be purchased at any specialized store; - Leave the unit for a couple of hours

.

Reason #6: dirty filters

Another reason for the column to malfunction can be dirty filters. Scale, rust and other insoluble impurities clog the grates over time, and they need to be cleaned. In this case, we are talking not about one object, but about several at once:

| Photo | Filter name and location |

| The water unit is in the column itself . In some cases, it can be cleaned using the method described above, in others you will have to disassemble the device and clean the grille manually or completely change it. | |

| Coarse filter . It is located on the pipe that supplies cold water to the water heater. | |

| Filter on mixer . |

Repair work on the water unit of the Neva-4511 dispenser

Hello people, please give me a quick hint, my NEVA column stopped lighting up yesterday. Does the spark work at all? I haven’t touched anything in it, I turn on the water as usual, the gas won’t ignite even if you crack it! I advise you to take a European-made piece, provided that such pieces are serviced by a local organization. If the column worked normally for 5 - 7 years, then there is no point in just changing it.

When starting water, you need to pay attention to the pusher, which presses the microswitch plate. The water unit can only be removed together with the gas

After this, the entire water-gas unit can be easily pulled out. Often in this place the steel screws turn sour in the silumin body of the gas block, and it can be difficult to move them

If the membrane is intact, then remove it carefully to prevent tearing in the place where it is put on the pipe connecting the upper and lower chambers of the “frog” (shown by the arrow in the photo above). When tightening the frog screws, it is recommended to coat them thickly with graphite or other water-resistant lubricant.

Conclusion - the slightest signs of moisture at the junction of the gas and water blocks must be stopped immediately.

Ways to prevent malfunctions

When purchasing a device, you should pay attention to the minimum water pressure required for the normal functioning of the device. The passport data must be compared with the water pressure in the apartment.

For the column to work properly, you must:

- carry out preventive maintenance once a year or more often;

- inspect the chimney a couple of times a year and clean it, if necessary;

- clean parts from scale and soot;

- provide adequate ventilation.

And don’t forget to change the batteries on time.